Water Heater Innovations 196284-001 User Manual

COMMERCIAL GAS W ATER HEATER

Glass-Lined Tank-Type Water Heater

• INSTALLATION • OPERATION • SERVICE • MAINTENANCE

Thank you for buying this energy efficient water heater. We

appreciate your confidence in our products.

PRINTED IN U.S.A. 1004

CAUTION

TEXT IN BLACK BOLD TYPE OR UNDERLINED

CONTAINS INFORMATION RELATIVE TO YOUR

SAFETY. PLEASE READ THOROUGHLY BEFORE

INST ALLING AND USING THIS APPLIANCE.

PLACE THESE INSTRUCTIONS ADJACENT TO HEA TER

AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PART NO. 196284-001

1

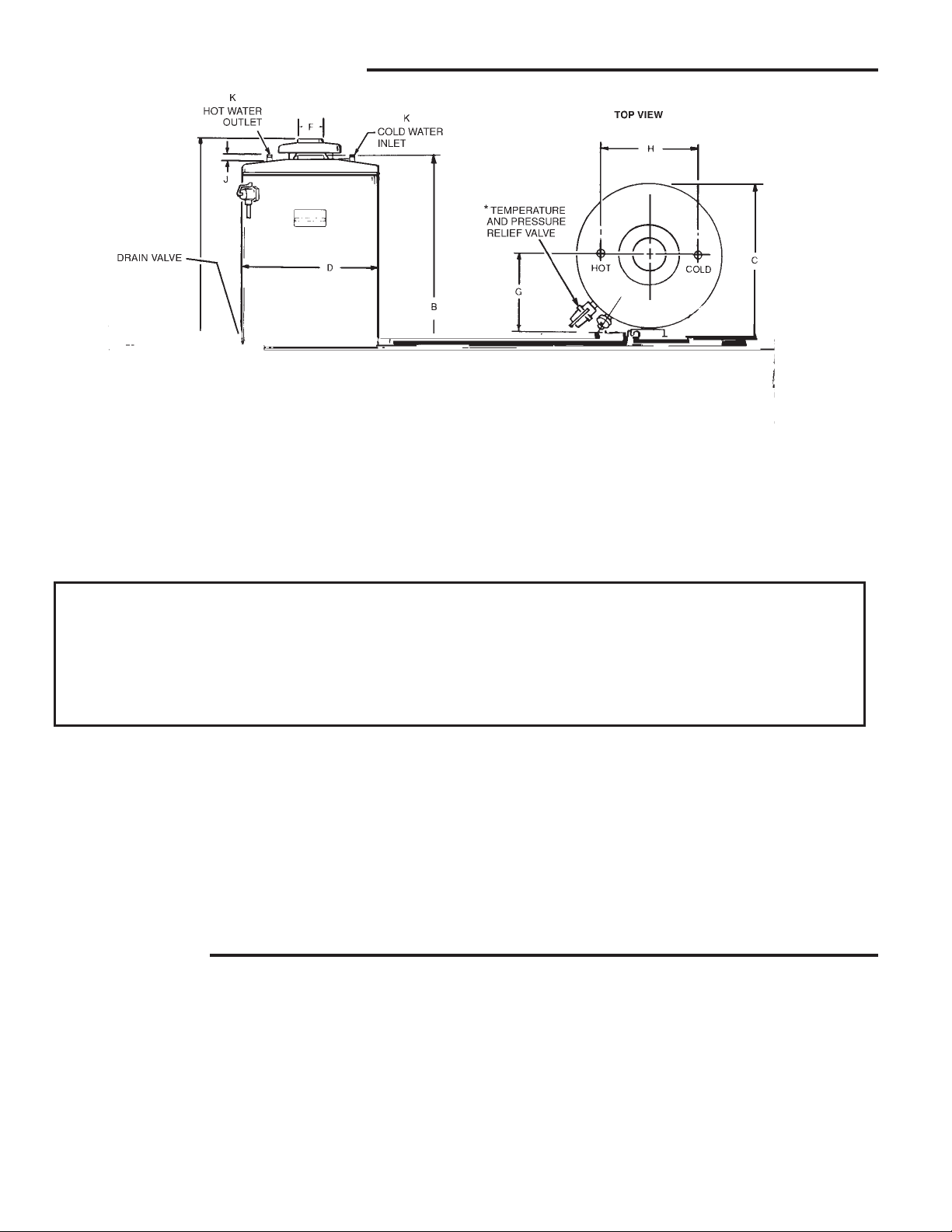

ROUGH-IN DIMENSIONS

FIGURE 1

UNDERSTANDING YOUR MODEL

Model Designator : Sample ***75 75 NE

*** = Letter Designator

75 = Gallons (Capacity of Unit)

75 = kBTU (Approx. Rating of Unit)

N = Gas Type (Natural)

E = 3 Year Warranty

DIMENSIONS

Model Units A B C D E F G H J K L M

75 Inches 61 1/8 58 1/2 29 11/16 26 1/2 15 3/16 4 14 1/2 16 1 1/4 1 1/2 11 15/16

Natural & LP C M 155.25 148.6 75.4 67.3 38.6 10.2 39.4 40.6 3.2 NPT NPT 30.3

100 Inches 69 3/4 66 1/2 29 11/16 26 1/2 15 3/16 4 14 1/2 16 1 1/4 1 1/4 1/2 11 15/16

Natural C M 177.2 168.9 75.4 67.3 38.6 10.2 39.4 40.6 3.2 NPT NPT 30.3

100 Inches 68 5/8 66 1/2 30 15/16 27 3/4 15 3/16 4 15 3/4 16 1 1/4 1 1/4 1 /2 11 15/16

LP CM 174.3 168.9 78.59 70.5 38.6 10.2 40.0 40.6 3.2 NPT NPT 30.3

FOREWORD

The design of models ***-75 and 100 comply with the latest version

of ANSI Z21.10.3-CSA 4.3 as automatic storage or automatic

circulating tank type water heaters.

local area where the installation is to be made. These shall be

carefully followed in all cases. Authorities having jurisdiction

should be consulted before installations are made.

Installation diagrams are found in this manual. These diagrams

will serve to provide the installer with a reference for the materials

and method of piping necessary. It is highly essential that all

water and gas piping be installed as shown on the diagrams.

In addition to these instructions, the equipment shall be installed

in accordance with those installation regulations in force in the

The installation must conform to these instructions and the local

code authority having jurisdiction. In the absence of local codes,

the installation must comply with the latest editions of the National

Fuel Gas Code, ANSI Z223.1/NFPA 54. This publication is available

from the Canadian Standards Association, 8501 East Pleasant

V alley Road, Cleveland, OH 44131, or the National Fire Protection

Association, 1 Batterymarch Park, Quincy, MA 02269.

2

TABLE OF CONTENTS

Page

ROUGH-IN DIMENSIONS ................................................................. 2

FOREWORD.................................................................................... 2

GENERAL SAFETY INFORMA TION ................................................ 3-4

Precautions................................................................................. 3

Chemical Vapor Corrosion ......................................................... 3

Improper Combustion.................................................................. 3

Liquid Petroleum Models ............................................................. 3-4

Extended Non-use Periods ........................................................ 4

Insulation Blankets...................................................................... 4

Circulating Pump ......................................................................... 4

INSTALLA TION INSTRUCTIONS ...................................................... 4-9

Required Ability........................................................................... 4

Locating The Heater ................................................................... 4-5

High Altitude Installations ........................................................... 5

Clearances ................................................................................. 5

Hard Water ................................................................................. 5

Air Requirements........................................................................ 5-6

Water (Potable) Heating and Space Heating ............................. 6

Venting........................................................................................ 6-7

Thermometers (Not Supplied) .................................................... 7

Relief Valve ................................................................................. 7

Gas Piping................................................................................... 7-8

Gas Pressure Regulator ............................................................ 9

OPERA TION..................................................................................... 9-13

Page

To Operate The Water Heater .................................................... 9

Purging ........................................................................................ 9

Lighting Instructions ................................................................... 10-11

T emperature Regulation ............................................................. 12

Check Venting ............................................................................ 12-13

High Temperature Limit Switch................................................... 13

SERVICE INFORMA TION ................................................................. 13-14

Pilot and Main Burner.................................................................. 13

Checking Gas Input .................................................................... 13-14

Vent System ............................................................................... 14

Relief Valve ................................................................................. 14

Hot Water Odor .......................................................................... 14

Anode Rod Inspection ................................................................ 14

Winter Protection ........................................................................ 14

Replacement Parts ..................................................................... 14

PREVENTIVE MAINTENANCE ......................................................... 15-16

Recommended Procedure For Periodic Removal Of Lime

Deposits From Tank Type Commercial Water Heaters .............. 15

Deliming Solvents ....................................................................... 15

Tank Cleanout Procedure ........................................................... 15-16

CHECKLIST ..................................................................................... 16-17

NOTES ............................................................................................ 18

LIMITED WARRANTY...................................................................... INSERT

GENERAL SAFETY

INFORMATION

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY P ART HAS BEEN UNDER

WATER. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and any

gas control which has been under water.

IF THE UNIT IS EXPOSED TO THE FOLLOWING, DO NOT

OPERATE HEA TER UNTIL ALL CORRECTIVE STEPS HA VE BEEN

MADE BY A QUALIFIED SERVICEMAN.

1. EXTERNAL FIRE.

2. DAMAGE.

3. FIRING WITHOUT WA TER.

4. SOOTING

CHEMICAL VAPOR CORROSION

WARNING

CORROSION OF THE FLUEWA YS AND VENT SYSTEM MA Y OCCUR

IF AIR FOR COMBUSTION CONT AINS CERTAIN CHEMICAL V APORS.

SUCH CORROSION MAY RESULT IN FAILURE AND RISK OF

ASPHYXIA TION.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium and

sodium chloride (water softener salt), waxes, and process

chemicals are typical compounds which are potentially corrosive.

Do not store products of this sort near the heater . Also, air which is

brought in contact with the heater should not contain any of these

chemicals. If necessary, uncontaminated air should be obtained

from remote or outside sources. The limited warranty is voided

when failure of water heater is due to a corrosive atmosphere.

(Refer to the limited warranty for complete terms and conditions.)

IMPROPER COMBUSTION

WARNING

ATTIC AND/OR EXHAUST FANS OPERATING ON THE PREMISES

WITH A WATER HEA TER CAN RESUL T IN CARBON MONOXIDE

POISONING AND DEATH.

OPERA TION OF THESE FANS CAN PRODUCE A NEGA TIVE DRAFT

IN THE AREA OF THE WATER HEATER PREVENTING THE

PRODUCTS OF COMBUSTION FROM EXHAUSTING THROUGH

THE CHIMNEY OR VENT PIPE.

The venting of the water heater should be inspected by a qualified

service technician at the time of installation and periodically

thereafter to ensure a down-draft condition does not exist.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATING AIR. ADEQUATE AIR FOR COMBUSTION AND

VENTILATION MUST BE PROVIDED FOR SAFE OPERA TION.

LIQUID PETROLEUM MODELS

Water heaters for propane or liquefied petroleum gas (LPG) are

different from natural gas models. A natural gas heater will not

function safely on LP gas and no attempt should be made to

convert a heater from natural gas to LP gas.

LP gas must be used with great caution. It is highly explosive

and heavier than air . It collects first in the low areas making it s

odor difficult to detect at nose level. If LP gas is present or even

suspected, do not attempt to find the cause yourself. Go to a

neighbor's house, leaving your doors open to ventilate the house,

then call your gas supplier or service agent. Keep area clear

until a service call has been made.

At times you may not be able to smell an LP gas leak. One cause

is odor fade, which is a loss of the chemical odorant that gives

LP gas its distinctive smell. Another cause can be your physical

condition, such as having a cold or diminishing sense of smell

with age. For these reasons, the use of a propane gas detector

is recommended.

3

IF YOU EXPERIENCE AN OUT -OF-GAS SITUATION, DO NOT TR Y TO

RELIGHT APPLIANCES YOURSELF, ask your LP delivery person to

relight pilots for you. Only trained LP professionals should conduct

the required safety checks in accordance with industry standards.

EXTENDED NON-USE PERIODS

WARNING

HYDROGEN GAS CAN BE PRODUCED IN A HOT W A TER SYSTEM

SERVED BY THIS HEA TER THAT HAS NOT BEEN USED FOR A LONG

PERIOD OF TIME (GENERALLY TWO WEEKS OR MORE).

HYDROGEN GAS IS EXTREMEL Y FLAMMABLE. T o reduce the risk

of injury under these conditions, it is recommended that the hot

water faucet be opened for several minutes at the kitchen sink

before using any electrical appliance connected to the hot water

system. If hydrogen is present, there will probably be an unusual

sound such as air escaping through the pipe as the water begins

to flow. THERE SHOULD BE NO SMOKING OR OPEN FLAME NEAR

THE FAUCET AT THE TIME IT IS OPEN.

INSULATION BLANKETS

Insulation blankets available to the general public for external use

on gas water heaters are not approved for use on your commercial

water heater. The purpose of an insulation blanket is to reduce the

standby heat loss encountered with storage tank water heaters.

Your commercial water heater meets or exceeds the ASHRAE/IES

90.1b-1999 standards with respect to insulation and standby loss

requirement making an insulation blanket unnecessary.

WARNING

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions. Failure to follow these

instructions can result in fire, asphyxiation , serious personal

injury or death.

• Do not apply insulation to the top of the water heater , as this

will interfere with safe operation of the draft hood.

• Do not cover the outer door, thermostat or temperature &

pressure relief valve.

• Do not allow insulation to come within 2" (5cm) of the floor to

prevent blockage of combustion air flow to the burner.

• Do not cover the instruction manual. Keep it on the side of

the water heater or nearby for future reference.

• Do obtain new warning and instruction labels from your

commercial water heater company for placement on the

blanket directly over the existing labels.

• Do inspect the insulation blanket frequently to make certain

it does not sag, thereby obstructing combustion air flow.

CIRCULATING PUMP

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the heater.

Install the system in accordance with the latest version of the

National Electric Code ANSI/NFPA No. 70.

4

Drain pans suitable for these heaters are available from your

distributor or Apcom Inc., 125 Southwest Parkway, Franklin,

TN 37065 or contact them by phone, 615-794-5574 or fax

615-791-0660.

Water heater life depends upon water quality, water pressure and

the environment in which the water heater is installed. Water heaters are sometimes installed in locations where leakage may result in property damage, even with the use of a drain pan piped to

a drain. However, unanticipated damage can be reduced or prevented by a leak detector or water shutoff device used in conjunction with a piped drain pan. These devices are available from

some plumbing supply wholesalers and retailers, and detect and

react to leakage in various ways:

• Sensors mounted in the drain pan that trigger an alarm or turn

off the incoming water to the water heater when leakage is

detected.

• Sensors mounted in the drain pan that turn off the water supply

to the entire home when water is detected in the drain pan.

• Water supply shutoff devices that activate based on the water

pressure differential between the cold water and hot water pipes

connected to the water heater.

• Devices that will turn off the gas supply to a gas water heater

while at the same time shutting off its water supply.

For appliance installation locations with elevations above 2000

feet (610 meters), refer to HIGH AL TITUDE INST ALLA TIONS section

of this manual for input reduction procedure.

HIGH AL TITUDE INST ALLATIONS

WARNING

INSTALLATIONS ABOVE 2000 FEET (610 METERS) REQUIRE

REPLACEMENT OF THE BURNER ORIFICE IN ACCORDANCE WITH

SECTION 8.1.2 OF THE NA TIONAL FUEL GAS CODE (ANSI Z223.1).

FAILURE T O REPLACE THE ORIFICE WILL RESUL T IN IMPROPER

AND INEFFICIENT OPERATION OF THE APPLIANCE RESULTING IN

THE PRODUCTION OF INCREASED LEVELS OF CARBON MONOXIDE

GAS IN EXCESS OF SAFE LIMITS WHICH COULD RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

You should contact your gas supplier for any specific changes

which may be required in your area.

As elevation above sea level is increased, there is less oxygen per

cubic foot of air. Therefore, the heater input rate should be reduced

at high altitudes for satisfactory operation with the reduced oxygen

supply. Failure to make this reduction would result in an overfiring

of the heater causing sooting, poor combustion and/or

unsatisfactory heater performance.

Ratings specified by manufacturers for most appliances apply for

elevations up to 2000 feet (610m). For elevations above 2000 feet

(610m), ratings must be reduced at the rate of 4% for each 1000

feet (305m) above sea level. For example, if a heater is rated at

75,100 Btu/Hr (22.0 kW) at sea level, to rate the heater at 4000 feet

(1219m), you subtract 4 (once for each thousand feet) x 0.04 (4%

input reduction) x 75,100 Btu/Hr (original rating) from the original

rating. Therefore, to calculate the input rating at 4000 feet (1219m):

4 x 0.04 x 75,100 Btu/Hr = 12,016 Btu/Hr (3.5 kW); 75,100 Btu/Hr

(22.0 kW) - 12,016 Btu/Hr (3.5 kW) = 63,084 Btu/Hr (18.5 kW). At

6000 feet (1829m) the correct input rating should be 57,076 Btu/Hr

(16.7 kW).

The input reduction is primarily achieved by reducing the size

of the main burner orifices. To do this, the main burner

orifices require replacement with orifices sized for the particular

installation elevation. Correct orifice sizing and parts may be

obtained from Apcom Inc., 125 Southwest Parkway, Franklin, TN

37065 or contact them by phone, 615-794-5574 or fax

615-791-0660. When ordering, be sure to state the model number

and the altitude of the location where the water heater is being

installed.

Upon completion of derating of the heater, adjustment to the gas

pressure regulator may be required. See CHECKING THE INPUT

section in this manual for inlet and manifold pressure

requirements.

Also due to the input rating reduction required at high altitudes, the

recovery rating of the appliance is also reduced and should be

compensated for in the sizing of the equipment for application.

CLEARANCES

These heaters are approved for installation on combustible flooring

in a closet having a ceiling 12" (30.5cm) above top cover and with

clearances to combustible construction of 6" (15.2cm) from flue or

vent connector, 0" (0cm) at the sides and rear and 4" (10.1cm) to

front to prevent a possible fire hazard condition. A minimum of 4"

(10.1cm) shall be allowed for installation of serviceable parts.

HARD WATER

Where hard water conditions exist, water softening or the threshold

type of water treatment is recommended. This will protect the

dishwashers, coffee urns, water heaters, water piping and other

equipment.

See PREVENTIVE MAINTENANCE section for details of tank

cleanout procedure.

AIR REQUIREMENTS

REFER TO THE LATEST EDITION OF THE "NATIONAL FUEL GAS

CODE" ANSI Z223.1/NFPA 54.

KEEP APPLIANCE AREA CLEAR AND FREE OF COMBUSTIBLE

MA TERIALS, GASOLINE AND OTHER FLAMMABLES, V APORS AND

LIQUIDS.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION OR VENTILA TING

AIR.

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR

COMBUSTION AND VENTILA TION. AN INSUFFICIENT SUPPL Y OF

AIR WILL CAUSE RECIRCULA TION OF COMBUSTION PRODUCTS

RESUL TING IN AIR CONT AMINA TION THAT MA Y BE HAZARDOUS

TO LIFE. SUCH A CONDITION OFTEN WILL RESULT IN A YELLOW ,

LUMINOUS BURNER FLAME, CAUSING CARBONING OR SOOTING

OF THE COMBUSTION CHAMBER, BURNERS AND FLUE TUBES

AND CREA TES A RISK OF ASPHYXIATION.

Where an exhaust fan is supplied in the same room with a heater,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRA WN INTO

THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MA Y RESUL T IN SERIOUS DAMAGE TO

THE HEA TER AND RISK OF FIRE OR EXPLOSION.

UNCONFINED SPACE

In buildings of conventional frame, brick, or stone construction,

unconfined spaces may provide adequate air for combustion,

ventilation and draft hood dilution.

5

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping, heavy

insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation and draft hood dilution must be obtained from outdoors.

The installation instructions for confined spaces in tightly

constructed buildings must be followed to ensure adequate air

supply.

CONFINED SPACE

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE IN

OR WITHIN 12 INCHES (305mm) OF THE ENCLOSURE TOP AND

ONE IN OR WITHIN 12 INCHES (305mm) OF THE ENCLOSURE

BOTTOM. Each opening shall have a free area of at least one

square inch per 1000 Btu/Hr (2203mm

appliances in the enclosure, but not less than 100 square inches

(645cm

2

).

2

/kW) of the total input of all

If the confined space is within a building of tight construction, air for

combustion, ventilation, and draft hood dilution must be obtained

from outdoors. When directly communicating with the outdoors or

communicating with the outdoors through vertical ducts, two

permanent openings, located in the above manner, shall be

provided. Each opening shall have a free area of not less than one

square inch per 4000 Btu/Hr (551mm

2

/kW) of the total input of all

appliances in the enclosure. If horizontal ducts are used, each

opening shall have a free area of not less than one square inch

per 2000 Btu/Hr (1102mm

2

/kW) of the total input of all appliances

in the enclosure.

OF FLUE GASES. SUCH CONDITIONS CAUSE SOOTING OR RISKS

OF FIRE AND ASPHYXIA TION.

Heater must be protected from freezing downdrafts.

Remove all soot or other obstructions from the chimney that will

retard a free draft.

Type B venting is recommended with these heaters.

This water heater must be vented in compliance with all local

codes, the current edition of the National Fuel Gas Code

(ANSI-Z223.1) and with the Category I Venting Tables.

If any part of the vent system is exposed to ambient temperatures

below 35 degrees F (2 degrees C) it must be insulated to prevent

condensation.

• Do not connect the heater to a common vent or chimney with

any oil-fired or solid fuel burning equipment. This practice is

prohibited by many local building codes as is the practice of

venting gas fired equipment to the duct work of ventilation

systems.

WATER (POTABLE) HEATING AND SPACE

HEATING

1. All piping components connected to this unit for space heating

applications shall be suitable for use with potable water.

2. Toxic chemicals, such as those used for boiler treatment, shall

NEVER be introduced into this system.

3. This unit may NEVER be connected to any existing heating

system or component(s) previously used with a non-potable

water heating appliance.

4. When the system requires water for space heating at

temperatures higher than required for domestic water

purposes, a tempering valve must be installed. see Figure 4.

CAUTION

A closed system will exist if a check valve (without bypass),

pressure reducing valve (without bypass), or a water meter

(without bypass) is installed in the cold water line between the

water heater and street main (or well).

Excessive pressure may develop in such closed systems,

causing premature tank failure or intermittent relief valve

operation.

a similar device is required in the inlet supply line between the

appliance and the meter or valve to compensate for the thermal

expansion of the water .

SYSTEM CONNECTIONS

The system installation must conform to these instructions and to

the local code authority having jurisdiction. Good practice requires

that all heavy piping be supported.

This is not a warranty failure. An expansion tank or

FIGURE 2

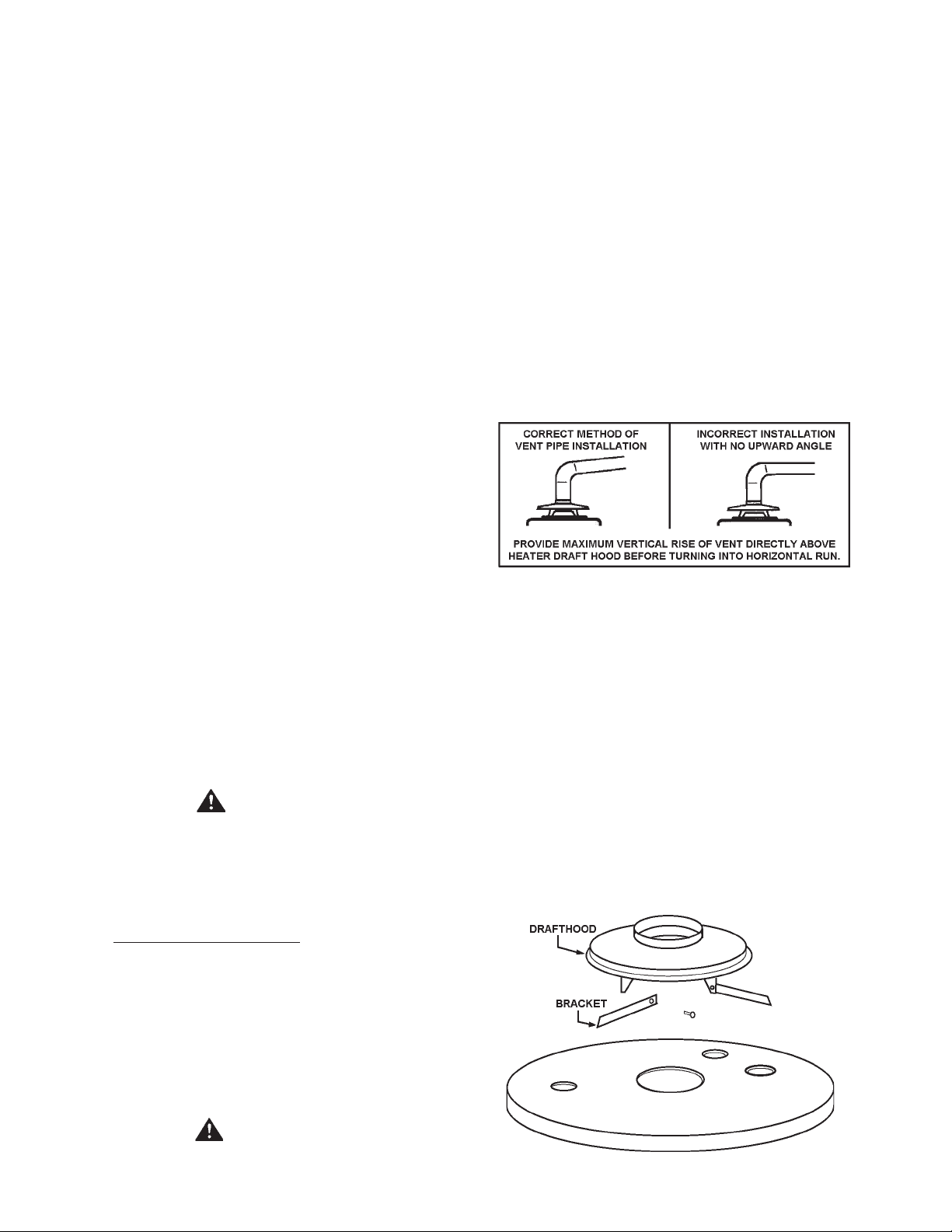

DRAFT HOOD

The draft hood furnished with this heater must be installed without

alteration. Provision must be made if it is installed in confined

space or a small room to accommodate draft hood spillage and

avoid risks described in previous steps. The upper air opening

called for in the AIR REQUIREMENTS section of this manual is for

this purpose.

Locate the 3 brackets and 6 screws in the installation instruction

bag. Secure each bracket to the draft hood leg with the screws

furnished. Place the draft hood on the water heater so that legs of

the draft hood fit into the slots on the jacket top, see figure 3. Once

the draft hood (with brackets attached) is in place, drill a small pilot

hole through bracket hole into the jacket top. WARNING, DO NOT

PENETRA TE THE JACKET TOP BY MORE THAN 1/4" (6.4 mm).

Secure the brackets to the jacket top with the screws furnished,

see Figure 3.

VENTING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST BE

FOLLOWED TO A VOID CHOKED COMBUSTION OR RECIRCULATION

FIGURE 3.

6

Loading...

Loading...