Watergroup FE30SXT, STFE30SXT, FE45SXT, STFE30SXT-DH, FE60MISXT User Manual

Operating and Service Manual

6200 SXT Iron Guard and Iron Guard Plus

Automatic Meter Initiated Iron Softener

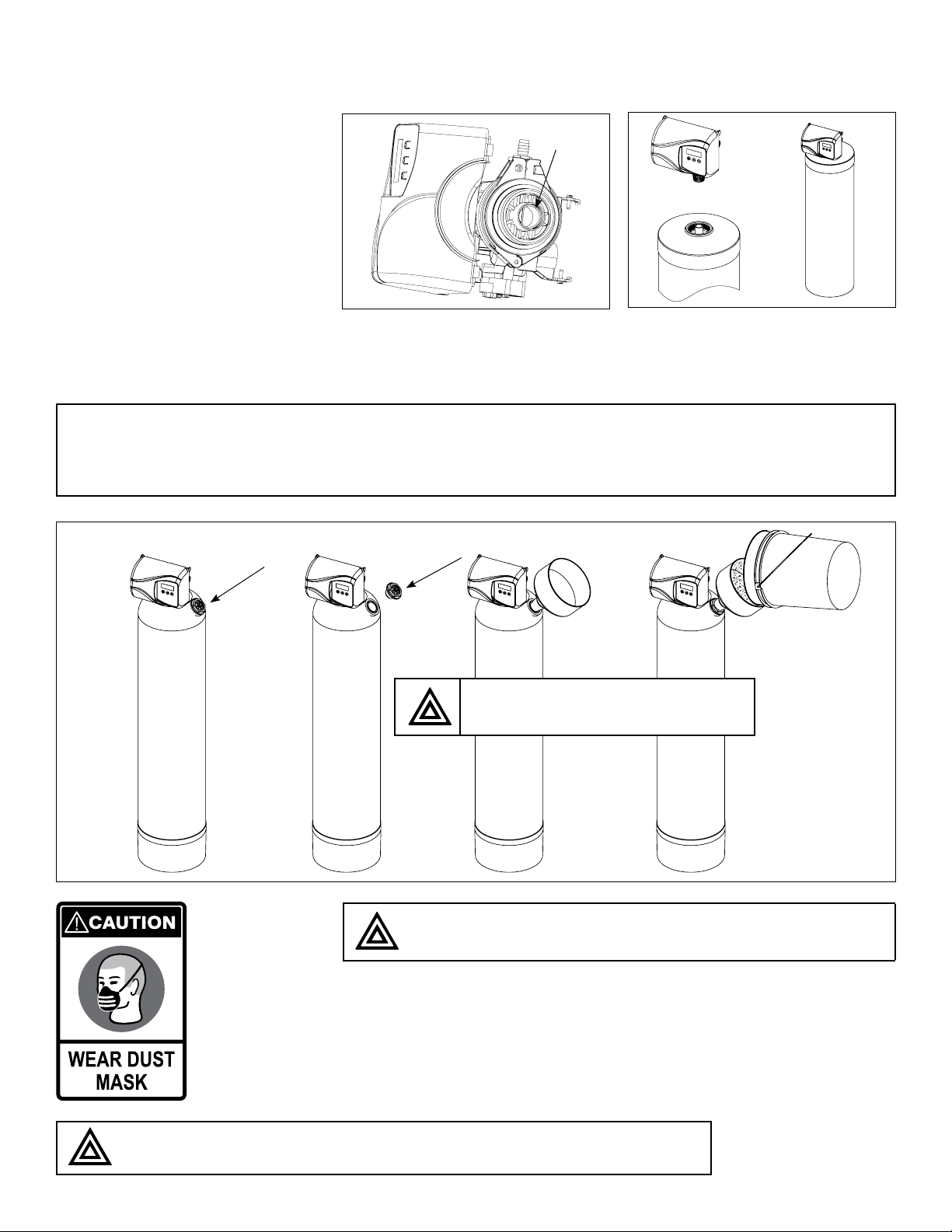

REMINDER: HAVE YOU ALSO PURCHASED WITH YOUR

IRON GUARD OR IRON GUARD PLUS SOFTENER

THE FOLLOWING ITEMS?

1. ITEM # 33010 RES-UP FEEDER

2. ITEM # 45148 PRO-RESCARE SOLUTION, 1 QUART

OR ITEM # 45147 PRO-RESCARE SOLUTION, 1 GALLON

THESE ITEMS ARE CRITICAL TO THE PERFORMANCE OF THE

SOFTENER FOR ITS INTENDED APPLICATION.

Made in Canada

Introduction

Read this Manual First

• Read this manual thoroughly to become familiar with the device and its capabilities before installing or operating your

Water Softener. Failure to follow instructions in this manual could result in personal injury or property damage. This manual

will also help you to get the most out of your softener.

• This system and its installation must comply with state and local regulations. Check with your local public works depart-

ment for plumbing and sanitation codes. In the event the codes conflict with any content in this manual the local codes

should be followed. For installations in Massachusetts, Massachusetts Plumbing Code 248 CMR shall be adhered to. Consult your licensed plumber for installation of this system.

• This water softener is designed to operate on pressures of 20 psig 125 psig. If the water pressure is higher than the maxi-

mum use a pressure reducing valve in the water supply line to the softener.

• This unit is capable of operating at temperatures between 40°F and 110°F (4°C - 43°C). Do not use this water softener on

hot water supplies.

• Do not install this unit where it may be exposed to wet weather, direct sunlight, or temperatures outside of the range

specified above.

• Do not use water that is microbiologically unsafe without adequate disinfection before or after this system.

• This publication is based on information available when approved for printing. Continuing design refinement could cause

changes that may not be included in this publication. WaterGroup reserves the right to change the specifications referred

to in this literature at any time, without prior notice.

Safety Messages

Watch for the following safety messages in this manual:

NOTE: used to emphasize installation, operation or maintenance information which is important but does not

present a hazard.

Example: NOTE: Check and comply with you state and local codes. You must follow these guidelines.

CAUTION: used when failure to follow directions could result in damage to equipment or property.

Example:

CAUTION! Disassembly while under pressure can result in flooding.

WARNING: used to indicate a hazard which could cause injury or death if ignored.

Example:

WARNING! ELECTRICAL SHOCK HAZARD! UNPLUG THE UNIT BEFORE REMOVING THE COVER OR ACCESSING

ANY INTERNAL CONTROL PARTS

NOTE: Do not remove or destroy the serial number. It must be referenced on request for

warranty repair or replacement

1

Iron in your Water

Iron is a common water problem. The chemical/physical nature of iron found in natural water supplies is exhibited in four

general types:

1. Dissolved Iron—Also called ferrous or “clear water” iron. This type of iron can be removed from the water by the

same ion exchange principle that removes the hardness elements, calcium and magnesium. Dissolved iron is soluble in water and is detected by taking a sample of the water to be treated in a clear glass. The water in the glass

is initially clear, but on standing exposed to the air, it may gradually turn cloudy or colored as it oxidizes.

2. Particulate Iron—Also called ferric or colloidal iron. This type of iron is an undissolved particle of iron. A softener will

remove larger particles, but they may not be washed out in regeneration effectively and will eventually foul the

ion exchange resin. A filtering treatment will be required to remove this type of iron.

3. Organic Bound Iron—This type of iron is strongly attached to an organic compound in the water. The ion exchange

process alone cannot break this attachment and the softener will not remove this type of iron.

4. Bacterial Iron—This type of iron is protected inside a bacteria cell. Like the organic bound iron, it is not removed by

a water softener.

When using a softener to remove both hardness and dissolved iron it is important that it regenerates more frequently than

ordinarily would be calculated for hardness removal alone. Although many factors and formulas have been used to determine this frequency, it is recommended that the softener be regenerated when it has reached 50–75% of the calculated

hardness alone capacity. This will minimize the potential for bed fouling.

If you are operating a water softener on clear water iron, regular resin bed cleaning is needed to keep the bed from coating with iron. Even when operating a softener on water with less than the maximum of dissolved iron, regular cleanings

should be performed. Clean every six months or more often if iron appears in your conditioned water supply. Use resin bed

cleaning compounds carefully following the directions on the container.

CAUTION! Do not use where the water is microbiologically unsafe or with water of unknown quality without

adequate disinfection before or after the unit.

2

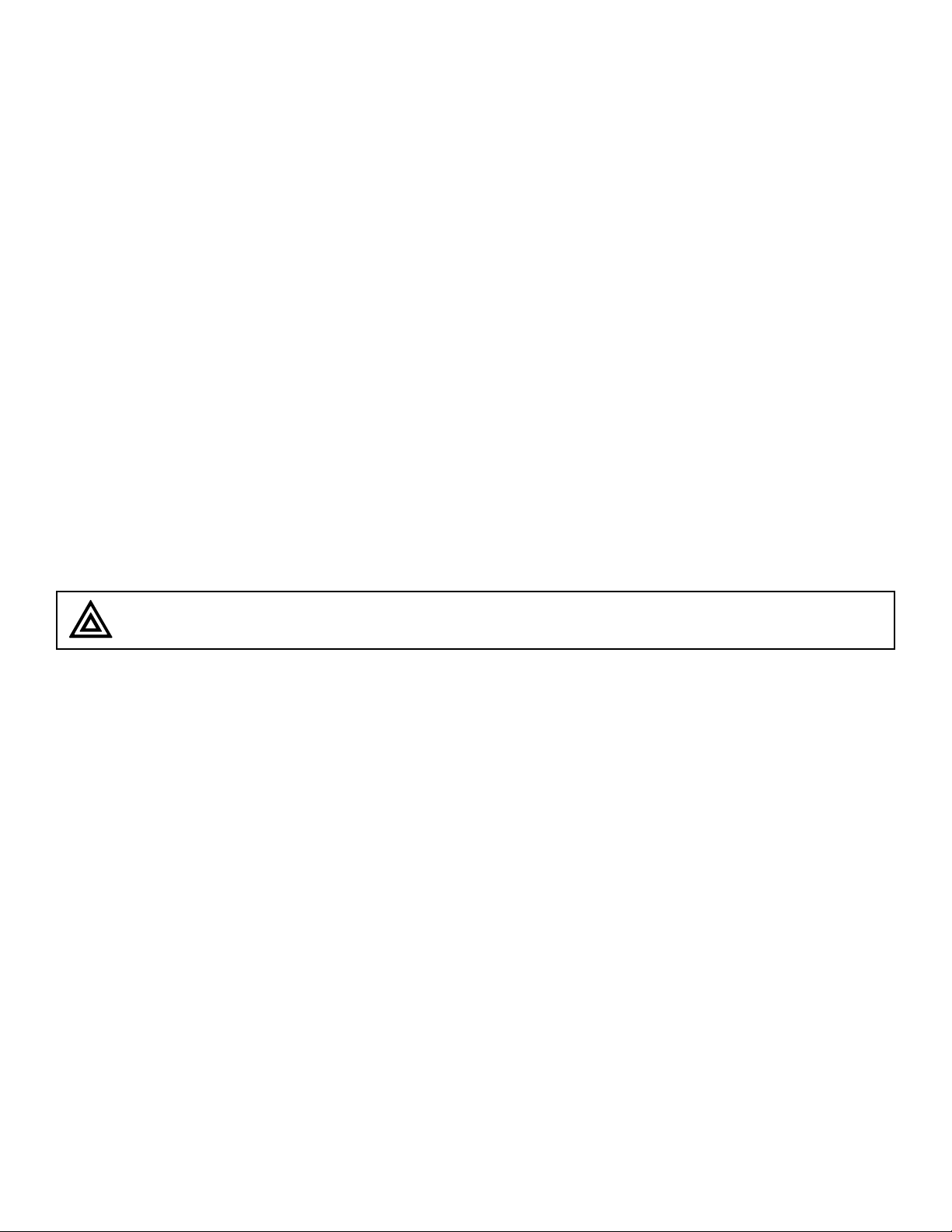

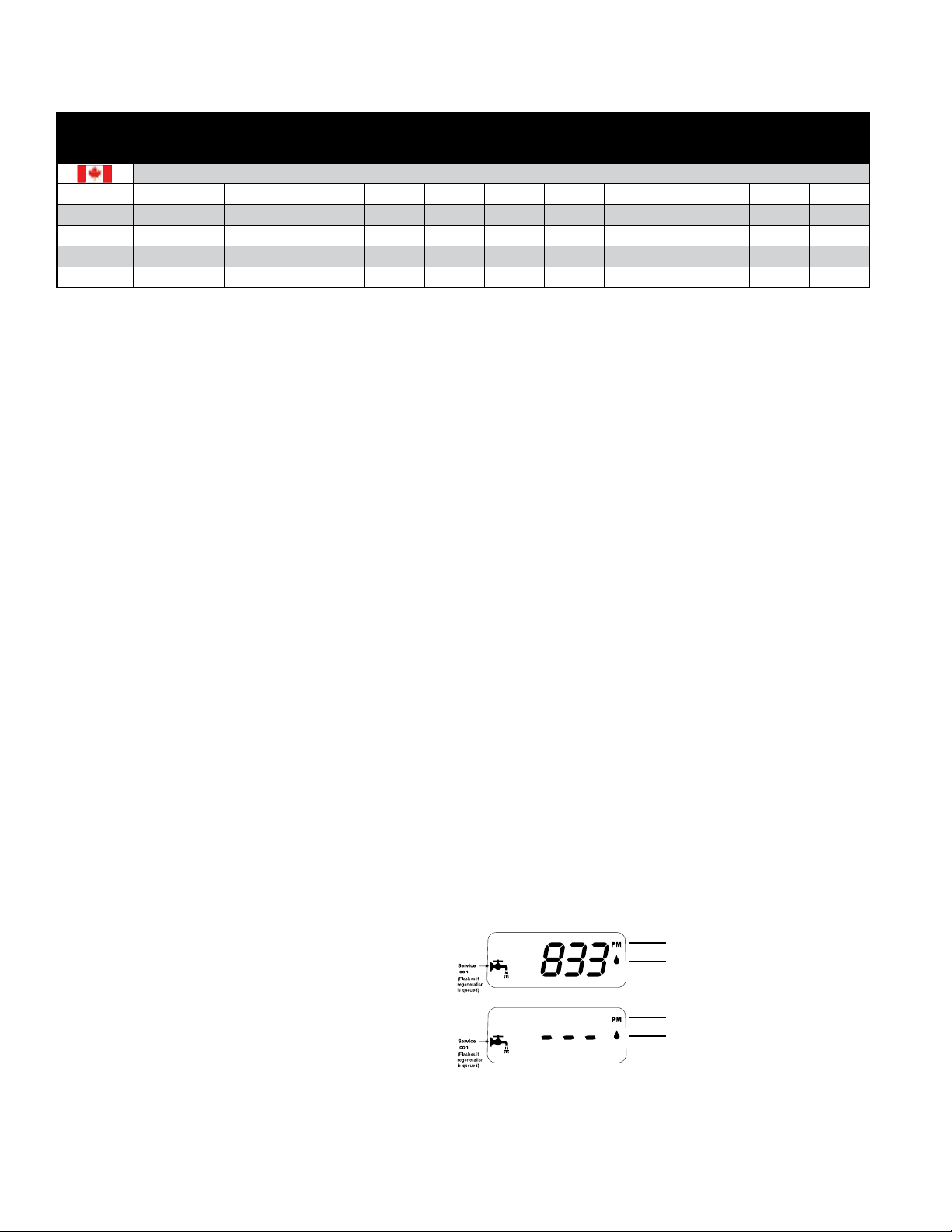

Performance Data Sheet

Iron Guard and Iron Guard Plus - Iron Softeners*

Unit Item # 4901 4902 4903 4904 4905

Model # FE30SXT FE45SXT FE60MISXT STFE30SXT STFE30SXT-DH

Tank Size 10 x 47 12 X 52 14 X 50 10 X 54 10 X 54 (DH)

Media (CF) 1 1.5 2 1 1

15 lbs of Salt/CF of Resin 32000 48000 64000 32000 32000

10 lbs of Salt/CF of Resin 30,000 45,000 60,000 30,000 30,000

6 lbs of Salt/CF of Resin 18000 27000 36000 18000 18000

3 lbs of Salt/CF of Resin 9000 13500 18000 9000 9000

Max Iron Conc (ppm) 10 10 10 10 10

Service Flow Rate (gpm) 8 10 12 8 8

Backwash Flow Rate (gpm) 1.5 2.4 3.5 1.5 1.5

Injector #00 #00 #00 #00 #00

BLFC 0.25 0.25 0.5 0.25 0.25

BF Time (15 lbs/CF dosage) 20 30 20 20 20

Slow Rinse Flow Rate (gpm) 0.254 0.254 0.254 0.254 0.254

For 3 lbs of Salt/CF of Resin

Brine Draw Slow Rinse Time (minutes) 60 60 60 60 60

Backwash Time (minutes) 10 10 10 10 10

Rapid Rinse (minutes) 10 10 10 10 10

Brine Refill (minutes) 4 6 4 4 4

Total Minutes 84 86 84 84 84

For 6 lbs of Salt/CF of Resin

Brine Draw Slow Rinse Time (minutes) 60 60 60 60 60

Backwash Time (minutes) 10 10 10 10 10

Rapid Rinse (minutes) 10 10 10 10 10

Brine Refill (minutes) 8 12 8 8 8

Total Minutes 88 92 88 88 88

For 10 lbs of Salt/CF of Resin

Brine Draw Slow Rinse Time (minutes) 60 60 60 60 60

Backwash Time (minutes) 10 10 10 10 10

Rapid Rinse (minutes) 10 10 10 10 10

Brine Refill (minutes) 13 20 13 13 13

Total Minutes 93 100 93 93 93

For 15 lbs of Salt/CF of Resin

Brine Draw Slow Rinse Time (minutes) 60 60 60 60 60

Backwash Time (minutes) 10 10 10 10 10

Rapid Rinse (minutes) 10 10 10 10 10

Brine Refill (minutes) 20 30 20 20 20

Total Minutes 100 110 100 100 100

Total Water Consumption during Regneration

For 3 lbs of Salt/CF of Resin (gallons) 46.24 64.74 87.24 46.24 46.24

For 6 lbs of Salt/CF of Resin (gallons) 47.24 66.24 89.24 47.24 47.24

For 10 lbs of Salt/CF of Resin (gallons) 49 68 92 49 49

For 15 lbs of Salt/CF of Resin (gallons) 50.24 70.74 95.24 50.24 50.24

3

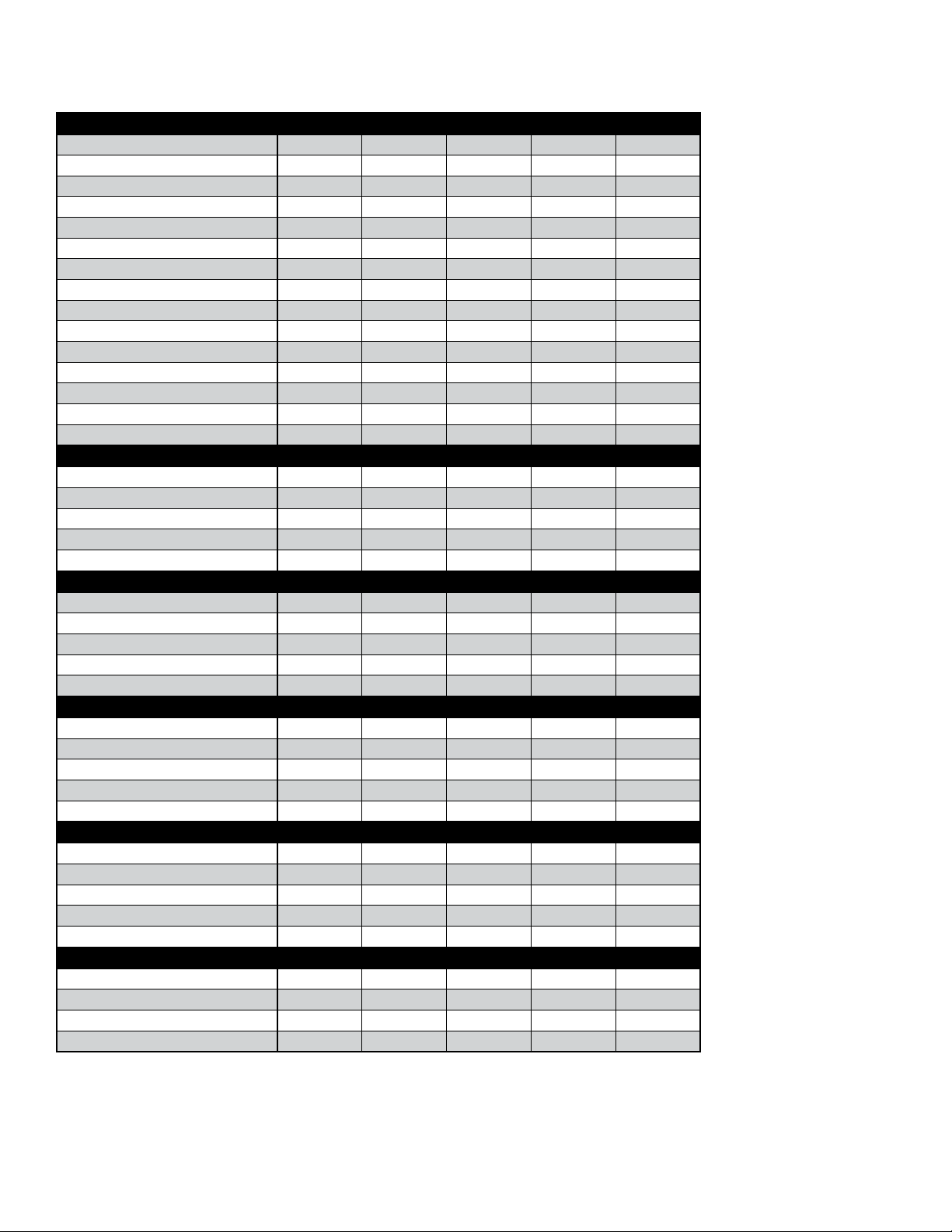

Specification

Unit †

Item # Model # Tank Size

Media

(CF)

10 lbs of

Salt/CF of

Resin

6 lbs of

Salt/CF of

Resin

3 lbs of

Salt/CF of

Resin

Service

Flow Rate

(gpm)

Backwash

Flow Rate

(gpm)

Brine Tank Dimension (W X

D X H) Inches

Salt

Capacity

(lbs)

Shipping

Weight

(lbs)

Iron Guard and Iron Guard Plus - Iron Softeners*

4901 FE30SXT 10 x 47 1 30,000 18000 9000 8 1.5 22 X 38 400 145

4902 FE45SXT 12 X 52 1.5 45,000 27000 13500 10 2.4 22 X 38 400 18 5

4903 FE60MISXT 14 X 50 2 60,000 36000 18000 12 3.5 22 X 38 400 230

4904 STFE30SXT** 10 X 54 1 30,000 18000 9000 8 1.5 22 X 38 400 145

4905 STFE30SXT-DH** 10 X 54 (DH) 1 30,000 18000 9000 8 1. 5 22 X 38 400 145

* Pro-Rescare Solution Dose is required to clean the media bed periodically.

Unit can be applied to 0.75 ppm manganese providing regular use of reisn

cleaner

** Should not be applied unless pH is less than 6.8

Application must be based on analysis by an authorized representative

or distributor.

Not recommended for iron bacteria or organically bound iron. Iron Guard

Plus (STFE30SXT ) should not be applied unless pH is 6.8 or lower.

Iron Guard Plus may require the addition of media over a period of time.

Inlet/outlet pipe size 3/4”, drain 1/2”.

Working Temperature = 34-110°F (1-43°C)

(Do not subject the unit to freezing temperatures)

Working Pressure = 20-125 PSIG (137-861 kPa)

Voltage = 120V / 60 Hz

Pipe Size = 3/4”

At the stated service flow rates, the pressure drop through these devices will

not exceed 15 psig.

Changing salt settings from factory setting may require changing injector

sizes to achieve stated capacities

The manufacturer reserves the right to make product improvements which

may deviate from the specifications and descriptions stated herein, without

obligation to change previously manufactured products or to note the

change.

Do not use water that is microbiologically unsafe without adequate

disinfection before or after the system.

Iron content must not exceed 1 ppm. Beyond 1 ppm an iron softener must

be used. Periodic media cleaning is required by

Pro-Res Cleaner is iron level exceed 0.3 ppm

†

USA customers will need to add “-4” to the item numbers for ordering.

NOTE: (gpg) refers to Grains per USGallon measurement of Total Hardness

Not recommended for iron bacteria or organically bound iron. Iron Guard Plus

(STFE30MI) should not be applied unless pH is 6.8 or lower. Unit can be applied

up to a maximum .75 mg/l manganese providing regular use of resin cleaner.

Regular use of resin cleaner is essential to the proper functioning of the

combination water softener and iron removal system.

† Iron Guard Plus may require the addition of media over a period of time.

STFE30SXT-DH comes with dome hole tank for easy media replenishment

How a WaterGroup Iron Softener Works

Water softeners remove hardness and iron in the water by exchanging particles in the water, or ions. They remove hard ions

the calcium and magnesium in the water by trading it for sodium ions producing soft water. Unlike the calcium and magnesium, sodium stays dissolved in water and does not form a scale. Sodium also does not interfere with the cleaning action of

soaps. The sodium is released by a charged resin contained in the softener, this resin also traps the calcium and magnesium

ions. Eventually this resin releases all of its sodium and has filled up with other ions, so it then must be regenerated. Regeneration is accomplished by washing the resin with a salt saturated brine solution that removes the calcium and magnesium

while replenishing the sodium. This is why the softener requires a brine tank and salt.

Hard water contains dissolved calcium and magnesium which build up inside your water heater, plumbing fixtures and appliances. The minerals also react with soap to form a scum which appears as bathtub ring, greys your laundry and leaves

your hair dull and your skin itchy. Iron water leaves yellow, orange or brown stains on your laundry, sinks, tubs and toilets.

Iron Guard contains a bed of special ion exchange resin beads. As water passes through the bed, calcium and magnesium,

the hardness minerals, and any clear or red water iron are removed and held by the resin. The Iron Guard Plus bed contains

calcium carbonate in addition to the fine mesh ion exchange resin. This media combines to raise low pH water to enable

the resin to removehardness and red water iron. The water softener can run for days before running out of sodium, and

when it does, the sodium is replenished in only a matter of a few hours.

In normal operation, the Time of Day display will alternate being viewed with the Volume Remaining display. This display will

be in gallons or liters. As treated water is used, the Volume Remaining display will count down from a maximum value to zero

or (---). Once this occurs, a regeneration cycle will be initiated at the Set Regeneration Time. Water flow through the valve is

indicated by the Flow Indicator that will flash in direct relationship to flow rate.

Example 833 Gallons of Treated

Water Remaining

0 Gallons of Treated

Water Remaining

PM Indicator

Flow Indicator

(Flashing with water flow)

PM Indicator

Flow Indicator

(Flashing with water flow)

4

Timer Behavior During Regeneration

In regeneration, the control will display a special regeneration display. In this display, the control will show the

current regeneration step abbreviation the valve is advancing to or has reached and the time remaining in that

step. The step abbreviation displayed will flash until the valve has completed driving into this regeneration step

position. Once all regeneration steps have been completed, the valve will return to Service and resume normal

operation.

Example Less than 6 minutes

remaining in Regeneration

Step Rapid Rinse

Pushing the

and resume normal step timing.

Please see the control valve manual for different regeneration step abbreviations.

IMPORTANT REMINDER: For the proper operation of your of Iron Guard or Iron Guard Plus Water Softener, a Res-Up Feeder

and a supply of PRO-ResCare solution is essential to extend the life of the resin media bed. If you have not purchased the

following items along with your softener, please contact your supplier or installer to obtain them. The PRO-ResCare in combination with the Res-Up Automatic Feeder delivers the appropriate amount of the solution to the brine tank. The PRO-ResCare solution added is used in the regeneration cycle to chemically clean the resin bed of iron and other contaminants.

Without the PRO-ResCare solution, iron will foul the media over time causing loss of performance, increased pressure drops

and leakage of hardness and iron. PLEASE TAKE THE TIME READ THE LABEL AND WARNINGS BEFORE USING THIS PRODUCT

WITH YOUR WATER SOFTENER. USE ALL SUGGESTED CAUTIONS WHEN USING AND STORING THE "PRO-ResCare" PRODUCT.

during a regeneration cycle will immediately advance the valve to the next cycle step position

5

Regeneration Step

Abbreviation

Application of Iron Guard & Iron Guard Plus Water Softeners

The Iron Guard or Iron Guard Plus Water softener is designed to soften water through

an ion exchange process as described

previously. In addition, the ion exchange resin used in the mineral tank is a special,

fine mesh resin, which is less likely to be prone toiron fouling than standard softener

resin. A resin cleaner solution should still be added to the brine tank with the use of

an automatic feeder. Our recommended automatic feeder and resin cleaner solution is available through your distributor or installer. The unit has been factory preset

to regenerate the resin with a higher salt setting than regular water softeners. We

recommend that you DO NOT ADJUST this salt setting of 15lb-salt/cf-resin. The higher

dosage is another important factor in the softeners’ ability to regenerate the resin

that removed iron during the last service cycle. Iron Guard Plus Softeners will require topping up of the calcium carbonate

media occasionally. The frequency of adding media is highly dependent on the chemistry of the water being treated and is

difficult to predict, however, it is unlikely it will need to be topped up more than once per year.

Some additional guidelines about the application of Iron Guard and Iron Guard Plus water softeners are as follows:

• The Iron Guard & Iron Guard Plus water softeners are not recommended for removal of iron that is organically bound.

• The Iron Guard & Iron Guard Plus water softeners are not recommended for removal of iron with iron

bacteria combinations.

• The Iron Guard & Iron Guard Plus water softeners are not recommended as the primary method of water treatment for

iron when found in combination with significant amounts of manganese. An Iron and Sulfur filter (Greensand) is recommended as pretreatment. The Iron Guard softeners can still be used as a polisher or backup treatment for iron.

• Regular use of a resin cleaner with an automatic feeder is essential to the proper functioning of the Iron Guard & Iron

Guard Plus water softeners when applied on water supplies containing iron.

• Iron Guard Plus water softeners only should not be applied unless the pH of the water is 6.8 or lower. The calcium

carbonate in the mineral tank raises the pH of the water allowing iron in the ferrous state (i.e. in solution) to be more

easily removed.

• When calculating the capacity of the Iron Guard or Iron Guard Plus water softener in gallons, remember to add the

converted Iron to the Total Hardness tested in the water. See page 5.

• Only use this product on water that is potable. DO NOT apply this product on water that is unsafe to drink without

proper disinfection.

5

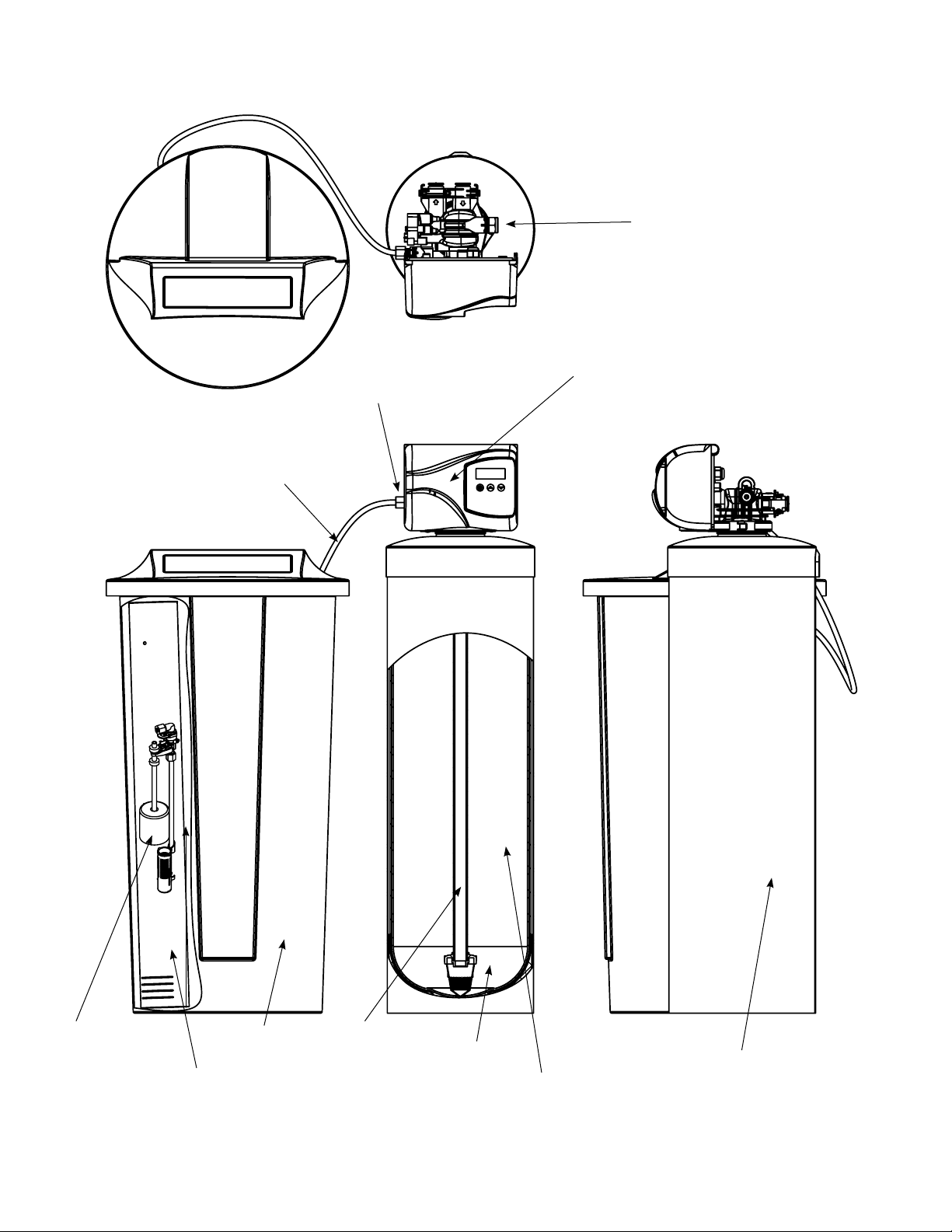

Familiarize yourself with the unit and components

Drain Line

Connection

to Valve

Brine Tube

Brine Line

Connection

to Valve

Control Valve

Safety Float/Air

Check Inside

Brine Tank

Brine Well

Distributor/Riser

Underbed

6

Media Bed

Mineral/Resin

Tank wrapped

with Jacket

Installation Instructions

Contact your local distributor to use WaterGroup laboratory for complete water analysis free of cost and no

obligation to you.

All government codes and regulations governing the installation of these devices must be observed.

.

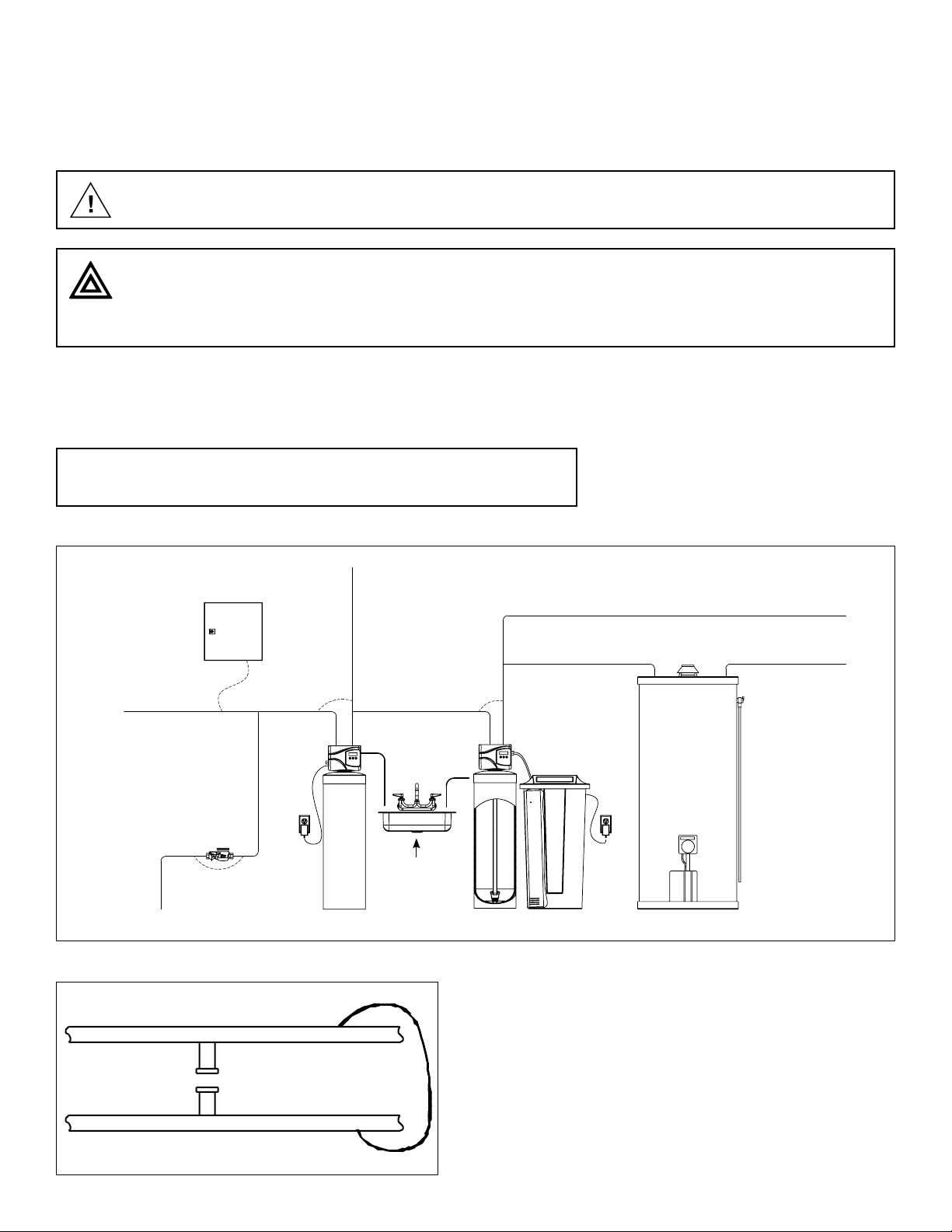

If the ground from the electrical panel or breaker box to the water meter or underground copper pipe is tied

to the copper water lines and these lines are cut during installation of the Noryl bypass valve and/or poly

pipe, an approved grounding strap must be used between the two lines that have been cut in order to maintain continuity. The length of the grounding strap will depend upon the number of units being installed and/or

the amount of copper pipe being replaced with plastic pipe. See Figure 1.

In all cases where metal pipe was originally used and is later interrupted by poly pipe or the Noryl bypass valve as in Figure

1 or by physical separation as in Figure 2, an approved ground clamp with no less than #6 copper conductor must be used

for continuity, to maintain proper metallic pipe bonding.

NOTE: Check your local electrical code for the correct clamp.

Figure 1

Raw Water

To Outdoors

Figure 2

Electrical Panel

Water Meter

Filter

Hard

Filtered

Water

Drain

Ground Strap

Drain

Drain

Iron Guard Softener

Cold Soft Water

Hard Soft Water

Water Heater

Unfiltered Water Bypass

Loop Cut & Capped

Filtered Water Line in Home

Ground Strap Required

Because of Break in Continuity

7

D

C

B

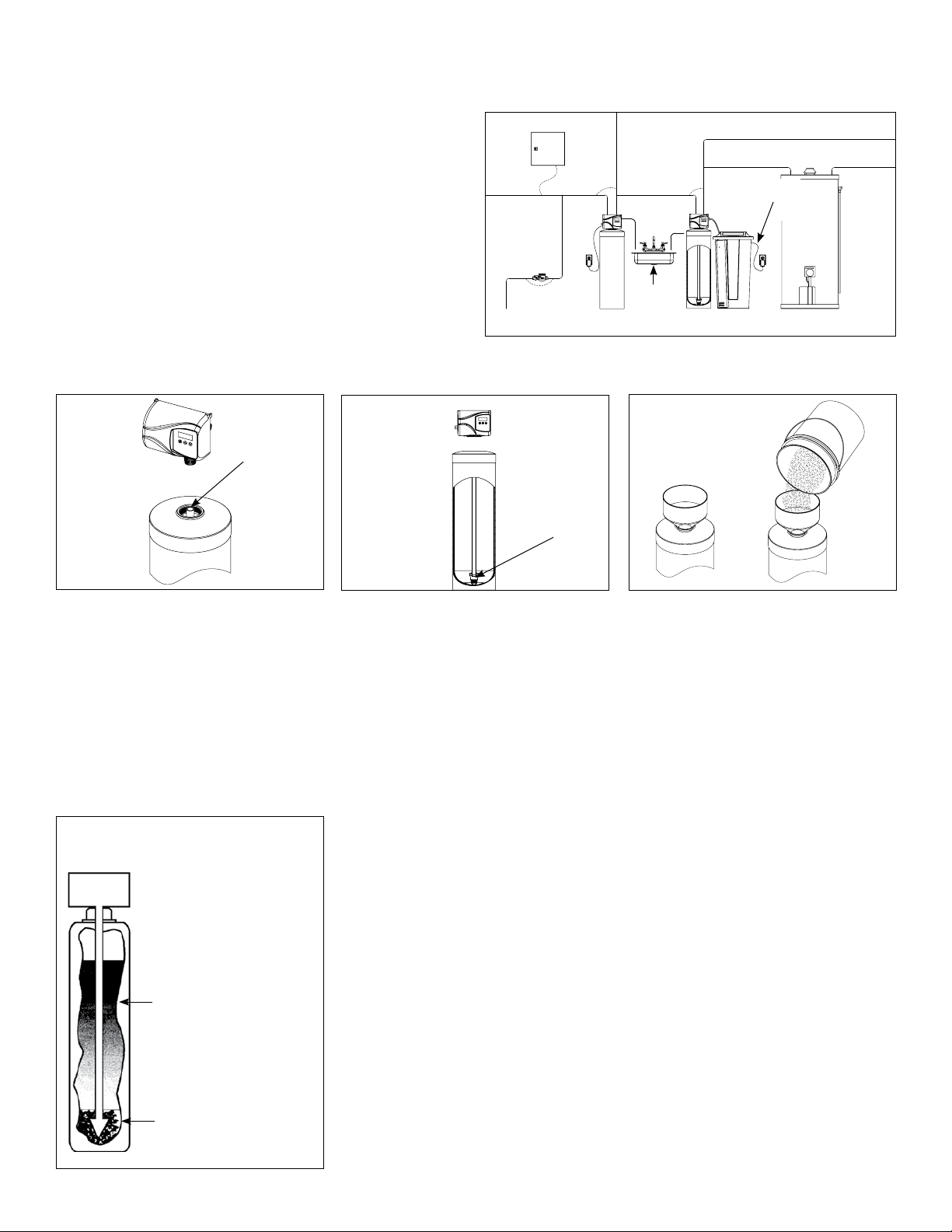

Preparations

1. Determine the best location for your water softener,

bearing in mind the location of your water supply lines,

drain line and 120 volt AC electrical outlet. Subjecting the

softener to freezing or temperatures above 43°C (110°F)

will void the warranty.

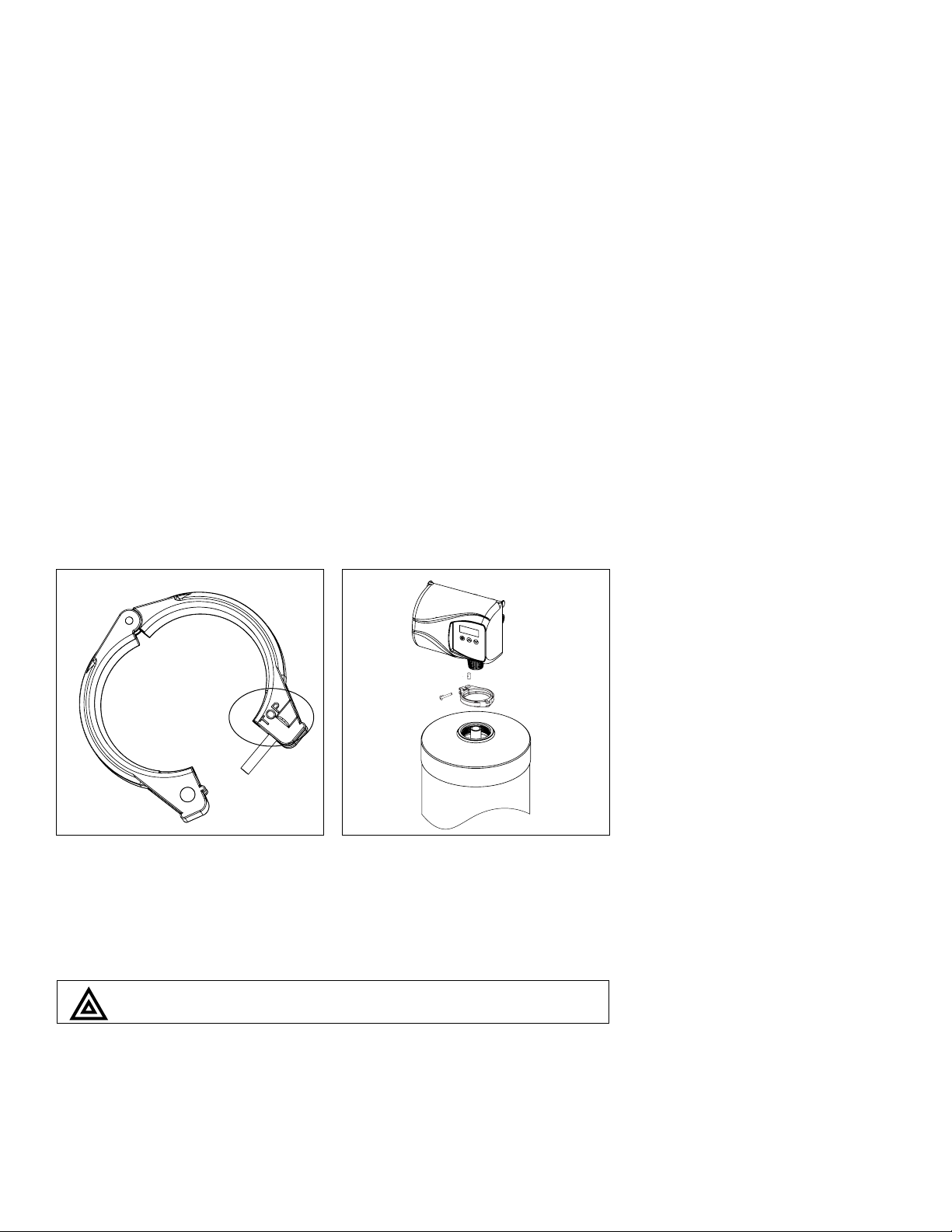

2. Media Installation (When Necessary). Models including

and higher than 1.5 CF of media are shipped with separate media in pails or boxes. Models lower than 1.5 CF of

media come loaded with media and this step can be

skipped for new installation.

a

Plug

the

Riser

Tube

b

e

Electrical Panel

1

Raw

Water

To Outdoors

Water Meter

The riser

(distributor)

remains inside

the tank seated

in the depression

at the bottom

Filter

Hard

Filtered

Water

Ground Strap

Drain

Drain

Drain

e

Iron Guard Softener

Electrical

Outlet

Cold Soft Water

Hard Soft Water

Water Heater

a) Remove the valve from

the mineral tank.

Iron

Softener

Resin

(Amber to Blonde)

& Garnet Fine

(purple) Mixed

Support Bed

(when supplied)

Fine, Medium and/or

Coarse Gravel

d

b) Temporarily plug the open end

of the riser tube to ensure that no

resin or gravel falls down into the

distribution.

The riser (distributor) remains

inside the tank seated in the

depression at the bottom

Plug tube with a tape.

Remove after media is loaded

c. Fill mineral tank one quarter full of

water to protect distribution during

gravel installation.

d. Place the media into the tank in the

order indicated above. Slowly and

carefully add the gravel support

bed and the softener or filtration

media leveling each layer as it is

placed into the tank.

Fill support bed first (if supplied)

The media will not always spill down

inside the tank and may need to be

swept inside.

e. Fill support bed (if supplied) first.

During the filling process, ensure the

distributor tube stays on the bottom

of the tank, reasonably centered.

Remove the tape from the distributor once media is loaded. Whenever

possible, fill the tank outdoors to

avoid problems with dust. If filling

indoors, a dust mask should be worn.

8

The large funnel (sold separately part

D

C

B

# 43000) makes filling the tank easier

f

O-ring

and neater. (Or an empty 1 gallon or 4

liter container with the bottom cut out

makes a good funnel.)

f. Unplug the riser tube, carefully position the valve over it and turn the valve into the threads in the fiberglass tank, tighten-

ing securely into tank. Note: Ensure that the internal O-ring in the valve fits securely over the riser tube. Silicone grease

(part # 92360) or other food grade lubricant may be applied to the O-ring to ease installation of the riser tube.

NOTE: Note: Some medias like used in Calcite are sacrificial and deplete faster depending on inlet water conditions

and usage. The media replenishment is more frequent in high water usage and more acidic water cases.

A dome hole models are available and supplied in which the dome hole is available for a quick addition or

replenishment of media in the tank

f

dome hole

cap

Dome Hole Cap

removed.

CAUTION: make sure the O-Ring is free of

defects. Use silicone based lubrication

(part # 92360) if neccesary

CAUTION! Make sure that the unit is de-pressurized before

conducting this task.

DO NOT use petroleum based lubricants as they will cause swelling of O-ring seals.

9

The softener is now charged with resin.

g. It is recommended that the softener or filter tank now be completely filled with water (SLOWLY) to soak the resin or filtra-

tion media before startup. This will allow the media to absorb water as well as help displace any trapped air. This will

reduce the chance of backwashing resin or filter media out of the tank during the initial backwash on startup.

3. Outside faucets used to water lawns and gardens should not supply softened water. A new water line is often required to

be connected to supply hard water to the inlet of the water softener and to the outside faucets.

Cut the water line between where it enters the house and before any lines that branch off to feed the hot water heater

or other fixtures in the house and as near the desired location of the water softener as possible. Install a tee fitting on

the feed end of the cut pipe, and an elbow fitting on the other end. Install piping from the tee to the inlet of the water

softener and from the elbow to the outlet of the softener. To sever the water lines which branch off to feed any outside

faucets, cut the branch lines approximately two inches from the fitting on the main water line. Install an elbow on the

end of the pipe nearest the outside faucet and a cap on the end connected to the existing water line. Install piping from

the tee installed on the inlet line to the water softener to the elbow installed on the pipe to the outside faucet. Following

this procedure will result in all lines in the house, with the exception of the outside faucets, but including the water heater

and therefore the hot water lines, being supplied with soft water.

Installation Steps:

1

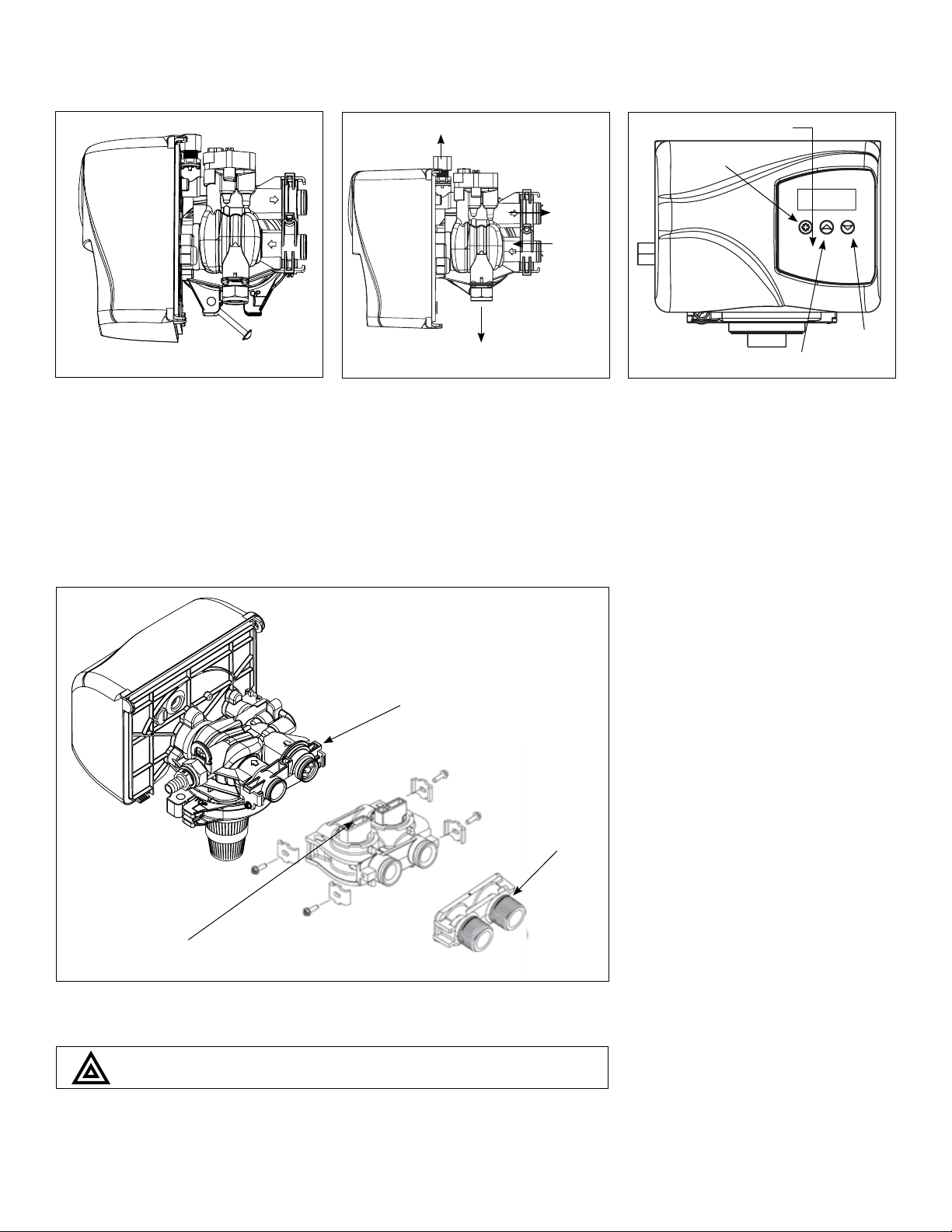

1. Clamp Ring – The clamp ring con-

nects the control valve to the tank

and provide an easy way to disconnect tank during control valve servicing. Make sure that the clamp ring

screw is tightened

The “Clamp Ring” should secure the valve with the top of the flange

facing up. Please note “top” on the clamp ring.

10

Brine Line 3/8”

Timer Controls

Extra Cycle

Button

Outlet

Inlet

4

2

2. Familiarize yourself with the location

of the inlet, outlet and drain on the

control valve. Be very careful not to

get the controls wet.

Make sure that the flow

meter is connected to the

outlet of the valve

Drain 1/2”

Yoke

3

3. Familiarize yourself with the buttons

on the timer control.

4. Attach the bypass valve to the control valve (and yoke if plastic bypass

is used). Connect the inlet and outlet

of the water softener to the plumbing in the house. The control valve

must not be submitted to temperatures above 43°C (110°F). When

sweat fittings are used, to avoid

damaging the control valve, solder

the threaded copper adapters to

the copper pipe and then, using

Teflon tape, screw the assembly into

the bypass valve.

UP button

DOWN

button

Bypass

Do not use pipe thread compound as it may attack the material

in the valve body

.

11

5

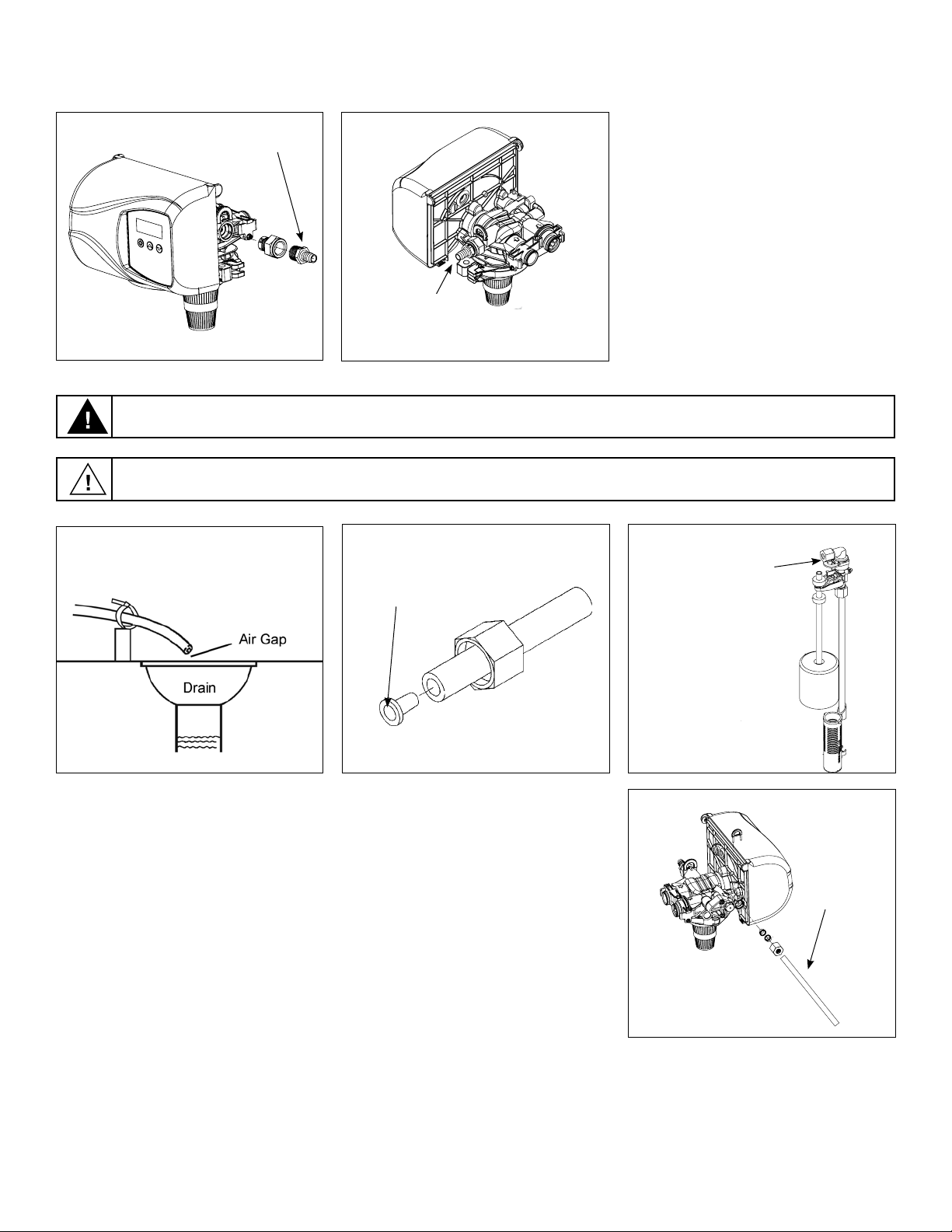

Waste connections or drain outlet shall be designed and constructed to provide for connection to the sanitary

waste system through an air-gap of 2 pipe diameters or 1 inch (22 mm) whichever is larger.

Never insert drain line directly into a drain, sewer line, or trap. Always allow an air gap between the drain line and

the wastewater to prevent the possibility of sewage being back-siphoned into the conditioner.

Hose Barb

5

Connect 1/2”

drain hose (not supplied)

with a hose clamp here

5. Drain Line Connection: Using teflon

tape, screw the 1/2” hose barb into

the drain port in the valve. Attach

1/2” drain hose to the hose barb and

tighten securely with a hose clamp.

Run the drain line to a floor drain or a

laundry drain. Complete any necessary plumbing.

5

6. The brine line is connected to the

safety float assembly of the brine

tank. Pull the 3/8” brine line through

the hole in the back of the brine

tank. Connect the brine line to the

fitting on the side of the valve using

the nut and ferrule. Tighten snugly.

Remove the nut from the brine line

of the valve and push the other end

of the brine tube inside it. Make sure

that the brass insert is snugged inside

the brine tubing. The brine tubing

should pass through both plastic

inserts of the black nut.

6

Tube Insert

7. Overflow Connection (Optional): In

the event of a malfunction, the brine

TANK OVERFLOW will direct “overflow”

to the drain instead of spilling on the

floor. This fitting should be installed at

the side of the cabinet or brine tank.

To connect the overflow line, drill

the hole on the side of the tank, 2 to

3 inches below from the top of the

brine tank. Insert overflow fitting (sold

separately part # 33006) into tank and

tighten with plastic thumb nut and

gasket as shown. Attach length of

1/2-inch (1.3-cm) I.D. tubing (not supplied) to fitting and run to drain. Do not

elevate overflow line higher than overflow fitting.

Do not tie into drain line of control unit. Overflow line must be a direct, separate line from overflow fitting to drain, sewer or tub. Allow an air gap as per

drain line instructions

6

One end of the

brine tubing come

attached to the

safety float

assembly

6

Brine

Tubing

12

Loading...

Loading...