WaterGroup 4VTFC09G-PB, 4VTFC25G-PB, 4VTFC50G-PB, 4VTFC75G-PB Owner's Manual

OWNER’S GUIDE

ADVANCED REVERSE OSMOSIS

WATER TREATMENT SYSTEMS

WQA Tested and Certified against

CSA B483.1:

4VTFC09G-PB 4VTFC50G-PB

4VTFC25G-PB 4VTFC75G-PB

These models are tested and certified by

WQA against NSF/ANSI 58 for the

reduction of TDS. Tested and Certified by

WQA against ORD0902 for “lead free”

compliance.

4VTFC09G-PB 4VTFC50G-PB

4VTFC25G-PB 4VTFC75G-PB

Please fill in the following information and retain for reference:

Unit Model Number: _________________________________

Serial Number: _____________________________________

Date Purchased: ____________________________________

Date Installed: ______________________________________

I

INTRODUCTION

Congratu lations, on the purc hase of your new Advanced Reverse Osmosis Water Treatment System. Treated with care and

regu lar maintenance, your new system will provide many years of service deliv er ing great tasting water to the tap .

By now, you have probably a lready opened the box to survey the contents. Please take a few moments to review this

manual before proceeding with the installation an d use of the system. So me important ite ms to review are as follows:

o Check all components for any da mage caused in shipment. Also, take a qu i ck inventory of all items suppl ied

to ensure none are missing. A che cklist in the next section wi l l assist you with ide ntifying these items.

o Ensure that the reverse osmosis system and storage tank wil l easily fit into th e desired lo cation. Th is reverse

osmosis system and tank needs to be re moved for regular ma intenanc e, so good a c cessibi l ity is an i mportant

tip to keep in mind.

o Read all CAUTIONS and NOTES c ontained within this manual. They prov ide valua b l e installation tips and

advice on how to properly install and maintain your Reverse Osmosis Drinking Water System.

o For installation in Massachusetts, the Massachusetts Plumbing Code 248 CMR shall be adhered to.

Consult your licensed plumber for installation of this system. The use of saddle (piercing) valves is not

permitted.

The water produced by the reverse osmosis (RO) process can b e used for many purposes arou nd the home.

o Drinking Water - keep a container of RO water in th e fridge to be able to enjoy the c leaner, fresher taste.

Alternat ive ly, take it directly from the tap.

o Ice Cubes - use RO water to fill ice cube trays. Ice cubes made from RO water are typ ically c learer and

better tasting than i c e made from tap water.

o Automatic Ice Makers - a water line from th e RO system can be plumb ed to refrigerators with automati c

icemakers. Addit ional ac cessories required to co mp lete this connection are no t inc l u ded. Please c onsult

the refrig erator’s owner’s manual on this installat ion.

o Kettles and Coffee Makers - tap water eventual ly causes fil ms and scale in these dev i c es that is d iffic u lt

to c lean. RO water is very low in d issolved minerals c ontent, greatly reducing the cha n c e of scale

buildup.

o Cooking - use RO water for boiling pasta, rice or any other re c ipe that calls for water.

o Washing Fresh Fruit & Vegetables - prevent tap water m inerals from being de posited onto food to

ma i ntain freshness.

o Family Pets – A l l ow your pets to enjoy the same gre at tasting water you do.

o Irons & Steamers - preve nt minera l bu i ldup in h ousehold applianc es that use water and eventually bui l d

up with scale when using tap water.

Now you can enjoy all the benefits of great tasting water supplied by your reverse osmosis drinkin g water system.

II

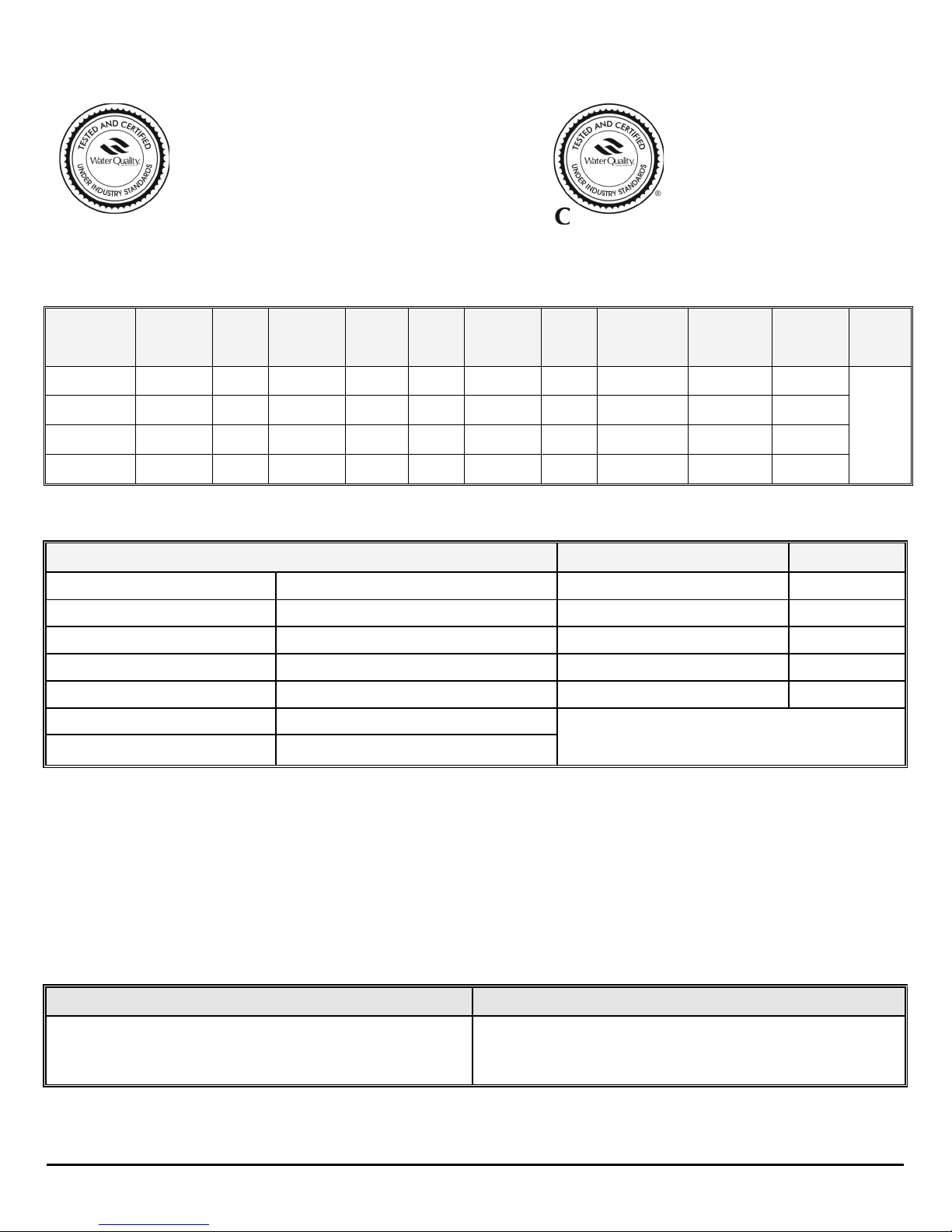

CERTIFIED CONTAMINANT REDUCTION PERFORMANCE

The following 12403 Series Reverse Osmosis Systems conform to NSF/ANSI 58 for the specific performance claims as verified and substantiated

by test data.

MODELS AND SYSTEM CONFIGURATIONS

Table 1

Model

Description

Storage

Tank

# of

Vessels

Storage

Tank

Capacity

Litres (gal)

Vessel

1

Vessel 2 Vessel

3

Vessel

4

Daily

Production

Rate

(2)

L/day

(G/day)

Efficiency

Rating

(3)

%

Recovery

Rating

(4)

%

Monitor

(6)

4VTFC09G-PB

Plastic/Metal

4

6.81 (1.8)

Sediment

Filter

Carbon

Filter

TFC

(1)

Membrane

Carbon

Filter

15.5 (4.1)

12.8

35

4VTFC25G-PB

Plastic/Metal

4

7.19 (1.9)

Sediment

Filter

Carbon

Filter

TFC

(1)

Membrane

Carbon

Filter

29.1 (7.7)

8.2

18

4VTFC50G-PB

Plastic/Metal

4

6.81 (1.8)

Sediment

Filter

Carbon

Filter

TFC

(1)

Membrane

Carbon

Filter

34.44 (9.1)

4.8

16.7

4VTFC75G-PB

Plastic/Metal

4

7.19 (1.9)

Sediment

Filter

Carbon

Filter

TFC

(1)

Membrane

Carbon

Filter

49.58 (13.1)

5.7

15.3

Smartap®

Push

Button

CONDITIONS FOR USE

Table 2

Source Water Supply Profile

Chemical Parameters

Max mg/L

Community/Private

Chlorinated/Non-Chlorinated

Hardness (CaCO3 )

<170 (10 gpg)

Feed Water Pressure

(5)

242-690 kPa (35-100 psig)

Iron (Fe )

<0.1

Temperature

4°-38° C (40°-100° F)

Manganese (Mn)

<0.05

pH Range

3.0 - 11.0

Hydrogen Sulfide (H2S )

0.00

Maximum TDS Level

2000 mg/L

Residual Chlorine (Cl2)

<2.0

Turbidity**

<1.0 NTU

Maximum SDI*** <4.0

** Nephelometric Turbidity Unit

*** Silt Density Index: Value stated in SDI units.

NOTES:

1. TFC refers to reverse osmosis membranes constructed from a THIN FILM COMPOSITE

2. The daily production rate is the volume of product water produced by the system per day and is determined by testing in accordance with the procedure

outlined in NSF/ANSI Standard 58.

3. System’s Efficiency rating as verified by testing in accordance with NSF/ANSI standard 58. Efficiency rating means the percentage of the influent water to

the system that is available to the user as reverse osmosis treated water under operating conditions that approximate typical daily usage.

4. System’s Recovery rating as verified by testing in accordance with NSF/ANSI Standard 58. System’s Recovery rating means the percentage of the

influent water to the membrane portion of the system that is available to the user as reverse osmosis treated water when the system is operated without a

storage tank or when the storage tank is bypassed.

5. PRESSURE REGULATOR IS RECOMMENDED FOR FEED WATER PRESSURES EXCEEDING 552 kPa (80 psig)

6. SMARTAP® PUSH BUTTON MONITOR. Indicator lights located on the module cover report system status.

OPTIONS AND ACCESSORIES

PRODUCT WATER FAUCETS

BOOSTER PUMP

Faucets will be supplied as Air Gap.

A booster pump may be used if system pressure is below 242 kPa (35 psi).

Pump should be placed near RO Module and installed in feed water line just

before it enters Module.

Models 4VTFC09G-PB, 4VTFC25G-PB, 4VTFC50G-PB

and 4VTFC75G-PB are tested and certified by WQA

against NSF/ANSI 58 for the reduction of TDS.

Tested and Certified by WQA against ORD0902 for

“lead free” compliance.

WQA Tested and

Certified against

CSA B483.1

III

GENERAL INFORMATION

This Owner’s Guide covers all components that may be included with a system. Information relating to any component that is NOT included with

your system may be disregarded.

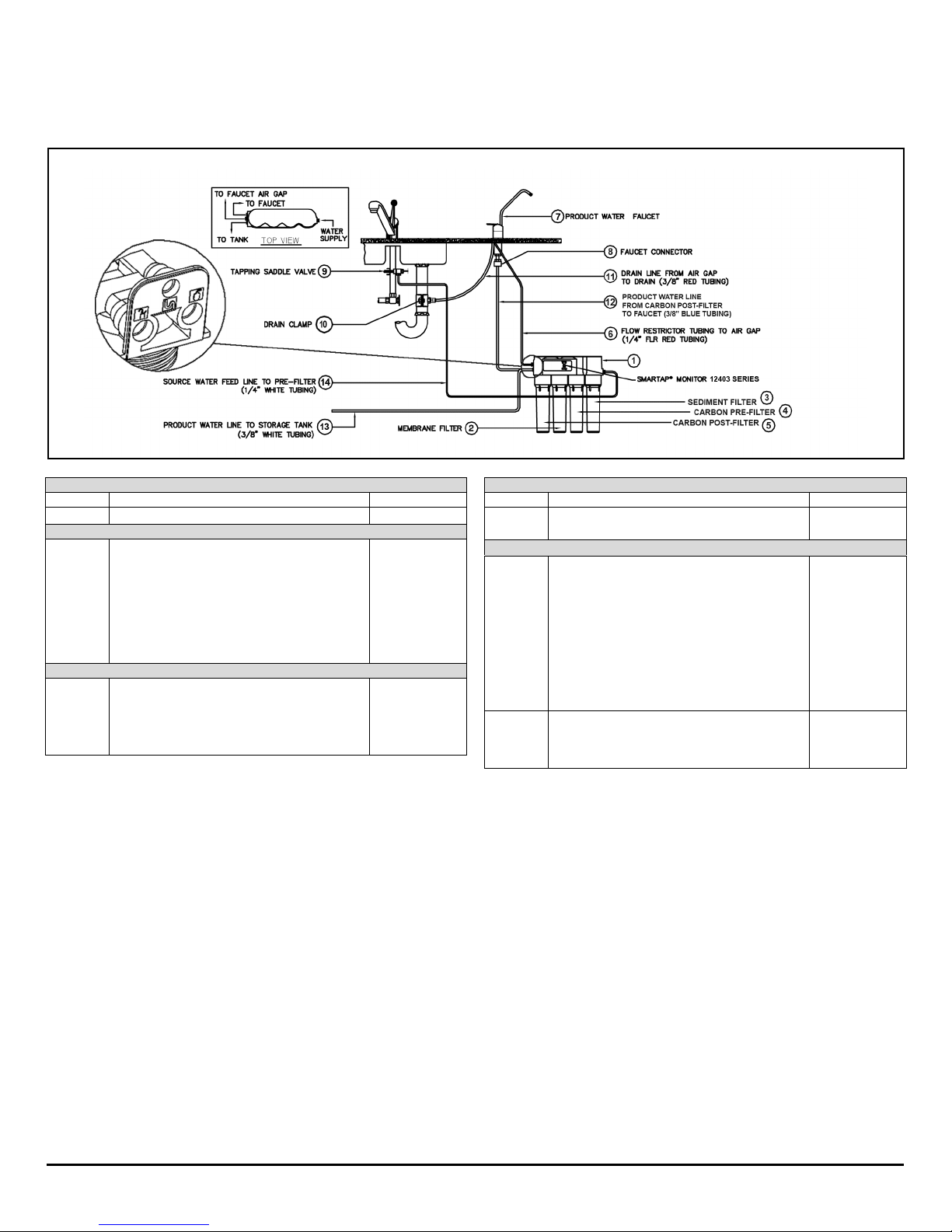

SYSTEMS WITH AIR GAP FAUCET, MODEL 12403

n/s - not shown

REVERSE OSMOSIS SYSTEM

Item

Description

Part No.

1

4 Vessel Module, With Quality Monitor

Fig 8

MEMBRANE AND FILTERS

2

3

4

5

Reverse Osmosis TFC Membrane

9 GPD, Yellow Casing, Red Tape

25 GPD, Yellow Casing, Black Tape

50 GPD, Yellow Casing, White Tape

75 GPD, Yellow Casing, Blue Tape

Sediment Filter

Carbon Pre-Filter

Carbon Post Filter

33001071

33001068

33001033

33001056

41400008

41400009

41400009

FLOW RESTRICTOR TUBING

6

Flow Restrictor Tubing

9 GPD

25 GPD

50 GPD

75 GPD

40600034

40600040

40600041

40600042

PRODUCT WATER FAUCETS

Item

Description

Part No.

7 8 Chrome-Plated Metal, Air Gap

Connector, Faucet 3/8” x 7/16”

92192, Fig 7

92407

INSTALLATION KIT

9

10

11

12

13

14

n/s

n/s

n/s

Complete Kit

Supply Valve, Saddle-Tapping

Drain Clamp, Saddle Clamp, Air Gap, 3/8”

Tubing, 3/8”, Red

Tubing, 3/8”, Blue

Tubing, 3/8”, White

Tubing, 1/4", White

Screw, Mounting Bracket (2 each)

Elbow, Stem, 3/8” (2 each)

Elbow, Stem ¼” (2 each)

92276

92160

87604

87600

115207

115200

32701006

33501071

33501064

n/s

n/s

n/s

n/s

Owner’s Guide

Kit, O-Rings, Collets, QC ¼” & 3/8”

Safety Clip 1/4”

Safety Clip 3/8”

36101291

92166

96345

92346

Figure 1.A: Component* and Interconnection Locators, Model 12403.

*Replacement parts can be obtained from your local dealer. Refer to your local dealer stamp at the back page of this manual.

IV

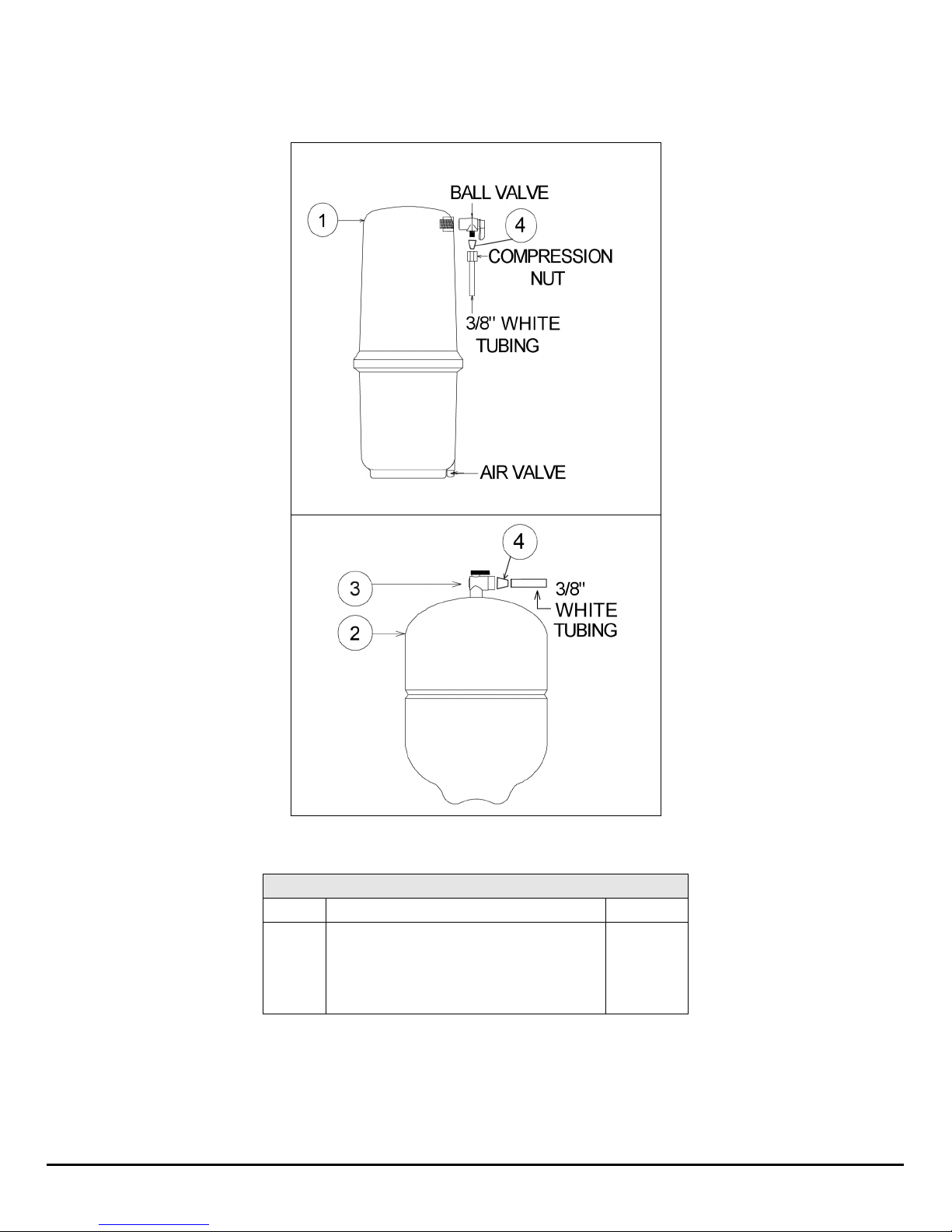

GENERAL INFORMATION

PRODUCT WATER STORAGE TANKS

PRODUCT WATER STORAGE TANKS - ALL SYSTEMS

Item

Description

Part No.

1

2

3

4

Storage Tank Assembly, Polymer

Storage Tank Assembly, Metal

Ball Valve, 3/8”, Steel Tank

Ball Valve, 3/8”, Plastic Tank

Insert, 3/8”

92313

92342/92294

33503601

80704

92329

Figure 1.B: Product Water Storage Tanks.

Loading...

Loading...