Waterford Appliances E61-NG, E61-LP User Manual

WARNING:

If the information in these instructions are not followed exactly,

a fire or explosion may result causing property damage,

personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

FOR YOUR SAFETY

What to do if you smell gas:

Do not try to light any appliance

Do not touch any electrical switch:

do not use any phone in your

building.

Immediately call your gas supplier

from a neighbour's phone. Follow

the gas supplier's instructions.

If you cannot reach your gas

supplier, call the fire department.

www.waterfordstoves.com

EMERALD Gas Fireplace Insert

Owners &

Installation Manual

MODELS: E61-NG Natural Gas E61-LP Propane

Tested by:

Installer: Please complete the details on the back cover

and leave this manual with the homeowner.

Homeowner: Please keep these instructions for future reference.

908-429a 04/21/05

FPI FIREPLACE PRODUCTS INTERNATIONAL LTD. 6988 Venture St., Delta, BC Canada, V4G 1H4

WATERFORD GAS FIREPLACE INSERT

TO THE NEW OWNER

Congratulations! You are the owner of a state-of-the-art Gas Insert by Waterford Irish Stoves. The Waterford

Gas Fireplace Series of hand crafted appliances has been designed to provide you with all the warmth and

charm of a fireplace, at the flick of a switch. This series has been approved by Warnock Hersey for both safety

and efficiency. As it also bears our own mark, it promises to provide you with economy, comfort, and security

for many trouble free years to follow. Please take a moment now to acquaint yourself with these instructions

and the many features of your Waterford Fireplace.

This appliance may be installed in an aftermarket permanently located, manufactured

(mobile) home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance

is not convertible for use with other gases unless a certified kit is used.

Minor imperfections such as

blisters, seeds or thin flaws visible

in this product are not defects.

These are inherent in the handcrafted enamel process and cannot

be avoided, and they substantiate

that this is genuine porcelain

enamel.

2 Waterford E61 Gas Fireplace Insert

TABLE OF CONTENTS

WATERFORD GAS FIREPLACE INSERT

Page Page

SAFETY LABEL

Safety Label.............................................................. 4

INSTALLATION REQUIREMENTS

For your safety............................................................ 6

Gas Pipe Testing ........................................................ 6

Specifications ............................................................. 6

Zero Clearance Fireplace Installation .............................6

Installation into a Factory Built Fireplace..................... 6

Before You Start ......................................................... 6

General Safety Information .......................................... 6

Installation Checklist ................................................... 6

Materials Required ....................................................... 7

Clearances to Combustibles ........................................ 7

-Floor Protection .....................................................7

INSTALLATION INSTRUCTIONS

Gas Connection .......................................................... 8

System Data Table .......................................................8

High Elevation ...............................................................8

Venting .........................................................................8

Flue Liner Installation ....................................................9

Conversion from Nat. Gas to Propane............................9

Reduction to Lower Btu ...............................................11

Gas Pressure Test ......................................................11

Valve Description ........................................................ 12

Aeration System .........................................................12

Shroud Surround Installation .......................................12

Optional Door Grill Installation ..................................... 13

Log Installation............................................................13

Optional Wall Thermostat Installation .......................... 13

Optional Remote Control Installation ...........................14

Wiring Diagram ......................................................... 14

OPERATING INSTRUCTIONS

Operating Instructions .................................................15

Lighting Procedure ......................................................15

Shutdown Procedure ................................................... 15

First Fire .....................................................................1 5

Automatic Convection Fan Operation .......................... 15

Normal Operating Sounds of Gas Appliances..............15

Copy of Lighting Plate Instructions ..............................16

MAINTENANCE

Maintenance ............................................................... 16

Log Replacement and Cleaning ...................................17

Door Gasket and Glass Gasket .................................. 17

Glass Replacement..................................................... 17

Fan Maintenance ........................................................ 17

Valve Maintenance ......................................................18

Parts List ....................................................................19

WARRANTY

Warranty .....................................................................23

3Waterford E61 Gas Fireplace Insert

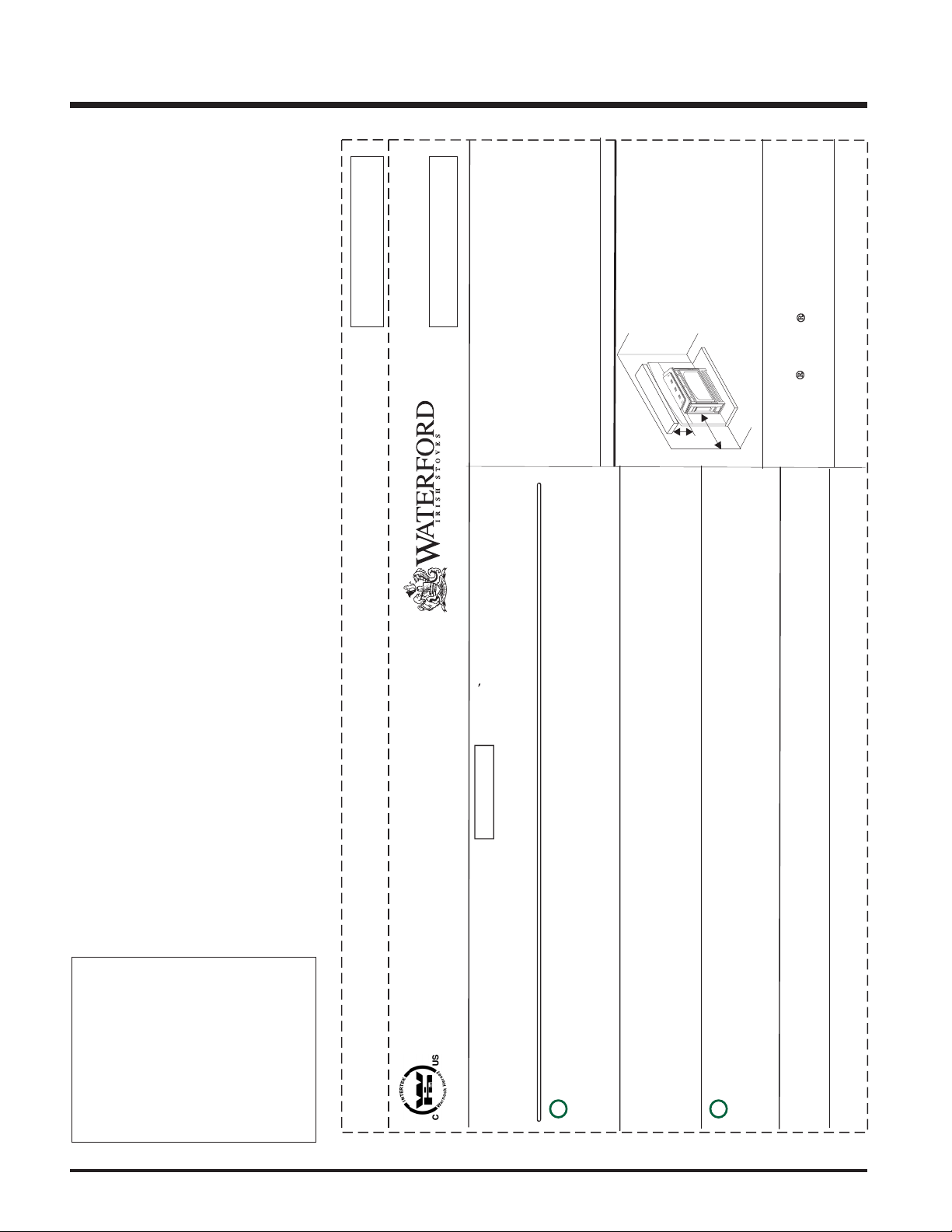

SAFETY LABEL

DUPLICATE SERIAL NO.

DO NOT REMOVE OR COVER THIS LABEL /

NE PAS ENLEVER CETTE TIQUETTEÉ

205

205

FPI Fireplace Products International Ltd., Delta, BC, Canada

Serial no./

No de serie

908-419b

Made in Canada/Fabrique au Canada

ÉÉQUIP A L'UISINE POUR GAZ NATURAL

5" WC/C.E. (1.25 kPa)

3.8" WC/C.E. (0.94 kPa)

1.1" WC/C.E. (0.27 kPa)

#33 DMS (2.87mm)

200

36,100 Btu/h (10.57 Kw/h)

18,000 Btu/h (5.28 Kw/h)

0-4500 ft/pi (610-1372m)

Minimum supply pressure

Manifold pressure High

Manifold pressure Low

Factory Equipped for Altitude 0-2000 ft.

Maximum Input

Minimum Input

Orifice size

Altitude

Convertible to 27,000 Btu for Altitude 0 - 4500 ft. with Kit #: 260-920

Maximum Input

Minimum Input

Orifice size

Altitude

Convertible for Altitude 2000-4500 ft.

Maximum Input

Minimum Input

Orifice size

Altitude

FACTORY EQUIPPED FOR NATURAL GAS Model:E61NG

Pression d'allimentation minimum

Pression la tubulure d' chappement lev e

Pression la tubulure d' chappement basse

à

à

ééé

é

38,000 Btu/h (11.14 Kw/h)

19,000 Btu/h (5.57 Kw/h)

#32 DMS (2.9mm)

0-2000 ft/pi (0-610m)

27,000 Btu/h (7.91 Kw/h)

13,500 Btu/h (3.95 Kw/h)

#40 DMS (2.49mm)

0-4500 ft/pi (0-1372m)

D bit Calorifique maximum

D bit Calorifique minimum

Dimensions de l'orifice

L'altitude

é

é

D bit Calorifique maximum

D bit Calorifique minimum

Dimensions de l'orifice

L'altitude

é

é

D bit Calorifique maximum

D bit Calorifique minimum

Dimensions de l'orifice

L'altitude

é

é

This appliance is only for use with the type of gas indicated on the rating plate and may be installed in an

aftermarket, permanenlty located,manufactured (mobile) home where not prohibited by local codes. See owner's

manual for details. This appliance is not convertible for use with other gases, unless a certified kit is used.

A

B

Minimum Clearances

to Combustibles/

Degagement Minimum

De Materiaux Combustibles

Unit to Sidewalls A 9"/230mm

Top of Hob to mantel:

unshielded B 16"/406mm

shielded B 12"/305mm

To ceiling from top of stove: 36"/ 915mm

A floor protector consisting of one layer of ½" thick

WonderBoard , Durock , or equivalent extending

at least 9" in front of the face of the unit and the full

width of the front surface is required.

Floor Protector

This appliance must be installed in accordance with

local codes, if any; if none, follow the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or Natural Gas and

Propane Installation Codes, CSA B149.1.

FOR USE WITH GLASS DOORS CERTIFIED

WITH APPLIANCE ONLY.

This vented gas fireplace heater is

not for use with air filters.

Not for use with solid fuel.

Electrical Supply (115 V, 1.13A, 60 Hz)

Approved for use with Emerald Zero Clearance Kit, Part No. 270-900.

Listed:

Report No.

VENT GAS FIREPLACE HEATER

476-1714-00 (Oct. 1999)

Certified for/Certifi e pour: CANADA and U.S.A.é

ANSI Z21.88b-2003/CSA 2.33b-2003, /CGA 2.17-M91Tested to: CAN

This is a copy of the label that accompanies

each Waterford E61-NG Gas Insert Natural

Gas. We have printed a copy of the contents

here for your review. The safety label is located

on the right side door panel.

NOTE: Waterford units are constantly being

improved. Check the label on the unit and if there

is a difference, the label on the unit is the correct

one.

For the State of Massachusetts, installation

and repair must be done by a plumber or

gasfitter licensed in the Commonwealth of

Massachusetts.

For the State of Massachusetts, flexible

connectors shall not exceed 36 inches in

length.

For the State of Massachusetts, the appliances individual manual shut-off must be a

t-handle type valve.

4 Waterford E61 Gas Fireplace Insert

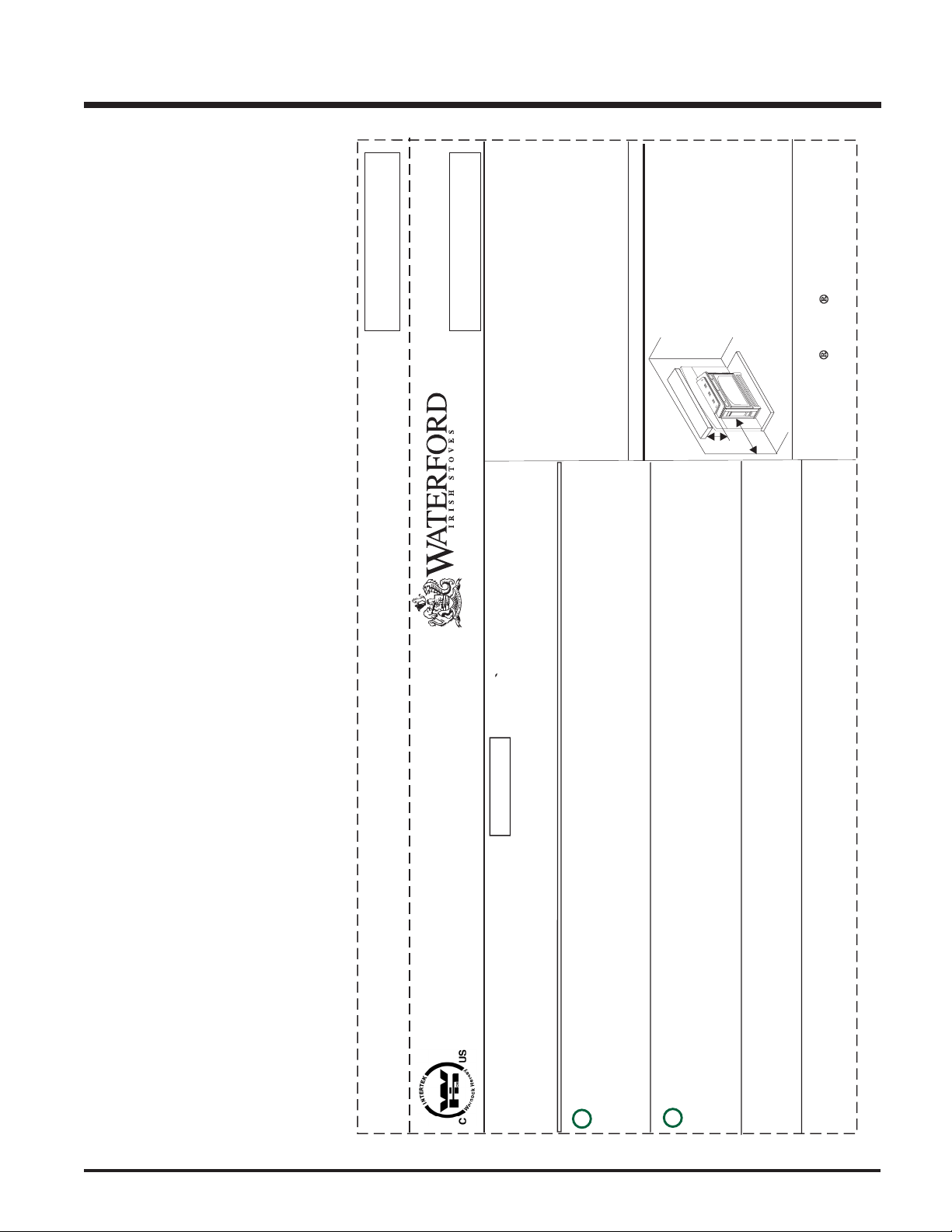

This is a copy of the label that accompanies

DUPLICATE SERIAL NO.

DO NOT REMOVE OR COVER THIS LABEL /

NE PAS ENLEVER CETTE TIQUETTEÉ

204

204

Serial no./

No de serie

908-438b

12" WC/C.E. (3.00 kPa)

11" WC/C.E. (2.74 kPa)

2.9" WC/C.E. (0.72 kPa)

Minimum supply pressure

Manifold pressure High

Manifold pressure Low

Factory Equipped for 35,000 Btu

Maximum Input

Minimum Input

Orifice size

Altitude

Convertible to 29,000 Btu for Altitude 0 - 4500 ft. with Kit #: 260-922

Maximum Input

Minimum Input

Orifice size

Altitude

FACTORY EQUIPPED FOR PROPANE Model:E61LP

Pression d'allimentation minimum

Pression la tubulure d' chappement lev e

Pression la tubulure d' chappement basse

à

à

ééé

é

35,000 Btu/h (10.26 Kw/h)

17,500 Btu/h (5.13 Kw/h)

#50 DMS (1.8mm)

0-2000 ft/pi (0-610m)

D bit Calorifique maximum

D bit Calorifique minimum

Dimensions de l'orifice

L'altitude

é

é

D bit Calorifique maximum

D bit Calorifique minimum

Dimensions de l'orifice

L'altitude

é

é

ÉÉQUIP A L'UISINE POUR GAZ PROPANE

29,000 Btu/h (8.50 Kw/h)

14,500 Btu/h (4.25 Kw/h)

#52 DMS (1.61mm)

0-4500 ft/pi (0-1372m)

Listed:

Report No.

VENT GAS FIREPLACE HEATER

476-1714-00 (Oct. 1999)

Certified for/Certifi e pour: CANADA and U.S.A.é

ANSI Z21.88b-2003/CSA 2.33b-2003, /CGA 2.17-M91Tested to: CAN

FPI Fireplace Products International Ltd., Delta, BC, Canada

Made in Canada/ Fabrique au Canada

This appliance must be installed in accordance with

local codes, if any; if none, follow the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or Natural Gas and

Propane Installation Codes, CSA B149.1.

FOR USE WITH GLASS DOORS CERTIFIED WITH

APPLIANCE ONLY.

This vented gas fireplace heater is not for

use with air filters.

Not for use with solid fuel.

Electrical Supply (115 V, 1.13A, 60 Hz)

This appliance is only for use with the type of gas indicated on the rating plate and may be installed in an

aftermarket, permanenlty located,manufactured (mobile) home where not prohibited by local codes. See owner's

manual for details. This appliance is not convertible for use with other gases, unless a certified kit is used.

A

B

Minimum Clearances

to Combustibles/

Degagement Minimum

De Materiaux Combustibles

Unit to Sidewalls A 9"/230mm

Top of Hob to mantel:

unshielded B 16"/406mm

shielded B 12"/305mm

To ceiling fromtop of stove: 36"/ 915mm

Approved for use with Emerald Zero Clearance Kit, Part No. 270-900.

Floor Protector

A floor protector consisting of one layer of ½" thick

WonderBoard , Durock , or equivalent extending

at least 9" in front of the face of the unit and the full

width of the front surface is required.

each Waterford E61-LP Gas Insert Propane.

We have printed a copy of the contents here for

your review. The safety label is located on the

right side door panel.

NOTE: Waterford units are constantly being

improved. Check the label on the unit and if there

is a difference, the label on the unit is the correct

one.

SAFETY LABEL

5Waterford E61 Gas Fireplace Insert

INSTALLATION

IMPORTANT:

SAVE THESE

INSTRUCTIONS

The Waterford Gas Fireplace must be installed

in accordance with these instructions. Carefully read all the instructions in this manual first.

Consult the building authority having jurisdiction

to determine the need for a permit prior to

starting the installation.

Note: Failure to follow these instructions

could cause a malfunction of the

heater which could result in death,

serious bodily injury, and/or property damage. Failure to follow these

instructions may also void your

fire insurance and/or warranty.

FOR YOUR SAFETY

This appliance requires air for proper combustion. Always provide adequate combustion and

ventilation air. Follow instructions and information in the current CAN/CGA B149 (in Canada)

or the current National Fuel Gas Code ANSI

Z223.1 (in the USA), regarding requirements for

combustion and ventilation air.

GAS PIPE TESTING

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.45

kPa).

SPECIFICATIONS

Fuel: Natural gas or Propane

Electrical: 120V A.C. system.

Fan/Blower: Variable speed, 140 CFM.

Log Sets: Ceramic fiber, 3 per set.

Vent System: Listed two 3" co-linear

aluminum flex liners.

ZERO CLEARANCE

INSTALLATION

The WATERFORD Gas Inserts are only approved for installation into the WATERFORD E61 Gas Insert Zero Clearance Fireplace Kit, model #270-900.

NOTE: There are changes in clearances

and other differences when installing

into the Zero Clearance Kit. Read the Zero

Clearance Kit manual and the decal on the

Kit.

INSTALLATION INTO

AFACTORY BUILT

FIREPLACE

The WATERFORD Gas Inserts have been tested and approved to be vented into any approved Factory Built Fireplace that will allow

the Insert to physically fit into the firebox.

If the factory built fireplace height is too

low for your Insert, you may remove the

smoke shelf, baffle plate, and damper

plate from the factory built fireplace if

removable without cutting or torching,

as long as these items are saved and are

re-installed in the event that the Insert is

removed.

BEFORE YOU START

Safe installation and operation of this appliance

requires common sense, however, we are

required by the Canadian Safety Standards

and ANSI Standards to make you aware of the

following:

General Safety Information

1) The appliance installation must conform

with local codes or in the absence of local

codes, with current CAN/CGA B149 (in

Canada) or the current National Fuel Gas

Code ANSI Z223.1. This appliance MUST be

installed by a qualified gas fitter technician

only.

2) Installation and repair should be done

by a qualified service person.

3) The appliance should be inspected before

use and at least annually by a professional

service person. More frequent cleaning

may be required due to excessive lint from

carpeting, bedding material, etc. It is imperative that control compartments, and circulating air passageways of the appliance be

kept clean and free from excessive lint from

carpeting and pet hair.

4) See general construction and assembly

instructions. This appliance may only be

installed in a vented, non-combustible fireplace.

5) This appliance may be installed into bedrooms when used with a Listed Millivolt

Thermostat. Some areas may have further

requirements, check local codes before

installation.

6) This unit is approved for installation into a

mobile home.

7) Always connect this fireplace to a chimney

and vent to the outside of the building

envelope. Never vent to another room or

inside a building. Make sure that the vent

is properly sized and is of adequate height

to provide the proper draft.

8) Inspect the venting system annually for

blockage and any signs of deterioration.

9) Any safety glass removed for servicing

must be replaced prior to operating the

appliance.

10)To prevent injury, do not allow anyone who

is unfamiliar with the operation to use the

fireplace.

11)Due to high temperatures, the appliance

should be located out of high traffic areas

and away from furniture and draperies.

Children and adults should be alerted to the

hazards of high surface temperatures,

especially the fireplace glass and gold

trims, and should stay away to avoid burns

or clothing ignition. Young children should

be carefully supervised when they are in

the same room as the appliance. Clothing or

other flammable material should not be

placed on or near the appliance.

12) WARNING: Failure to position the parts

in accordance with the diagrams in

this manual or failure to use only

parts specifically approved with this

appliance may result in property damage or personal injury.

13)Do not use this appliance if any part has

been under water. Immediately call a qualified service technician to inspect the appliance and to replace any part of the

control system and any gas control which

has been under water.

Emissions from burning wood or gas could

contain chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

INSTALLATION

CHECKLIST

The Waterford Gas Insert is installed as listed

below.

1) Unit Location - check Clearances to Combustibles on page 7.

2) Make the gas connections and electrical

connection for fan. See page 8.

3) Install the 3" flue liner to the sliding connector plate. See page 9.

4) Slide the unit half way into the fireplace.

6 Waterford E61 Gas Fireplace Insert

INSTALLATION

5) Pull the vent connector plate through the

tapered brackets and fasten to the front

plate. See page 9.

6) Slide the unit fully into the fireplace and

level.

7) Test gas pressure, page 11. Check aeration, page 12.

8) Assemble and install the shroud. See page

12.

9) Install Optional Door Grill. See page 13.

10)Install the log set. See page 13.

11)Install Optional Remote Control, and Op-

tional Wall Thermostat, if required. See

pages 13 and 14.

12)Explain controls to the homeowner.

15) Final check: Before leaving this unit with

the customer, the installer must ensure that

the appliance is firing correctly. This includes:

a) Clocking the appliance to ensure the

correct firing rate.

b) Adjusting the primary air, if required, to

ensure that the flame does not carbon.

See page 12.

c) Ensuring that the appliance is venting

correctly.

MATERIALS

REQUIRED

WARNING:

Electrical Grounding Instructions

This appliance is equipped with a

three pronged (grounding) plug

for your protection against shock

hazard and should be plugged

directly into a properly grounded

three-prong receptacle. Do not cut

or remove the grounding prong

from this plug.

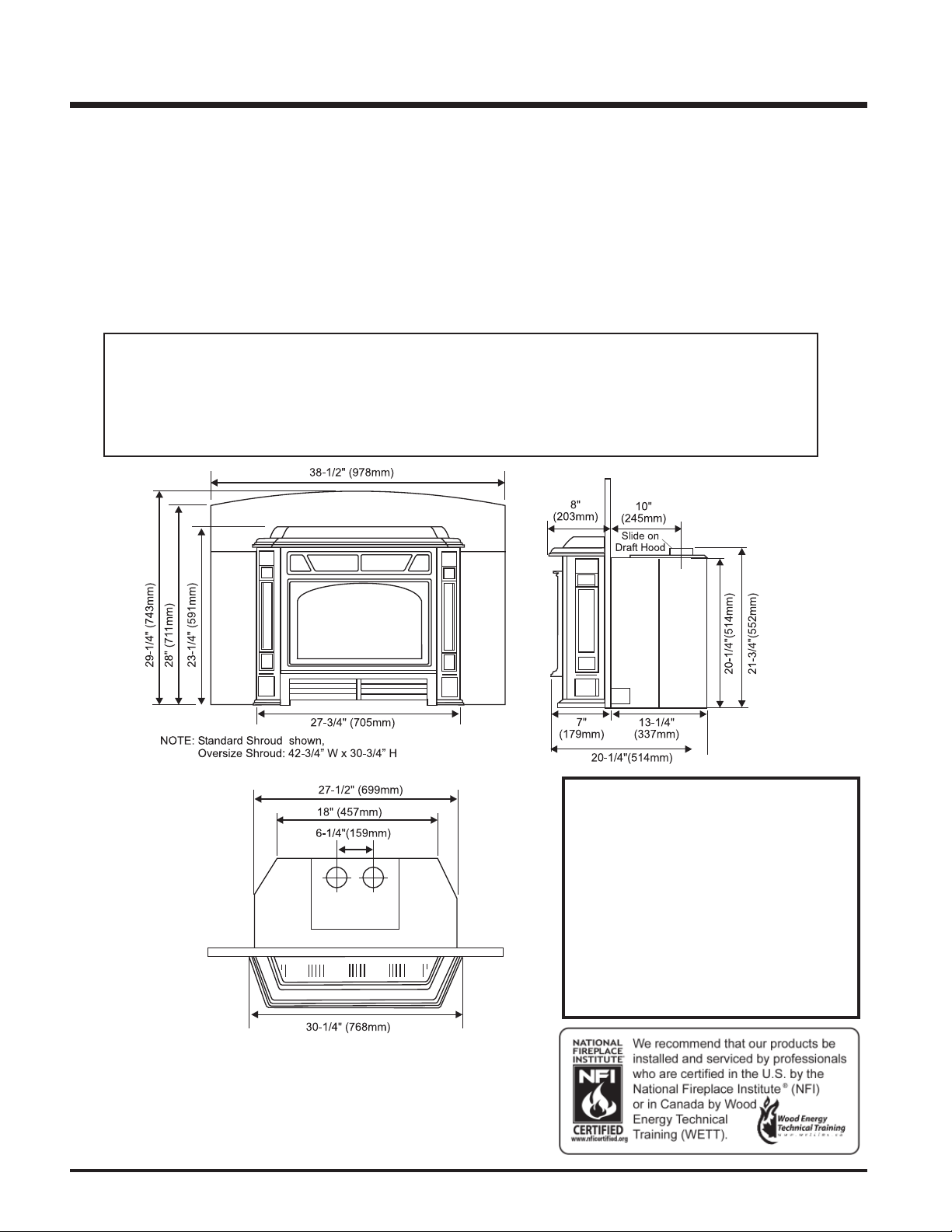

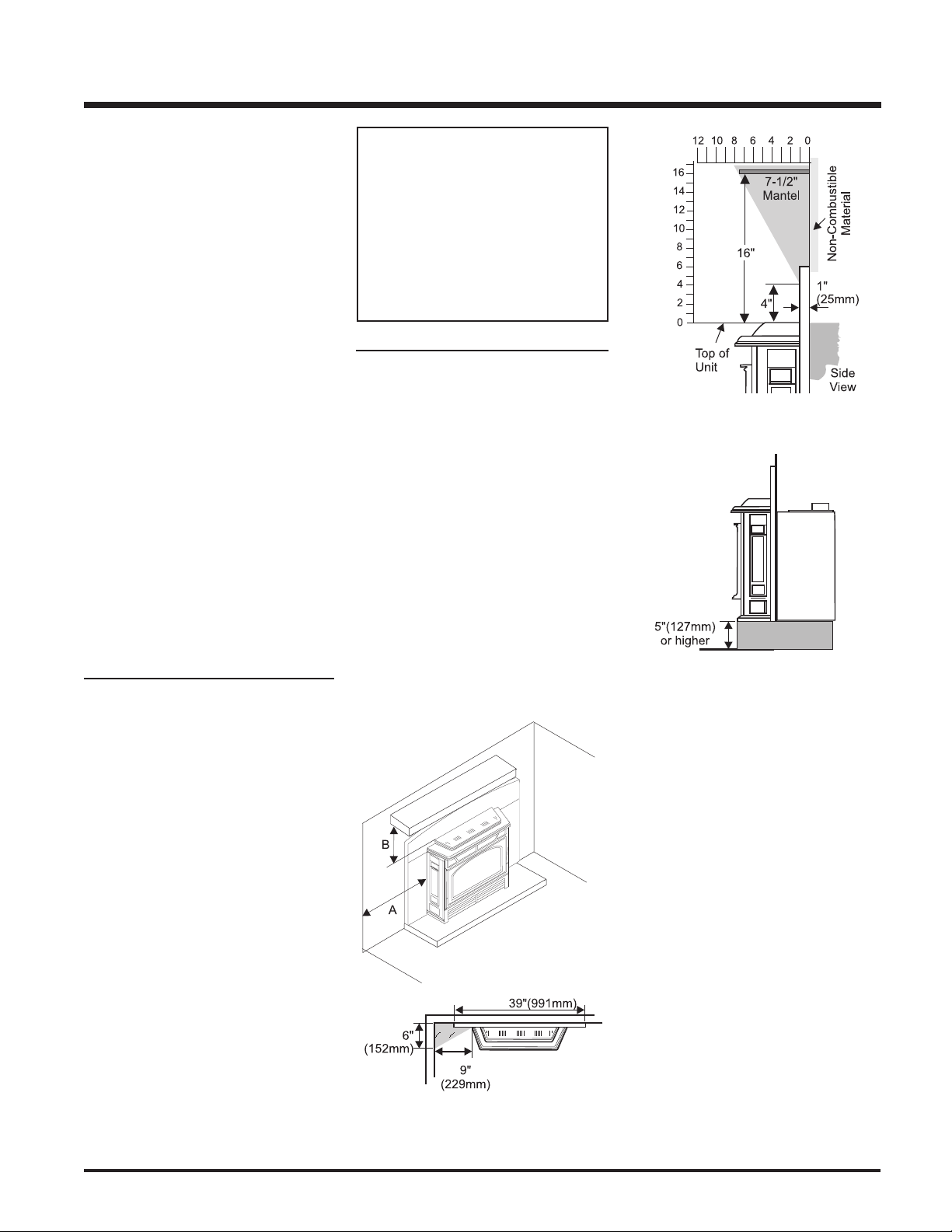

CLEARANCES TO

COMBUSTIBLES

The following clearances to combustibles must

be observed:

From Unit

Sides A 9" / 229 mm

Unit to Unprotected Mantel B 16" / 406 mm

Unit to Protected Mantel* B 12" / 305mm

*Mantel shield must have a 1" (25mm) air space

between the mantel and shield and a 1" (25mm)

gap between on the back of the shield and the

facing.

In addition to these clearances, adequate accessibility clearance for servicing and proper

operation must be maintained.

Do not in any way obstruct the air inlets that are

located on the front of the heater.

Combustible Mantels are permitted within the

shaded area.

When the Insert is installed in a fireplace that is

elevated 5" or higher, no floor protection is

required in front of the appliance.

No electrical power supply is required for the

gas control to operate. A 120 Volt AC power

cord is hooked up to the fan switch and blower.

Plug 3 wire cord into a suitable receptacle. Do

not cut the ground terminal off under any

circumstances.

When connected with 120 volts, the appliance

must be electrically grounded in accordance

with local codes, with a current version of CSA

C22.1 (in Canada) or in the absence of local

codes, with the National Electrical Code ANSI/

NFPA 70-1987.

Note: This unit is equipped with a heat

sensor thermodisc which will

prevent the blower from operating until the unit reaches the correct temperature.

Floor Protection

An approved floor protector is required consisting of a layer of 1/2" (13mm) Wonderboard

(or Durock or equivalent) that extends 9"

(229mm) in front of the fireplace measured at

the base (this equals 16" from the fireplace

opening), and as wide as the appliance.

Note: If the appliance is installed in a

fireplace that is elevated 5"

(127mm) or higher (i.e., a Waterford Zero Clearance Cabinet, zero

clearance fireplace, brick plinth,

etc.), no floor protection is required in front of the appliance.

Combustibles are permitted within

the shaded area, on either side.

7Waterford E61 Gas Fireplace Insert

INSTALLATION

GAS CONNECTION

The Emerald Insert is factory equipped to burn

Natural Gas, if necessary the unit can be

converted to burn Propane by using Conversion Kit # 260-960. For minimum and maximum

supply pressure see the System Data table on

page 8.

Note: Prior to any pressure testing of

the gas supply piping system that

exceeds test pressures of 1/2

psig, this appliance and its individual shut-off valve must be disconnected from the piping system. If

test pressures equal to or less

than 1/2 psig are used then this

appliance must be isolated from

the piping system by closing its

individual manual shut-off valve

during the testing.

GAS CONNECTION WARNING:

Only persons licensed to work with gas piping

may make the necessary gas connections to

this appliance.

1) The gas inlet is located on the end of the

flexible pipe that emerges from the lower

left rear corner of the unit. The inlet fitting is

a 1/2" female flare.

A separate gas shut-off valve and a 1/8" IPS

plugged tapping should be installed immediately upstream of the connection to the

appliance.

2) The gas inlet is located on the end of the

flexible pipe that emerges from the lower

left rear corner of the unit. The inlet fitting is

a 1/2" female flare.

A separate gas shut-off valve and a 1/8" IPS

plugged tapping should be installed immediately upstream of the connection to the

appliance.

3) Locate the center point where the vent will

pass through the chimney above the appliance. Move the appliance into the exact

location where it is to be installed. Ensure

that the Insert is level.

4) The gas control valve is provided with two

"IN" and "OUT" pressure taps, and are

easily accessible for a test gauge connection (see diagram on page 12).

5) Once the gas has been connected ensure

that the pilot valve is in line with burner.

CAUTION: If the door is removed or

opened for servicing, it must be replaced

and closed prior to operating the appliance. The glass must be fixed in the door

when operating.

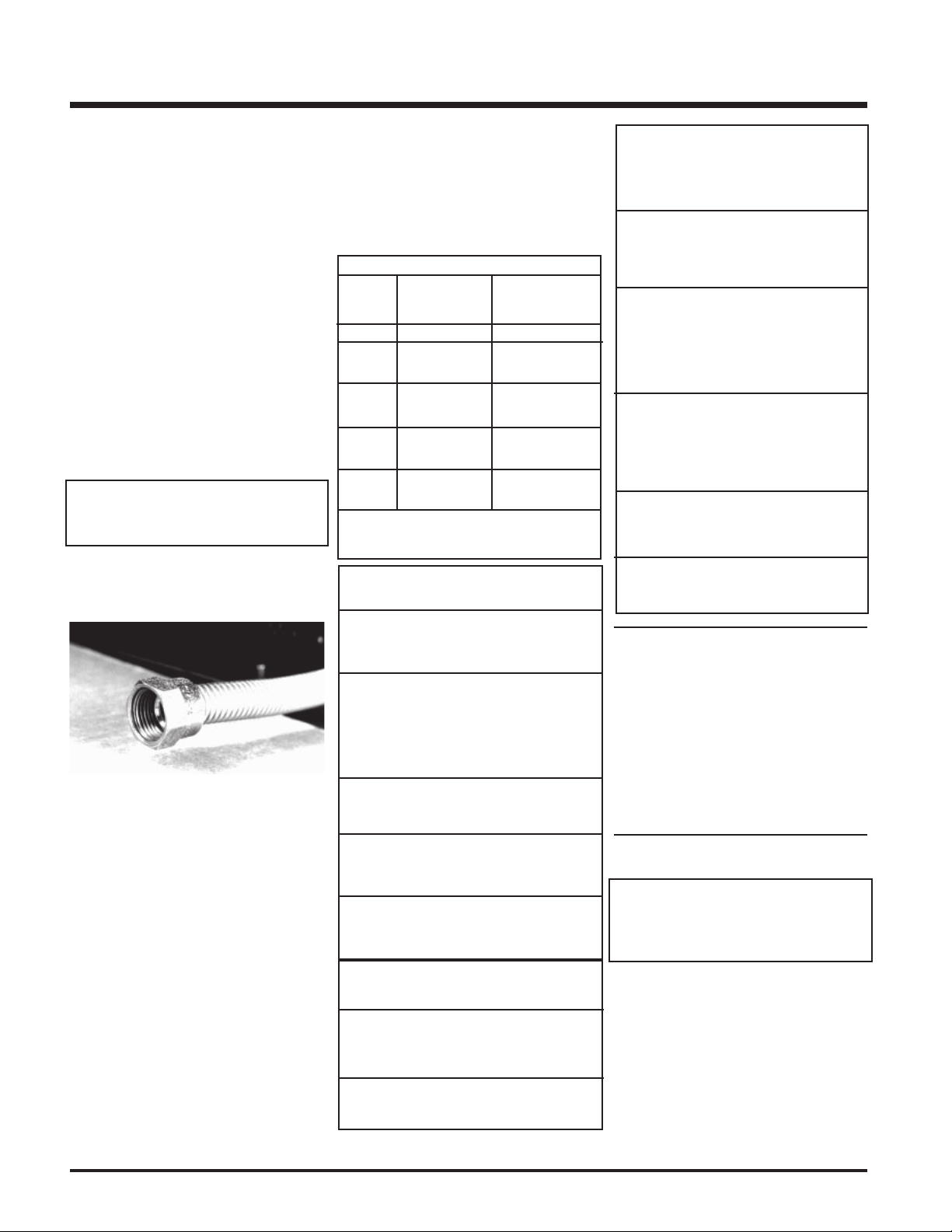

Recommended Gas Pipe Diameter

Pipe Schedule 40 Tubing,

Length Pipe Type L

(feet) Inside Diameter Outside Diameter

NG LP NG LP

0 - 10 1/2" 3/8" 1/2" 3/8"

1.3cm 1.0cm 1.3cm 1.0cm

10 - 40 1/2" 1/2" 5/8" 1/2"

1.3cm 1.3cm 1.6cm 1.3cm

40 - 100 1/2" 1/2" 3/4" 1/2"

1.3cm 1.3cm 2.0cm 1.3cm

100 - 150 3/4" 1/2" 7/8" 3/4"

2.0cm 1.3cm 2.3cm 2.0cm

Note: Never use plastic pipe. Check to confirm

whether your local codes allow copper tubing

or galvanized pipe.

System Data

For 0 to 2000 feet altitude

Burner Inlet Orifice Sizes:

Natural Gas Propane

Burner #32 #50

Max. Input

- Natural Gas 38,000 Btu/h

- Propane 35,000 Btu/h

Min. Input

- Natural Gas 19,000 Btu/h

- Propane 17,500 Btu/h

Max. Output Capacity with blower On

Natural Gas 30,666 Btu/h

Propane 28,700 Btu/h

Supply Pressure:

Nat. Gas min. 5" w.c. (1.25 kPa)

Propane min. 12" w.c. (3.0 kPa)

Manifold Pressure

Natural Gas 3.8" +/- 0.2" w.c. (0.94 kPa)

Propane 11" +/- 0.2" w.c. (2.7 kPa)

System Data - HIGH ELEVATION

For 2,000 - 4,500 feet altitude

Burner Inlet Orifice Sizes:

Natural Gas

Burner #33

Max. Input .

- Natural Gas 36,100 Btu/h

System Data:

E61 Converted to

27,000 (Natural Gas)

or 29,000 (Propane)

For 0 to 4500 feet altitude

Burner Inlet Orifice Sizes:

Natural Gas Propane

Burner #40 #52

Max. Input Rating

- Natural Gas 27,000 Btu/h

- Propane 29,000 Btu/h

Min. Input Rating

- Natural Gas 13,500 Btu/h

- Propane 14,500 Btu/h

Output Capacity with blower Off

Natural Gas 21,168 Btu/h

Propane 23,258 Btu/h

Output Capacity with blower On

Natural Gas 21,708 Btu/h

Propane 23,925 Btu/h

Supply Pressure

Natura l Gas min. 5.0" w.c.

Propane min. 12.0" w.c.

Manifold Pressure

Natural Gas 3.8" +/- 0.2" w.c.

Propane 11" +/- 0.2" w.c.

HIGH ELEVATION

This unit is approved in Canada (CAN/CGA-

2.17-M91) for altitudes to 2000 ft. (610m) using

the factory -installed burner orifice. For installations from 2000 ft (610m) to 4500 ft (1370m)

the orifice sizes (DMS) for the Natural Gas and

Propane units must be changed. See the rating

plate for details. For installations above 4500 ft.

refer to current ANSI Z223.1 Sc8-8.1.2a appendix F or CAN/CGA-B149.1, for resizing

orifice.

VENTING

THE APPLIANCE MUST NOT BE CONNECTED TO A CHIMNEY FLUE SERVING A SEPARATE SOLID FUEL BURNING APPLIANCE.

This appliance is designed to be attached to two

3" (76mm) co-linear aluminium flex running the

full length of the chimney. The flue length must

be a minimum length of 8' (2.44m) and a maximum of 35' (10.7m). See chart for minimum

distances from roof. Periodically check that the

vent is unrestricted.

Masonry chimneys may take various contours

which the flexible liner will accommodate. However, keep the flexible liner as straight as

possible, avoid unnecessary bending.

8 Waterford E61 Gas Fireplace Insert

Loading...

Loading...