Waterford ERIN 90 T/V, ERIN 90 R/V Installation & Operating Instructions

ERIN 90 T/V & R/V

WoodBurning Stove

IMPORTANT

This stove has two U.s. Environmental Protection Agency Temporary labels on the front door. One of the labels

reads; “Heat output 10,200 to 39,900 BTU’s/Hr (5.7 grams per hour) 63% efficiency.” This label shows the performance of the unit when connected to a Rear Exit configuration.

The second label reads; “Heat output 10,500 to 40,900 BTU’s/Hr. (4.2 grams per hour), 63% efficiency. This

label shows the performance of the unit when connected to a Top Exit configuration.

SAFETY NOTICE

Please read this entire manual before you install and use your new room heater. Failure to follow instructions

may result in property damage, bodily injury or even death.

If this stove is not properly installed, a house fire may result. For your safety, follow the installation directions.

Contact local building or fire officials about restrictions and installation inspection requirements in your area.

The stove must be connected to a UL/ULC listed high temperature residential type H.T. and building heat appliance chimney or an approved masonry chimney with flue liner.

MANUFACTURED BY: WATERFORD STANLEY LIMITED,

BILBERRY, WATERFORD, IRELAND.

INSTALLATION & OPERATING INSTRUCTIONS

WATERFORD ERIN 90 WOODBURNING STOVE INSTALLATION

& OPERATING INSTRUCTIONS

GENERAL

When installing, operating and maintaining your

Waterford Erin 90 T/V & R/V Stove respect basic

standards of fire safety. Read these instructions

carefully before commencing the installation.

Failure to do so may result in damage to persons

and property. Consult your local Municipal office

and your insurance representative to determine

what regulations are in force. Save these instructions for future reference.

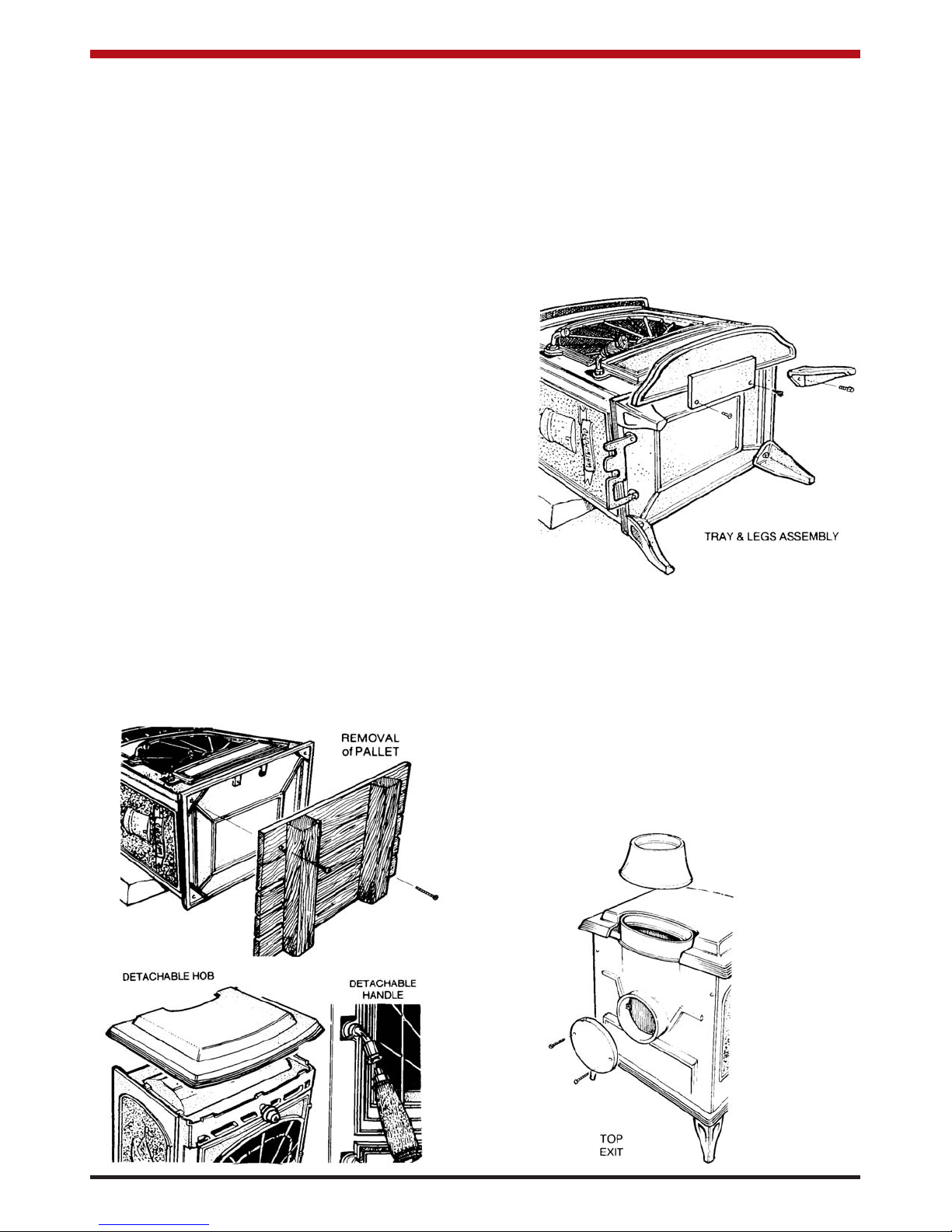

PRE-INSTALLATION ASSEMBLY

(a) After removing the stove from its packing,

open the ashpit door (item 9 in exploded

view) and remove the contents.

(b) Open the firedoor (item 8) using the detach

able handle - found in the ashpan (item 36)

and remove the contents of the firebox, leav

ing the bricks in place.

(c) Remove the ash lip (item 19) from the rear of

the stove if you have not already done so.

Remove the loose fitting hob and place on a

non-abrasive surface.

(d) Place the plastic packing on the ground at

the back of the stove and lay the stove on its

back on top of the packing.

(e) Remove the wooden pallet by taking out the

two retaining screws from the base of the

stove.

(f) Fit the four legs (item 2) to the base (item 1)

of the stove with the four 5/8” x 5/16” screws

provided. Fit the ash lip with the two 3/4” x

1/4” screws provided. Fit the tool carrier to

the left side of the base with the two 3/4” x

1/4” screws provided. Tighten all screws.

Stand the stove upright taking care not to

strain the back leg bolts.

THIS STOVE MAY BE CONNECTED TO EITHER A

TOP OR REAR EXIT.

TOP FLUE EXIT

Take the top flue spigot (item 6). Place a small

amount of fire cement on the inside flange of the flue

outlet (item 18) before fitting it to the stove. Push the

flue spigot (item 6) into place, making sure that it is

fully sealed to the stove. Any excess cement on the

inside of the flue spigot should be removed to prevent any obstruction of the flue passage.

2

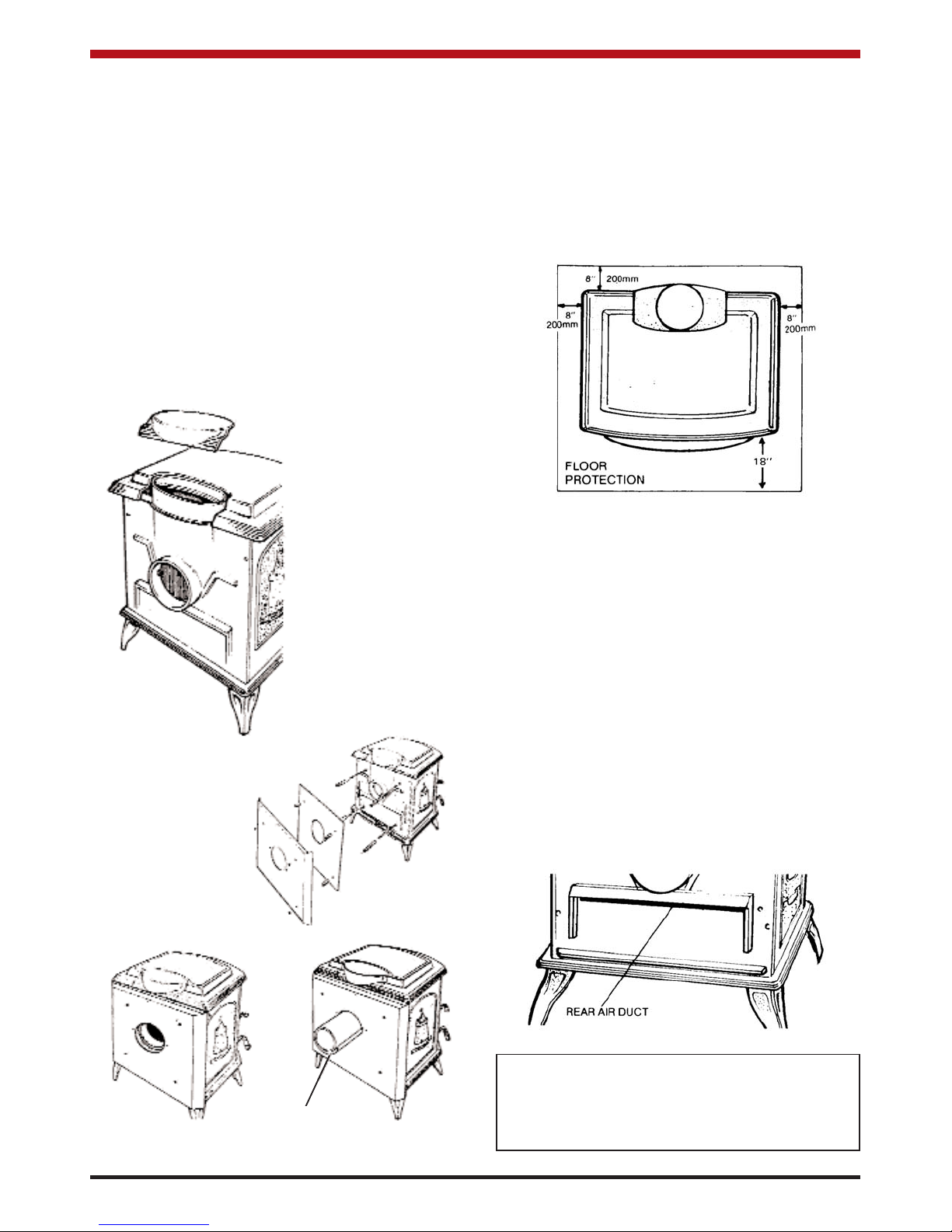

REAR FLUE EXIT

Fit the top cover plate (item 5) to the stove with the

screws holding on the rear exit cover plate (item 68).

Make sure that all the sealing rope is properly

sealed to the stove flue outlet (item 18).

HEAT SHIELD

Fit the rear heat shield as follows: Screw the four 4”

x 1/4” bolts (item 69) to the back plate (item 23). Fit

the four 2” spacers (item 70) over the tie bolts. Fit

the inner heat shield (item 75) without the blanking

plate (item 72) onto the four tie bolts. Now fit the 1”

spacers (item 71) over the tie bolts and fit the outer

heat shield panel (item 76) without the blanking plate

(item 72). Tighten the whole assembly together

using the four 1/4” nuts provided.

FLOOR PROTECTION

When installing this heater on a combustible floor, a

floor protector, consisting of a layer of non-combustible material at least 3/8” thick or 1/4” thick covered with 1/8” sheet metal is required to cover the

area under the heater and to extend to at least 18”

at the front and 8” to the sides, and embers which

may fall out from the door when stoking or fuelling.

LOCATION

There are several conditions to be considered when

selecting a location for your Waterford Erin 90 T/V &

R/V Stove.

(a) Distance from a safe chimney.

(b) Position in the area to be heated - central

locations are usually best.

(c) Allowance for proper clearances to com

bustibles.

(d) Obstruction in the ceiling, upper floor or roof,

for example, ducting plumbing, electrical fit

tings and wiring, overhead fixed furnishings

etc.

WARNING

DO NOT OBSTRUCT FREE AIR SUPPLY TO THE

SECONDARY AIR DUCT AT THE REAR OF THE

STOVE.

3

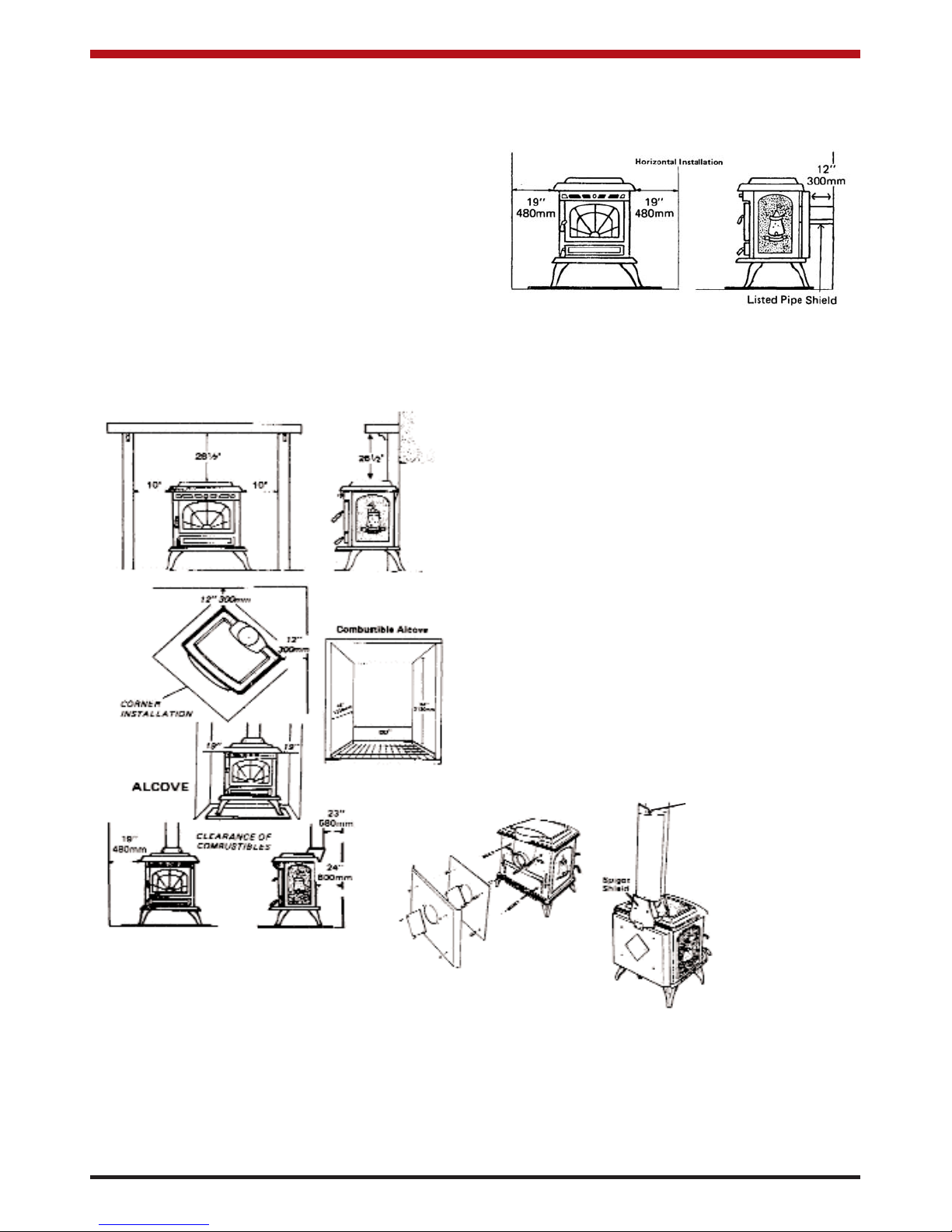

With rear heatshield fitted

for rear outlet configuration.

Rear heat

shield fitted

complete with

shielded chimney connector

for a rear outlet

configuration.

Chimney connector and pipe

shield not supplied as standard.

1 inch space

REAR

EXIT

FITTING OF REAR HEAT

SHIELD

MINIMUM CLEARANCES TO COMBUSTIBLES

From the front of the stove 48” - 1200mm

From back of stove 24” - 600mm

From the side of stove 19” - 480mm

From corner installation 12” - 300mm

From the flue pipe 23” - 580mm

Mantle clearance 26 1/2” - 675mm

Side trim, which extends

less than 2” from the face

of the fireplace 10” - 250mm

MANTLE & TRIM CLEARANCES

If the stove is to be installed using the rear exit

option then the UL/ULC listed Optional rear heat

shield must be fitted together with a listed pipe

shield fitted from the heat shield to the back wall on

the underside of the chimney connector.

(See horizontal installation).

Rear Exit

From back of stove 12” - 300mm

From side of stove 19” - 480mm

plate (item 72) and the double top flue spigot shield

(item 74) over the tie bolts and tighten the whole

assembly together using the four

1/4” nuts provided.

When the Waterford listed heat shields are used

together with a listed pipe shield using the top exit

option the clearances may be reduced to 9

1/2”.

(Pipe shield and heat shields are not supplied as

standard.

4

REDUCED CLEARANCES

Under certain conditions the minimum clearances

may be reduced by means of:

(a) Listed Waterford rear heat shield assembly

installed in accordance with the manufactur

ers instructions.

(b) Shields constructed in accordance with

NFPA211 (USA) Can3-B365 installation

code for solid fuel fired appliances.

(c) Fitting the listed Waterford Heat Shield and

chimney connector pipe shield.

REAR HEAT SHIELD

If the stove e is to be connected to a top flue exit

then the rear heat shield assembly must be fitted as

follows: Screw the four 4” x 1/4” heat shield tie bolts

(item 69) to the back plate (item 23). Fit the four 2”

spacers (item 70) over the heat shield tie bolts. Fit

the inner heat shield (item 75) complete with rear

heat shield blanking plate (item 72) onto the four

heat shield tie bolts. Now fit the four 1” spacers

(item 71) over the tie bolts and fit the outer heat

shield (item 76) complete with heat shield blanking

1 inch spacer

Fitting of listed pipe

shield.

Pipe shield and chimney

connector are not supplied as standard with

the stove

.

Fitting of rear heat

shield

Loading...

Loading...