Waterford 104 MK II Installation And Operating Instructions

104 MK II WOOD-BURNING STOVE

SAFETY NOTICE

PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW ROOM HEATER. FAILURE TO

FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH. SAVE THESE

INSTRUCTIONS FOR FUTURE REFERENCE.

IF THIS STOVE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. FOR YOUR SAFETY, FOLLOW THE

INSTALLATION DIRECTIONS. CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND

INSTALLATION IN YOUR AREA.

THIS STOVE MUST BE CONNECTED TO A LISTED HIGH TEMPERATURE RESIDENTIAL TYPE AND BUILDING HEATING APPLIANCE CHIMNEY OR AN APPROVED MASONRY CHIMNEY WITH FLUE LINER.

MANUFACTURED BY: WATERFORD STANLEY (MARKETING) LIMITED

BILBERRY, WATERFORD, IRELAND.

INSTALLATION AND OPERATING INSTRUCTIONS

104 - MKII

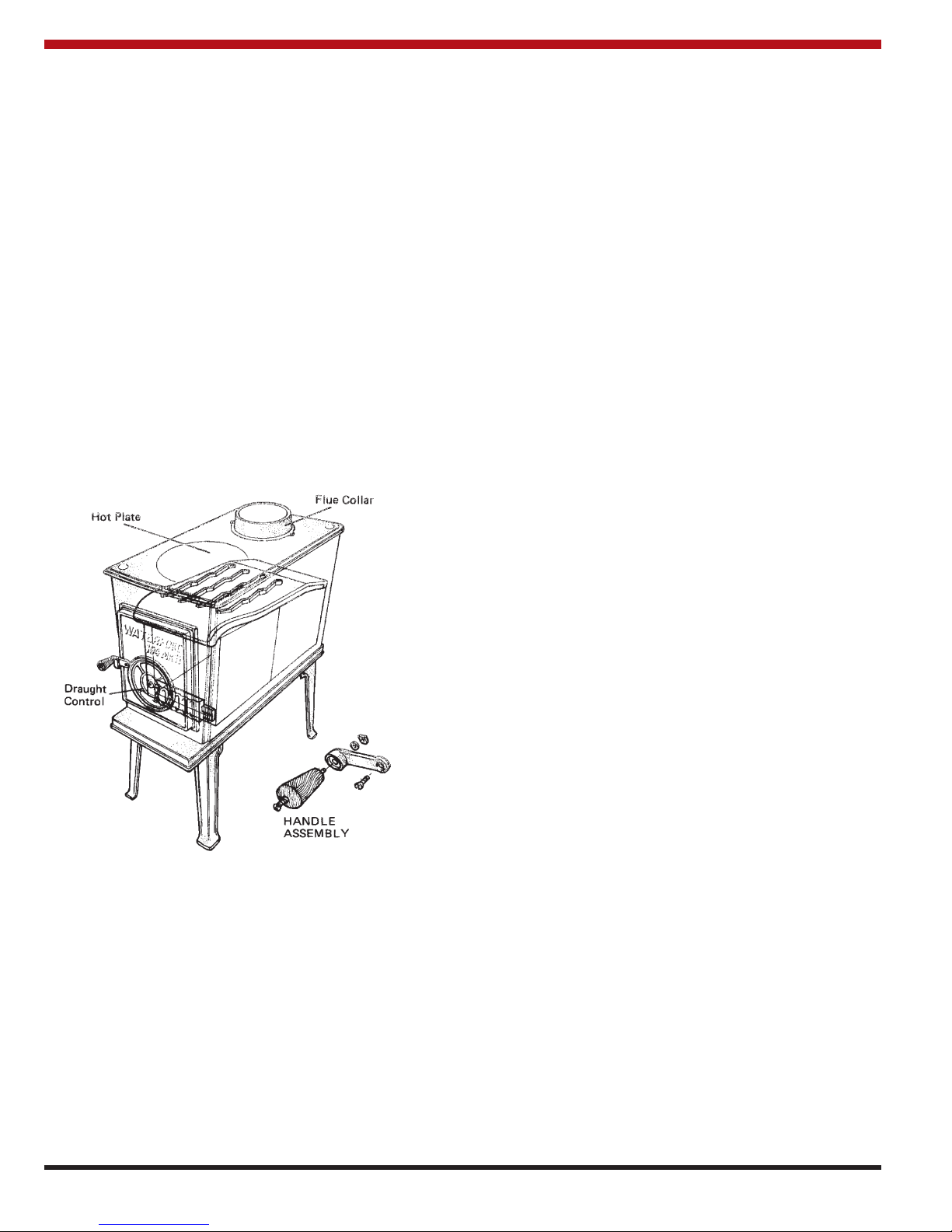

PRE-INSTALLATION ASSEMBLY

Step 1:

After removing the stove from the pack, open the fire door

and remove packed contents from the Firebox. Empty

the Jiffy Bag.

Step 2:

Lay the stove on its side. Insert and secure a leg in the

recess at each corner of the base using 25mm x 6mm (1

in. x 1/4 in.) flat head screws and 6mm (1/4 in.) flat washers.

Step 3:

Carefully stand the unit upright on its legs.

Step 4:

Remove the nut and washer from the knob. Place in position, insert the screw in position with spring washer and

nut provided. See Sketch.

104 MK II

GENERAL INSTRUCTIONS

BUILDING CODES

Consult the LOCAL BUILDING CODE in all cases as to

the particular requirements concerning the installation of

SOLID FUEL TYPE ROOM HEATERS. This 104 MK II

WOOD BURNING STOVE is intended to be installed in

accordance with National Fire Protection Associations

Standard for Chimneys, Fireplaces and Vents, NFPA 211-

1977.

This stove has been tested and listed by UNDERWRITERS LABORATORIES INC, and as such carries the U.L.

and U.L.C. LABEL. All building codes which recognise

the value of U.L. Listing will accept applications for and

approve installations of this product.

INSTALLATION INSTRUCTIONS

MUST BE FOLLOWED.

CHIMNEYS

The 104 MK II Wood Stove is a Radiant Room Heater and

must be connected to a CHIMNEY of the proper size and

type.

The complete installation must be done in accordance

with current Standards and Local Codes. It should be

noted that the requirements and these publications may

be superseded during the life of this manual.

The chimney must have a CROSS-SECTIONAL AREA of

at least 182.39 sq. cm. (28.27 square inches). It is best

to connect to a chimney of the same size, as connection

to a larger size may result in somewhat less draught. DO

NOT CONNECT TO A CHIMNEY SERVING ANOTHER

APPLIANCE. Minimum chimney height 4.57 meters (15

ft.) from floor on which stove is installed. An existing

masonry chimney should be inspected, and, if necessary,

repaired by a competent mason or relined, using an

approved relining system.

DO NOT CONNECT TO OR USE IN CONJUNCTION

WITH ANY AIR DISTRIBUTION DUCTWORK UNLESS

SPECIFICALLY APPROVED FOR SUCH INSTALLATION.

Note: Connection to type “B” Gas Vents, approved for

connection to a certain gas burning appliance only, will

result in a fire.

CHIMNEY TYPES - USA ONLY

The stove must be connected to a U.L. 103 Listed

Residential type H.T. and Building Heating Appliance.

Chimney installed in accordance with the manufacturers

instructions or a masonry chimney constructed in accordance with NFPA 211 Chimney vents and Solid Fuel

Burning Appliances.

2

Step 5:

Take the hotplate (WIF 008) and place it in the large

opening on the top. Do not remove the Hot Plate when

the unit is in operation. Remove only for cleaning.

Step 6:

Attach the Spigot, item number 18, in the exploded view

to the hob, item number 16 using the two 1/4” (6mm)

counter sunk screws provided.

Check that all parts are securely fitted before firing the

unit.

The stove is now ready for installation.

Fig.1

CHIMNEY TYPES - CANADA ONLY

The stove must be connected to an Underwriters

Laboratories of Canada Labelled Factory Built 650 C

Chimney, installed in accordance with the manufacturers

instructions or a lined Masonry Chimney, constructed

acceptable to the authority having jurisdiction.

CHIMNEY CONNECTOR

THE CHIMNEY CONNECTOR is a smokepipe used to

connect the 104 MK II Stove to the approved chimney

described above. The CHIMNEY CONNECTOR must be

made of CORROSION RESISTANT STEEL 24 gauge or

heavier (“black or blued” or equivalent treated steel).

SINGLE WALL STOVE PIPE MUST NOT PENETRATE

COMBUSTIBLE WALLS OR CEILINGS.

A 127mm to 153mm (5 to 6 inch) increaser is included in

the Stove kit. When using the 127mm to 153mm ( 5 to 6

inch) increaser, 153mm (6 inch) diameter connector pipe

is used. Be sure to fasten the chimney connectors

together and also to the flue outlet of the stove through

the two holes provided. Use at least two screws for each

joint. Be sure the joints are tight and fully secured.

CHIMNEY CONNECTOR USA ONLY

Connectors should maintain a pitch or rise of at least 1/4”

(6mm) to the foot from the stove to the chimney. It should

be installed so as to avoid sharp turns or other construction features that would create excessive resistance to

the flow of flue gases. It should be securely supported

with joints fastened with sheet-metal screws, rivets, or

other approved means. The entire length of a connector

should be readily accessible for inspection, cleaning and

replacement.

The connector may pass through walls or partitions constructed of combustible materials provided the connector

is either listed for wall pass-through or is routed through a

device listed for wall pass-through and is installed in

accordance with the conditions of the listing, NFPA 211 or

CAN/CSA - B365. Any unexposed metal that is used as

part of a wall pass-through system and is exposed to the

flue gases shall be constructed of stainless steel or other

equivalent material that will resist corrosion, softening, or

cracking from flue gas at temperatures up to 982

o

C

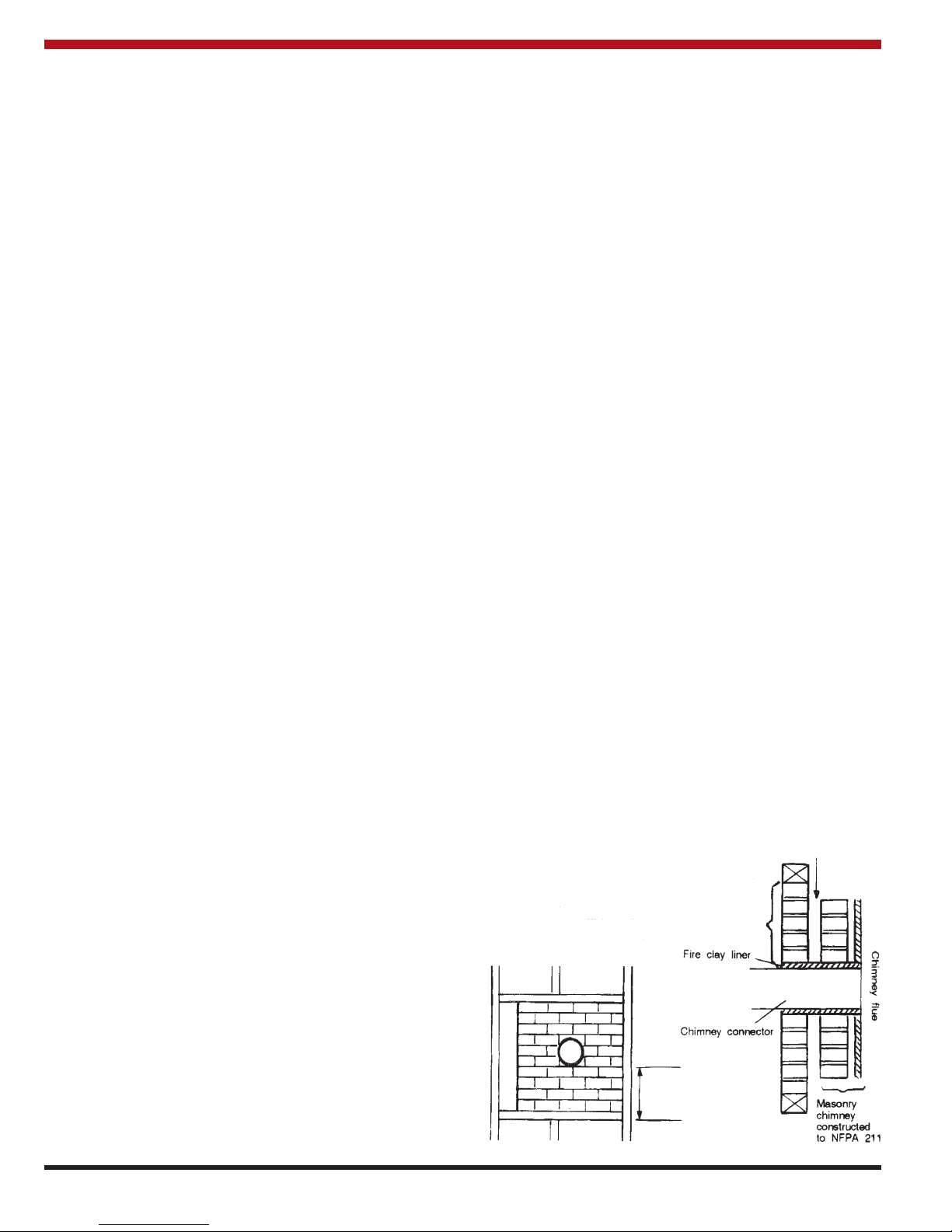

CONNECTING TO MASONRY CHIMNEY

The connector to a masonry chimney must extend

through the wall to the inner face or liner but not

beyond,and must be firmly cemented to masonry.

The connector may pass through walls or partitions constructed of combustible material to a masonry chimney

provided the connector system selected is installed in

accordance with the proper clearances and conditions.

(See figures 2, 3, 4, 5 & 6 pages 3 & 4).

THIMBLES

Thimbles for chimneys or vent connector should be of fire

clay (ASTM C 315, Specifications for Clay Flue Linings)

galvanised steel of minimum thickness of 24 gauge, or

material of equivalent durability. Thimbles should be

installed without damage to the liner. The thimble should

extend through the wall to, but not beyond, the inner face

of the liner and should be firmly cemented to masonry.

Thimbles should be located to provide adequate pitch or

rise of chimney or vent connectors and, where the ceiling

above the appliance is constructed of combustible material, the location of the thimble should provide minimum

clearance required for the connector as specified in

Section under minimum clearances to combustibles.

Insulation material used as part of wall pass-through system should be of non-combustible material and should

have a thermal conductivity of 1.0 Btu.in./ft.F

(4.88kg.cal/hr.m.C) or less. All clearances and thicknesses are minimums; larger clearances and thicknesses are

acceptable. Any material used to close up an opening for

the connector should be of non-combustible material. A

connector to a masonry chimney, except for system 2

(Under heading Chimney Connector Systems, Thimbles

and Clearances), shall extend to piece through the wall

pass-through system and the chimney wall to the inner

face of the flue liner, but not beyond.

CHIMNEY CONNECTOR SYSTEMS, THIMBLES,

AND CLEARANCES FROM COMBUSTIBLE

WALLS

1. Minimum 3 1/2” (90mm) thick brick masonry wall

framed into combustible wall with a min. of 12”

(305mm) brick separation form clay liner to combustibles. Fire clay liner (ASTM C315 or equiva

lent) min. 5/8” (16mm) wall thickness, should run

from outer surface of brick wall to, but not

beyond, the inner surface of chimney flue liner

and should be firmly cemented in place.

3

Fig.2

Minimum clearance 12” (305mm) of brick

Minimum 12” (305mm)

to combustibles

Minimum chimney clearance

to brick and combustibles 2” (50mm)

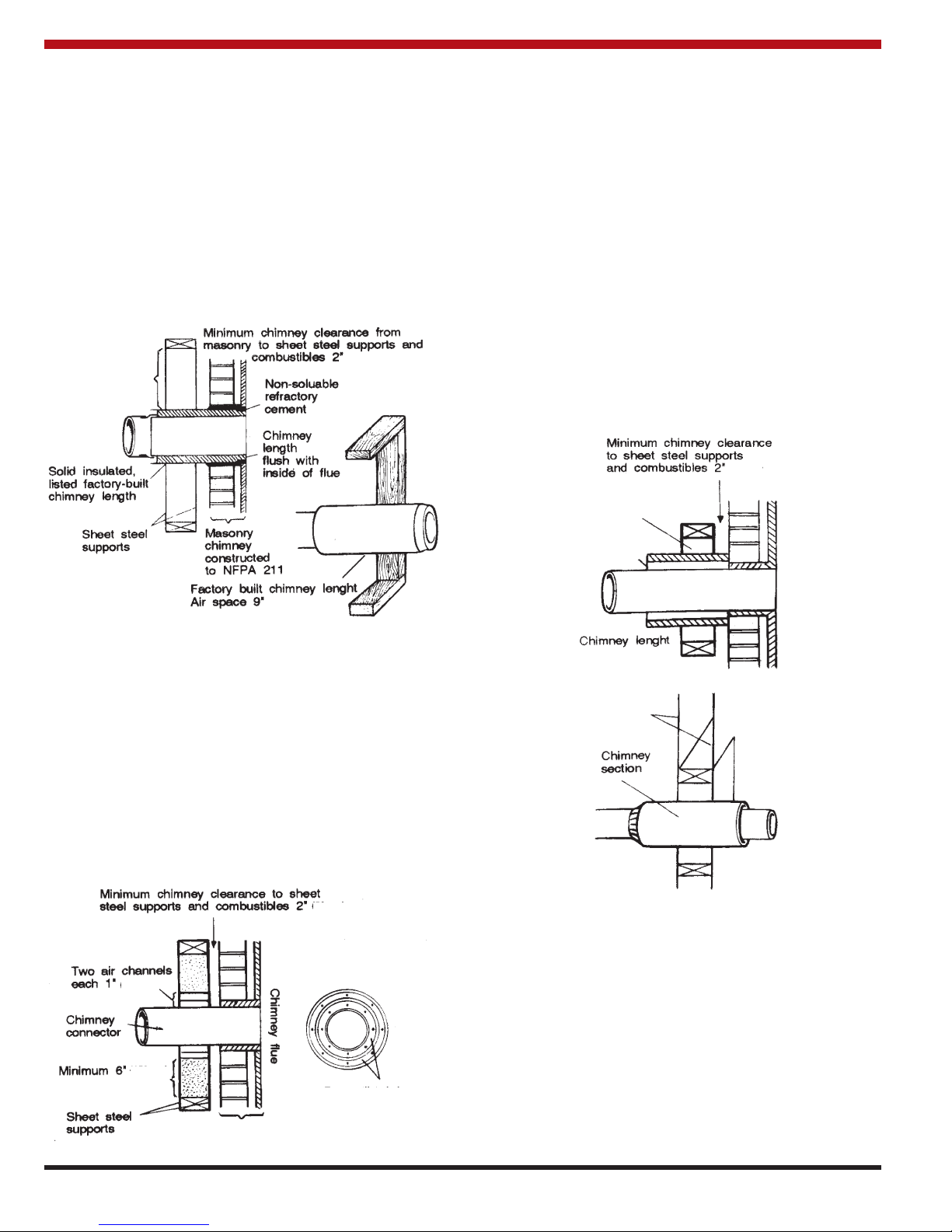

2. Solid insulated listed factory-built chimney length

of the same inside diameter as the chimney

connector and having 1” (25mm) or more of insulation with a min. 9” (229mm) air space between

the outer wall of the chimney length and combustibles. The inner end of the chimney length

shall be flush with the inside of the masonry

chimney flue and shall be sealed to the flue and

to the brick masonry penetration with nonwatersoluble refractory cement. Supports should be

securely fastened to wall surfaces on all sides.

Fasteners between supports and the chimney

length shall not penetrate the chimney liner.

4. Solid insulated listed factory-built chimney length

with an inside diameter 2” (50mm) larger than the

chimney connector and having 1” (25mm) or

more of insulation, serving as a pass-through for

a single wall sheet steel chimney connector of

min. 24 gauge thickness, with a min. 2” (50mm)

air space between the outer wall of chimney section and combustibles. Min. length of chimney

section shall be 12” (305mm). Chimney section

concentric with and spaced 1” (25mm) away from

connector by means of sheet steel support plates

on both ends of chimney section. Opening shall

be covered and chimney section supported on

both sides with sheet steel supports of min. 24

gauge thickness.

Supports should be securely fastened to wall surfaces on

all sides and shall be sized to fit and hold chimney section. Fasteners used to secure chimney sections should

not penetrate chimney flue liner.

3. Sheet steel chimney connector, min. 24 gauge in

thickness, with a ventilated thimble, min 24

gauge in thickness, having two 1” (25mm) air

channels, separated from combustibles by a min.

of 6” (150mm) of glass fibre insulation. Opening

should be covered and thimble supported with a

sheet steel support, min. 24 gauge in thickness.

Supports should be securely fastened to wall surfaces on all sides and should be sized to fit and

hold chimney section. Fasteners used to secure

chimney sections should not penetrate chimney

flue liner.

4

Fig3

Fig.4

Fig.5

Fig.6

(50mm)

(229mm)

minimum

Minimum

clearance 9”

(229mm)

(50mm)

(25mm)

(150mm)

glass fibre insulation

Two ventilated air

channels each 1”

(25mm) constructed of

sheet steel

(50mm)

Minimum clearances 2” (50mm)

1” (25mm)

air space to

chimney

length

Air space 2” (50mm)

Loading...

Loading...