WECO

HydroSense Reverse

Osmosis Water Filter

Installation Manual

Water Engineering Corporation

Long Beach, CA U.S.A

1 (888) 675-5187

sales@wecofilters.com

www.wecofilters.com

1

Installation Manual

INTRODUCTION

Congratulations! By choosing WECO Reverse Osmosis (RO) water purification system for your

home, you have not only ensured the highest quality, healthy drinking water, you have also

selected the most efficient and convenient system in the industry.

While the elegant, yet simple, design complements any décor, the aesthetic qualities are only the

beginning. We designed the premier RO system as a highly efficient, easily maintained addition to

every home and business.

The RO System filters multiple substances harmful to humans and pets including, impurities, residual

chlorine, heavy metals, chemicals, and filterable, viruses to name a few, and also removes 96

percent of ions in the water.

Before installing your new RO System, please read the instructions thoroughly and make sure you

have all the necessary tools at hand.

Your new Reverse Osmosis Drinking Water system used a combination of filtration technologies to

reduce unwanted contaminants in a water supply. The following steps combine to give you the

best in clear sparkling drinking water.

Mechanical Filtration – The sediment pre-filter will remove the larger particles such as silt, rust, and

scale. Its 5-micron (equal to 0.0002 inch) nominal rating helps to give maximum life to the RO

membrane and carbon filter.

Activated Carbon Pre-filters- The activated carbon in a pre-filter will remove any chlorine that

may be present in the feed water.

This pre-treatment is also necessary for membrane protection in chlorinated water.

Reverse Osmosis Membrane – The RO membrane is the heart of the filtration system. It is designed

to reduce the dissolved mineral content of the water. Minerals picked up in the environment by

the water are measured as Total Dissolved Solids (TDS). In the reverse osmosis process, dissolved

minerals are separated from the incoming water (feed water) to produce the product water (the

permeate). The excess minerals are rinsed to drain (the reject water). The spiral-wound

construction of the RO membrane provides maximum surface area for water production and is

less susceptible to fouling by particulate matter, turbidity, and colloidal materials.

Inline Carbon Absorption Post-filter- The activated carbon post-filter cartridge contains carbon

particles with a vast network of pores. The tremendous surface area of these pores (typically

800-1,200 square meters per gram of carbon) gives the carbon very good absorption sites for

chlorine as well as other substances that contribute to tasted and odors. The product water from

the membrane and the holding tank passes through the inline carbon post-filter on the way to the

dispensing faucet. The activated carbon post-filter reduces tastes and odors that may pass

through the systems. It adds a final “polish” to the water.

Booster Pump Models – The booster pump consists of the pump, transformer unit, and the tank

shut-off switch. The tank shut-off switch will shut down the pump when the water production is not

necessary, such as when the tank is full, to prevent prematurely burning out the pump. Booster

pumps are used when there is little or no water pressure (below 30 psi is considered very low water

pressure). The booster pump increases and maintains your water pressure at the optimum level for

maximum rejection of total dissolved solids (TDS) and filtered water production.

© 2017 Water Engineering Corporation

Installation Manual

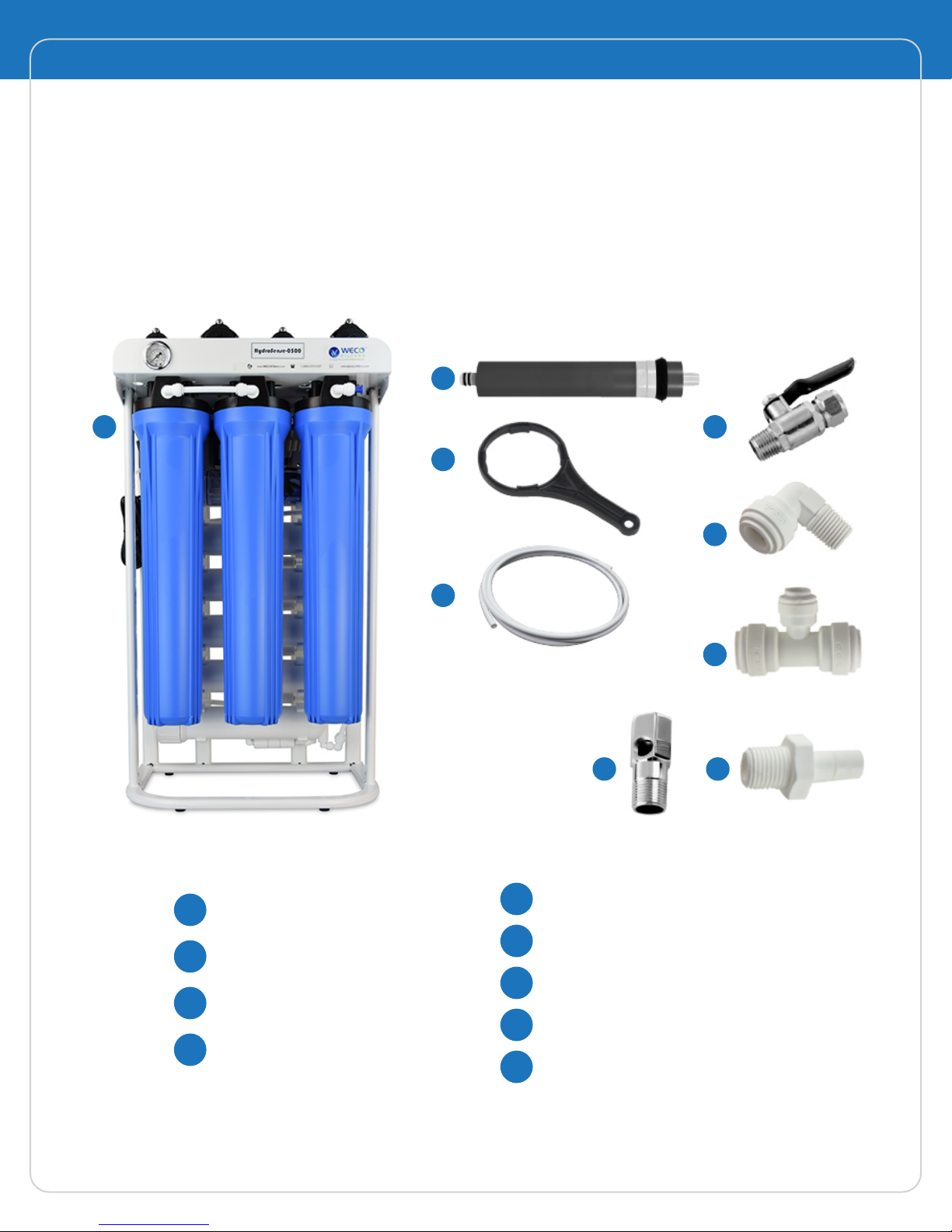

Components List

Your new WECO Reverse Osmosis System should include the following items. If any item is missing,

please contact your supplier, retailer, or any local professional plumbing service. Please take a

few moments to check all following components.

2

2

1

3

4

8 9

Fig. #1

5

6

7

Reverse Osmosis System Unit

1

RO Membrane Filter Cartridge

2

Filetr Housing Wrench

3

Polyethlene Tubing

4

© 2017 Water Engineering Corporation

5

6

7

8

9

Chromed Ball Valve

Male Elbow Fitting Connector

Union Tee Fitting Connector

Chrome Feed Water Adapter

Stem Adapter Fitting

3

Installation Manual

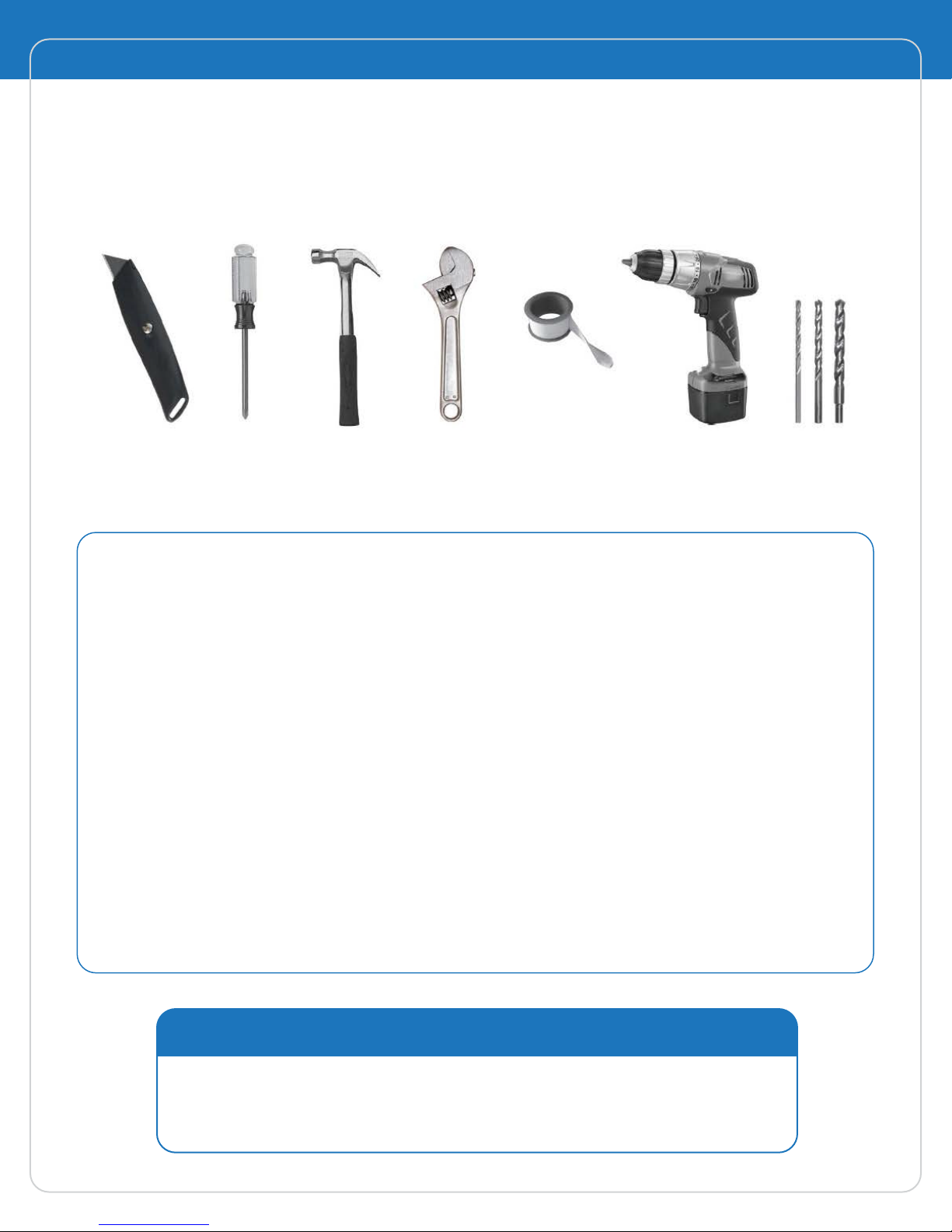

Before Installation

Before you begin, make sure the installation kit and tools are complete and ready to use.

Fig. #2

Tools required for installation: utility knife, Phillips screwdriver, hammer, adjustable

wrench, Teflon seal tape, electric drill, and drill bits (1/8”, 1/4” and 7/16”).

Before you Begin - Important Notes

Important Note: Feed Water Quality - Reverse osmosis drinking water systems are not

intended to be used for the treatment of water that is microbiologically unsafe or of

unknown quality. If the feed water quality is unsafe or unknown, have a sample of the

water tested by a qualified laboratory or agency and implement the necessary measures

to ensure a safe water supply.

Check with Local Codes - Some codes may require installation by a licensad plumber;

check with the local plumbing authority prior to installation.

Air Gap - An Air Gap (not included) should be installed prior to the drain to prevent

backflow of contaminated wastes from the drainpipe.

Drain Connections - Some state orlocal codes may require that the drain saddle be

served by a trap other than the one serving the garbage disposal. Before making a

connection, please check with code authorities.

Do not use water that is microbiologically unsafe or of unknown quality

without adequate disinfection before or after the system.

CAUTION

© 2017 Water Engineering Corporation

Installation Manual

4

Quick Connect EZ Fitting Guide

Your Reverse Osmosis Drinking Water Appliance is outfitted with the new generation of userfriendly

EZ connect push-in fittings. Proper use of the fittings is shown in the diagrams below.

It is important that the tubing selected for use with these connectors be of high quality, exact size

and roundness, and with no surface nicks or scratches. If it is necessary to cut the tubing, use a

plastic tubing cutter or sharp razor knife. Make a clean, square cut.

Should a leak occur at a fitting, the cause is

usually a defective tubing end cut.

To fix:

• Relieve pressure

• Release tubing

• Cut off at least ¼” from end

• Reattach tubing

• Confirm connection is leak free

To Attach Tubing

1

Collet

Cut the tube squarely, and insert tube

into the lock fitting (be sure the lock

fitting is flush for secure insert).

Push tube inward while pushing the

lock fitting outward and insert the

lock pin.

Pull the tube to ensure tube is tightlly

fitted.

Fig. #3

To Release Tubing

Tubing

Push tubing straight in as far as it will go.

2

Tubing is secured in position.

© 2017 Water Engineering Corporation

Fig. #4

Push in collet to release tubing.

To Insert Locking Clip

Optional Blue

Locking clip

slides between

collet and fitting.

Fig. #5

Fig. #6

5

Installation Manual

Component Recognition / Product Overview

6

8

7

5

6

7

23

1

5

4

1st stage - 20” STND White Filter

1

HSG 3/4” ports (Sedim ent Filter)

2nd stage - 20” STND White Filter

2

HSG 3/4” ports ( Carbon Block Filter )

3rd stage - 20” STND White Filter

3

HSG 3/4” ports ( Carbon Block Filter)

4th stage - RO Membrane Housings

4

(100 GPD RO Membrane Element x5 - 500 GPD)

Fig. #7

5

6

7

8

Flow Restrictor

High FlowBooster Pumps

Power Supply (transformer)

Pressure Gauge

© 2017 Water Engineering Corporation

Installation Manual

6

Installation Instructions

Pipe Connection:

CAUTION

The water supply to this reverse osmosis system MUST be from the

COLD water line. Hot water will damage the RO system. Before

installation, be sure to shut off the house’s main water line.

Tapping into the cold water line

1. If the feed water tubing connection is too short, future filter cartridge replacement will be very

difficult. Place the machine in a location convenient for service and installation. Measure the

distance between the feed water valve point to the RO system inlet point, then cut the RED PE

(polyethylene) tube to measured length. An additional PE tube is included in the installation kit.

2. Locate the self-piercing feed water valve, turn off cold water supply under the sink, and open

faucet to relieve water pressure.

To install on (soft) copper tubing supply line:

• Turn the handle of the feed water saddle value counter clockwise (outward) until the lance does

not protrude from the gasket. It may have to be pushed in.

• Assemble the feed water saddle on the tubing.

• To pierce the tubing, turn the valve handle fully in the clockwise direction until the copper tube is

pierced and the valve is closed.

To install on (hard) steel, galvanized, or CPVC tubing supply line.

• The supply line should now be drained. Use a battery-powered or properly grounded drill to avoid

shock hazard.

• Drill a 3/16” hole in the supply line; (do not drill through the opposite wall)/

• Turn the handle to expose the lance no more than 3/16” beyond the rubber gasket.

• Place the body of the valve over the hole so that the lance fits into the hole.

• Assemble and tighten the brass screw.

• Turn the valve handle clockwise (inward) until firmly seated and the valve is closed.

3. With the feed water saddle valve closed, open the sink faucet and the water supply and

allow the water to run for a few minutes to flush out any debris caused by the installation.

Close the faucet and check the feed water saddle valve for leaks.

© 2017 Water Engineering Corporation

7

Installation Manual

Power Supply Installation

Locate the power outlet under the sink or near

the RO system unit. Make sure the power cord is

long enough to reach the power outlet; if not,

contact a licensed electrician to install a power

outlet.

RO Membrane Cartridge Installation

1. Release the tubing from the end cap of the membrane housing

2. Unscrew the end cap from the membrane housing on the appliance, and insert the

membrane as illustrated below.

Fig. #8

3. The O-rings on the product water tube of the membrane MUST FULLY SEAT in the membrane

housing for proper operation. Make sure that the brine seal on the membrane seals with no

gaps or wrinkles inside the membrane housing.

4. Once the membrane is installed, replace the end cap and reconnect the tubing.

To ensure that all preservatives are flushed from the system before use, DO NOT use the first

two tankfuls of water produced by the system.

Step 1

Step 3

Step 2

Step 4

Turning counter clockwise

to unscrew the end cap

O-rings on the product water tube

Insert the RO membrane cartridge

this direction

Fig. #9

Installation Manual

Maintenance and Cartridge replacement

Important Note: The RO System functions directionally. Please do not randomly fill or drain water or

interchange the cartridge from left to right.

The need for filter replacement varies with water quality and usage. Replace cartridges on a regular

basis to ensure the highest quality water and extend the life of the system.

1. Before replacing filter cartridges, turn off water, power, and tank ball valve, then turn the RO

faucet (black lever) up to let the water flow out completely.

2. Using filter housing wrench to turn ( unscrew ) the filter housing clockwise to open the filter

housing.

3. Discard of recycle the used cartridge. Replace the new filter cartridge and screw the filter

housing back on the cap. Turn the filter housing counter clockwise until tight and seal.

8

4. Repeat previous steps on the next filter.

5. Turn on the water supply and check for leaks.

6. After replacing all filter catridge stages, flush

the system with one tankful of water before

use.

7. Replace filter cartridge regularly to ensure

the quality of drinking water and extend the

life of the system.

Reverse Osmosis Systems Replacement Cartridges

System

HydroSense-0400

HydroSense-0500

HydroSense-0500DI

HydroSense-0500GAC

HydroSense-0500UV

HydroSense-0500GAC-CAL-UV

Stage 1

Filter

PD-5-20

Polydepth

PD-5-20

Polydepth

PD-5-20

Polydepth

PD-5-20

Polydepth

PD-5-20

Polydepth

PD-5-20

Polydepth

Stage 2

Filter

EP-20

Carbon Block

EP-20

Carbon Block

EP-20

Carbon Block

EP-20

Carbon Block

EP-20

Carbon Block

EP-20

Carbon Block

twist-off to remove twist-on to lock it

Fig. #10

Stage 3

Filter

CBC-20

Carbon Block

CBC-20

Carbon Block

CBC-20

Carbon Block

CBC-20

Carbon Block

CBC-20

Carbon Block

CBC-20

Carbon Block

Stage 4

Filter

TW - 1812-

100

TW - 1812-

100

TW - 1812-

100

TW - 1812-

100

TW - 1812-

100

TW - 1812-

100

Stage 5

Filter

GS - 210DI

GS - 215RO

GL10SE4P

GS -

10CAL/RO

Stage 6

Filter

GL10SE4P

© 2017 Water Engineering Corporation

9

System Performance and Operating Limits

Production Rate GPD (m3/d) 50 GPD

Stabilized Salt Rejection 98%

Minimum Salt Rejection 98%

Feed Water TDS 2000 ppm Max

Feed Water Temperature 40 ~ 113 °F

Feed Water Pressure 40 ~ 85 psi

Feed Water pH 5 ~ 10

Installation Manual

Feed Water Hardness < 10 grains per gallon

Feed Water Iron < 0.1 ppm

Feed Water Manganese < 0.05 ppm

1. Production flow and salt rejection based on the folllowing test condition: 250 ppm softened tapwater, 77 °F (25 °C), 50 psig

and 15% recovery

2. Permeate flow rates for individual elements may vary +/- 20%

3. Booster Pump models may significantly increase production and TDS reduction rates, average pressure increased by 60 psi.

_

_

_

Troubleshooting

RO System does NOT start up

Power cord not plugged in, Power outage

Transformer burned out

Insufficient water (water cut off) and inlet pressures

Booster pump malfunction

Post filter cartridges are clogged

High pressure switch failure

Low pressure switch failure

Check and connect power

Check the transformer input voltage/overload burned out

Check the inlet water pressure

Replace Booster pump

Check if post filter cartridge is clogging the water flow

Replace high pressure switch

Replace low pressure switch

Insufficient Output RO Water

Insufficient water pressure coming out of booster pump

RO membrane filter element got clogged

Insufficient water input

Stage 1,2 or 3 filter cartridge is clogged

No or Little Decrease in TDS Value in Product Water

RO membrane connector O-RING deformed with leakage

RO membrane ruptured/aperture enlarged

Replace booster pump

Replace RO membrane

Check if the Stage 1,2 or 3 filter cartridge is clogged

Check if the Stage 1,2 or 3 filter cartridge is clogged/replace

Replace O-RING

Replace RO membrane element cartridge

© 2017 Water Engineering Corporation

Installation Manual

System NOT Treating Water After Replacing Filter Cartridge

10

Air in the tubing (AIR)

Pressurized Motor Continues to Restart Frequently

Outlet check valve is not blocking water completely

Leakage in the tubing

Booster Pump Motor Burned Out

Abnormal frequent startup and overheat

Pressurized Motor Junction Leakage

Motor triangular diaphragm rupture

Motor Does NOT Pump Up the Pressure

Air in the motor

Insufficient water input

Release the air in the tubing

Replace check valve

Lock tight/replace tubing

Replace booster pump

Replace booster pump

Release the air

Check if water supply and post filters cartridge are clogged

RO Water Smells or Tastes Strange

Inline active carbon is saturated

Intermittent usage, water ceases flowing

Stage 1,2 or 3 filter cartridge Junction Leakage

Filter housing not locking tightly

Filter housing o-ring deformed

Transformer Burning Smell

Power input specification error/burned out

Replace inline activated carbon filter cartridge (polished filter)

Drain tank water/replace inline active carbon cartridge

Lock each filter housing ( canister ) tightly

Replace housing o-ring

Check if power input complies with standard specs

© 2017 Water Engineering Corporation

11

Installation Manual

This page is intentionally left blank

WECO HydroSense

WECO

Reverse Osmosis

Water Filter

Installation Manual

www.wecofilters.com

Water Engineering Corporation

Long Beach, CA U.S.A

1 (888) 675-5187

sales@wecofilters.com

Loading...

Loading...