Gemini / Filterking Water Purifiers

Inst Manual Layout - Front Page (A4 size) Date : 29 June 2004

Gemini / Filterking Water Purifiers

Fitting and Operating Instructions

Clean,

Healthy Water

at the Touch of a tap!

(W99151) 06/ 2004

Distributed By :

Damage caused during installation can void your warranty. Find an installer who

is prepared to guarantee their workmanship.

Your warranty covers faulty parts, but does not cover leaks that appear during

or after installation and does not cover any water damage that may result from

such leaks.

Please Use a Skilled Installer

Waterco 12 month warranty. Void if correct fitting and operating instructions are

not observed.

Warranty

Replacement Intervals

The replacement intervals of both cartridges are dependent on water quality

and the volume of water passing through the filter:

If flow is affected, it is time to change the Sediment Cartridge in the first

housing. As a general guideline the Sediment Cartridge should be changed

every 6-12 months.

If taste/ odour is affected, it is time to change the Purifying Cartridge in the

second housing. As a general guideline the Purifying Cartridge should be

changed every 8-12 months.

If you have installed a Filterking, if either flow or taste/ odour is affected please

change the carbon cartridge. If the flow is affected within a short time period, Waterco

recommends the installation of a Gemini Undersink Unit with a 5 micron pre-filter.

Sediment Cartridges

Purifying Cartridges

5 Micron Sediment Cartridge

(3651993)

Extruded Carbon Block 1 micron

(3651970)

Ceramic Cartridge 1 micron

(3649020)

CZR/ Carbon Cartridge

(3651919)

Extruded Carbon Block 5 micron

(3651971)

Troubleshooting

Problem Reason Solution

Water has an

offensive odour

Not enough

water

No water

Under sink

is wet

Sediment/ Carbon filter

are depleted

Low water pressure

Water supply is blocked

Clogged pre-filter cartridge

Water supply is turned off

Leak from valve,

faucet or fitting

Replace filters, clean system.

If line pressure is below 30psi

install a booster pump.

Clear restriction.

Replace prefilter.

Turn on water.

Dry everything to isolate the leak.

Before replacing any fitting, re-cut

the tubing and re-insert into the

fitting to see if that solves the leak.

If pipe threads are leaking, remove

and retape with Teflon tape.

Waterco stocks an extensive range of water filtration products,

contact your local Waterco stockist for more information.

Or visit our website at www.waterco.com

Waterco Limited ABN 62 002 070 733

MALAYSIA

Kuala Lumpur

Tel : +60 3 6250 8169

Fax : +60 3 6250 8175

CHINA

Guangzhou

Tel : +8620 8335 1107

Fax : +8620 8335 1114

QLD

Brisban

e

Tel : +61 7 3299

9900

Fax : +61 7 3299 9911

SA/ NT

Adelaide

Tel : +61 8 8244 6000

Fax : +61 8 8244 6011

WA

Perth

Tel : +61 8 9344 5533

Fax : +61 8 9344 5506

DISTRIBUTOR ACT

Canberra

Tel : +61 2 6280 647

6

F

ax : +61 2 6239 1

395

NEW ZEALAND

Auckland

Tel : +64 9 525 7570

Fax : +64 9 525 6580

NSW

(

HEAD OFFICE

)

Sydne

y

Tel : +61 2

9898 8686

Fax : +61 2

9898

175

4

O

FFICES - AUSTRALI

A

VIC/ TAS

Melbourne

Tel : +61 3 9879 514

1

Fax : +61 3 9879 514

3

UNITED STATES OF AMERICA

Phoenix

Tel : +1 623 434 4703

Fax : +1 623 434 4704

O

FFICES - OVERSEA

S

EUROPE

Lacron (UK) Ltd

Kent, United Kingdom

Tel : +44(0) 1795 521 733

Fax : +44(0) 1795 522 085

✽

✽

✽

✽

To Ensure the Purest Water Possible

Restrict the flow rate to 1-3 litres per minute. If the resulting flow rate is

more than 3 litres per minute, use a flow inhibitor.

Flush your purifier for 5-10 seconds each time you use it.

Regularly maintain the filter and purifying cartridges.

If filter is not in use for more than 24 hours, flush filter for a minimum

of 1 minute prior to using.

Please read this entire guide prior to beginning installation.

The Gemini/ Filterking drinking water purifier has been designed for quick and

simple installation and maintenance. By carefully reading this instruction manual

and following the operational guidelines you will ensure a successful installation

and reliable operation.

Do not use on water that is microbiologically unsafe or of unknown quality. The

Gemini/ Filterking is normally installed under a sink or basin, but can also be

plumbed-in or wall-mounted. In all cases you need a pressurised, sterilised and

drinkable cold water supply.

Your Gemini/ Filterking is supplied with an installation kit that allows connection

to a dishwasher type cold tap with a 3/4" BSP male thread. If a convenient tap

is not available, you may either have one installed or purchase the suitable inlet

fittings from your supplier.

Fitting and Operating Instructions

G

g

emini/ Filterkin

g

W

ater Purifier

s

Plumbing the system

1. Locate the water shut-off valve for the cold water feed line you choose to use

for the supply. To assure you are using the cold water line, turn on both the hot

and cold faucet. After the water is warm to touch, feel the pipes under the sink.

It will be easy to identify the hot and cold pipes.

2. Close the cold water valve. Turn on the cold water faucet to assure that the line

is completely shut off and the line is drained. If no shut off valve is located

underneath the sink, turn off the main supply at the entry to the house.

3. The Gemini/ Filterking is supplied with an installation kit that allows connection

to a dishwasher type cold tap with a 3/4" BSP male thread. If a convenient tap

is not available, you may either have one installed or purchase the suitable inlet

fittings from your supplier. Connecting to the cold water main will require a

qualified plumber. There must be a tap to turn off the water for maintenance.

Use cold water only.

Activating the system

Once the Gemini/ Filterking is connected, open the faucet before turning on

the tap to displace air inside the filters. Let the water run for at least 5 to 10

minutes to flush the filter of fines (these particles are harmless). Turn the faucet

off and check for leakage. Recheck overnight.

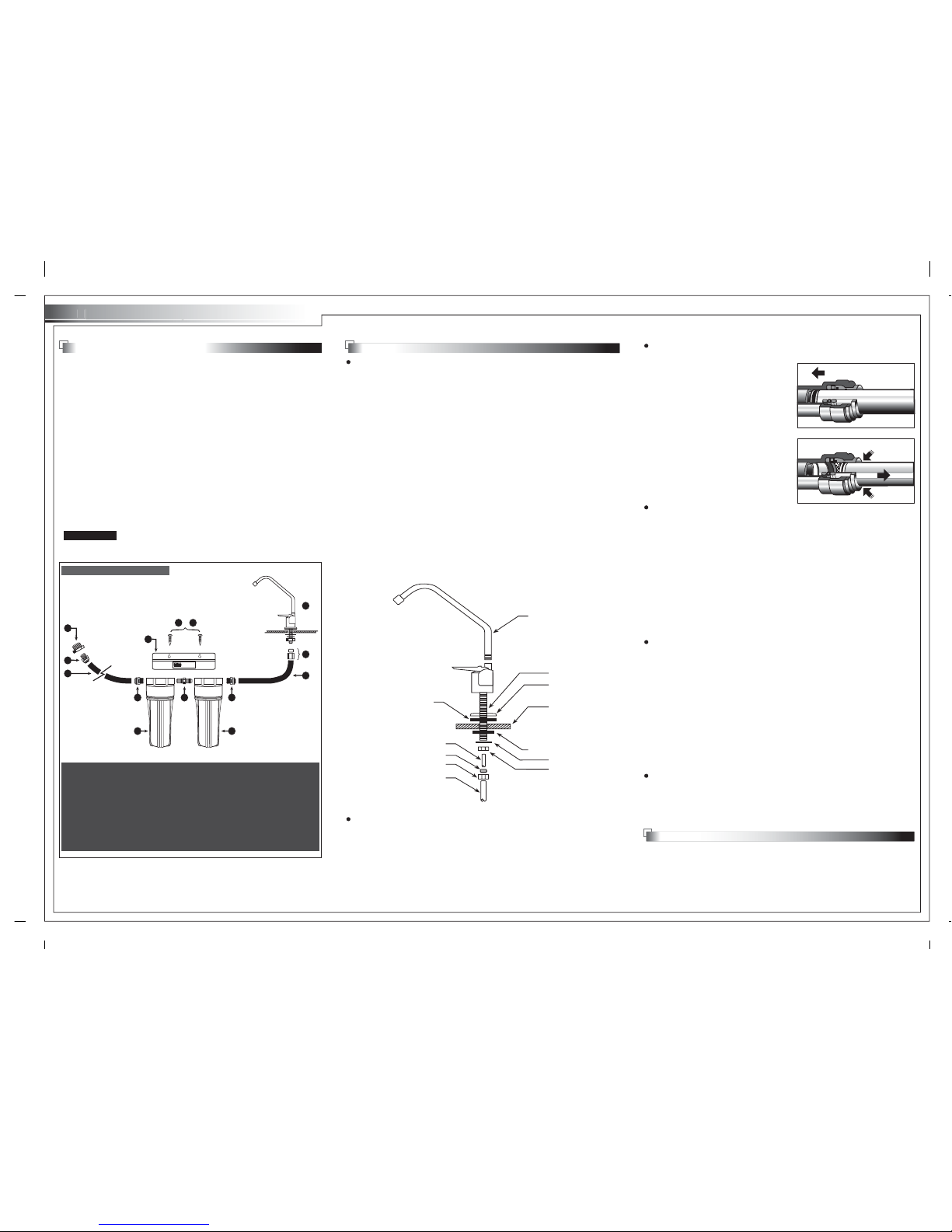

Components

Check the following list of components to ensure that all parts are packed with

your system.

5, 6, 7, 8 & 11 are factory fitted.

1. Faucet set.

2. 1/4" BSP nut with brass olive.

3. 6mm blue tube x 1m.

4. 1/4" BSP John Guest Straight

Adaptor (3 sets).

5. 1/4" x 1/4" BSP nipple.

6. Filter Housing with Purifying

Cartridge.

7. Filter housing with Sediment Cartridge.

8. Mounting bracket.

9. 3/4" x 1/4" BSP brass reducing coupling.

10. 6mm yellow tube x 1m.

11. Filter housing's mounting screws

(8 supplied).

12. Wall mounting screws with plugs

(2 supplied).

Gemini Plus

TWIN U/SINK UNIT

Sink or

Bench top

4

9

10

4

8

7

1

6

4

5

11

&

12

2

3

* Filterking consists of only one filter housing with an extruded carbon block

and a single mounting bracket.

Gemini / Filterking Water Purifiers

Inst Manual Layout - Inner Page (A4 size) Date : 30 June 2004

Escutcheon

Plate

Mounting

Surface

Lock Washer

Lock Nut

Tube Insert

Spout

Shank

Black Locating Washer

Ferrule

Compression Nut

Black Rubber Washer

Blue Tubing

1. Decide the location of the faucet on top of the bench top or sink top. This should

not be more than 1.8m from the cold water supply. Make sure that drilling a 7/16"

diameter hole in that location will not damage pipes or wires running under the sink.

2. Place a piece of masking tape or duct tape on the determined location where hole

is to be drilled.

3. Use a variable speed drill at slow speed with 1/8" (3mm) drill and drill a centering

hole in the center of the desired faucet location. Use lubricating oil to keep the drill

bit cool while drilling.

4. Enlarge the hole using a 1/4" (6.4mm) drill bit.

5. Enlarge the hole to 7/16" (11mm) diameter. Keep bit well oiled and drill slowly.

6. Pass the Escutcheon Plate (chrome base plate) and the Black Rubber Washer in

that order onto the shank on the base of the faucet.

7. From under the sink, install the Black Locating Washer and the Lock Washer over

the threaded shank. Screw on the Lock Nut and tighten.

8. Sleeve the Compression Nut and the Ferrule over the Blue tube, insert the Tube

Insert and push to the end of the threaded stem. Screw on the Compression Nut

and tighten with a spanner.

Installation

Faucet Installation.

John Guest Fittings and Tubing

John Guest fittings are used throughout the system.

1.

To install the tube, push it through the

collet until it seats firmly. The collet

has stainless steel teeth which grip

the pipe whilst the o-ring provides a

permanent leak-proof seal. Pull on

the pipe to check it is secure. It is

good practice to test the system prior

to leaving the site and/ or before use.

2.

To remove the tube, please ensure the

system is depressurised. Push in the

collet squarely against the face of

fitting. With the collet held in this

position, the tube can be removed.

Push Pipe To Stop

Push In Collet

Remove Pipe

Housing Installation

1. Using the filter housing assembly to mark the position of the 2 mounting screws,

making sure there is room for maintenance, drill 2 x 3mm holes for the mounting

screws. Insert the wall plugs; screw the screws in the gap for the Mounting

Bracket.

2.

Apply 2 turns of Teflon tape to the nipple side of the John Guest Adaptors (items 4).

Screw the nipples into the inlet and outlet of the filter housing assembly. Connect

the blue tube to the outlet side and the yellow tube to the inlet side. Screw the

nipple on the other end of the yellow tube into the 3/4" x 1/4" BSP brass reducing

coupling (item 9).

The spout can be rotated through 360˚ for added convenience.

When small amounts of water are required from the faucet, push down or gently

pull up on the faucet handle.

For large amounts of water delivered hands-free from the faucet, pull up on the

faucet handle until it locks into the open position.

Operation

Warning !

Excessive pressure or water hammer can damage plumb-in systems. Do not,

under any circumstances, connect to a pressurised water supply without testing

pressure with an accurate gauge. If pressure is above 125 psi (875 kPa) day

or night, or if any water hammer problems exist, a high quality pressure limiting

/ anti-hammer valve must be installed.

A non-return valve must be installed in the water supply line or between the

supply line and the first filter housing. This will ensure no water returns to the

supply.

The responsibility must always lie with the installer to check the water-tightness

of all fittings and connections after the product is subjected to full line pressure.

The installation must be checked last thing at night and again early the next

morning after the day of installation, to make sure there are no drips from

inadequately sealed connections.

Loading...

Loading...