Waterco ElectroHeat MKIV, ElectroHeat Plus, ElectroHeat Eco-V Installation And Operation Manual

Waterco Limited ABN 62 002 070 733

www.waterco.com.au

WARNING

!

(W99341) 01/2018

AUSTRALIA

NSW - Sydney (HEAD OFFICE)

Tel : +61 2 9898 8600

VIC/ TAS - Melbourne

Tel : +61 3 9764 1211

WA - Perth

Tel : +61 8 9273 1900

QLD - Brisbane

Tel : +61 7 3299 9900

SA/ NT - Adelaide

Tel : +61 8 8244 6000

CANADA / NORTH-EAST USA

Waterco Canada Inc

Longueuil, Quebec, Canada

Tel : +1 450 748 1421

USA

Waterco USA Inc

Augusta, Georgia, USA

Tel : +1 706 793 7291

www.waterco.com.au

This web site address will enable you to select the appropriate country website.

NEW ZEALAND

Waterco (NZ) Limited

Auckland, New Zealand

Tel : +64 9 525 7570

EUROPE

Waterco (Europe) Limited

Sittingbourne, Kent. UK

Tel : +44(0) 1795 521 733

CHINA

Waterco (C) Limited

Guangzhou, China

Tel : +8620 3222 2180

MALAYSIA

Waterco (Far East) Sdn. Bhd.

Selangor, Malaysia

Tel : +60 3 6145 6000

WATERCO POOL HEAT PUMP

L’eau, le liquide de la vie

Installation and

Operation Manual

Manuel d’installation

et d’utilisation

This equipment must be installed and serviced by a qualified technician.

Improper installation can create electrical hazards which could result in property

damage, serious injury or death. Improper installation will void the warranty.

Cet équipement doit être installé st réparé par un technicien qualiflié.

Une mauvaise installation peut entraîner des risques électriques qui pourraient

provoquer des dommages, des blessures graves ou la mort. Une installation

inadéquate annulera la garantie.

Notice to Installer / Avis à l’installateur

This manual contains important information about the installation, operation and

safe use of this product. Once the product has been installed this manual must

be given to the owner/operator of this equipment.

Ce manual contient des informations importantes sur l’installation, I’exploitation

et l’utilisation sécuritaire de ce produit. Une fois que le produit a été installé, ce

manuel doit être remis à l’acheteur et/ou utilisateur de cet équipement.

FLOW

I pg 02

Pool Heat Pump

Table of

IMPORTANT SAFETY INSTRUCTIONS

When using this electrical equipment, basic safety precautions should always be

followed, including the following:

READ AND FOLLOW ALL INSTRUCTIONS

! WARNING: Disconnect all AC power during installation and servicing.

! WARNING: In order to avoid the possibility of hyperthermia (heat stress) occurring

it is recommended the average temperature of the spa - pool water does not exceed

40˚C.

! WARNING: The pool heat pump is not intended for use by persons (including

children) with reduced physical sensory or mental capabilities, or lack of experience

and knowledge, unless they have been provided supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be

supervised to ensure they do not play with the appliance.

• In certain situations unexpected start up may occur when the appliance is in

automatic mode.

• The installer should assess the risk associated with unexpected start-up of this

device which, in any circumstance should have no hazardous effect.

• The pool heat pump is not meant to provide safety protection for other devices.

• The pool heat pump should be deactivated if the pool or spa has been drained.

• Waterco pool heat pumps must be installed by a suitably qualified person in

accordance with current Regulatory Standards, the applicable Wiring Rules

(AS3000) and local statutory authority regulations.

• Parts containing live parts, except parts supplied with safety extra-low voltage

not exceeding 12V, must be inaccessible to a person in the spa – pool.

• Parts incorporating electrical components, except remote control devices, must

be located or fixed so that they cannot fall into the spa – pool.

• The appliance should be supplied through a residual current device (RCD) having

a rated residual operating current not exceeding 30mA.

• An Earth terminal is located inside the wiring enclosure. To reduce the risk of

electric shock, this terminal must be connected to the grounding means provided

in the electric supply service panel with a continuous copper wire as sized to

comply with current Standards and local statutory authorities in relation to the

circuit conductors supplying the equipment.

• A cable connector is provided on this unit to connect a suitably sized copper

conductor between this unit and any metal equipment, metal enclosures of

electrical equipment, metal water pipe, or conduit within 1.5m of the unit via

equipotential bonding.

SAVE THESE INSTRUCTIONS.

IMPORTANT SAFETY INSTRUCTIONS

------------

02

A NOTE TO YOU

--------------------------------------

03

INSTALLATION INSTRUCTIONS

--------------------

05

Location

------------------------------------------

05

Installation Clearances

--------------------------

06

Water Piping

-------------------------------------

07

Water Flow Rate

---------------------------------

08

Water By-pass Kit

-------------------------------

08

Plumbing Diagram

------------------------------

08

Electrical

------------------------------------------

09

Electrical Connection

---------------------------

09

Breaker Size -------------------------------------- 09

Electrical Wire Size

------------------------------

09

Bonding

-------------------------------------------

10

Bonding Diagram

--------------------------------

10

Remote Control Connections

------------------

11

Usage Of Chemical Products

------------------

12

OPERATION OF YOUR POOL HEAT PUMP

--------

13

CONTROLLER TYPES

Initial Heating

------------------------------------

13

Adjustment Of The Bypass Valves

------------

13

Pool Heat Pump Running Time

----------------

14

Pool Solar Blanket

-------------------------------

14

Defrost Cycle

-------------------------------------

14

To Start The Pool Heat Pump ------------------ 15

To Stop The Pool Heat Pump ------------------ 15

To Check and Adjust Temperature

Settings ------------------------------------------- 16

Temperature Calibration

------------------------

17

To Change Display From Farenheit To

Celcius

--------------------------------------------

18

Defrost for Electroheat Ultra

-------------------

18

Protection Devices

------------------------------

18

Codes

---------------------------------------------

18

INVERTER POOL HEAT PUMP CONTROLLER

----

19

Inverter Controller Operation

------------------------

20

Timer Function

-----------------------------------

20

Function Descriptions

--------------------------

21

Buzzer --------------------------------------------- 21

Memory Function

--------------------------------

21

MAINTENANCE OF YOUR POOL HEAT PUMP

----

22

Cabinet Cleaning

--------------------------------------

22

Cleaning Evaporator

----------------------------------

22

Cleaning drainage holes

------------------------------

22

Units Located In Coastal Locations

-----------------

22

Winterising Procedure

--------------------------------

23

GENERAL SAFETY INSTRUCTIONS

----------------

24

TROUBLESHOOTING

---------------------------------

25

Nothing Is Working and The

Electronic Control Does Not Operate

--------

25

Nothing Is Working But The Electronic

Control Temperature Displays Digits

or a Code

---------------------------------------

25

Fan Doesn’t Work (The Fan Blades

Are Not Moving)

--------------------------------

25

Fan Blades Turn, But Compressor Is Not

Functioning

----------------------------------------

26

Compressor Starts and Stops

-----------------

26

There Is Water Around The Pool Heat

Pump ------------------------------------------------

26

Pool Heat Pump Has Ice Formed On The

Evaporator Coil

---------------------------------

27

Pool Heat Pump Is Functioning, But Does

Not Reach The Desired Temperature

Setting -------------------------------------------- 27

Analysis Chart

------------------------------------

28

Circuit Breaker Trips

-----------------------------

28

The Pool Heat Pump Is Noisy

------------------

29

The Temperature Shown On Pool Heat

Pump Is Not The Same That Is

Shown By The Pool Thermometer

-------------

29

Service Analyser Codes

-------------------------

30

WARRANTY -------------------------------------------- 35

I pg 04

Pool Heat Pump

A NOTE TO YOU

Congratulations!

Thank you for choosing a Waterco pool heat pump to heat your pool.

Using the latest technology in heat capture, the Waterco pool heat pump converts

the energy released by the sun and transfers it efficiently to your swimming pool.

During certain periods it may be necessary to operate your pool heat pump

continuously during the day in cooler periods however, this should not be of concern

as your Waterco pool heat pump can heat up your pool 80% more economically than

the fossil fuel heating or heaters with electric elements.Waterco pool heat pumps are

designed specifically to heat up your swimming pool economically.

To appreciate the benefits that the product will bring you, make sure to operate

the unit when the atmospheric conditions specified in this document are present in

addition of using a solar blanket to minimize heat loss which will influence operating

costs and size of the unit required. Pools not covered with a solar blanket lose 2 to 3

times more heat, regardless of types of heating!

Record your model’s information.

Keep this manual and your original proof of purchase receipt for warranty and

future

reference.

On the base of your pool heat pump is a name plate which contains information

such as model number, serial number and electrical information.

Please write these down below and have them handy incase of a service call request.

Model Number _______________________________________________________________

Serial Number _______________________________________________________________

Purchase Date _______________________________________________________________

Dealer Name _______________________________________________________________

Dealer Address _______________________________________________________________

Dealer Phone _______________________________________________________________

To find detailed product information, the location of the nearest dealer or to

register your pool heat pump please visit our website www.waterco.com and

select your location.

I pg 06

Pool Heat Pump

Installation Clearances

Air is pulled through the evaporator coil and discharged through the top or front

grill. Clearances must be allowed in front and around the unit for unrestricted

air discharge and service access. See Figure 1 and Figure 2. Failure to comply

to the set clearances may cause diminished unit performance and reduced unit

longevity.

INSTALLATION INSTRUCTIONS

Location

To gain maximum efficiency for your pool heat pump please follow all instructions

when “positioning the unit”. It is also important to allow clearances for future

service and maintenance procedures.

The unit is designed for outdoor installation and should not be installed in a totally

enclosed area such as a shed, garage, etc., unless assisted ventilation of the cold

exhaust air is provided to ensure adequate air exchange for correct operation. Recirculation of cold discharged air back into the evaporator coil should be avoided

and will greatly reduce unit’s heating capacity and efficiency.

The unit should be located as close as practically possible to the existing pool

pump and filter to minimize water piping. The use of 90 degree bends and short

radius elbows in the water piping should be kept to a minimum.

Mount the unit on a sturdy base, preferably a concrete slab or blocks. The base

should be completely isolated from the building foundation or wall to prevent the

possibility of sound or vibration transmission into the building. The size of the

base should not be less than the base of the pool heat pump.

Use of anti vibration mat between the base of the unit and final installation location

material is highly recommended to reduce potential vibration noise issues.

No obstruction above to allow cold air dispersal

clearance to rear

minimum 30cm

Clearance to side

minimum 60cm

Clearance to side

minimum 60cm

Top Discharge Models

Figure 1

Clearance to rear minimum 30cm

Side Discharge Models

Figure 2

No obstruction in front to

allow cold air dispersal

clearance to side

minimum 60cm

clearance to side

minimum 60cm

clearance to top

minimum 60cm

I pg 08

Pool Heat Pump

Water Flow Rate

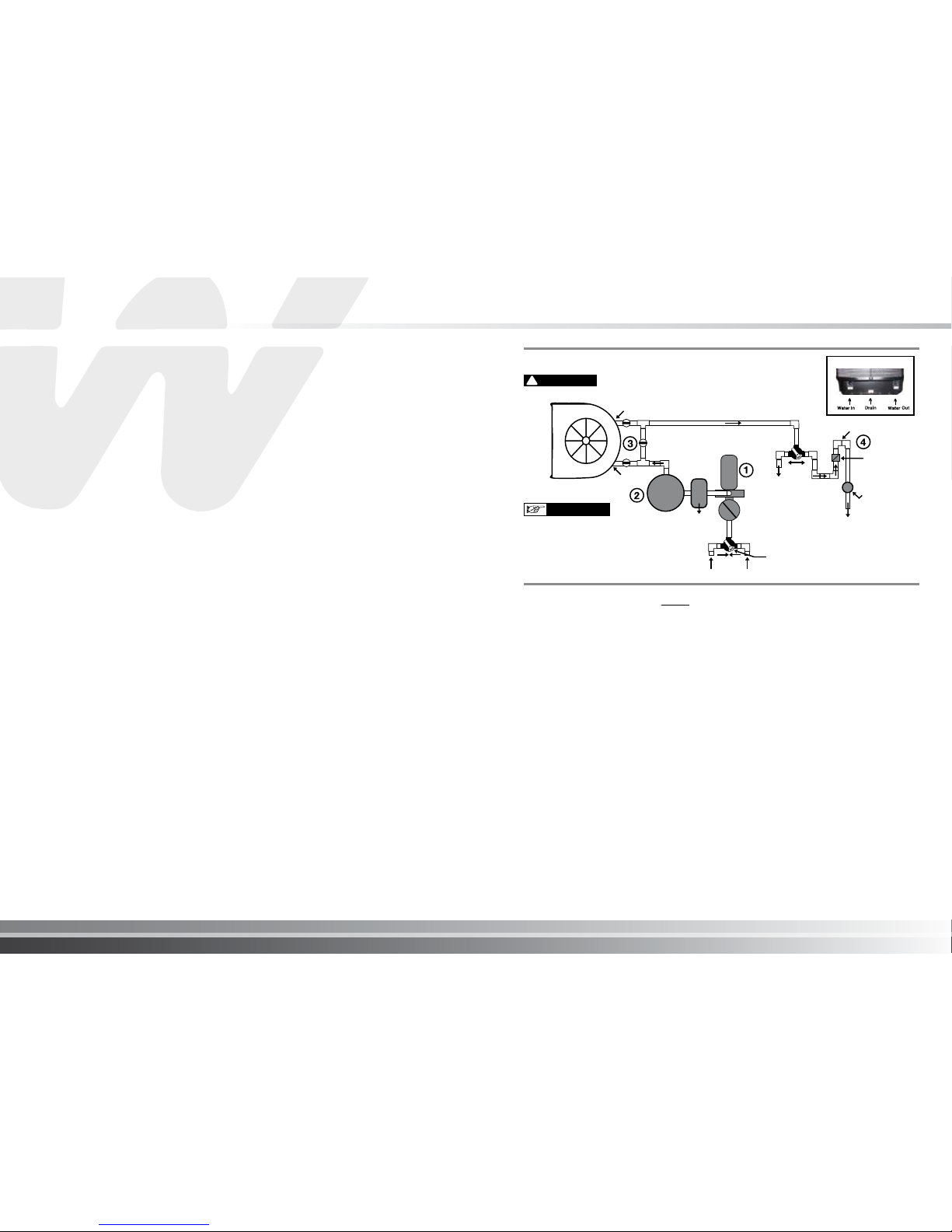

The recommended water flow rate to ensure maximum heat transfer efficiency is between

120 - 300 litres per minute. The optimal flow rate is the mid point of this range. Use the

bypass valve to adjust the flow rate to within the recommended range.

Water By-pass Kit

A bypass kit consisting of three X two way valves must be installed for adjustment of water

flow and ease of service. Waterco offer prefabricated water bypass kits to fit their heat pump

domestic range. Ask your local Waterco sales office for details.

1. A check valve or a loop MUST be installed between the pool heat pump and

any automatic chlorinator to prevent highly chlorine concentrated water from

flowing back to the pool heat pump when the pool pump is not running.

2. Units which are located below the water level of the swimming pool may require

the pressure switch to be adjusted.

This can be checked by the following method:

i) switch on the water pump and pool heat pump.

ii) while the pool heat pump is running switch “OFF” the water pump.

If the pool heat pump shuts down automatically no further action is

required.

3. Units which are installed more than 1 metre below water level will require a

flocheck valve to be fitted to prevent the heat pump from cycling when no water

flow is detected.

4. For units installed above the pool water level the return water to the pool valve

on the bypass valve set should be closed approximately 15 - 20% to ensure the

heat exchanger is completely full of water to allow the heat transfer to occur.

!

VITAL

Plumbing connections to

the heater must be made

by hand only as it may

break the water Inlet or

Outlet connections.

IMPORTANT

Plumbing Diagram

Hookup

HEAT PUMP

Water Out

Water By-pass

PUMP

Filter

Water In

From Spa

From Pool

3 Way Valve

To Spa

SPA POOL

SPA POOL

Vertical Trap

Check

Valve

Chlorinator

or Chlorine

Generator

To Pool

MultiCyclone

Water Piping

The below plumbing layout must be followed without exception:

1. pool pump

2. filter

3. pool heat pump

4. chlorinator (when installed).

Rigid PVC piping is recommended with all joints primed and glued with a suitable PVC

adhesive cement. If rigid PVC pipe is not available,a suitable flexible hose of adequate

diameter may be utilised with stainless steel clamps. When the piping installation is complete,

operate the pool pump and check the system for leaks. Then check the filter pressure gauge

to see that excessive pump head pressure is not indicated.

IMPORTANT

Electrical

All electrical work should be performed by a fully qualified and licensed

electrician in accordance with local electrical codes.

An adequate circuit breaker and copper wiring must be used. Electrical

requirements are available on the name plate of the pool heat pump. It may be

necessary to install an earth leakage circuit breaker.

THE POOL HEAT PUMP MUST BE DISCONNECTED BEFORE

OPENING THE ACCESS PANEL.

WARNING

!

Electrical Connection

Standard 60 Hz power supply : 208/240 v - 60Hz-1 phase

Standard 50 Hz power supply : 208/240 v - 50Hz-1 phase

3 phase power supply : 200/230 v - 50/60 Hz - 3 phase

380/420 v - 50/60 Hz - 3 phase

Breaker Size

Please consult name plate on the base or the side of your pool heat pump for

starting amperage and required breaker size.

Electrical Wire Size

Please consult a qualified and licensed electrician.

The power cable ground must be connected to the electrical panel and to the

ground lug of the pool heat pump. An improper installation may be a potential

cause of fire, electrical shock or injury.

WARNING

!

I pg 10

Pool Heat Pump

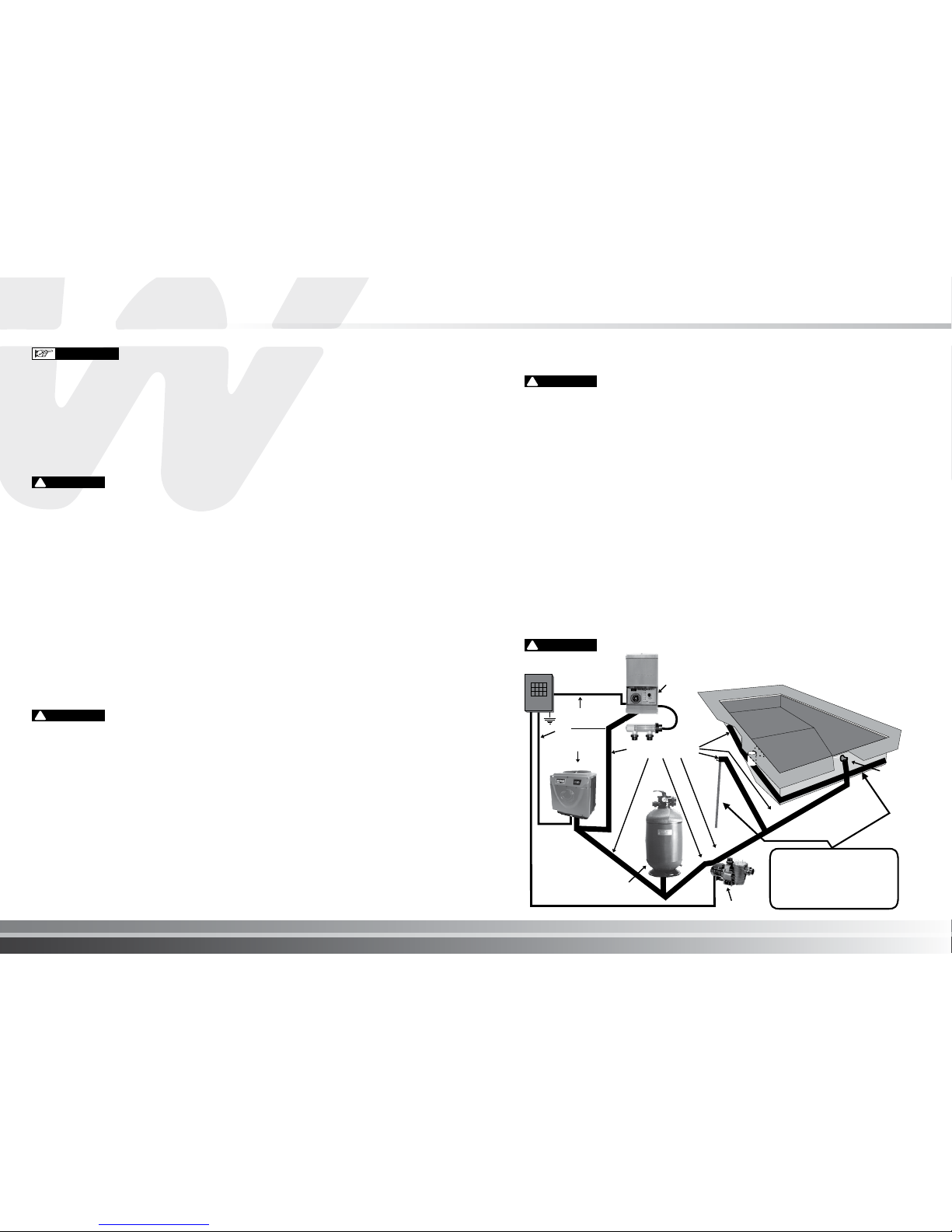

Bonding

Because all metals have different electrical potentials, ALL metal and electrical components of

the pool system MUST be bonded together. This includes the metal framework of the pool, the

light, the pump, the filter (if metal), the pool heat pump, any automatic chlorine generator, and any

other metal or electrical equipment bonded to your pool.

On some older pools, this substructure bond wire may not exist. In these cases, a 3 - 4 foot solid

copper rod must be driven into the ground near equipment; all electric and metal components

must be bonded to each other, and to the copper rod. Warranty will be voided if system is not

properly bonded.

CAUTION: Some of these systems may leak stray voltage and currents into the water causing

severe electrolysis. This dramatically shortens the life of the pool heat pump and will void the

warranty.

When an automatic chlorinator is installed on a pool circulation system, it is important the

equipment is correctly installed and bonded (earthed). Some systems may leak stray voltage

and currents into the water causing severe electrolysis which could shorten the life of the pool

heat pump.

NOTE: Bonding to pool pump is not required to above ground pool pumps but all other

equipment must be bonded.

!

VITAL

Bonding Diagram

Pool House

Breaker Box

Power Supply

and Grounding

Wires Conduits

Chlorine

Generator

Heat Pump

Need bonding

if it is a metal filter

Pool Pump

If Pool Bonding Wire does

not exist, then a 3’ to

4’ Copper Rod must be

driven into the ground and

equipment bonded to it.

Light

3’ to 4’ Copper Rod

Bonding Wires

Pool Bonding Wire

!

VITAL

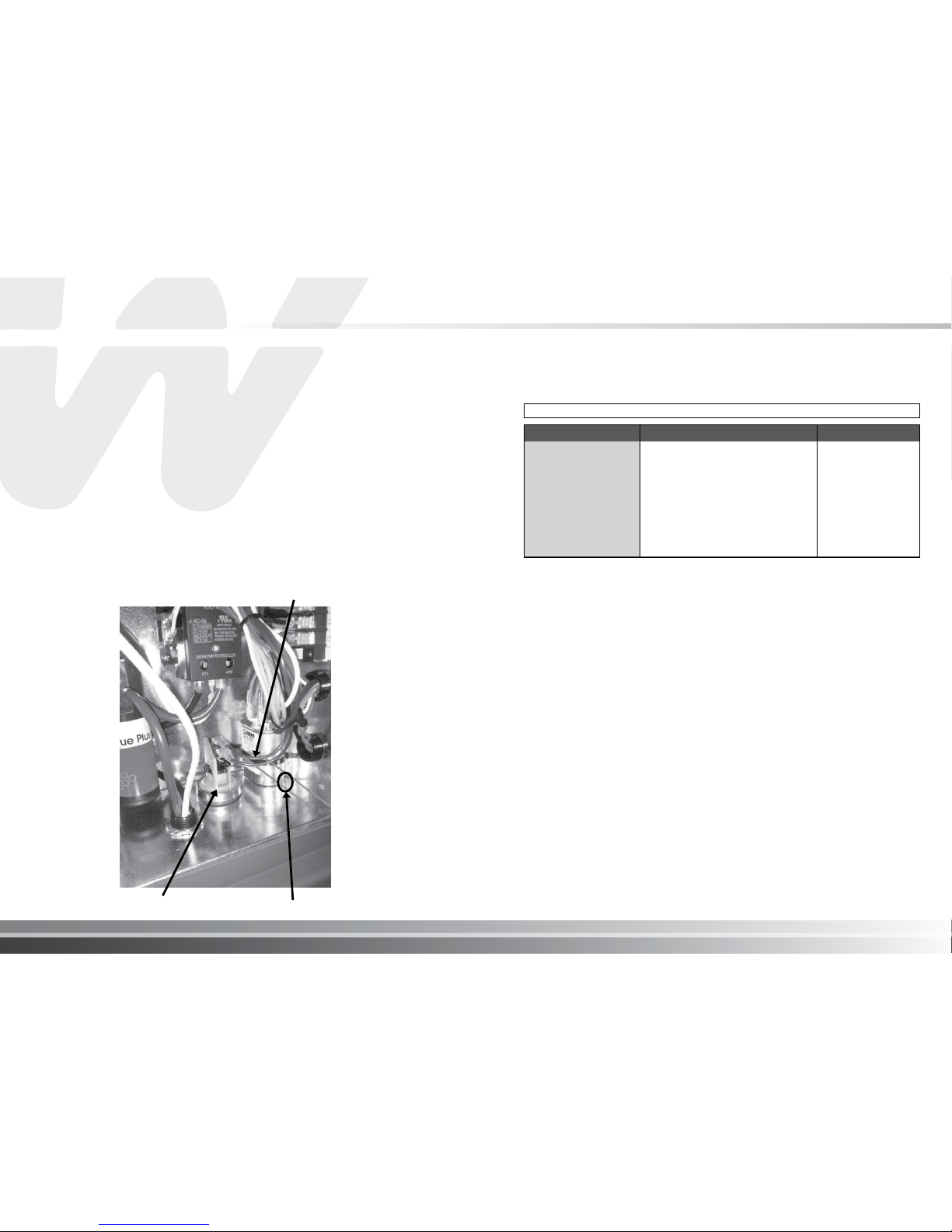

Remote Control Connections

1. Switch off power to heat pump at main circuit breaker panel.

2. Unbolt and remove the front access panel.

3. Open control box cover.

4. To connect a 2-Wire Control such as Waterco Aquamaster™, flocheck valve or timer:

ii) Locate the pressure switch either mounted on the bottom plate of the electrical

enclosure or the heat exchanger.

ii) Cut one of the cables connected to the pressure switch. Connect the two wires

from the Controller Normally Open Contact or flocheck valve to the two ends

of the cut cable and make electrically safe. Controller, timer or relay should be

sized to handle 24VAC at 0.5 Amp (because it will be completing the 24VAC

control board circuit on the heater as shown in Figure 24). Use 1mm2 minimum

cable with a minimum 1.2 mm thick insulation rated for a temperature rise of at

least 105°C.

5. Close control box cover.

6. Re-install the access panel. To control heaters that are operated in parallel, connect

wiring at same locations on heater Control. It is imperative that each control circuit is

isolated from the other control circuits; to avoid that current will flow from one heater to

another through the control circuits.

Pressure Switch 2 core cable from controller

cut one wire

* Warranty can be voided if not maintained within these ranges.

Usage Of Chemical Products

Never add liquid chlorine, granular chlorine, or slow dissolving tablets/ pucks into

the skimmer basket. This high concentration of chemicals should be avoided.

Water quality standards that must be strictly adhered to*:

I pg 12

Pool Heat Pump

DESCRIPTION NORMAL RANGE* VERIFY

PH Level 7.4 to 7.8 1 per week

Chlorine Concentration

1.0 to 4.0 PPM 1 per 2-3 days

Total Alkalinity

100 to 120 PPM 1 per 2-3 weeks

Total Dissolved Solids

Below 1800 PPM Reg. Pool 1 per month

Below 3500 PPM Salt. Pool 1 per month

Calcium Hardness

200 to 300 PPM 1 per month

I pg 14

Pool Heat Pump

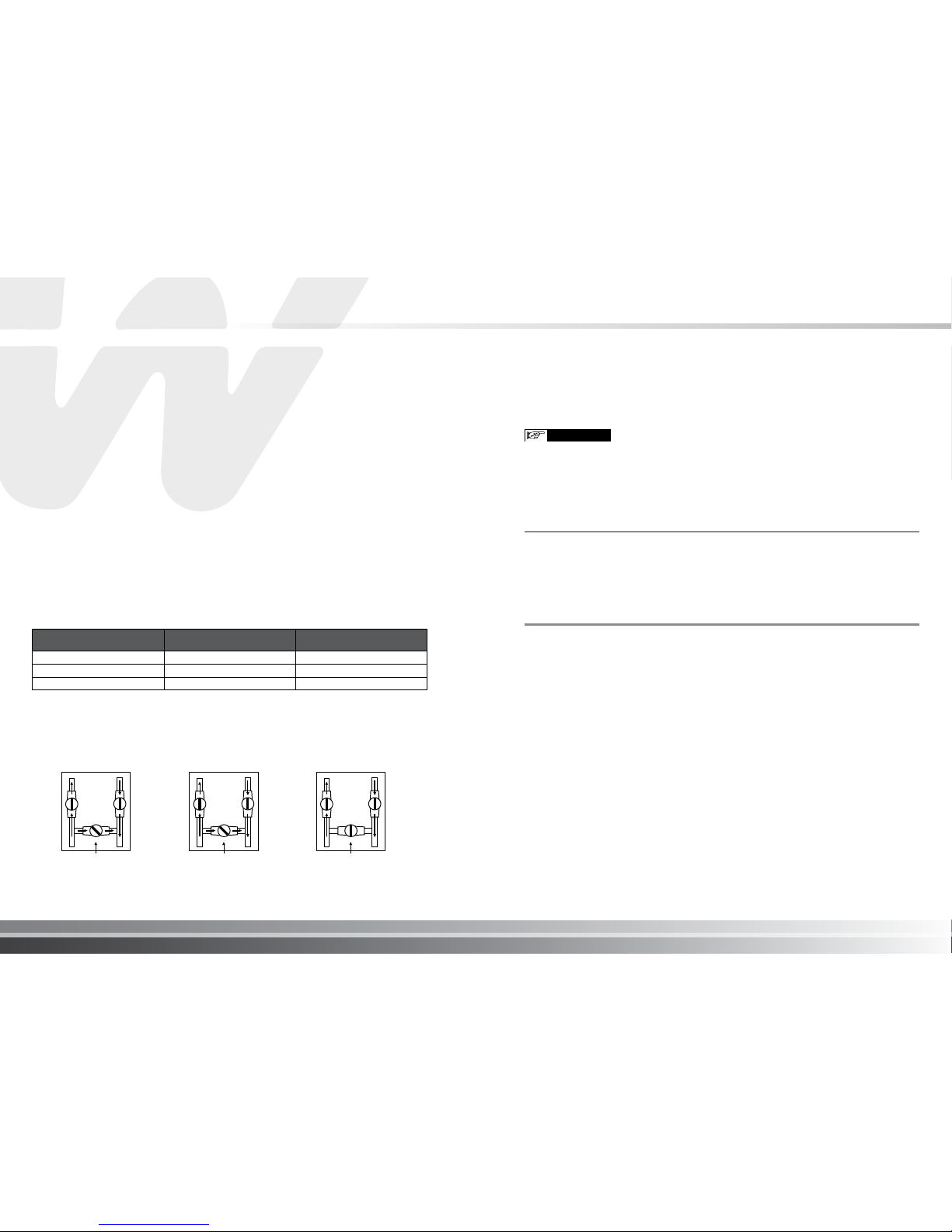

When the pool water

temperature is

between 65°F (18°C) and

70°F (21°C) please adjust

the bypass valve as shown.

Approx. 60% of the water is

circulating in the unit.

OPEN

VALVE POSITION

HEAT

PUMP

INLET

OULET

OPEN

VALVE POSITION

HEAT

PUMP

INLET

OULET

When the pool water

temperature is between

70°F (21°C) and 78°F (26°C)

please adjust the bypass

valve as shown. Approx. 80%

of the water is circulating in

the unit.

VALVE POSITION

CLOSED

HEAT

PUMP

INLET

OULET

When the pool water

temperature is above

79°F (26°C) please close the

bypass valve

as shown. 100% of the water

is circulating in the unit.

Model

Atmospheric conditions

must be above

Pool water temperature

must be above

Electroheat Ultra

32°F (0°C) 50°F (10°C)

Reversible (XLR) and Inverter

43°F (6°C) 65°F (18°C)

All others

52°F (11°C) 65°F (18°C)

Initial Heating

To achieve initial heating, your pool heat pump and the pool pump may require extended operation

until desired temperature is achieved. The initial heating time may vary depending upon the five

factors listed below. After initial heating, operating time may be reduced to match daily heat loss.

1. Size of the pool.

2. How many degrees the water is to be heated.

3. Ambient air temperature - the warmer the air, the less time required to heat.

4. Use of a solar blanket .

5. The size of the pool heat pump.

Atmospheric conditions as well as the pool water temperature should not be below the minimum

operating temperatures as stated below in order to obtain efficiency and avoid codes from

appearing on the electronic control temperature display; these codes are not generally a problem

with the pool heat pump at these conditions and is not covered by the warranty.

If a combination of the atmospheric and water temperatures are below the minimum listed

concurrently the pool heat pump should not be operated and be switched off.

Generally, atmospheric conditions (air temperature) will be warmer during day time hours. To

accelerate the initial heating period owners may opt to increase the ambient air temperature

artificially around the evaporator area of the pool heat pump until the pool water temperature has

reached the minimum required as stated below.

For Electroheat Ultra, Inverter and Reversible (XLR) units, they will automatically stop without

human intervention.

Adjustment Of The Bypass Valves

The adjustment may vary according to pool pump size and ambient temperatures.

ATTENTION: IT IS VERY IMPORTANT THAT THE BYPASS VALVES ARE SET AS DESCRIBED BELOW

FOR THE CORRECT FUNCTION OF YOUR POOL HEAT PUMP

Pool Solar Blanket

A pool solar blanket should be used whenever possible. Blankets minimize heat loss

through evaporation and conserve heat in your pool. Un-blanketed pool can lose

2-3 times more heat than a blanketed pool.

Defrost Cycle

When any of the following conditions occur the electronic control of your unit will

activate a defrost mode until all frost from the evaporator has melted. Condensation

of water on the evaporator coil tends to frost up quicker when the following occur.

1. When atomospheric conditions are as stated above;

2. When the evaporator is dirty;

3. When installation clearances are not respected.

Defrost is activated for between 3 to 20 minutes.

Pool Heat Pump Running Time

Most units should be sized to operate during the pool filtering cycle time of 8-12

daytime hours daily during warmer months and up to 8 hours daily during the

daytime in winter months. On warmer days the pool heat pump will run less

because the heat loss will be less.

Condensation

Your pool heat pump will accumulate condensed water (approx. 1 to 1.5 gallons or 4

to 6 litres per hour), therefore causing water to drain out of the unit base. In order to

avoid water accumulation, you may use decorative rocks around the concrete slab or

a basin under the unit. (Please note this is a normal characteristic of a pool heat pump

and not a service or warranty issue.)

IMPORTANT

OPERATION OF YOUR POOL HEAT PUMP

I pg 16

Pool Heat Pump

CONTROLLER TYPES

Electronic Control with Diagnostics for Standard

Models and Electronic Control with Diagnostics for

Reversible de-icing Models

Electronic Control

with diagnostics

Reversible (XLR) electronic control

with diagnostics

To Start The Pool Heat Pump

Press the button on the electronic control ON/OFF to start the pool heat pump.

The temperature display will show the pool water temperature flowing in your

pool heat pump and the fan motor starts (fan blade turns) but the compressor

does not start.

The temperature display flashes until the compressor starts and when the timer

will complete its cycle of 3 to 5 minutes. After 5 minutes, the compressor starts

and the temperature on the display stops flashing.

You can now program the desired temperature for the pool water.

To Stop The Pool Heat Pump

The pool heat pump can be stopped by pressing the ON/OFF button once.

To Check and Adjust Temperature Settings

To program the desired water temperature, press BOTH the UP and DOWN arrow keys at

the same time until the temperature degree displays change degree, then release them.

Press the UP arrow or DOWN arrow to program the desired temperature. The temperature

setting will automatically flash and will be saved. The display temperature will be revert

back to the pool water temperature when all keys have remained untouched for 5

seconds.

To change the temperature display from Fahrneheit (˚F) to Celcius (˚C). Press, the

button ˚C/˚F. The led below the ˚F or ˚C will be lit to indicate the current selection.

Note: The pool heat pump will cut out at once when the programmed temperature has

been reached.

Electronic Control

with diagnostics

Reversible (XLR) electronic control

with diagnostics

In addition to controlling the temperature of the water, this electronic control

informs you on the operation of your pool heat pump or any faults that may arise

by displaying codes on the temperature display.

When the unit is in defrost mode the code “DEF” is dispalyed on the temperature

display. This under normal conditions is not considered to be a fault.

I pg 18

Pool Heat Pump

Temperature Calibration

It is possible to have a temperature variation between the water in the swimming

pool and the reading of the pool heat pump temperature probe (sensor).

Example:if the water in the pool is 26º C (80º F) and the heat pump electronic

control displays 24ºC (76º F).

To calibrate this variation, perform the following procedure:

1. With the use of an accurate thermometer read the pool water temperature (e.g:

26˚C).

2. Read the temperature displayed on the pool heat pump electronic control (eg:

24˚C).

3. To determine the differential subtract the pool water temperature from the pool

heat pump displayed temperature, 26 - 24 = 2˚C. Therefore we must compensate

for the 2˚C variation.

4. Press BOTH the UP and DOWN arrow keys until the programmed temperature

is displayed (the temperature you have previously set) then release both

buttons.

5. Press the ON/OFF button and release.

6. Using the UP and DOWN arrows, enter the calibration value, (2˚C). In this case,

by pressing the UP arrow twice.

7. After 5 seconds when all the buttons have remained untouched , the display

temperature will show the pool water temperature as per your thermometer. If

this is the case the calibration process was successful.

To Change Display From Farenheit To Celcius

1. Press and release the SET key until F-C appears on the temperature display.

2. Whilst F-C is still on the display Press and release the UP or DOWN arrow key until C is

displayed.

3. Release all keys and the control will now be set for Celcius. (do not press any other keys

for 5 seconds)

To go back to Farenheit follow the same instructions above, however when you are at step 2,

F will need to be shown on the display before releasing all keys.

Defrost for Electroheat Ultra

During the defrost cycle, the fan motor stops working and the hot gas is injected into the

evaporator to melt the frost. However, when the pool heat pump makes 5 consecutive

cycles (heating and defrost) in less than 15 minutes, the unit goes into protection mode to

avoid inefficient use of electricity. These frequent defrost cycle’s mean that the conditions

of ambient temperature and humidity do not allow to heat your pool water. The FS4 code

will be displayed on the electronic control. Refer to the section titled ¨ Service Analyser

Codes ¨ to validate what you should do.

Protection Devices

The integrity and performance of your pool heat pump and its components are protected

by internal safety controls. In normal use, your Waterco unit should never reach the thermal

protection level. However, if it should happen, you should identify the stated code on the

temparature display and refer to Service Analyser codes.

Codes

If a code appears on the electronic control refer to Service Analyser codes (all standard

models) on page 29.

Inverter Controller Operation

Button functions are as indicated below:

“

” button: Press briefly then release to switch the machine on/off, press 3

seconds to lock or unlock buttons.

“

” (Up), “ ” (Down) buttons: To set temperature, off timer, to increase or

decrease parameters.

“

” button: Press briefly then release for on and off timer functions, press 3

seconds to set clock.

“

” button: Press briefly then release to set low-auto when set to heat,

intermediate-frequency, high-frequency and auto when set to heat.

“

” button: Press 3 seconds to switch between cooling, heating and automatic

mode.

Timer Function

1. A 24hr timer function is included in the units controller which may be set in one

minute increments.

2. On timer function: - When the heat pump is switched off, enter the settings

menu and set the on timer to switch the unit on automatically.

3. Off timer function: - When the heat pump is switched on, enter the settings

menu and set the off timer to switch the unit off automatically.

4. The timer function may repeat and is only deactivated when the ON / OFF

button is selected.

5. Timer error is less than 1min/h.

Note: Timer time is calculated based on Clock time.

I pg 20

Pool Heat Pump

Inverter Pool Heat Pump Controller

This controller applies to DC inverter air source pool heat pumps, for heating.

Heating

Automatic Mode

Clock/ Timer/ Function Display

Clock Adjustment Icon

On Timer Icon

Off Timer Icon

Temperature Display - the numerals on the left side indicate the set

water temperature. The numerals on the right side of the display

indicate the pool water temperature.

Temperature Icon (in degree Celsius)

Function Settings Icon

Keypad button lock is active

Real-time Temperature Distinction Icon

Set Temperature Icon

,

When heating mode is selected the units operating speed is indicated

as follows - one bar - low speed, two bars - medium speed and three

bars - high speed. The unit also has an AUTO mode where the units

heating rate is automatically selected according to the air, set and pool

water temperatures.

MAINTENANCE OF YOUR POOL HEAT PUMP

Waterco pool heat pumps have been specifically engineered to give you years of

satisfaction and enjoyment in the pool.

Cabinet Cleaning

To clean the plastic surfaces use mild soapy water and a soft clean cloth. Never use

solvents or abrasives.

Cleaning Evaporator

The evaporator at the rear of the unit must be kept clean and un-obstructed in order for

your pool heat pump to have better efficiency and avoid problems which may void your

warranty. The dirt collected in the evaporator can be removed with a gentle water spray

and the use of a soft brush. Be careful not to damage the aluminum fins.

Cleaning drainage holes

The condensate drainage holes in the base of the unit must be kept free of debris. Blocked

drainage holes may cause water to collect in the unit and become stagnant or, interfere

with electrical components and wiring.

Issues caused by blocked drainage holes in the base of the unit are not covered under

warranty.

Units Located In Coastal Locations

Care and maintenance procedures for Waterco Pool Heat Pumps installed in coastal

locations.

Exposure to salt may result in evaporator coil damage shortening the life of the equipment.

Bare aluminium fins can deteriorate rapidly depending on a number of factors including

fin design, location of the equipment relative to salt water, and maintenance.

For Waterco pool heat pumps located within one kilometre from the coast a coating must

be applied to the unit prior to site delivery on the evaporator fins and exposed metal

surfaces to reduce the incidence of corrosion.

A monthly rinse with potable water straight from the garden hose connected to the

municipal water system to remove the salt build up on the evaporator coil and exposed

metal surfaces is necessary.

I pg 22

Pool Heat Pump

Function Descriptions

1. When power to the unit is switched on the controller display will illuminate.

2. Use the UP and DOWN arrow buttons on the keypad to adjust. Adjustable

functions: For users, the current temperature, flash, “ ” and “ ” to adjust, press

ON/OFF button to return to the current status. To fully adjust cooling, heating,

automatic temperature, users need to enter cooling, heating and automatic

mode respectively for adjustment.

3. In auto mode, the units operating speed is displayed on screen.

4. Backlight will be illuminated when buttons are pressed. Backlight will be turned

off if button is not pressed in 1 minute.

Buzzer

Under any operation, a buzzer will sound when any button on the keypad is pressed.

When the unit reports a fault the buzzer will be silent and the code will be displayed

on the controller screen.

Memory Function

The heat pump controller should memorise ON / OFF status, operating mode,

parameter and timer settings. When power is connected and the heat pump is

switched on, the unit will start operation based on the settings when power was

switched off previously.

GENERAL SAFETY INSTRUCTIONS

DO NOT DEPRIVE YOUR POOL HEAT PUMP OF WATER FLOW FOR MORE

THAN 24 HOURS WITHOUT DRAINING IT. Make sure you leave the bypass

valves as shown in Figure 1.

At the end of each season, when the pool heat pump is no longer in use, and

proper pool water chemistry is not maintained, it should be disconnected from the

water line and drained to prevent any possible corrosion or damage to the pool

heat pump. Refer to Figure 1 below or winterising procedure (page 24).

Pool heat pump Pool heat pump

OUT

IN

OUT

IN

When your valves position are as

shown on Figure 1, the water is

bypassing the pool heat pump.

Figure 1

When your valves position are as

shown on Figure 2, the water is

going through the pool heat pump.

Figure 2

The valves shown above may be different to the ones installed on your system.

Please ensure you understand how your bypass valve operates.

I pg 24

Pool Heat Pump

Winterising Procedure

If the pool heat pump is stored in a place where the temperature drops below

the freezing point of 0˚C (32°F); it is mandatory that the water accumulated in

the pool heat pump be drained completely before freezing weather prevails.

Improper winterizing may damage the pool heat pump and will void the warranty.

• Turn the pool heat pump “OFF”.

• Turn the pool heat pump breaker “OFF”.

• The water piping MUST be disconnected to drain the pool heat pump’s heat

exchanger in preparation for winter.

• Once the piping is disconnected, the pool heat pump’s heat exchanger MUST

be emptied; the use of a water vacuum cleaner is strongly recommended or if

you do not have this tool you may tilt the unit (75˚) until all the water is out.

• It is recommended that pool heat pump’s heat exchanger is rinsed out with a

gentle water spray at the inlet and outlet water connections of the pool heat

pump and then drain the heat exchanger again.

• With the help of 2 pool return winter plugs, block the water Inlet and Outlet

connections to prevent access by vermin.

• Clean the drainage holes located at the bottom of the base of the unit.

• Unit may be covered for the winter.

• It is also possible to fill the heat exchanger with pool anti-freeze, but ensure that

the antifreeze contains an elevated pH to prevent corrosion. This is optional

and requires appropriate hardware.

!

VITAL

Fan Blades Turn, But Compressor Is Not Functioning

The pool heat pump has a built in delay timer which prevents the compressor from starting

immediately. The delay can be 3 to 5 minutes in duration after the fan blades have turned.

Furthermore if the unit is in defrost mode the compressor will not start for 3 to 20 minutes.

1. Check that air being discharged from the fan blades is colder than the ambient air. If

the air being discharged by the fan blades is colder, it means that the compressor is

functioning correctly.

2. Turn off the pool heat pump then immediately turn it back on;

3. As soon as the fan blades start turning, wait a minimum of 3-5 minutes. The compressor

should start up after this time and you will be able to identify a different sound made by

the compressor when it starts;

4. If the compressor is functioning, but shuts off immediately, consult the following section

“ Compressor Starts and Stops “.

5. If the problem persists, call your local Waterco office for assistance.

Compressor Starts And Stops

1. Check that the unit has been installed correctly (refer to installation procedures).

2. Check that the water inlet and outlet of the unit have not been connected incorrectly.

There Is Water Around The Pool Heat Pump

It is a normal occurrence for water condensation, to be seen running from the unit base. There

will be on average 1 to 1.5 gallons (4 to 6 litres) of condensed water per hour being discharged

from the unit base. In order to avoid water accumulation, you may use decorative

rocks around the concrete slab or a basin under the unit. Be sure that clearances around the

unit are respected.

To test the unit and confirm you have no pool water leaking from the unit perform the

following test which is best performed early in the morning and continuing for the whole day:

1. Turn off the pool heat pump from the circuit breaker and the pool pump.

2. Open the bypass valve. (refer to drawing on page 5)

3. Close the IN and OUT water valves on the unit.

4. Restart the pool pump. The pool heat pump must remain OFF.

5. When all of the water around the base of the pool heat pump has dried, open the water

IN and water OUT valves on the pool heat pump.

6. Close the bypass valve to allow full water flow through the pool heat pump.

If water is now seen running from the outside of the pool heat pump or inside the pool heat

pump after a short period of time you should call for service. If no water is seen after a short

period of time it would be assumed the water was condensation which is normal.

I pg 26

Pool Heat Pump

TROUBLESHOOTING

Please ensure the unit and any related equipment is installed in accordance with the

installation manual. If not, the Waterco warranty will not apply and the customer may

be liable for service call charges.

Nothing Is Working And The Electronic Control

Does Not Operate

1. Ensure the circuit-breaker has not tripped and/or the fuses have not blown;

**Take note that only an electrician can verify if the circuit breaker is defective;

if this is the case, repairs will not be covered under the warranty.

2. For three phase models, this situation could occur when phases are not in the appropriate

order. The green led light on the front panel will not light up.

Please have a qualified electrician swap over two of the incoming phase wires.

Nothing Is Working But The Electronic Control

Temperature Displays Digits Or A Code

1. Identify the analyser code that the electronic control displays and refer to the

Service Analyser codes section;

2. If the electronic control displays digits, make sure that the electronic control

is programmed correctly, refer to the Operation of your pool heat pump and

reprogram if necessary.

**Note that this situation could occur when the electrical voltage is not respected

as stated on the pool heat pump name plate. This situation is not covered by the

manufacturer warranty.

Fan Doesn’t Work (the fan blades are not moving)

1. IMPORTANT: For safety, switch OFF the circuit-breaker.

2. Try to rotate the fan blades of the fan with a rod to see if the motor is jammed or seized

3. If the fan blades do not turn freely leave the unit switched OFF and call for service;

4. If the fan blades turn freely switch ON the circuit breaker and the pool heat pump again.

** Note that your fan motor may have an electrical fault if the blades turn freely when the

unit is switched OFF and does not start when the unit is switched ON.

Circuit Breaker Trips

If you have purchased a remote control (or other equipment), ensure the equipment

is correctly installed. If an operational issue originates from incorrect operation or

installation of this equipment, Waterco’s warranty will not apply and you will have to

pay the cost of the service call.

1. The amperage of the circuit breaker AND the electrical wiring must be as the

instructions on the pool heat pump name plate, otherwise notify your installer or

electrician to correct this problem, as this is not covered under the warranty.

2. If the circuit breaker and electrical wiring are as stated, make sure the drains,

located on each side of the base of the pool heat pump are not obstructed.

IMPORTANT

Analysis Chart

Important: Please record all information

for three consecutive days at 12h00

Day 1 Day 2 Day 3

Outside air temperature .................................................................

Weather conditions outside (eg: cloudy, sunny or rainy) ................

Pool water temperature ......................................**Use a pool

thermometer

Pool water temperature ..................................... **use the reading

from the electronic control on the pool heat pump

Important: Please record all information

for three consecutive days at 20h00

Day 1 Day 2 Day 3

Outside air temperature .................................................................

Weather conditions outside (eg: cloudy, sunny or rainy) ................

Pool water temperature ......................................**Use a pool

thermometer

Pool water temperature ..................................... **use the reading

from the electronic control on the pool heat pump

I pg 28

Pool Heat Pump

Pool Heat Pump Is Functioning, But Does Not

Reach The Desired Temperature Setting

Improper installation may cause this situation and will need to be corrected by the

owner.

1. Ensure the by-pass valves are in the correct positions to ensure sufficient water

flow, insufficient water flow will cause the compressor to shut off early.

2. If you have installed a timer or the pool heat pump is equipped with an integrated

timer, be sure it is programmed to allow the pool pump to work for sufficient time

in order to reach the programmed temperature.

3. Ensure the evaporator is cleaned regularly with a light spray of water and allowed

to dry before re-starting the pool heat pump to avoid premature ice build up on the

evaporator.

4. Waterco recommend the use of a solar cover to retain heat in pool water. Pools

without covers lose 2 to 3 times more heat than pools with solar covers.

5. Make sure the electronic control of your pool heat pump has been programmed

correctly;during this test the pool heat pump and water pump must be working

continuously (eg; the desired water temperature must be set correctly).

6. If the unit continually fails to reach the desired water temperature, we suggest

completing the following analysis chart and forwarding it to Waterco in order to

avoid unnecessary service fees.

IMPORTANT

Pool Heat Pump Has Ice Formed On The Evaporator

Coil

1. IMPORTANT: For safety, switch OFF the circuit-breaker.

2. Allow the ice to melt and then inspect the evaporator to ensure it is free of debris and

leaves.

3. If the evaporator is dusty or dirty, clean it with a light spray of water and allow it to dry

(do not use high pressure it may damage the evaporator fins).

4. When the unit is dry, you may switch it back ON from the circuit breaker.

5. Ensure that the clearances around the unit are respected.

6. When the unit has been switched ON ensure the fan motor is working (fan blades will

be turning) while the compressor is operating.

7. If the fan blade does not turn and the compressor is functioning; notify customer service.

**If the pool heat pump requires service, the owner of the pool heat pump will need to

ensure the unit has been switched OFF to allow any ice to melt prior to any technician

attending.

Code Problem - Action / Remedy

dPd, oC2,

Sc2

Problem: The air intake temperature defrost probe has a loose

connection or is faulty. The probe will need to be checked

(defrost probe), and replaced if required.

Action / Remedy: Contact customer service.

FLo, FL3

nFL

Problem: No water flow, not sufficient water flow through the pool

heat pump or the water pressure switch needs to be adjusted or is

defective.

Action / Remedy: If the pool pump is connected to the pool heat

pump make sure the electronic control that runs the pool pump

and pool heat pump are programmed correctly

If the code is still displayed:

- Make sure the pool pump is switched ON;

- Press ¨SET¨ or ¨ON/OFF¨ depending on the model, to restart the

pool heat pump;

- On new installations, ensure the installation instructions were

respected;

- Check that the pool water level is correct, that the pool pump is

filled with water to the rim and that water is flowing correctly

through the pool pump to the pool heat pump;

- Check swimming pool and pool pump skimmer baskets and the

drain at the bottom of the pool for obstructions;

- Check the filter cartridges for obstructions (wash or change the

cartridges);

- Carry out a backwash for sand filters and ensure they are working

correctly;

- Ensure that the bypass valves are in the correct positions so that

the water flows adequately;

- Ensure vacuum robot or other cleaners are disconnected so that

the water flows freely.

- Check that there are no leaks on the pool plumbing (there should

be no air leaks in the pipework);

Service Analyser Codes (Standard Models)

Most operating issues will be detected by the electronic control and a code will

appear on the temperature display. Ensure the Action / Remedy suggestions are

followed prior to booking a service call and avoid unnecessary call out fees. If

the code remains on the display after you have followed the Action / Remedy

instructions, please contact Waterco.

I pg 30

Pool Heat Pump

The Pool Heat Pump Is Noisy

1. Check the pool heat pump is level and on a solid base to prevent any vibrations

issues.

2. Ensure the noise is coming from the pool heat pump, not from other equipment

which will not be covered by the warranty (for example: noise coming from the

bypass valve, pool pump, etc);

3. An improper installation may cause this situation it will need to be corrected by the

owner.

The Temperature Shown On Pool Heat Pump

Is Not The Same That Is Shown By The Pool

Thermometer

It is possible to have a temperature variation between the temperature shown

on the electronic control temperature display of the pool heat pump and a pool

thermometer which may be read from different locations. Please refer to the

temperature calibration section in order to adequately recalibrate temperature if

required.

- Check that there are no leaks on the pool plumbing (there should be no air leaks in

the pipework);

Code Problem - Action / Remedy

LP, LP3 Problem:

Low refrigerant level in the pool heat pump or the low-

pressure safety control is defective.

Atmospheric conditions as well as the pool water temperature

should not be below the minimum operating temperatures as stated

below in order to obtain efficiency and avoid codes from appearing

on the electronic control temperature display ; these codes are not

generally a problem with the pool heat pump at these conditions

and is not covered by the warranty.

If temperatures are below the minimum temperatures listed below

the pool heat pump should not be operated and must be switched

off.

Model

Atmospheric

conditions

must be above

Pool water

temperature

must be above

Electroheat Ultra 32°F (0°C) 50°F (10°C)

Reversible (XLR) 43°F (6°C) 65°F (18°C)

All others 52°F (11°C) 65°F (18°C)

Action / Remedy:

- If the LP or LP3 code is shown permanently, press “SET” or “ON/

OFF” depending of the model you have before to get to next step;

- Ensure the evaporator is clean. If not switch the unit OFF from

the circuit breaker (fuse) and use a garden hose to lightly clean

the evaporator, then allow it to dry before re-starting the pool heat

pump to avoid premature ice build up on the evaporator.

- Ensure installation instructions have been followed. Improper

installation, e.g. no air circulation could lead to the pool heat pump

continually going into LP or LP3 mode and the installation will

need to be corrected by the owner.

HP, HP3 Problem:

Low water circulation in the unit or the high-pressure

control is defective. If the HP code is triggered and displayed

3 times; this will cause the pool heat pump to shut down

automatically. The HP3 code will then appear permanently

(except for reversible electronic control with diagnostics).

Note: The pool pump will stop functioning only if the internal

time delay of the pool heat pump is being used.

IMPORTANT: When the code HP3 is permanently displayed,

before performing the steps below, please press the ¨SET¨ button

for the electronic control Multi Function and ¨ON / OFF¨ for the

electronic control with diagnostics and the reversible electronic

control with diagnostics (XLR) and electronic control with

diagnostics.

I pg 32

Pool Heat Pump

Code

Problem - Action / Remedy

FS, DEF, FS4 Problem:

Normal defrost cycle. The fan blades are turning, but

the compressor has stopped. For Electroheat Ultra and Reversible

model, the fan blades do not turn but the compressor runs.

Action / Remedy:

Normal during defrost duration.

Atmospheric conditions as well as the pool water temperature

should not be below the minimum operating temperatures as

stated below in order to obtain efficiency and avoid codes from

appearing on the electronic control temperature display ; these

codes are not generally a problem with the pool heat pump at

these conditions and is not covered under warranty.

If temperatures are below the minimum temperatures the pool heat

pump should not be operated and must be switched off.

For Electroheat and Reversible (XLR) units, they will automatically

stop without human intervention.

Model

Atmospheric

conditions

must be above

Pool water

temperature

must be above

Electroheat Ultra 32°F (0°C) 50°F (10°C)

Reversible (XLR) 43°F (6°C) 65°F (18°C)

All others 52°F (11°C) 65°F (18°C)

For Electroheat model: If the unit carries out 5 consecutives defrost

cycles every 15 minutes or less, the pool heat pump is then put into

protection mode (FS4). During this mode, the fan blade turns for

30 minutes in order to cool the evaporator. The pool heat pump

restarts automatically when the external temperature is at: 34˚F

(1˚C).

For Reversible (XLR) Model: If the unit performs 4 consecutive

cycles (heating and defrost) within 1-hour, the unit goes into

protection mode and alternately displays the water temperature

and the DEF code. The fan motor runs for 30 minutes to cool the

evaporator and then stops. The compressor is always off. The unit

restarts automatically when the outside temperature is 43°F (6°C)

and more.

If the code stays on permanently:

- Ensure the evaporator is clean. If not

switch the unit OFF from

the circuit breaker

(fuse) and use a garden hose to lightly clean

the evaporator, then allow it to dry before re-starting the pool heat

pump to avoid premature ice build up on the evaporator.

- Ensure installation instructions have been followed, Improper

installation, e.g. no air circulation could lead to the pool heat pump

continually going into defrost mode and the installation will need to

be corrected by the owner.

I pg 34

Pool Heat Pump

Code Action

EE 01

High-pressure Failure

EE 02

Low-pressure Failure

EE 03

Water Flow Failure

EE 04

Heating Water Temperature Overheating Failure

EE 05

Exhaust Temperature Failure

EE 06

Wired Controller EEPROM Data Read/Write Failure

EE 07

Converter Board EEPROM Data Read/Write Failure

EE 08

Wired Controller and Converter Board Communication Failure

EE 09

Converter Board and Outdoor Board Communication Failure

EE 10

Outdoor Board and Module Board Communication Failure

EE 11

Module Board Failure

EE 12

DC Bus Overvoltage, Low-Voltage Protection

EE 13

Overcurrent Protection

EE 31

Outdoor DC Fan Failure (only for DC Fan Model)

PP 01

Inlet Water Temperature Sensor Failure

PP 02

Outlet Water Temperature Sensor Failure

PP 03

Outdoor Coil Sensor Failure

PP 04

Return Air Sensor Failure

PP 05

Outdoor Environment Sensor Failure

PP 06

Compressor Exhaust Sensor Failure

PP 07

Winter Antifreeze Protection

PP 08

Low Ambient Temperature Protection

PP 09

Heating Ambient Temperature Overheating Protection

PP 10

Cooling Outer Coil Overheating Protection

Defrosting

Defrosting Indicator Heating Icon Flash Prompt

Code Problem - Action / Remedy

HP, HP3 Action / Remedy:

Make sure the water reaches the pool heat

pump and the pool pump is completely filled to the rim. Otherwise:

- Fill the pool pump with water, and check to see if the pipes

between the pool pump and the pool are watertight (there should

be no air intake);

- Check the swimming pool and pool skimmer baskets and the drain

at the bottom of the pool for obstructions;

- Check the filter cartridges for obstructions (wash or change the

cartridges, as the case may be);

- Insure that the bypass valves are in the correct positions so that

the water flows adequately;

- Backwash sand filter (insure that there is a sufficient amount of

sand and verify that it does not have to be changed. Consult a

swimming pool specialist if necessary);

- Make sure the vacuum robot is disconnected so that the water

flows freely.

OFF Problem:

The desired water temperature setting programmed

is below 60°F (15°C) for the Multi function electronic control

OR the electronic control with diagnostics is OFF or could be

defective.

Action / Remedy:

Reprogram the desired water temperature

setting to a higher setting for the electronic control with Multi

Function. For the electronic control with diagnostics and the

reversible electronic control with diagnostics (XLR), press on key

¨ON/OFF¨.

PSD, oC1 &

Sc1

Problem:

The water temperature probe has a loose connection

or is faulty. The probe will need to be checked and replaced if

required.

Action / Remedy: Contact customer service.

ot

Problem:

Water temperature is higher than 45°C (113°F) within

the unit (this code is only displayed on the electronic control with

diagnostics).

Action / Remedy:

- Make sure the bypass valves are in the correct positions;

- Proceed to the calibration of the electronic control with diagnotics

and reversible electronic control with diagnostics (XLR).

Service Analyser Codes (Inverter Models)

WARRANTY

Waterco’s obligation to repair or replace at Waterco’s option, shall be the original

purchaser’s sole and exclusive remedy under this warranty. Waterco shall not be liable for

incidental, consequential or special damages arising out of or in connection with product

use or performance.

Waterco is not responsible for direct or indirect damages resulting from defective

components. This warranty gives you specific legal rights and you may also have other

rights, which vary from state, province or country to another.

Prior to contacting Waterco for assistance or service, please check the

“Troubleshooting” and the information stated in this section. Warranty will only cover

manufacturing defects. All service call requests which are not of this nature must be

paid by the purchaser to the service company authorized by Waterco.

All services will be handled by the authorized service company. Warranty may be

voided if service is not carried out by a Waterco authorised service agent.

DO NOT

return the pool heat pump to your dealer as they do not provide the service

work.

Prior to contacting Waterco for assistance Waterco for assistance or service, in order to

qualify for a warranty claim, the original purchaser must have the model name and serial

number along with a proof of the original purchase date. Proof of purchase must be

forwarded to Waterco and they will inform you of the applicable warranty.

Once connected with a Waterco customer service agent, proceed to describe in detail

the issue associated with your pool heat pump. If a permanent code appears on the

electronic control panel, please advise the Waterco service agent.

There are no other warranties, express or implied, including, but not limited to, implied

warranties of merchantability or fitness for a particular purpose. During warranty period,

Waterco will, at its option, repair or replace, without charge, any product or part, which

is found to be defective under normal use and service.

IMPORTANT :

The warranty is not transferable and no action can be exercised by a

consumer subsequent purchaser of the pool heat pump.

IMPORTANT

Waterco does not guarantee and will not pay for:

A. Service calls to:

1. Inspect and/or correct the installation of your pool heat pump.

2. Instruct you on how to use your pool heat pump.

3. Replace house fuses or correct power supply problem.

4. Adjust or reestablish water flow to the pool heat pump.

B. When a service call with no manufacturing problem has been detected, on site, by

the service company mandated by Waterco.

C. Damage to your pool heat pump caused by accident, misuse, fire, flood, acts of

God, improper installation, harsh environment, chemical feeding before the pool

heat pump, improper maintenance of water chemistry or any problem related with

installation instructions not followed and described in this manual by the purchaser

and/or the end-user.

D. Damage to internal piping or components due to improper winterizing before

freezing conditions.

E. Repairs to parts or system resulting from unauthorized modification made to the

pool heat pump.

F. Repairs not previously authorized by Waterco.

G. Parts and pool heat pump transportation.

H. Fees charged for excessive time to repair your pool heat pump due to incorrect or

un-accessible location This may void warranty cover and the owner will be required

to pay a service call fee even if the unit is not repaired.

I pg 36

Pool Heat Pump

I pg 02

Thermopompe

Table des

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

Lors de l’utilisation de cet équipement électrique, des précautions de sécurité de

base doivent toujours être suivies, notamment :

Lisez et suivez les instructions

! AVERTISSEMENT : Débranchez de toute alimentation en courant alternatif (AC)

pendant l’installation et l’entretien !

! AVERTISSEMENT : Afin d’éviter toute possibilité d’hyperthermie (stress thermique),

il est recommandé que la température moyenne de l’eau de la piscine ne dépasse

pas 40 ° C. !

! MISE EN GARDE : La Thermopompe de la piscine n’est pas destinée aux personnes

ayant des capacités sensorielles physiques ou mentales réduites (y compris les

enfants), ou manquant d’expérience et de connaissances, à moins de recevoir

une supervision ou des instructions concernant l’utilisation de l’appareil pour leur

sécurité. Les enfants doivent être surveillés pour s’assurer qu’ils ne jouent pas avec

l’appareil.

• Dans certaines situations, un démarrage inattendu peut se produire lorsque

l’appareil est en mode automatique.

• L’installateur devrait évaluer le risque associé au démarrage intempestif de ce

dispositif qui, en toute circonstance ne devrait avoir aucun effet dangereux.

• La Thermopompe n’est pas supposée fournir une protection de sécurité pour

d’autres appareils.

• La Thermopompe doit être désactivée si la piscine ou le Spa a été vidangé.

• Les thermopompes Waterco pour le chauffage de piscine doivent être installées

par une personne qualifiée ; conformément aux normes réglementaires, aux règles

de câblage applicables (AS3000) et aux réglementations locales en vigueur.

• Les pièces comportant des composants électriques, à l’exception des dispositifs

de commande à distance, doivent être situées ou fixées de manière à ne pas

pouvoir tomber dans la piscine.

• L’appareil doit être alimenté par un dispositif à courant résiduel (RCD) ayant un

courant de fonctionnement résiduel nominal ne dépassant pas 30 mA.

• Une borne de terre est située à l’intérieur de l’enceinte de câblage. Pour réduire

le risque d’électrocution, cette borne doit être connectée aux moyens de mise

à la terre fournis dans le panneau d’alimentation électrique avec un fil de cuivre

continu conforme aux normes en vigueur et aux prescriptions locales en vigueur

en ce qui concerne les conducteurs de circuit.

• Un connecteur de câble est fourni sur cet appareil pour connecter un conducteur

en cuivre de taille appropriée entre cet appareil et tout équipement métallique,

boîtiers métalliques d’équipement électrique, tuyau d’eau métallique ou tout

conduit à 1,5 m de l’appareil par liaison équipotentielle.

VEUILLEZ CONSERVER CES INSTRUCTIONS.

IMPOINSTRUCTIONS DE SÉCURITÉ IMPORTANTES

------------

02

Une note à vous

---------------------------------------

03

INSTRUCTIONS D’INSTALLATION

-----------------

05

Emplacement

------------------------------------

05

Dégagements d’installation

--------------------

06

Tuyauterie d’eau

---------------------------------

07

Débit d’eau

---------------------------------------

08

Kit de dérivation d’eau

-------------------------

08

Diagramme de plomberie

----------------------

08

Électrique

-----------------------------------------

09

Connexion électrique

---------------------------

09

Taille du disjoncteur ----------------------------- 09

Taille du fil électrique

----------------------------

09

Collage

--------------------------------------------

10

Diagramme de collage

--------------------------

10

Connexions de contrôle à distance

-----------

11

Utilisation de produits chimiques

-------------

12

FONCTIONNEMENT DE LA POMPE À CHALEUR DE

VOTRE PISCINE

-----------------------------------------

13

TYPES DE CONTRÔLEUR

Chauffage initial

---------------------------------

13

Ajustement des vannes de dérivation

--------

13

Temps de fonctionnement de la pompe à

chaleur de piscine

-------------------------------

14

Couverture solaire de piscine

------------------

14

Cycle de dégivrage

------------------------------

14

Pour démarrer la pompe à chaleur de

piscine -------------------------------------------- 15

Pour arrêter la pompe à chaleur de

piscine -------------------------------------------- 15

Pour vérifier et ajuster Paramètres de

temperature -------------------------------------- 16

Étalonnage de la température

-----------------

17

Pour changer l’affichage de Farenheit

à Celcius

------------------------------------------

18

Dégivrage pour Electroheat Ultra

-------------

18

Dispositifs de protection

-----------------------

18

Codes

---------------------------------------------

18

CONTRÔLEUR DE POMPE À CHALEUR

D’INVERTER POOL

------------------------------------

19

Fonctionnement du contrôleur de l’onduleur

-----

20

Fonction de minuterie

--------------------------

20

Descriptions des fonctions

---------------------

21

Buzzer --------------------------------------------- 21

Fonction de mémoire

---------------------------

21

ENTRETIEN DE VOTRE POMPE À CHALEUR

POOL

------------------------------------------------------------

22

Nettoyage de l’armoire

-------------------------------

22

Nettoyage de l’évaporateur

--------------------------

22

Nettoyage des trous de drainage

-------------------

22

Unités situées dans des endroits côtiers

-----------

22

Procédure d’hivernage

--------------------------------

23

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

------

24

DÉPANNAGE

-------------------------------------------

25

Rien ne fonctionne et le Le contrôle

électronique ne fonctionne pas -------

--------

25

Rien ne fonctionne mais l’électronique La

température de contrôle affiche les chiffres

ou un code

-------------------------------------

25

Le ventilateur ne fonctionne pas (les lames du

ventilateur Ne bouge pas)

---------------------

25

Le ventilateur tourne, mais le compresseur

Ne fonctionne pas

--------------------------------

26

Le compresseur démarre et s’arrête

----------

26

Il y a de l’eau autour de la pompe à chaleur de la

piscine ----------------------------------------------

26

Pompe à chaleur de piscine a formé de

la glace

------------------------------------------

27

Pompe à chaleur piscine fonctionne, mais

fait Ne pas atteindre le paramètre de

température souhaité --------------------------- 27

Tableau d’analyse

--------------------------------

28

Circuits de disjoncteur

--------------------------

28

La pompe à chaleur de la piscine est

bruyante

------------------------------------------

29

La température affichée sur la chaleur de la

piscine La pompe n’est pas la même que

celle qui est Montré par le thermomètre

de piscine

--------------------------------------------

29

Codes d’analyseur de service

------------------

30

GARANTIE -------------------------------------------- 35

I pg 04

Thermopompe

Une REMARQUE POUR VOUS

Félicitations !

Merci d’avoir choisi une thermopompe Waterco pour le chauffage de l’eau de

votre piscine. Grâce aux dernières technologies en matière de capture de chaleur,

la thermopompe Waterco convertit la chaleur libérée par le soleil et la transfère

efficacement à votre piscine.

Pendant certaines périodes, il peut être nécessaire de faire fonctionner votre

Thermopompe pendant la journée pendant les périodes plus froides, mais cela

ne devrait pas poser de problème puisque votre thermopompe Waterco peut

chauffer votre piscine à un niveau 80% plus économique que les chauffages à

combustible fossile ou les thermopompes comportant des éléments électriques. Les

thermopompes thermiques Waterco sont spécialement conçues pour chauffer votre

piscine de manière économique.

Pour apprécier les avantages que le produit vous apportera, Vérifier le fonctionnement

de l’appareil lorsque les conditions atmosphériques spécifiées dans ce document

sont présentes ; tout en utilisant une toile solaire pour minimiser les pertes de chaleur

qui influenceront les coûts d’exploitation et la taille de l’appareil requis. Les piscines

non recouvertes d’une toile solaire perdent 2 à 3 fois plus de chaleur, quel que soit le

type de chauffage !

Enregistrez votre modèle d’information.

Conservez ce manuel et votre reçu d’achat original de la preuve de garantie et

pour référence future.

Sur la base de votre Thermopompe est une plaque qui contient des informations

telles que numéro de modèle, le numéro de série et de l’information électrique.

Veuillez les noter ci-dessous et les avoir à portée de main en cas d’une demande

d’appel de service.

Numéro de modèle : ____________________________________________________________

Numéro de série _______________________________________________________________

Date d’achat ___________________________________________________________________

Nom du vendeur _______________________________________________________________

Adresse du Concessionnaire ____________________________________________________

Numéro de Téléphone du Concessionnaire ______________________________________

Pour trouver des informations détaillées sur le produit, le lieu de résidence du

revendeur le plus proche ou pour enregistrer votre thermopompe piscine, veuillez

visiter notre site Web www.waterco.com et sélectionnez votre lieu de résidence.

I pg 06

Thermopompe

Les instructions d’installation

L’air est aspiré à travers la bobine de l’évaporateur et dispersé par la grille du

haut ou de devant. Jeu des valves doit être admis à l’avant et autour de l’appareil

de décharge dans l’air et sans restriction d’accès aux services. Voir le schéma 1

et le schéma 2. Le non-respect des règles de dégagements peut entraîner une

diminution des performances et une réduction de la longévité de l’appareil.

INSTRUCTIONS D’INSTALLATION

Emplacement

Pour optimiser l’efficacité de la thermopompe de votre piscine, veuillez suivre

toutes les instructions lors de la “mise en place de l’appareil”. Il est également

important de s’assurer de toutes les instructions concernant les procédures

d’entretien et de maintenance futures.

L’appareil est conçu pour une installation à l’extérieur et ne doit pas être installée

dans une zone totalement fermée telle qu’un abri, un garage, etc., sauf si une

ventilation climatisée est fournie pour assurer un échange d’air adéquat. La

recirculation de l’air froid rejeté dans le conduit d’évaporation doit être évitée et

réduira considérablement la capacité de chauffage et l’efficacité de l’appareil.

L’appareil doit être situé le plus près possible de la thermopompe et du filtre de la

piscine en place pour minimiser la fuite d’eau. L’utilisation de coudes à 90 degrés

et de coudes à rayon court dans la tuyauterie d’eau doit être réduite au minimum.

Veuillez monter l’appareil sur une base solide, de préférence une dalle ou des

blocs de béton. La base doit être complètement isolée de la fondation ou du mur

du bâtiment pour éviter la possibilité de transmission du bruit ou des vibrations

dans le bâtiment. La taille de la base ne doit pas être inférieure à la base de la

thermopompe de la piscine.

L’utilisation d’un tapis anti-vibration entre la base de l’appareil et le matériau

d’emplacement de l’installation finale est fortement recommandée afin de réduire

les problèmes potentiels de bruit issus des vibrations.

Pas d’obstruction au-dessus pour permettre la dispersion de l’air froid

Avoir un

Dégagement

d’au moins

30 cm à l’arrière

Avoir un Dégagement

d’au moins 60 cm

de ce côté

Avoir un Dégagement

de ce côté d’au

moins 60 cm

Dégagements au niveau de

l’installation

Image 1

Avoir un Dégagement d’au moins 30 cm

Modèles de décharge latérale

Image 2

Ne pas obstruer la façade

pour la bonne diffusion

de l’air rafraîchie

Avoir un Dégagement

d’au moins 60 cm

à l’arrière

Avoir un Dégagement

d’au moins 60 cm

de ce côté

clearance to top

minimum 60cm

I pg 08