Waterax STRIKER-2/3 Owner's Manual

STRIKER-2/3

Owner's Manual

Publication Date: 09/2015

Publication Number: 701223, Rev. 3

This document provides information proprietary to WATERAX Inc. and cannot be used

or disclosed without WATERAX’s written authorization.

WATERAX Inc. reserves the right to make changes without notice in its products or

components as research and development or marketing conditions warrant. Changes

affecting the operation of any component in this manual will be reflected in a subsequent

revision. WATERAX Inc. assumes no responsibility for any omissions or errors that may

appear in this document or for any damages that may result from the use of information

contained herein.

The following are trademarks or brand names of WATERAX Inc.: WATERAX, ‘WE

MOVE WATER’. All other trademarks used in this manual are the exclusive property of

their owner.

STRIKER-2/3 Owner's Manual

Publication No.: 701223, Rev. 3

Publication Date: 09/2015

First Edition: March 2015

Published by:

WATERAX Inc.

6635 Henri-Bourassa W.

Montreal, Quebec, CANADA

H4R 1E1

Copyright © 2015 WATERAX Inc.

All rights reserved

Printed in Canada

WATERAX STRIKER-2/3 Owner's Manual

Contents

Important Safety Instructions ............................................................................................ 2

Personal Safety Advisory .................................................................................................................. 2

Warnings ........................................................................................................................................... 2

Preventing Damage to Equipment .................................................................................... 3

Introduction ........................................................................................................................ 4

About this Manual ............................................................................................................................. 4

Abbreviations and Terms .................................................................................................................. 4

About the STRIKER-2/3 Series ......................................................................................................... 5

Parts Identification ............................................................................................................................. 6

Installation .......................................................................................................................... 6

Plumbing ........................................................................................................................................... 6

Pump End Mounting .......................................................................................................................... 6

Fastening to Truck/Apparatus ........................................................................................................... 7

Installing a Control Panel .................................................................................................................. 7

Using a Battery for Electric Starters and Control Panels .................................................................. 7

Operating STRIKER-2/3 Series Pumps ............................................................................. 8

Pre-Operation Checklist .................................................................................................................... 8

Flooded Suction ................................................................................................................................ 8

Drafting .............................................................................................................................................. 9

Priming the Pump ............................................................................................................................ 10

Startup and Discharge .................................................................................................................... 11

Shutdown ........................................................................................................................................ 11

Cold Weather Operation ................................................................................................................. 12

Basic Care and Storage .................................................................................................................. 12

Troubleshooting .............................................................................................................................. 13

Service .............................................................................................................................. 15

Drive Assembly Parts Breakdown ................................................................................................... 15

Installing the Drive Assembly .......................................................................................................... 16

Removal of Pulley Assembly ........................................................................................................... 19

Removing or Attaching the Pump End ............................................................................................ 19

Pump Tool Kit .................................................................................................................................. 20

Disassembly Procedure for Pump End 18-16S .............................................................................. 20

Assembly Procedure for Pump End 18-16S ................................................................................... 21

Pump Clamp.................................................................................................................................... 22

STRIKER-2/3 Wiring ....................................................................................................................... 23

FastWire Wiring Diagrams .............................................................................................................. 24

Pump End Technical Data................................................................................................ 25

Warranty............................................................................................................................ 29

09/2015 1

WATERAX STRIKER-2/3 Owner's Manual

Important Safety Instructions

It is recommended that all information provided in this manual be carefully read and

understood before performing any operation of or maintenance to the pump.

The procedures listed in this manual are general operating and maintenance procedures.

They should be taken in addition to any procedures, policies and guidelines established

by the authority having jurisdiction or the apparatus manufacturer. Where conflicts arise,

all parties (authority having jurisdiction, the apparatus manufacturer, and WATERAX Inc.)

will need to be contacted to determine the best resolution. The solution will need to

address the safety of the operator along with the proper performance and life expectancy

of the unit.

Personal Safety Advisory

READ YOUR ENGINE MANUAL FIRST!

Before proceeding further, locate and read the engine manufacturer’s manual. It contains

very important safety information that MUST be read, understood and followed to

safeguard you and your equipment from harm, as well as specific information on the

proper use and care of your engine.

READ THIS MANUAL BEFORE OPERATING YOUR PUMP!

The improper use of the WATERAX pump could result in serious injuries as well as

damage to the pump. Any operator should familiarize himself with the apparatus and its

capabilities before trying to operate the equipment in an emergency situation. Please read

this entire manual before using your WATERAX pump and follow all Personal Safety

Advisories.

Warnings

Always wear eye and ear protection when operating the pump unit.

Do not operate if mentally or physically fatigued.

Always inspect hoses and piping to avoid burst injuries.

Use only pipe, hose, and fittings that are rated at or above the maximum pressure

No modifications and/or alterations may be made to the pump. Any such modifications

Do not operate the pump higher than the maximum rated pressure. Always run the unit

Slowly close valves and use slow close valves wherever possible to prevent danger to

Relieve all system pressure before doing any service work on the pump.

Never run the pump in a closed or confined area. Exhaust gas contains carbon

Refuel engine with care. Gasoline and diesel are flammable, and gasoline vapor can

Be alert and never touch any part of the engine exhaust system (muffler, shield,

rating of the pump shown below, or according to what maximum pressure the system

was designed for, whichever is lower.

Maximum Allowable Pressure STRIKER-2/3: 600 PSI (41 bar)

Maximum Allowable Pump Intake Pressure STRIKER-2/3: 150 PSI (10 bar)

not only void the pump warranty but can make the unit dangerous to anyone operating

the pump.

at the lowest pressure required for the application to enhance operator and equipment

safety.

other line operators and to prevent water hammer which could damage the pump and

its piping components.

monoxide which is poisonous to humans. Avoid inhalation of exhaust gas.

explode. Refuel in a well-ventilated area, with the engine stopped.

header pipes, etc.) while the engine is running. Always allow enough time, after

stopping the unit, for proper cooling of the muffler and surrounding parts.

2 09/2015

WATERAX STRIKER-2/3 Owner's Manual

Do not ground the battery (if applicable) through the pump’s frame members; always

ground to a bare metal (unpainted) part of the engine block to ensure proper ground.

Preventing Damage to Equipment

The following recommendations will help avoid damage to your equipment:

Flush the pump with fresh water if the pump has been used to pump salty, brackish,

high mineral content water, water containing debris, or foam injected water. Check that

debris is cleared before using pump again.

Always draft water using a suction hose strainer.

During freezing weather, drain the pump, manifolds, and lines of all water. You can

also pour some antifreeze into the pump and circulate it through the pump and

plumbing system.

Let the engine warm up before using the unit at full speed.

Always use the proper unleaded gasoline or diesel fuel as recommended in the engine

manufacturer’s manual.

Always check for sufficient oil quantity in the engine crankcase before use (see engine

manual for details on checking the oil level, as well as for the type of oil to use).

If applicable, always check for sufficient coolant quantity in the engine radiator before

use (see engine manual for details on checking the coolant level, as well as for the

type of coolant to use).

Pumps should not be operated without water for any extended period of time or without

discharging water. Operating the pump in such a manner can overheat the pump

causing damage to seals, or pump internals.

It is recommended that all fasteners be replaced with genuine WATERAX parts.

When mounting manifolds to the pump, the manifolds must be self-supporting and

coupled to the pump by means of a flex coupling such as a Victaulic® coupling or flex

hose.

When hoisting the pump onto an apparatus, take care when using lifting hooks (if

applicable) and avoid any contact with components adjacent to the fixation points.

Never disconnect the battery (if applicable) while the engine is running, as this may

damage the control panel’s electrical components.

09/2015 3

WATERAX STRIKER-2/3 Owner's Manual

Pump designation

Engine used

STRIKER-2

Honda GX390 13HP gasoline engine

STRIKER-3

Honda GX390 13HP gasoline engine

Cavitation

Formation of air bubbles in a liquid inside a centrifugal pump,

causing low pressure points and loss of pump capacity.

Dead-heading

Also called shut-off. Leaving the pump running with all the

discharge valves closed. The pump should not be left in this

mode for more than a minute since the pump can overheat and

become damaged. To avoid this, a re-circulation line (if

provided) should be opened or a discharge line left slightly open

to allow fresh water to continue to enter the pump.

Drafting

Process of using vacuum (suction) to take water from a stream

or impoundment.

NH

National Hose. This is a type thread specified in NFPA 1963.

Formerly known as NST (National Standard Thread).

NPSH

National Pipe Straight Hose. This is a type of thread that is

slightly smaller in diameter than NH, with more threads per inch

than the same nominal size of NH thread. NPSH is also called

IPT (Iron Pipe Thread).

RPM

Revolutions Per Minute.

Introduction

About this Manual

This manual contains general operation, care and servicing procedures for the following

WATERAX STRIKER-2/3 high pressure centrifugal pumps:

These instructions cover most wildland and municipal pump applications. If the application

the pump is being used for does not fall into these general guidelines, consult WATERAX

Inc. for any additional safeguards, operating, or maintenance considerations that may be

required.

For full service and maintenance instructions regarding the pump, please refer to the

Service section. For maintenance instructions regarding the engine, as well as for oil and

fuel recommendations, refer to the engine manufacturer’s manual.

Please see www.waterax.com additional documentation related to this product such as

the WATERAX product guide, technical notes, links to the engine manufacturer’s

manuals, news and other updates about WATERAX and its goods and services.

Abbreviations and Terms

The following terms and abbreviations are used in this manual:

4 09/2015

WATERAX STRIKER-2/3 Owner's Manual

About the STRIKER-2/3 Series

Features

For full specifications and performance curves, see the Product Data Sheet for your

pump end model.

Applications of the WATERAX STRIKER-2/3 series include:

Slip-on units

Attack line firefighting

Long hose lay for remote watering during firefighting operations

High elevation firefighting in mountainous areas

Accuracy in flow trajectory when structure firefighting

Tandem pumping over long distances

Parallel pumping for higher volumes

Features and Benefits of the WATERAX STRIKER-2/3 series include:

Quick release clamp and swappable pump ends for minimal equipment downtime and

inventory

Sealed bearing to eliminate pump end greasing in the field

Belt drive system for reliable, low maintenance performance

Aluminum alloy pump components and anodized parts for lighter weight and greater

resistance to corrosion

Compatible with foam applications

Blister resistant mechanical rotary seal

Comprehensive manuals

EPA Certified

Configurations

The STRIKER-2/3 series is used for a variety of wildland and municipal firefighting

applications. Your model may be configured as a portable, standalone pump installed on

a carry frame, or it may be purchased in the vehicle-mount configuration which includes

a mounting frame or legs to fasten the pump onto a fire apparatus.

09/2015 5

WATERAX STRIKER-2/3 Owner's Manual

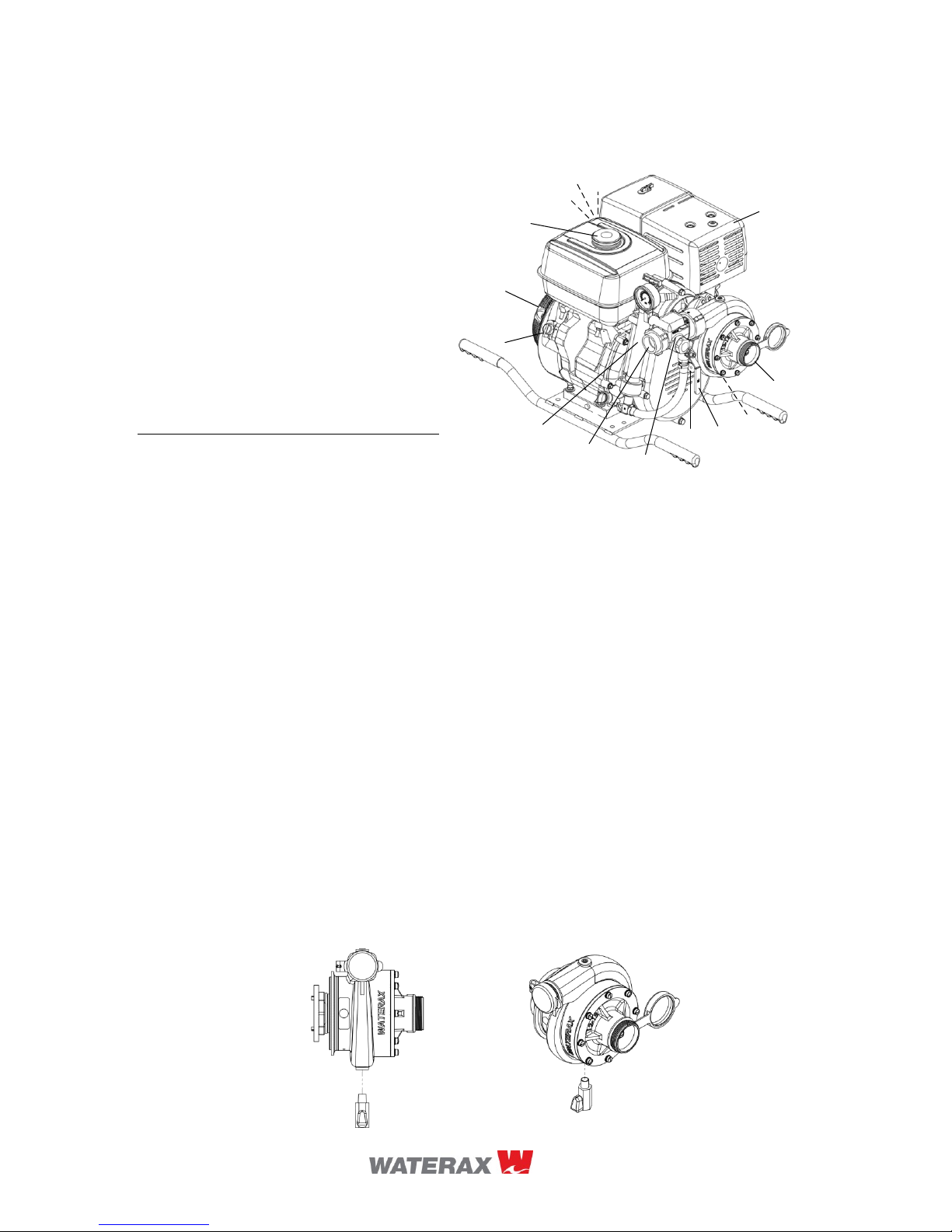

STRIKER-2/3

A. Pump intake (suction)

B. Pump drain port (not shown)

C. Priming valve

D. Quick release pump clamp

E. Discharge check valve*

F. Pump discharge

G. Hand primer*

H. Ignition switch

I. Recoil starter

J. Fuel cap

K. Throttle (not shown)

L. Fuel valve (not shown)

M. Choke (not shown)

N. Muffler

Note: Portable 2-stage STRIKER-2 pump model

shown. Other configurations available for both 2stage STRIKER-2 and 3-stage STRIKER-3 pumps.

* Available on portable models.

C

A

F

H

K

L

N

E

G

M

I

J

D

B

Parts Identification

Installation

Depending on your model and configuration ordered, you may require additional

accessories from WATERAX or from third-party vendors, for example, control panels,

batteries, and fuel lines. You will also require hoses and nozzles as well as other fire

apparatus plumbing which can be purchased through your WATERAX representative.

Follow the instructions and heed all warnings in any documentation that you receive with

the accessories you purchase.

Plumbing

When mounting manifolds to the pump, the manifolds must be self-supporting and

coupled to the pump by means of a flex coupling such as a Victaulic® coupling or flex

hose.

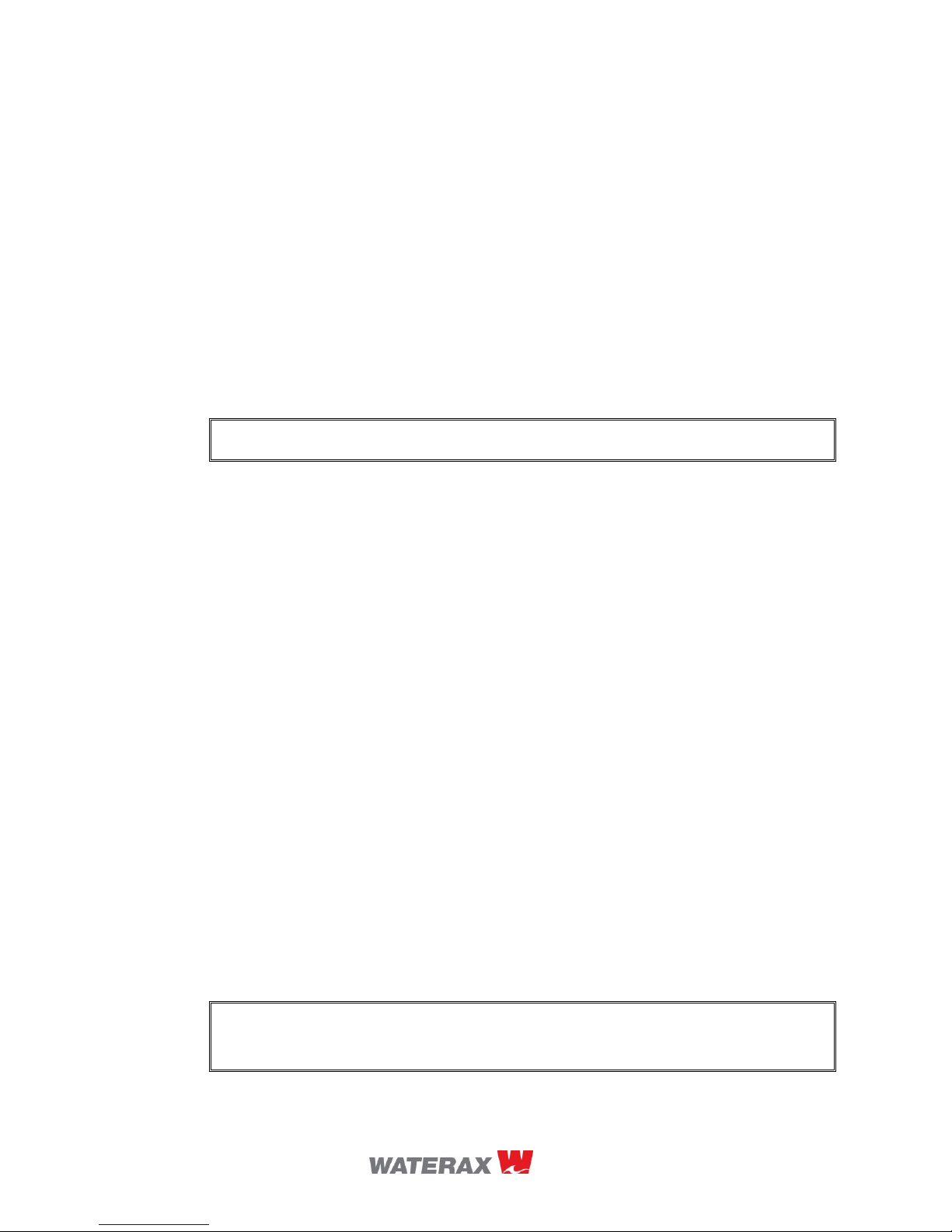

Pump End Mounting

6 09/2015

The pump end can be rotated to aid with the apparatus piping connections. The quick

release pump clamp securely holds the pump end in the desired position. Always ensure

that the water can be drained from the pump end to keep it from cracking in freezing

weather. A drain valve is available from WATERAX (item no 801104).

WATERAX STRIKER-2/3 Owner's Manual

Fastening to Truck/Apparatus

When adding any equipment to a vehicle, follow all instructions and heed all warnings

provided by manufacturers of the apparatus and any third-party accessories. WATERAX

provides certain accessories used in vehicle-mount configurations of the STRIKER-2/3

series pumps. Follow all documentation that ships with any accessories you have ordered

such as vibration mounts or rails. Your company’s internal policies and guidelines must

also be followed.

Before installing the pump in a vehicle, plan for adequate access to any fill caps such as

those for oil and fuel, as well as any other part of the pump or engine that is frequently

accessed or inspected (valves, panels, primers, filters, etc.). Make note of components

that become hot when operating such as mufflers and engine blocks, and always ensure

a safe clearance around them.

Installing a Control Panel

See User Instructions shipped with the specific model of control panel you ordered for

your pump.

Using a Battery for Electric Starters and Control Panels

Some STRIKER-2/3 pumps require a battery to power electrical and electronic

components such as; starters, pump primers and control panels. Make sure to follow all

instructions and heed all warnings provided by your battery manufacturer. Refer to the

engine manual for battery requirements. Always follow safety guidelines set out by your

company. Never connect or disconnect a battery to a pump that is operating.

09/2015 7

WATERAX STRIKER-2/3 Owner's Manual

Operating STRIKER-2/3 Series Pumps

Pre-Operation Checklist

Before using your pump, follow this verification procedure:

1. Visually inspect product

When you first receive your STRIKER-2/3 pump, inspect the product and check for any

damage. Notify the supplier if any damage is found.

2. Check all fluid levels regarding the pump and any related equipment. Before first use,

you must prepare the engine which is shipped dry. Before each subsequent use, check

levels and top up as needed.

Engine/apparatus fuel level

Engine/apparatus oil level

All batteries electrolyte level (not required for sealed batteries)

Refer to the engine manufacturer’s manual for specific instructions

regarding the engine.

3. Check that all suction and discharge hoses are structurally sound and do not leak.

4. Visually inspect any electrical or electronic components for damage.

5. Inspect all safety features and verify that they are in good order before using the pump.

6. Visually inspect the pump’s drive belt and ensure it is in good condition without cracks

or excessive wear.

7. Each time you plan to use the pump, check for damage that may have occurred during

previous use. Notify your manager that the equipment requires repair. Remember that

damaged equipment can expose you to safety hazards.

Flooded Suction

Use this procedure if you are taking water from a hydrant, another pump, or a closed tank.

Be sure to understand and follow all related equipment, apparatus, departmental, and

governmental procedures, policies, recommendations, and guidelines concerning hydrant

connecting and operation before performing this mode of operation.

1. Connect the intake hose to the pump intake or intake piping.

2. Connect opposing end of the hose to the hydrant or water source (a tank may already

be connected). Make sure that all connections are strong and tight and that all pump

valves are closed.

3. Check that all equipment is rated to the proper pressure limits that they will be exposed

to during this mode of operation. DO NOT exceed the maximum intake pressure of the

pump (150 PSI).

4. Slowly open the pump inlet valves allowing the water into the pump body.

5. Slowly open the discharge valves to allow for entrapped air in the piping to escape.

6. Once all the air has escaped, close any opened valves so that the unit may be started.

7. Go to the Startup and Discharge section of this manual to begin pumping water.

The pump will not discharge more water than the capacity of the water source

(hydrant). The pressure reading on the pump’s master intake gauge should never

fall below 0 PSI during the pump operation in this mode.

8 09/2015

Loading...

Loading...