Waterax MARK-3 User Instructions

USER INSTRUCTIONS

03/2018

1

MARK-3® DIS Digital Ignition Solution

Overview:

WATERAX offers a conversion kit Digital Ignition Solution (DIS) for users that want to convert a MARK-3® from breaker

points and mechanical cut-out switch to the upgraded electronic ignition and Digital Overspeed Switch systems. These

instructions will guide you through the conversion process.

Parts Breakdown:

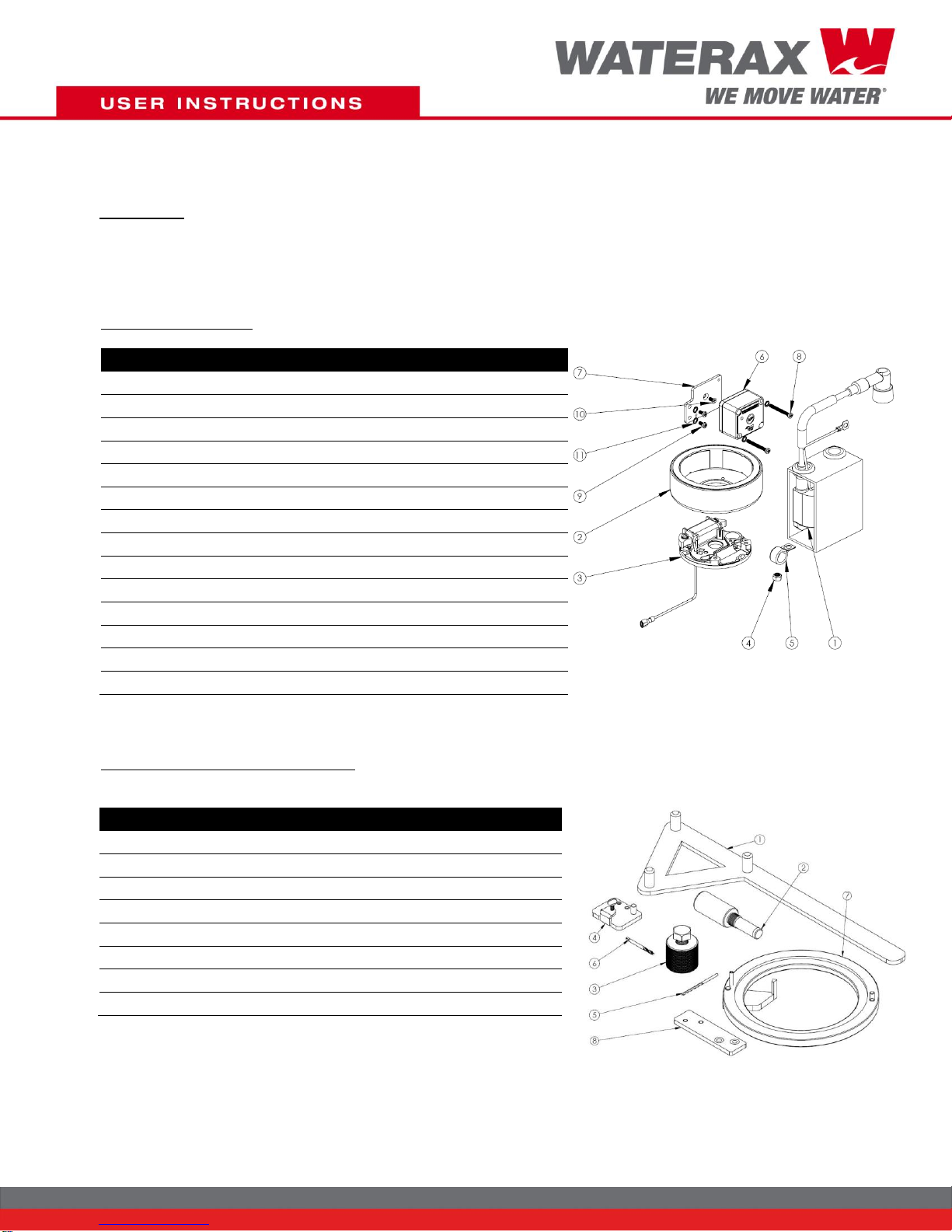

Figure 1: Digital Ignition Solution (DIS) (600556)

Tools and Materials Required:

To complete the installation, you will require the following tools:

ID

ITEM NO

DESCRIPTION

QTY

1

600154

R-929 FLYWHEEL HOLDING TOOL, PLATED STEEL

1

2

701159

PISTON LOCKING TOOL FOR 185CC

1

3

700723

R-927 PULLER - MAGNETO (M38 X 1.5)

1 4 701158

JIG FOR DOS BRACKET DRILLING

1

5

801117

DRILL BIT #30 HIGH SPEED STEEL 2-3/4"LG

1

6

801118

TAP M4X.7 D4 SPRIAL POINT PLUG HIGH SPEED STEEL

1

7

801146

CDI IGNITION TIMING ADJUSTMENT TOOL

1

8

801162

DIS - FRAME DRILLING TOOL

1

Figure 2: Special tools for conversion (available from WATERAX)

ID

ITEM NO

DESCRIPTION

QTY

-

600556

DIS MK-3 CONVERSION KIT UPG TO CDI / DOS

1

1

600125

B-7592 ELECTRONIC IGNITION BOX ASSY

1

2

701109

R-668E MAGNETO FOR 185CC

1

3

800073

R-661-CDI STATOR, COIL/ARMATURE ASSEMBLY

1

4

800544

R-150 NUT M6X1.0 HEX FUJI LOCK ZINC

1

5

800408

B-5562-18 CLAMP PLASTIC COATED 9/16" ID

1 6 700593

B-6289-1 DOS PRODUCTION UNIT

1 7 700616

B-6289-2 DOS MK-3 BRACKET

1 8 800443

B-6289-3 SCREW M4X0.7X35 PHILLIPS CHEESE HEAD ZINC

2

9

800402

B-6289-4 SCREW M4X0.7X8 PHILLIPS RAISED CHEESE ZINC

2

10

800413

B-6289-5 SCREW M4X0.7X8 PHILLIPS FLAT ZINC

1

11

800400

B-6289-6 LOCKWASHER M4 EXTERNAL TOOTH ZINC

4

-

801116

CABLE TIE 4" NYLON BLACK

3

-

701161

USER INST DIGITAL IGNITION SOLUTION DIS

1

USER INSTRUCTIONS

03/2018

2

Figure 3: Required tools for conversion

DESCRIPTION

QTY

TORQUE WRENCH

1

13 MM WRENCH

1

10 MM WRENCH

4

7/16” WRENCH

3

13 MM SOCKET

1

10 MM SOCKET

1

7/16” SOCKET

1

17 MM SOCKET

1

RATCHET WRENCH

1

CUTTER

1

FLAT SCREWDRIVER

1

PHILLIPS SCREWDRIVER

1

NEEDLE NOSE PLIERS

1

17/64” DRILL BIT

1

VARIABLE SPEED ELECTRIC DRILL

1

M4X0.7 TAP

1

#30 DRILL BIT

TAPPING LUBRICANT

1

PENCIL OR MARKER (IF NOT EQUIPPED WITH DOS DRILLING JIG)

1

CENTER PUNCH (IF NOT EQUIPPED WITH DOS DRILLING JIG)

1

THREAD LOCKER LOCTITE 243 OR EQUIVALENT

-

THREAD LOCKER LOCTITE 648 OR EQUIVALENT

-

RTV SILICONE SEALANT LOCTITE 5910 OR EQUIVALENT

-

USER INSTRUCTIONS

03/2018

3

Flywheel (magneto housing):

On very old engines, the flywheel may need to be replaced in order for the DIS and CDI to be correctly timed. On these older

engines, the flywheel magneto mounting stud hole location differs from the newer flywheel.

To differentiate between old and new flywheel, locate the center hub. Older flywheels do not have a recess/step on the

center hub; new flywheels have a recess/step.

Engines that have a serial number below 2776900 will require a newer flywheel (600534); failure to replace the flywheel will

lead to incorrect timing and kickbacks during starting.

Difference between old and more recent flywheels: different magneto mounting stud location.

Old flywheel from engine with serial # below 2776900

Newer flywheel (item no 600534)

Old flywheel: no recess on center hub

Newer flywheel: recess/step on center hub

117.5°

125°

117.5°

117.5°

117.5°

125°

1

2

3

1

2

3

Recess

Loading...

Loading...