Water Ace RSP7, RSP10, RSP15 Installation Manual

INSTALLATION MANUAL Pgs. 2–8

SWIMMING POOL PUMPS

CONSUMER HOT-LINE: 1-800-942-3343

Monday–Friday 7 AM to 5 PM EST

www.waterace.com

MANUEL D’INSTALLATION Pgs. 9–16

POMPES POUR PISCINES

MANUAL DE INSTALACIÓN Pgs. 17–24

BOMBAS PARA PISCINAS

RSP7

3/4 HP

RSP10

1 HP

RSP15

1-1/2 HP

Read and follow all safety warning notices and instructions before installing or using this product. Failure

to follow safety warnings and instructions can result in severe injury, death, or property damage. Please call the Water

Ace Consumer Hot Line at 1-800-942-3343 for any questions about safe installation, operation, use, or maintenance, or for

additional free copies of these instructions. You may also visit the Water Ace website at www.waterace.com.

Lire et observer toutes les consignes de sécurité et tous les avertissements avant d’installer ou d’utiliser ce produit,

sinon on risque de subir des blessures corporelles graves, mortelles, ou causer des dommages matériels importants. Pour toute

question concernant l’installation, le fonctionnement, l’utilisation, l’entretien ou pour obtenir des exemplaires supplémentaires de ces

instructions, appeler le Service à la clientèle Ace au 800 942-3343. On peut aussi visiter le site Web Ace au www.waterace.com.

Lea y siga todas las advertencias e instrucciones sobre seguridad antes de instalar o usar este producto. El no seguir

las advertencias e instrucciones sobre seguridad puede ocasionar lesiones graves, muerte o daño a la propiedad. Sírvase llamar a la

Línea de Información al Consumidor de Water Ace al 1-800-942-3343 si tiene preguntas sobre la instalación, funcionamiento, uso o

mantenimiento seguros o para obtener copias adicionales gratis de estas instrucciones. También puede visitar el sitio web de Water Ace

en www.waterace.com.

WATER ACE PUMP COMPANY | 1101 MYERS PARKWAY | ASHLAND, OHIO 44805-1969 (USA ONLY)

23833A157 (Rev. 7/9/08)

IMPORTANT INSTRUCTIONS BEFORE INSTALLATION

B

od

y

F

or

e

A

r

m

Up

p

e

r

A

rm

L

eg

J

o

i

n

t

L

eg

J

oi

nt

Leg

J

oi

nt

L

eg

Jo

i

n

t

Failure to follow these instructions may cause serious bodily injury and/or property damage.

Save this manual for future reference.

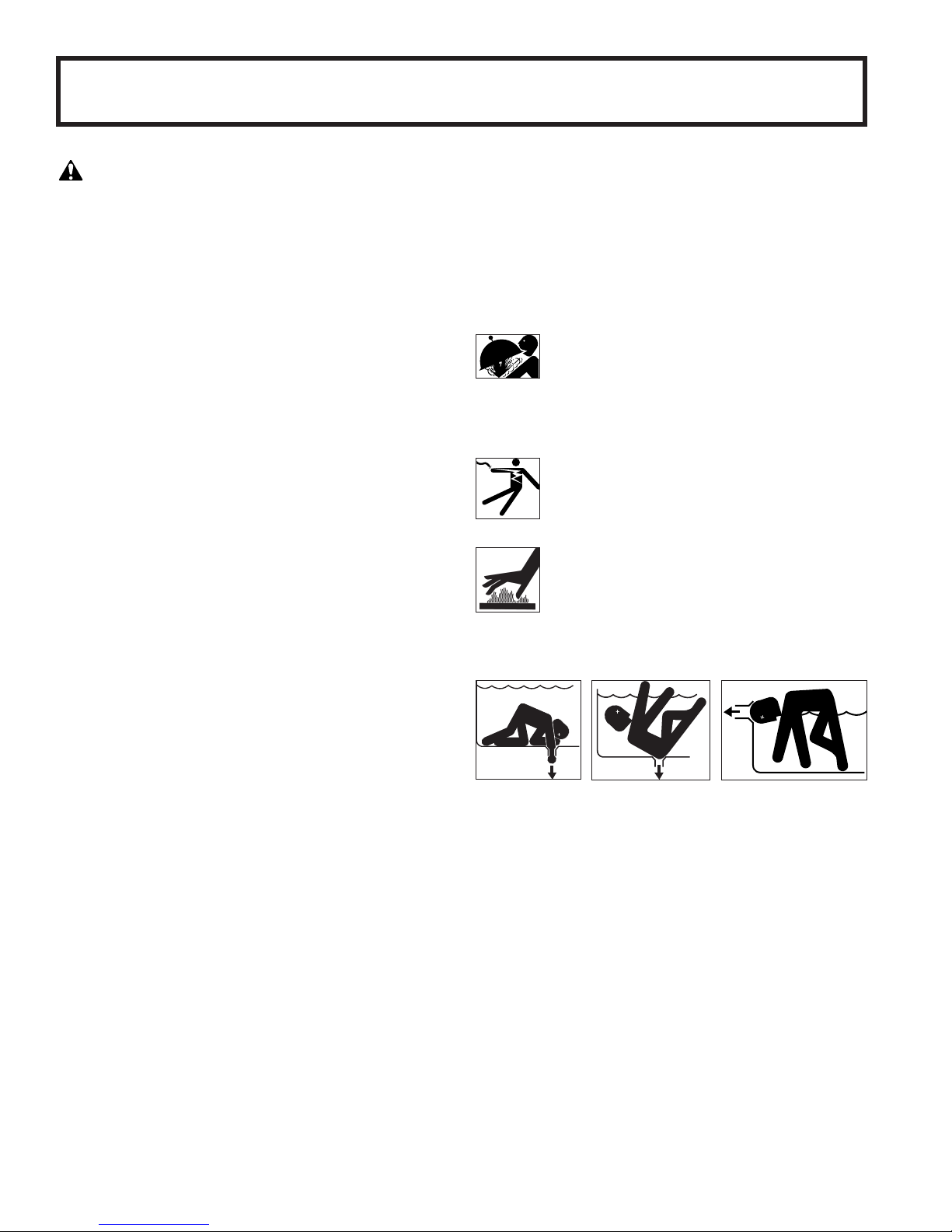

This is the safety alert symbol. When you see this symbol

on your pump or in this manual, look for one of the following

signal words and be alert to the potential for personal injury:

DANGER warns about hazards that will cause serious personal

injury, death or major property damage if ignored.

WARNING warns about hazards that can cause serious personal

injury, death or major property damage if ignored.

CAUTION warns about hazards that will or can cause minor

personal injury or property damage if ignored.

The label NOTICE indicates special instructions which are

important but not related to hazards.

Carefully read and follow all safety instructions in this manual

and on pump.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

WARNING. Severe personal injury or death could result from

improperly sizing the pump, or from using it for any purpose

other than as an in-ground pool pump. Hazards may include,

but are not limited to, electrical shock, fire, flooding, suction

entrapment, or structural failure of the pump or other system

component.

WARNING. Pressure testing hazards.

• Do not allow people to work around components under test.

• Post appropriate warnings and barriers around pressurized

equipment.

• Test for the minimum time allowed by local codes.

• If the equipment is located in a separate room, close and lock

the door and post warning signs.

GENERAL

Pool main drain installation must comply with current local and

national building, electrical, plumbing and pool/spa codes, as

applicable.

Prime the pump (fill the pump and piping system with water)

before starting it for the first time. If you do not get satisfactory

circulation within 5 minutes, stop the pump and reprime it. Do

not allow the pump to run for an extended period of time with no

water moving. In these conditions, the pump may overheat and

start a fire or possibly explode.

WARNING. Explosion hazard, with risk of severe

injury or death. Always stop the pump and relieve all

pressure in the system before adjusting or releasing

any fastenings. Make sure there is no air in the system (use the

air bleed valve on the pool filter to release any trapped air in the

system). NEVER adjust, loosen or tighten any lid clamps or bolts

while the system is pressurized.

WARNING. Risk of electrical shock – can burn or

kill. Always disconnect power to the pump at the

circuit breaker before servicing or working on the

pump. Make sure that no one can connect the power

without your knowledge and consent.

WARNING. Fire and burn hazard. Do not allow leaves

and debris to collect around the pump. Do not allow

children around the pump and filter areas. Allow the

pump motor to cool for 20 minutes before working

on it.

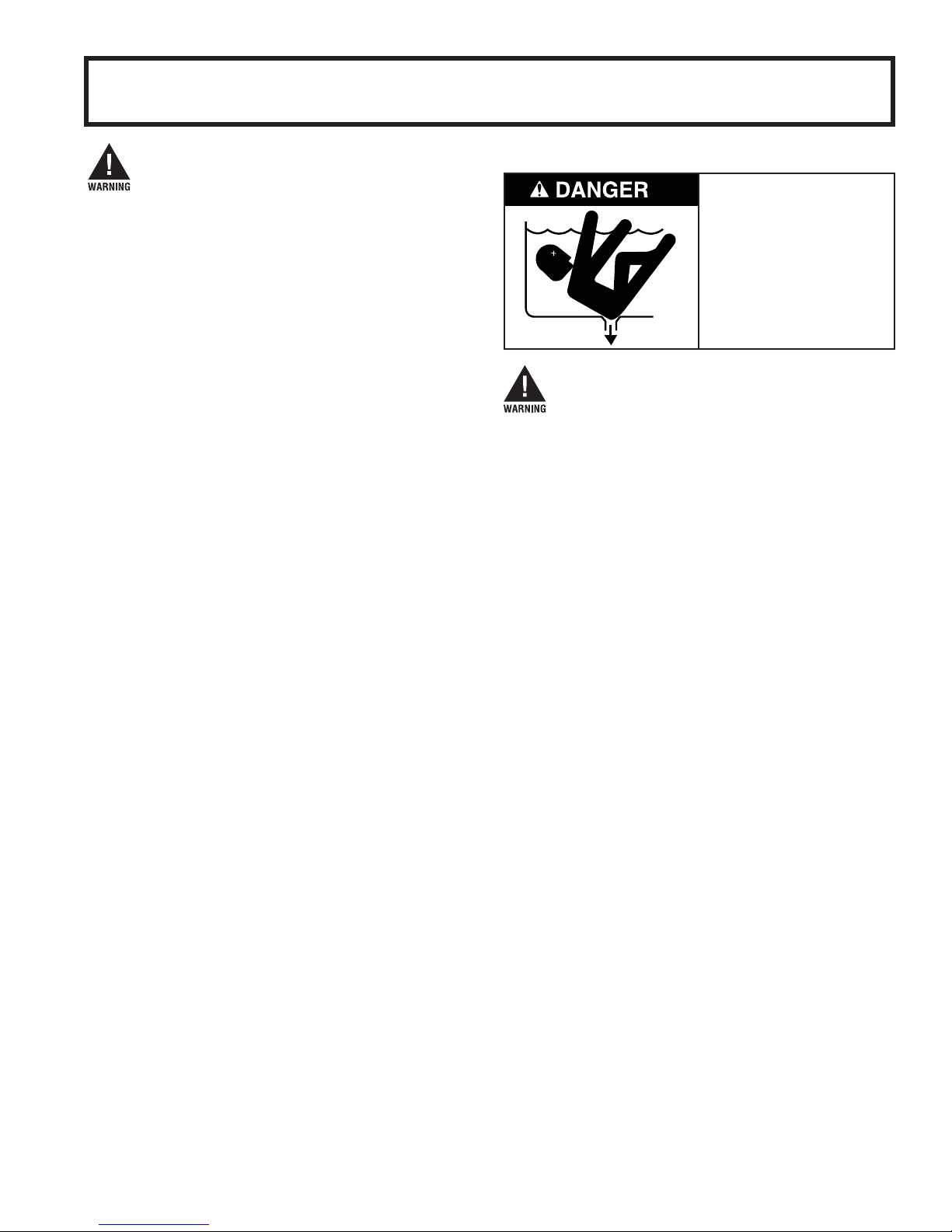

DANGER. Hazardous Suction. Can trap hair or body, causing

severe injury or death.

ELECTRICAL

This pump must be wired through a Ground Fault Circuit

Interrupter (GFCI) to protect the circuit. To reduce the risk of

electrical shock, connect the green terminal on the pump to the

grounding terminal of your electrical service or supply panel. Use

a conductor at least as large as the wires conducting power to the

pump. Refer to local or national codes for details.

Installations must comply with the National Electrical Code or the

Canadian Electrical Code, as applicable, and all applicable local

codes and ordinances.

23833A157

• Do not block circulation pump suction. MAKE SURE that all main

drains are correctly installed, with anti-entrapment covers,

listed to ASME A112.19.8, screw-fastened in place, and that

any vacuum outlets are protected by self-closing, self-latching

vacuum covers listed to IAPMO SPS-4 2000.

• Keep small children under close adult supervision around the

pool at all times.

• NEVER allow anyone (adult or child) to sit on a pool main drain.

• Very small children sometimes think that a main drain is really

a place to “go potty”. Don’t let them do this!

2

IMPORTANT INSTRUCTIONS BEFORE INSTALLATION

Hazardous Suction.

Can trap hair or body,

causing severe injury

or death.

• Do not block suction.

• Keep small children

under close adult

supervision at all times.

Failure to follow these instructions may cause serious bodily injury and/or property damage.

Warranty void if product modified, drilled, painted,

or altered in any way; if used to pump hot water, or

to pump liquids other than water (such as but not

limited to chemicals, fertilizers, flammable liquids, herbicides,

mud, tar, cement, wood chips); or otherwise abused.

Rules for Safe Installation and Operation

When installing and using this electrical equipment, basic safety

precautions should always be followed, including the following:

1. READ THESE RULES AND INSTRUCTIONS CAREFULLY.

Failure to follow them could cause serious bodily injury and/or

property damage.

2. WARNING. To reduce the risk of injury, do not permit children

to use or operate this product.

3. WARNING. Risk of electric shock. Connect only to a circuit

protected by a ground fault circuit interrupter (GFCI). Contact a

qualified electrician if you cannot verify that the receptacle is

protected by a GFCI.

4. Check National Electric Code and state and local codes before

installing. You must comply with these rules.

5. Before installing pump, have the electrical circuit checked by

an electrician to make sure it is properly grounded.

6. Before installing or servicing your pump, BE CERTAIN pump

power source is disconnected.

7. Match supply voltage to nameplate voltage. Wrong voltage can

cause fire or motor damage and voids warranty. If in doubt, consult

a licensed electrician.

8. Complete pump and piping system must be protected against

below-freezing temperatures. Failure to do so could cause severe

damage and will void the warranty.

9. WARNING. Do not pump chemicals or corrosive liquids with

this pump. To do so will shorten the life of pump seals and moving

parts, voiding the warranty.

10. After carefully removing your pump from the carton, make a

visual inspection for any apparent shipping damage.

11. Do not use extension cords.

12. Do not pump gasoline or other flammable liquids.

13. If you need to close the valve on the discharge side of the

pump, shut the valve slowly. Rapid closing of the valve could cause

a water hammer effect and damage the pump.

14. SAVE THESE INSTRUCTIONS.

Pump must be primed! Make sure pump is full of water before

running! Failure to do so will cause damage to mechanical seal,

leakage and flooding.

WARNING. Explosion hazard. Never run pump against closed

discharge valve! To do so can cause high temperatures, pump

damage, personal injury and property damage.

WARNING. Hazardous voltage! Can shock, burn or cause death.

Read instructions before installing. To avoid dangerous or fatal

shock hazard, turn off power and ground motor before connecting

motor to electrical power supply. Do not ground to a gas supply

line.

Pump may be HOT to touch. Use caution.

POOL PUMP SUCTION REQUIREMENTS

Pump suction is hazardous and can trap and drown or

disembowel bathers. Do not use or operate swimming

pools, spas, or hot tubs if a suction outlet cover is

missing, broken, or loose. Follow the guidelines below

for a minimimum risk installation.

Suction Outlet Covers

All suction outlet covers must be maintained, and replaced if

cracked, broken, or missing. See “Testing/Certification”, below, for

outlet cover certification requirements.

All suction outlets must have correctly installed, screw-fastened

covers in place.

Suction Outlets Per Pump

Provide at least two hydraulically balanced main drains, with

covers, as suction outlets for each circulating pump suction

line. The centers of the main drains (suction outlets) on any one

suction line must be at least three feet apart.

The system must be built so that it has at least two main drains

connected to the pump whenever it is running (see “Typical

Installation Drawing”, Page 4). However, if two main drains

run into a single suction line, that line may be equipped with a

valve to shut off both main drains from the pump (see “Typical

Installation Drawing”).

More than one pump can be connected to a single suction line as

long as the requirements above are met.

Testing/Certification

Suction outlet covers must have been tested by a nationally

recognized testing laboratory and found to comply with the latest

ASME/ANSI A112.19.8 Standard Specification for Suction Fittings

For Use in Swimming Pools, Spas, Hot Tubs, and Whirlpool Bathtub

Applications.

3

23833A157

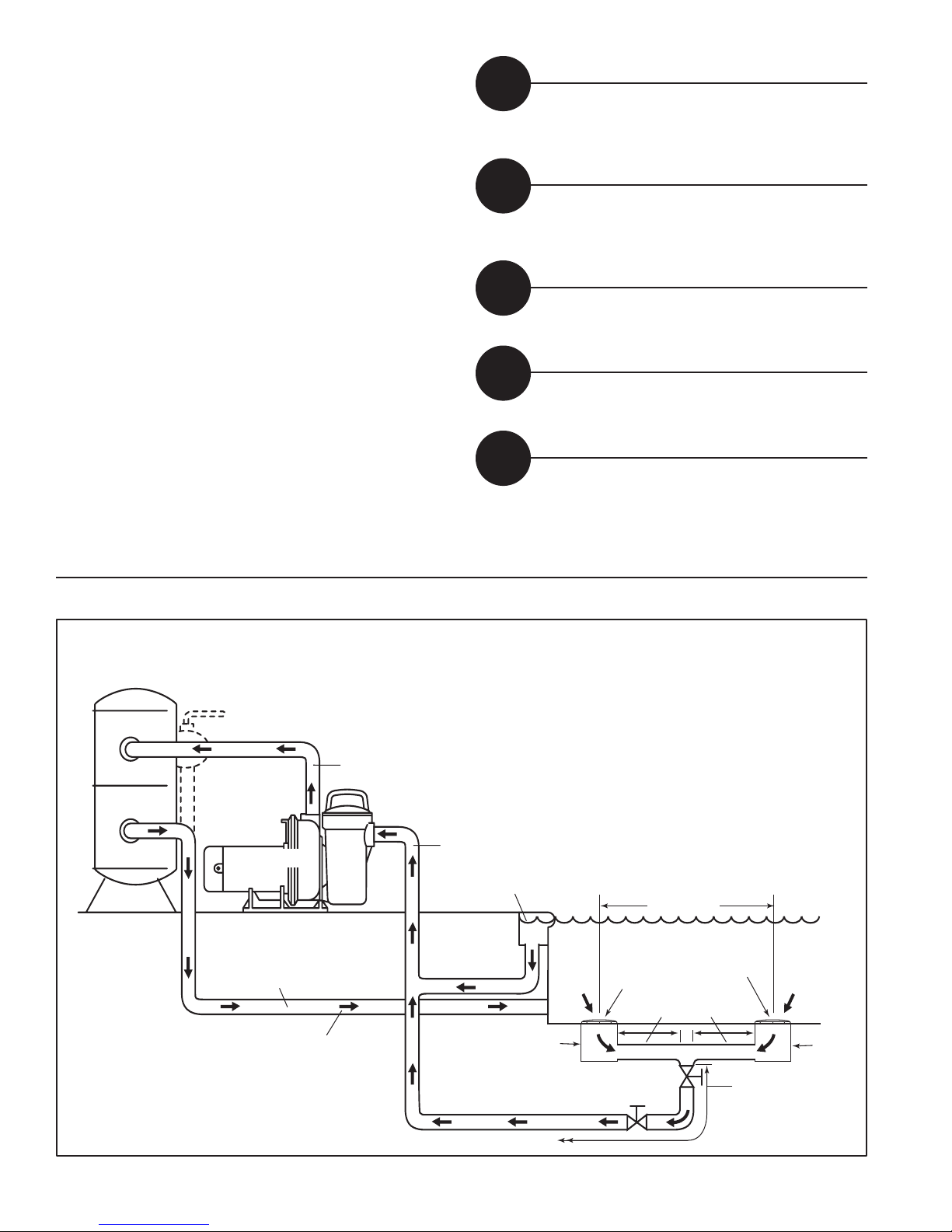

SWIMMING POOL PUMP INSTALLATION

Filter: Cartridge filters require no backwash valve.

Sand or diatomaceous earth filters require a

backwash valve.

Backwash Valve

Pump Discharge Line

Pump Suction Line

Circulation

Pump

Optional Shut-O Valves

can be installed in the

lter inlet and outlet lines

to allow isolation of the

lter for service.

Skimmer

Return Line

Inlet Line

from Skimmer

At Least 3 Feet

Suction Outlets (Main Drains)

with

IAPMO Certified Antientrapment Covers or Suction

Fittings, screw-fastened.

Valves OK

between Tee

and Pump

No valves between

Tee and Main Drains

Main Drain Sump

Main

Drain

Sump

Direction of Flow

STEP

General Tools and Materials Needed

• Electrical cable with ground wire

• Ground fault circuit breaker

• Rigid 1-1/2" PVC pipe and fittings or reinforced flex hose and

hose clamps

• Pump

• Filter

• Backwash valve (not required on cartridge filter)

• Shut-off valves

• Hacksaw with 24-tooth blade for cutting plastic pipe

• Knife or round file for smoothing inside of plastic pipe connections

• Screwdriver, pipe wrench, adjustable wrench

• PVC cleaner and adhesive

• Hose clamp fittings (required only for flex hose)

1

Locate pump and filter on a solid level ground. Make

sure pump is protected from the weather and pool

splash. (Water should not come in contact with motor.)

STEP

2

Connect the suction line from the pool skimmer and/or

drain to the pump inlet. A shut-off valve is required on

above ground pools.

STEP

3

Connect the discharge line from the pump to the

filter inlet.

STEP

4

Connect the return line from the filter outlet to the

swimming pool return inlet.

STEP

5

Connect the electrical cable from the pump to a ground

fault circuit breaker. Make sure power is off before

connecting the wires. (SEE ELECTRICAL INFORMATION,

PAGE 5).

TYPICAL INSTALLATION DRAWING

23833A157

4

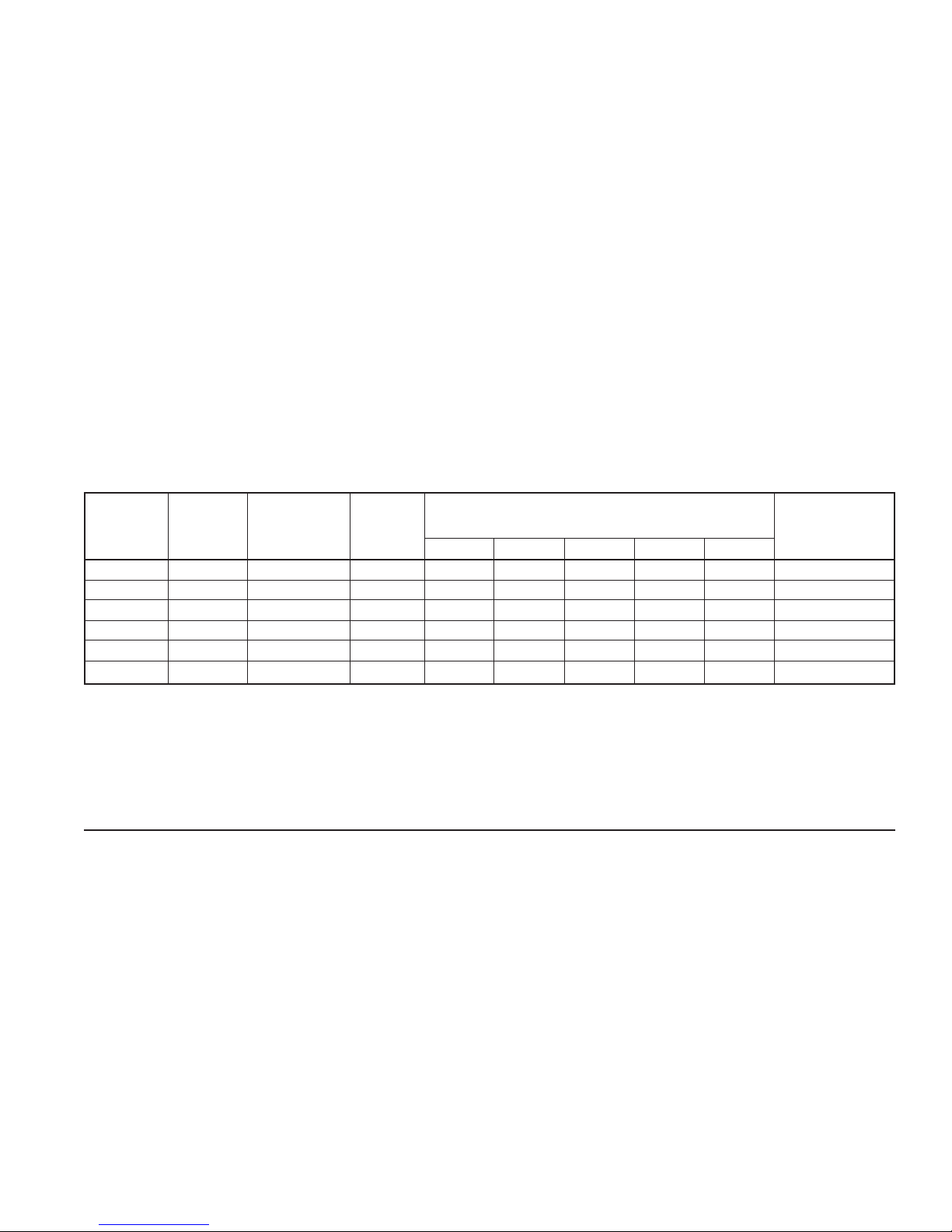

ELECTRICAL INFORMATION

NAME- FUSE OR

PUMP MOTOR PLATE

MAX. WIRE LENGTH USING AWG WIRE SIZE

CIRCUIT

MODEL HP VOLTAGE AMPS

14 12 10 8 6

RSP7

BREAKER

3/4 115 11.8 100 160 250 385 600

RSP7

15

3/4

230 5.9 400 630 990 1545 2405

RSP10

10

1 115 14.4 — 128 200 310 485

RSP10

20

1 230 7.2 300 475 660 1030 1650

RSP15

10

1-1/2 115 20.8 — — 142 222 345

RSP15

25

1-1/2 230 10.4 220 350 545 860 1325 15

Installation Instructions

Wiring to this pump must be installed and maintained in

accordance with the National Electric Code, state and local codes.

If more information is needed, call your local licensed electrician

or your power company.

Grounding the Motor: Permanently ground the motor in

accordance with the National Electric Code Article 250 and

applicable local codes and ordinances. It is recommended that

permanent ground connection be made to the unit using a

conductor no smaller than No. 8 AWG (8.4 mm2). This ground

conductor should be connected from the accessible wire connector

on the motor to all metal parts of the swimming pool structure

and to all electrical equipment, metal conduit, and metal piping

within 5 feet (1.5 m) of the inside walls of a swimming pool, when

the motor is installed within 5 feet of the inside walls of the

swimming pool. This permanent ground should be from a metal

underground water pipe or a grounded lead in the service panel. A

metal underground water pipe or well casing at least 10 feet long

makes the best ground electrode.

If plastic pipe or insulated fittings are used, run the ground wire

directly to the ground electrode furnished by the power company.

Caution: Do not ground to a gas supply line and do not connect

to an electric power supply until unit is permanently grounded.

Connect the ground wire to the approved ground and then connect

to the terminal provided.

Important: For your safety, be sure electrical circuit to pump is

shut off (disconnected) before attempting to wire pump. Pump

should be connected to a separate electrical circuit directly from

main switch. A fuse box or circuit breaker must be used in this

line (see fuse chart). Plugging into existing outlets can cause

low voltage at motor, resulting in blown fuses, tripping of motor

overload, or burned-out motor. All wiring must follow local codes.

Note: If ever in doubt, call a licensed electrician.

Motor Voltage: The pumps are wired for 230 volts, but may

be converted to 115 volts by referring to instructions printed

on motor. If motor is converted to 115 volts, have a qualified

electrician check the entire electrical and power leads system to

be sure they can handle the higher amps.

To Wire Pump: Make electrical connections with ground. First

connect bare copper ground to ground screw on back of motor.

Next make power connections.(See chart for wire size.)

SWIMMING POOL WIRE & FUSE SELECTION CHART

MAINTENANCE AND SERVICE

Priming the Pump

To prime the pump, remove the lid from the strainer and fill the

pump and basket with water. Turn cover counterclockwise to

remove. CAUTION: Be sure pump has been shut off and pressure

relieved before removing cover.

POOL WINTERIZING

In areas where freezing temperatures occur, protect pump and

pipes from freezing. When water freezes, it expands and damages

the pump and piping.

WARNING. Do not use commonly available antifreeze solutions.

Automotive antifreeze solutions are commonly made up of

ethylene glycol, which is highly poisonous and does not evaporate.

Methyl alcohol is also highly poisonous, but will evaporate if given

enough exposure to the atmosphere. Many windshield washer

solutions are compounded with methylhydrate, which is very

poisonous. All of these above-mentioned antifreezes have a strong

deteriorating effect on some plastic materials commonly found in

pool pumps, valves, and filter components. Some plastics, such as

those used in pump impellers, will become crystalline and brittle

when in contact with antifreeze solutions or are exposed to the

fumes. Other materials, such as clear trap lids can become milky in

appearance, soften or lose rigidity when exposed to the fumes of

antifreeze compounds.

When basket and pump are filled with water, replace strainer lid.

Lubricate O-ring each time with petroleum jelly. Be sure O-ring

seal is in place before tightening cover. Turn clockwise to tighten.

The pump will now prime, with the priming time depending on the

suction lift and the horizontal distance of the suction piping.

The recommended procedures for winterizing pool piping

are as follows:

1. Use low pressure air flow to blow accumulated water from

the piping system after the water level has been pumped down

below all inlets to the pool. Drained inlet piping may be capped to

prevent re-entry of water into the pipes.

2. There is one antifreeze solution that is compatible with

plastics and is nontoxic. Preliminary investigations show that

DOWFROSTTM, a product of Dow Chemical Company, is safe and

effective for use in pools and all types of fresh water piping

systems for winterizing, including solar systems. It is compounded

of propyleneglycol, and has a very low evaporation rate.

A solution of 40% Dowfrost and 60% water will protect pipes from

bursting to –50° F. A unique property of Dowfrost is that it contracts

as it approaches its freezing point, counteracting the expansion

characteristics of water and preventing bursting of pipes.

5

23833A157

PUMP SERVICE

CAUTION: Always turn power off and drain the pump before

servicing. If pump is below the water level of the pool, close

shut-off valve on both suction and discharge lines.

Step 1: Disconnect the power and remove drain plugs.

Step 2: Remove strainer lid; let drain.

Step 3: Disconnect piping.

Step 4: Remove clamp by turning tee handle.

CAUTION: Be sure pump is drained and pressure has been

released before removing clamp.

Step 5: Remove the case.

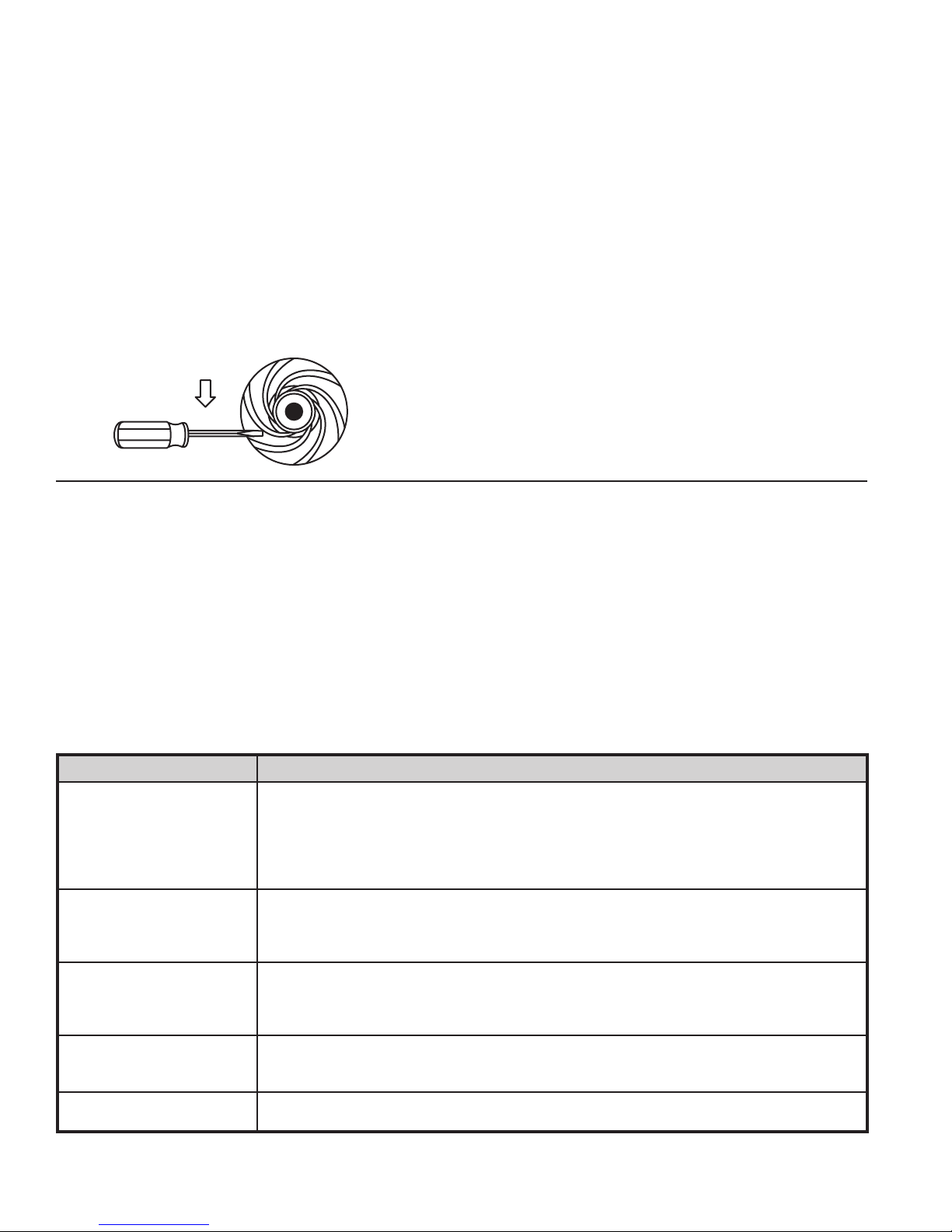

Step 6: Remove the impeller by turning counterclockwise. The

best way to remove impeller is by inserting a screwdriver in the

blade area and sharply hitting screwdriver with a rubber hammer.

Step 7: The motor can be removed by unscrewing 4 bolts.

Step 8: Install new seal following instructions in seal

repair package.

Step 9: Inspect O-rings for knicks and cuts. If damaged,

replace with new ones.

Step 10: Clean O-ring seat area. Lubricate O-rings with

petroleum jelly.

Step 11: Attach motor to seal plate and base.

Step 12: Attach case to seal plate with clamp.

Step 13: Install pipe plugs.

Step 14: Connect piping.

Step 15: Fill pump with water.

Step 16: Replace strainer lid.

Step 17: Reconnect power.

TROUBLESHOOTING CHECKLIST (CAUTION: SHUT OFF POWER TO PUMP)

This information is for checking pool pump installations that are

not operating properly. It is based on the premise that the installed

system will consist of a swimming pool pump taking water from a pool

and forcing it through a filter and back to the pool.

Warning: To guard against accidental personal injury,

the electric power to the pump must be turned off when

conducting the checking procedures outlined herein.

There are obvious exceptions, however, and authorized service

personnel should take necessary safeguards against the hazard of

electrical shock.

PROBLEM POSSIBLE CAUSES

Pump will not prime. • Stop motor, remove strainer lid, and fill case with water.

• Make sure suction line has no leaks, and that it slopes gradually from pump to pool with no high or

low spots.

• Make sure pump shaft turns clockwise when viewed from motor end opposite shaft.

• Check for plugged impeller.

• Make sure the check valve is not sitting in sand or mud, and that it is not stuck shut.

Pump delivers water for a period

of time, then stops pumping.

Pump does not deliver

rated capacity.

Motor overheats and shuts

off (overload).

Motor fails or does not

operate properly.

• Check for plugged impeller.

• Check for a suction leak.

• Check for blocked suction line.

• Check to see if impeller is rubbing.

• Check for plugged impeller.

• Check for a suction leak.

• Check for a blocked suction line.

• Check to see if impeller is rubbing.

• Make sure motor is properly wired for the correct voltage.

• Check wire size - wire may be too small. See selection chart on page 3.

• Make sure the impeller is not rubbing against the pump case.

• If within warranty, return pump/motor unit to place of purchase (with proof of purchase) for exchange.

23833A157

6

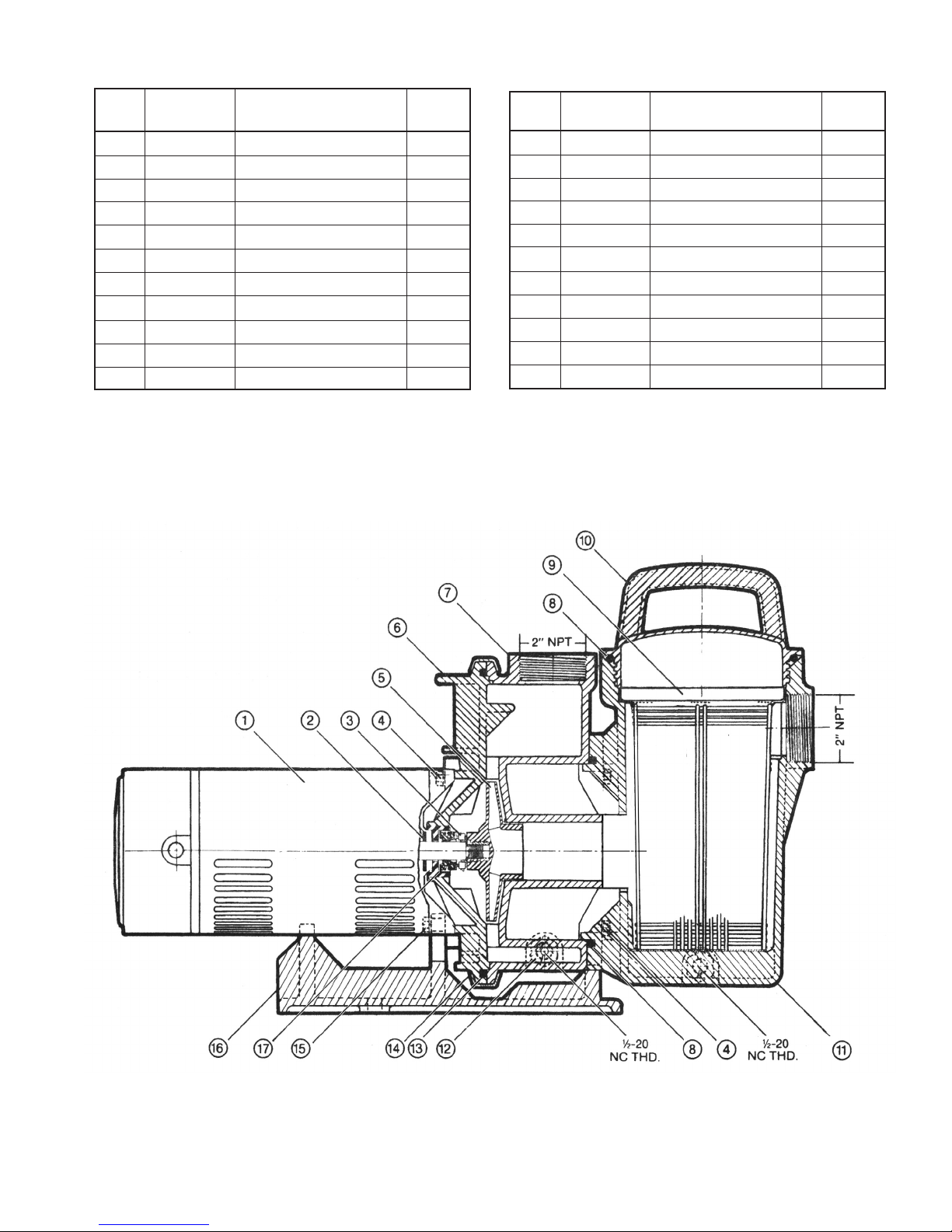

Ref. Part Qty.

No. No. Description Req'd.

8 05876A169 O-Ring 2

9 25061C000 Strainer Basket, B.G. 1

10 25062C000 Lid, B.G. 1

11 25063D000 Strainer Housing, B.G. 1

12 25064A000 Drain Plug 2

2

13 05876A170 O-Ring 1

14 25058C000 Clamp 1

15 19101A021 Cap Screw, 3/8" x 1-1/2"

16 25065C000 Foot, Mtg. 1

*17 25198A000 Seal Cup 1

— 25281A007 Seal Repair Kit** 1

Ref. Part Qty.

No. No. Description Req'd.

1 25051A008 3/4 HP Motor, RSP7 1

1 25051A009 1 HP Motor, RSP10 1

1 25051A010 1-1/2 HP Motor, RSP15 1

2 05059A318 Slinger 1

*3 25053A000 Shaft Seal 1

4 19101A010 Cap Screw, 3/8" x 1" 6

5 25054B001 Impeller, RSP7 1

5 25054B002 Impeller, RSP10 1

5 25054B003 Impeller, RSP15 1

6 25059D000 Seal Plate 1

7 25060D000 Diffuser Housing 1

B.G. = Below Ground

* If shaft seal (3) is replaced, also replace seal cup (17).

** Seal Repair Kit (25281A007) contains seal, seal cup and all O-rings.

Use only Water Ace Pump Co. approved components.

POOL PUMP PARTS LIST

7

23833A157

LIMITED WARRANTY

WATER ACE warrants to the original consumer purchaser (“Purchaser”) of its products that they are free from defects in material or

workmanship.

If within twelve (12) months from the date of the original consumer purchase any such product shall prove to be defective, it shall be

repaired or replaced at WATER ACE’s option, subject to the terms and conditions set forth below. Your original receipt of purchase is

required to determine warranty eligibility.

Exceptions to the Twelve (12) Month Warranty

Product Warranty Period

R106, R107 Non-Submersible Utility 90 Days

RES Submersible Utility

R33SP Submersible Sump Pump

R50SP Submersible Sump Pump

R3S Submersible Sump Pump 3 Years

R7PBS Pressure Booster Pump

R5V Submersible Sump Pump 5 Years

R50VLT, R75VLT Sump/Effluent Pumps

R5PILT Pedestal Sump Pump

R7W Submersible Sewage Pump

General Terms and Conditions

Purchaser must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty shall

not apply to acts of God, nor shall it apply to products which, in the sole judgement of WATER ACE, have been subject to negligence,

abuse, accident, misapplication, tampering, alteration; nor due to improper installation, operation, maintenance or storage; nor to

other than normal application, use or service, including but not limited to, operational failures caused by corrosion, rust or other

foreign materials in the system, or operation at pressures in excess of recommended maximums.

Requests for service under this warranty shall be made by returning the defective product to the Retail outlet or to WATER ACE as soon

as possible after the discovery of any alleged defect. WATER ACE will subsequently take corrective action as promptly as reasonably

possible. No requests for service under this warranty will be accepted if received more than thirty (30) days after the term of the

warranty.

2 Years

Lifetime

This warranty sets forth WATER ACE’s sole obligation and purchaser’s exclusive remedy for defective products.

WATER ACE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL NOT EXTEND

BEYOND THE DURATION OF THE APPLICABLE EXPRESS WARRANTIES PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied

warranty lasts, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights and you may

also have other rights which vary from state to state.

Water Ace Pump Co. | 1101 Myers Parkway | Ashland, Ohio 44805-1969

23833A157

1-800-942-3343 (U.S.A. only)

8

Loading...

Loading...