Watec WAT-600CX Operation Manuals

Wrench

Color CCD Camera

WAT-600CX

Operation Manual

This Operation Manual covers safety, camera functions, installation and the

correct operating procedure for the WAT-600CX. First, we ask you to read

this Operation Manual thoroughly, then install and operate the WAT-600CX

as advised. In addition, for future reference, we also advise safekeeping of

this manual.

Please contact the distributor or dealer from which the WAT-600CX was

purchased, if you do not understand the installation, operation or safety

instructions laid out in this manual. Not understanding the contents of the

Operation Manual sufficiently may cause damage to the camera.

Guide to the Safety Symbols

The definitions of the symbols used in this operation manual are:

Cautions for Safety

The WAT-600CX is designed to be used safely; however, it may lead to a

physical accident caused by fire and electric shock if not used correctly.

Therefore, please keep and read the “Cautions for safety” below for

protection against accidents.

When you do not adhere to or take notice of the “Danger” sign,

Dan ger

it may lead to a serious accident such as death or injury caused

by fire or electric shock.

When you do not adhere to or take notice of the “Warning” sign,

War ning

it may cause severe damage such as a physical injury.

When you do not adhere to or take notice of the “Caution” sign,

Cau tion

it may incur injury and cause damage to peripheral objects in

the immediate surroundings.

•

Dan ger

War nin g

Do not disassemble and/or modify the WAT-600CX.

•

Do not operate the WAT-600CX with wet hands.

• Use only the AD-156 with the WAT- 600CX set

• Do not use the WAT- 600CX under unusual environmental

conditions.

The WAT-600CX is designed and approved for indoor use only.

The WAT-600CX is not water-resistant, dustproof, or

explosion proof. If the location of the camera is outdoors or in

an outdoor like environment, we recommend that you use an

outdoor camera housing.

•

Protect the WAT-600CX from condensation.

Keep the WAT-600CX dry at all times during storage and

operation.

•

Should the camera not work properly, switch off the power

immediately. Then check the camera according to the

“Problems and Trouble shooting” section.

•

Cau tion

Avoid the striking of hard objects or dropping the WAT-

600CX.

The WAT-600CX uses high quality electrical parts and

precision components.

• The WAT-400RX must be used with the WAT-600CX.

Only the WAT-400RX should be attached to the WAT-600CX

BNC terminal. Connecting a monitor directly to this terminal

will not provide a picture.

•

Do not install the WAT-600CX in a position subject to

direct sunlight.

Sunlight shinning directly onto the WAT-600CX lens can

cause damage to the CCD.

•

Select a stable place for installation of the WAT-600CX.

Use a support of durable strength around an installation

position on a ceiling or wall when a camera stand or tripod is

used.

•

Do not move the WAT-600CX with the cables connected.

Before moving the WAT-600CX, always remove the cable(s)

from the rear of the camera first.

.

•

Avoid using the WAT-600CX near any strong

electromagnetic field.

After installing into main equipment, if the WAT-600CX is

exposed to electromagnetic waves causing the monitored

image to become distorted, we recommend the camera be

shielded by appropriate protective casing.

Problems and Trouble Shooting

If any of the following problems occur when using the WAT-600CX,

•

An optimal picture cannot be obtained, after checking that all the cables

and connections are correctly in place

•

Smoke or any unusual odor emerges from the WAT-600CX

•

An object becomes embedded or a quantity of liquid seeps into the

camera housing

•

More than the recommended voltage or/and amperage has been applied

to the WAT-600CX by mistake

•

Anything unusual occurring to any equipment connected to the WAT-

600CX

disconnect the camera immediately according to the following

procedures:

①Switch off the main power supply to the camera.

②Remove the cable(s) connected to the WAT-600CX.

③Contact the distributor or dealer from which the WAT-600CX was

purchased.

About EMC

The WAT-600CX is in conformity with EMC test standards carried out by

authorized organizations in Japan.

NTSC FCC Part15 class B

P A L EN61000-6-3/EN50130-4

Dan ger

Do not modify the WAT-600CX. A modified camera may not

conform to EMC test standards.

Contents

Using the contents figures below, check to make sure all parts are present

before use.

Lens WAT-

Mount Cap

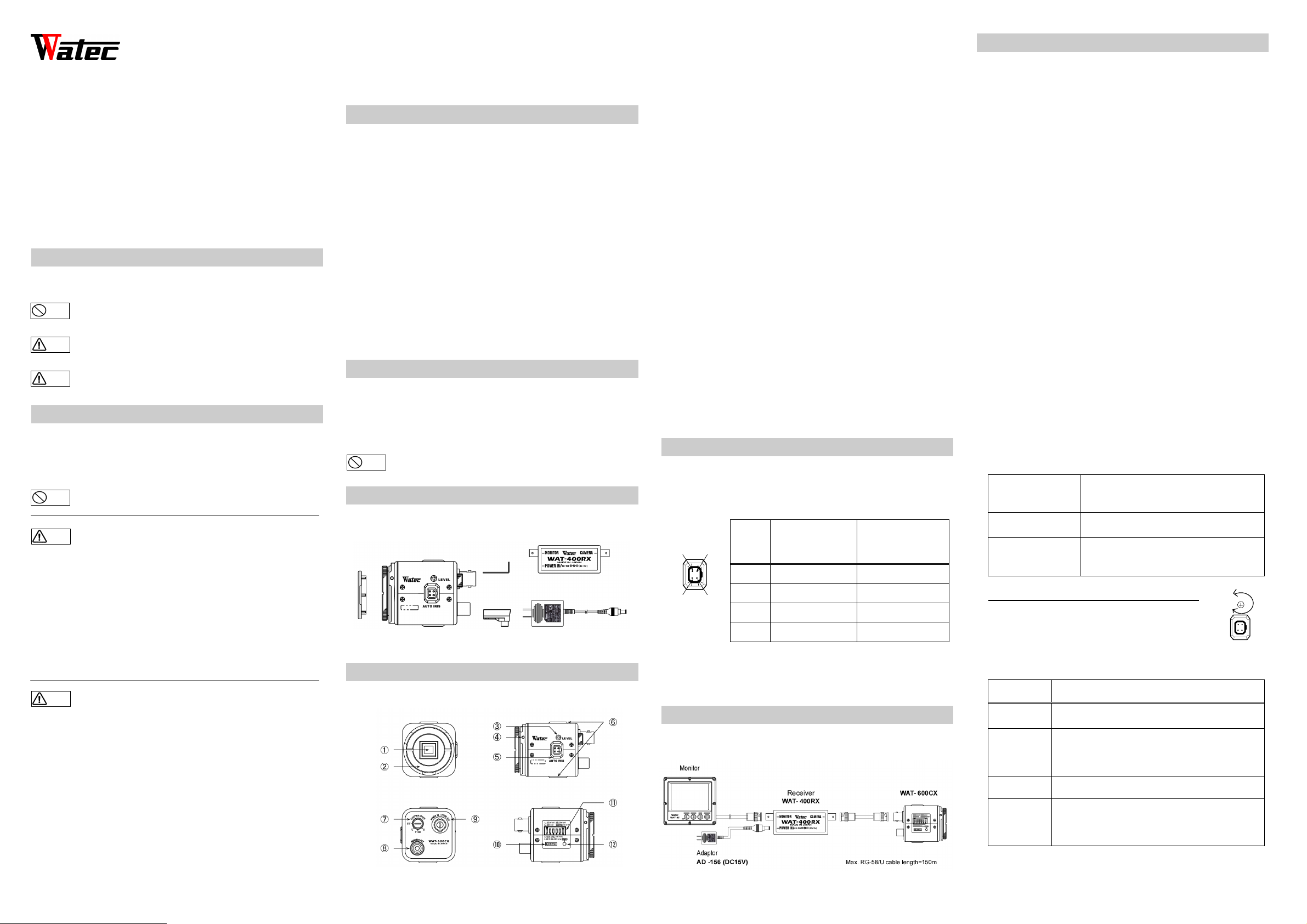

Description of Parts

Hex.

600CX

DC Plug AC Adaptor (AD-156)

Receiver

(WAT- 400RX)

①CCD FRONT FACE

・・・・The light receiving face of the CCD camera

(Dirt, water or oil deposits on the CCD will cause an unclear picture on

the monitor. Attach the lens cap to protect the lens and the CCD from

contamination and damage.)

②LENS MOUNT

・・・・Mount for the lens (CS-mount)

③IRIS LEVEL VOLUME

・・・・By controlling the volume, the iris level of the DC iris lens can be adjusted.

④FOCUSING ADJUSTMENT SCREWS

・・・・There are 3 hex. adjustment screws each placed at intervals of 120゜for

fine focusing of the lens.

⑤AUTO-IRIS SOCKET

・・・・This socket is for the video/DC auto-iris lens cable connector.

(Video/DC: Auto selected by the camera)

⑥TRIPOD MOUNTING SCREW HOLES

・・・・Mounting holes for stands. The size of these threads are 1/4”, 20 threads,

4.5±0.2mm, which is the same as any standard camera tripod (U1/4”).

⑦AE MODE CONTROL

・・・・The switch for the shutter speed mode control according to the object

being monitored.

⑧TEST VIDEO OUT (RCA)

・・・・The video out terminal for test monitoring at the camera location.

⑨VIDEO OUT/POWER IN (BNC)

・・・・The terminal for composite video signal output and power input

⑩WHITE BLEMISH CORRECTION

・・・・The button for correction of white blemish.

⑪FUNCTION SWITCHES

・・・・Functional switches for setting AGC, gamma control, BLC (Back light

compensation), video level, and white balance modes.

⑫PUSH-LOCK WHITE BALANCE BUTTON

・・・・The button for manual setting of the white balance if the white balance

mode is set to PWB.

Auto-iris Lens

Before connecting the auto-iris lens, please make sure that the pin

configuration is correct by confirming with the following table. If the

configuration of your iris connector is different from the following, the plug

and pins will need to be rewired.

EIAJ Video

④

③

②

①

Pin No.

①

②

③

④

Auto-iris Lens

Arrangement

Power

Not used

Iris signals

Common (GND)

・Maximum cable length for operation of the WAT-600CX depends on which

lens is used. For example, 100m is the maximum cable length for the

WAT-600CX when an auto-iris lens with a current consumption of 50mA

is applied.

Wiring Diagram

The following diagram is the basic connection of the WAT-600CX, WAT400RX, AD-156 and monitor.

EIAJ DC

Auto-iris Lens

Arrangement

Control -

Control +

Drive +

Drive -

Set-up and Operation

1) Ensure that the power to the WAT-600CX and the peripheral equipment

is turned off before making any connections.

2) Remove the lens mount cap from the WAT-600CX and attach the

CS-mount lens. Use the optional C-mount adaptor (30CMA-R) when a

C-mount lens is used.

3) Connect the iris control cable to ⑤AUTO-IRIS SOCKET on the WAT600CX when an auto-iris lens is being used.

4) Connect ⑨VIDEO OUT/POWER IN of the WAT-600CX to the

“CAMERA” connection terminal of the WAT-400RX. Use a coaxial cable

with 75Ω impedance, such as an RG-58/U. The maximum cable length

for the WAT-600CX attached to a manual iris lens is 150m using an

RG-58/U cable.

5) Connect the VIDEO OUT (MONITOR) on the WAT-400RX to the video

signal input terminal of a monitor using a coaxial cable with 75 Ω

impedance, such as an RG-58/U.

※

Select a monitor with the same television system as the WAT-600CX:

NTSC or PAL. A monitor with more than 600TV lines is recommended.

※

Do not connect the WAT-600CX or the WAT-400RX with any monitor

using a video in/power out single transmission terminal. The

WAT-600CX and the WAT-400RX are not designed for use with this

type of equipment and receiving power through a monitor will cause

damage to both the WAT-600CX and the WAT-400RX.

6) Connect the attached AC adaptor (AD-156) to the POWER IN connector

of the WAT-400RX.

7) When a monitor test of the camera angle of view and functional settings

at the location is required, connect ⑧ TEST VIDEO OUT of the

WAT-600CX to the monitor using a coaxial cable with 75Ω impedance,

such as an RG-58/U.

8) Turn on the power to the WAT-600CX, monitor and all the other allied

equipment. When a picture cannot be obtained on the monitor, check

and follow the procedure mentioned in the “Problems and Trouble

Shooting” section.

9) After following the procedure below and the picture is still out of focus,

open the iris fully and loosen ④FOCUSING ADJUSTMENT SCREWS

with the hex. wrench and move the lens forwards until a clear picture is

obtained.

Manual Lens

Adjust the focus and iris to the best position

on the lens.

Video Auto-iris Lens Adjust the focus on the lens.

DC Auto-iris Lens

Iris Level Adjustment (for DC auto-iris lenses only)

Adjust ③IRIS LEVEL VOLUME placed on the side

Adjust the iris level on the camera, then

adjust the focus on the lens. See below.

CLOSE D

LEVE L

OPEN

of the unit until an acceptable light level is attained.

No change will occur if a video iris lens or manual

iris lens is fitted.

10) Select any required shutter speed mode by the ⑦AE MODE

CONTROL. (Factory default: EI)

AE Mode Effect

OFF Fixes the shutter speed to NTSC1/60, PAL1/50.

Reduces the flickering phenomena occurring on the

FL

monitor screen caused by fluorescent or mercury

lamps.

1/1000

Fixes the shutter speed to 1/1000

EI

(Flicker suppress)

※

In EI mode, intense light may leave a trail on the screen longitude.

For electronic iris reducing the flickering phenomena

occurring on the monitor screen caused by

fluorescent or mercury lamps.

This smearing is a natural phenomenon and is not due to equipment

failure or fault.

11) Set the ⑪FUNCTION SWITCHES according

Contact information

Mini Stand (MS50)

A convenient stand for the WAT

.

damages

Bracket (B003)

C-mount Adaptor (34CMA

-R)

to requirements.

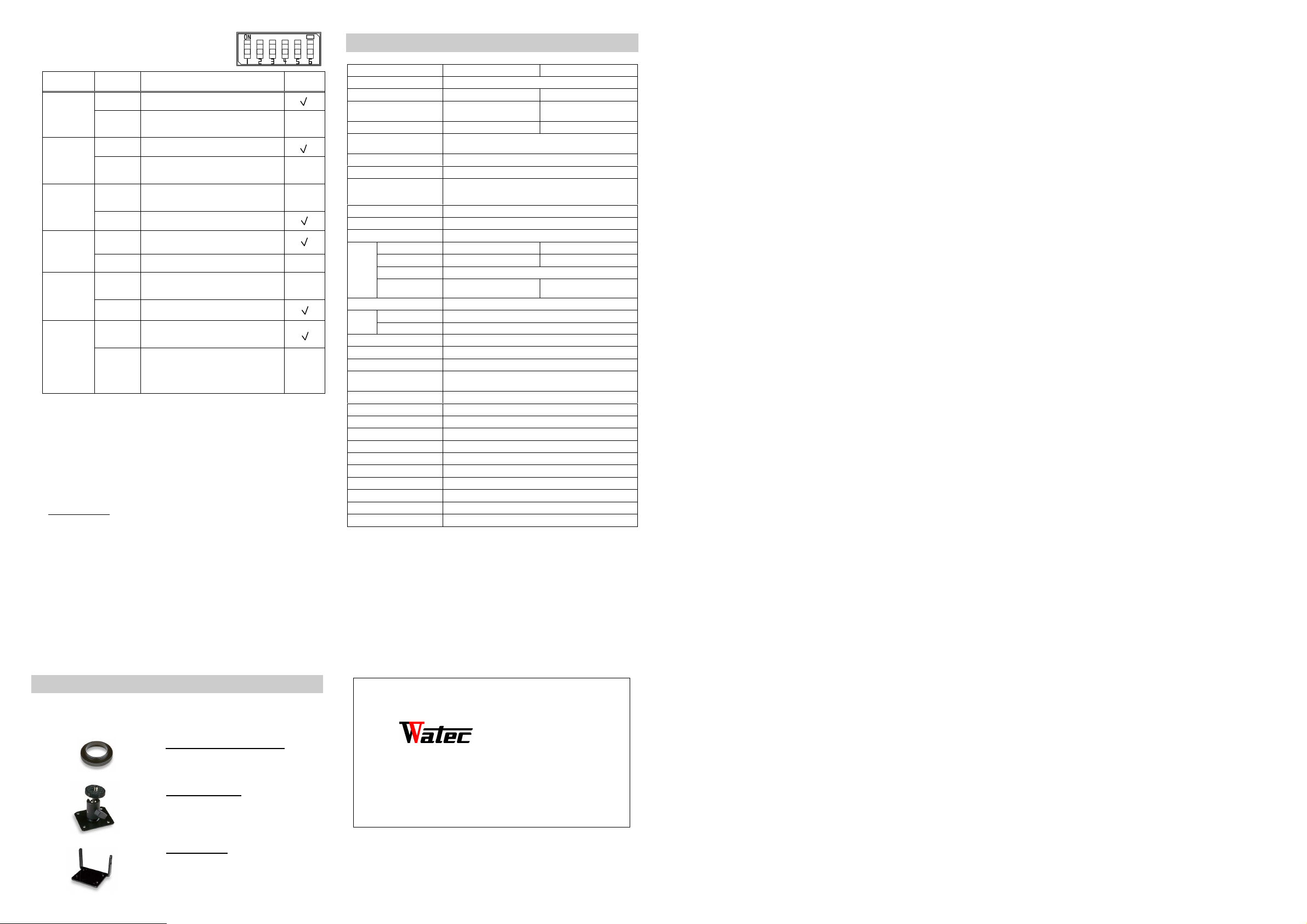

Switch Setting Effective Condition

1.

AGC

2.

AGC

3.

BLC※

4.

Gamma

Correction

5.

Video

Level

6.

ON

OFF

ON

【HI】

OFF

【LO】

ON

OFF

ON

OFF

ON

【100】

OFF

【75】

ON

【ATW】

White

Balance

※

When BLC is used and ⑦AE MODE CONTROL setting is set to either

OFF

【PWB】

When sensitivity is more important than

the SN ratio

When SN ratio is more important than

sensitivity, or when a stable lighting

condition is present

When sensitivity is more important than

SN ratio

When SN ratio is more important than

sensitivity, in addition AGC is also

required

When the picture of the monitored

object is silhouetted due to strong

lighting from above or behind

When the illumination differences

between a monitored object is narrow

Applicable to a general surveillance

monitoring system

When gamma correction is not

required for image processing

When dark areas on an object with

contrasting light and dark area are

monitored

When the standard video output level

is required

Automatically follows and adjusts to the

changing color temperature of the

illumination

Adjusted with ⑫PUSH-LOCK WHITE

BALANCE BUTTON according to the

color temperature of the environment

and fixes the resultant color

temperature at that setting

Factory

default

OFF, FL, or 1/1000, please apply an auto iris lens.

12) Correct white blemish(s) by ⑩WHITE BLEMISH CORRECTION

BUTTON. The WAT-600CX is manufactured using high-grade CCD

devices that are selected by tough standards by the manufacturer.

However, it is impossible to prevent the white blemishes from occurring

after shipment because the white blemish phenomena can be caused

by cosmic rays. The WAT-600CX has a white blemish correction circuit

to help control the white blemish phenomena. Correct according to the

following procedures, if white blemishes are present.

[PROCEDURE]

1. Completely cover the lens to prevent light entering.

2. Set to AGC ON by ⑪FUNCTION SWITCHES.

3. Set the white balance mode to PWB by ⑪FUNCTION SWITCHES.

4. Press the ⑩WHITE BLEMISH CORRECTION BUTTON using a

fine stick.

5. After 5 seconds, the white blemishes are automatically detected, and

then recorded to the camera.

※

Make sure that the lens is completely shielded from light before

correction of the white blemishes. If the lens is not covered properly

and light can enter into the lens on to the CCD face, the correction of

the white blemish may not be detected correctly.

※

Make sure that “PWB” setting is selected by ⑪FUNCTION

SWITCHES. If ATW position is selected; the data cannot be saved to

the camera.

Options

To purchase these options, please contact the distributor or dealer from

which you purchased the WAT-600CX.

This lens mount adaptor is used to

convert a CS-mount to a C-mount.

-600CX

With this stand, the camera can be

adjusted to any desired angle.

This bracket is effective for a stable

installation of the WAT-600CX.

Specifications

Model

Pick-up Element

Number of Total Pixels

Number of

Effective Pixels

Unit Cell Size

Imaging System

Sync. System

Scanning System

Video Outputs

Resolution (H)

Minimum Illumination

S/N

OFF 1/60 sec.

AE

Mode

White Balance

AGC

Gamma Characteristics

Compensation

White blemish correction

Power Supply

FL

ES

EI

(Flicker suppress)

ON

OFF

Video level

Lens iris

Back Light

Power Consumption

Operating Temperature

Operating Humidity

Storage Temperature

Storage Humidity

Lens Mount

Size

Max. cable length※

Weight

※

The normal operation of the WAT-600CX with a maximum cable length

(150m) is only ensured when a manual iris lens is used.

•

Design and specifications are subject to change without notice.

•

Watec is not responsible for any inconvenience or the attendant

WAT-600CX (NTSC) WAT-600CX (PAL)

1/3 inch interline transfer CCD image sensor

811(H)×508(V) 795(H)×596(V)

768(H)×494(V) 752(H)×582(V)

6.35μm(H)×7.4μm(V) 6.5μm(H)×6.25μm(V)

Ye, Cy, Mg, and G complementary

color mosaic filters on chip

Internal

2:1 interlace

・

BNC: VIDEO OUT/POWER IN

・

RCA: Composite video, 1.0 V(p-p) 75Ω

More than 540TVL (Center)

0.02 lx. F1.2

More than 50dB (AGC=0dB, γ= 1.0)

1/100 sec. 1/120 sec.

1/1000 sec.

1/60-1/100000 sec. 1/50-1/100000 sec.

ATW (Color rolling less), PWB

HI: 0-38dB / LO: 0-32dB

γ≒0.45(ON) / γ=1.0(OFF)

100IRE / 75IRE

Video / DC (EIAJ arrangement, Auto-select)

ON / OFF

Up to 32 dots

DC+15V

3.3W (220mA)

-10 - +50℃ (Without condensation)

Less than 95% RH

-30 - +70℃ (Without condensation)

Less than 95% RH

CS-mount (Back focus adjustable)

44(W)×44(H)×64(D) mm

150m (RG-58/U)

Approx. 140g

1/50 sec.

0dB

to the video and monitoring recording equipment caused by misuse, misoperation or improper wiring of our equipment.

•

If for any reason the WAT-600CX does not work properly, or if you have

any questions regarding installation or operation, please contact the

distributor or dealer from which it was purchased.

Watec Co., Ltd.

Watec Co., Ltd.

Add.: 254-2 Nihonkoku, Daihoji, Tsuruoka- Shi,

Yamagata-Ken, 997-0017 Japan

TEL: +81-235-23-4400 FAX: +81-235-23-4409

Email: info-o@watec.co.jp

URL: http://www.watec.net

Watec Co., Ltd.Watec Co., Ltd.

1503Z00-Y2000001

(Unbalanced)

Loading...

Loading...