Page 1

®

Sprayer Station

PRODUCT MANUAL

Item # 3349SS

Page 2

Contents

Introduction 3

Components 3

Installing the Station 4

Installing SpecWare Mobile Software 13

Configuring the WatchDog Weather Station 14

Using the WatchDog Weather Station 20

Logging Weather and GPS Data 25

Log File Format 27

Troubleshooting 28

How the Sprayer Station Works 31

Specifications 35

Copyright 2008 Spectrum Technologies, Inc.

Updated Feb 19, 2008 for 2nd Generation Connector Box

Page 3

Introduction

Thank you for purchasing the WatchDog Sprayer Station.

The Sprayer Station is designed to provide an accurate

indication and record of the environmental conditions

around a vehicle, whether it is stationary or in motion. It

allows for real-time measurement of weather data before,

during, and after a field operation.

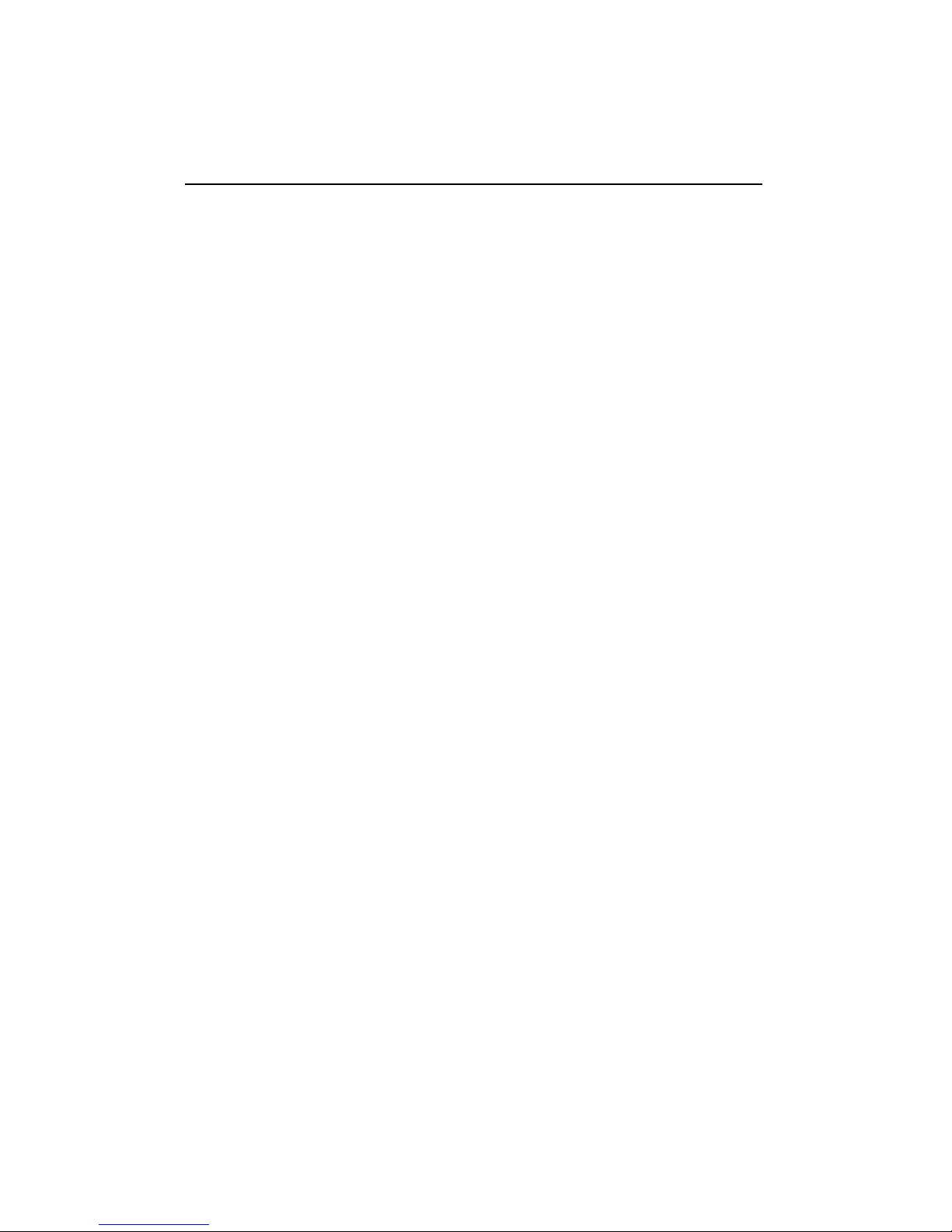

Components

Your WatchDog Sprayer Station package should contain

the following components:

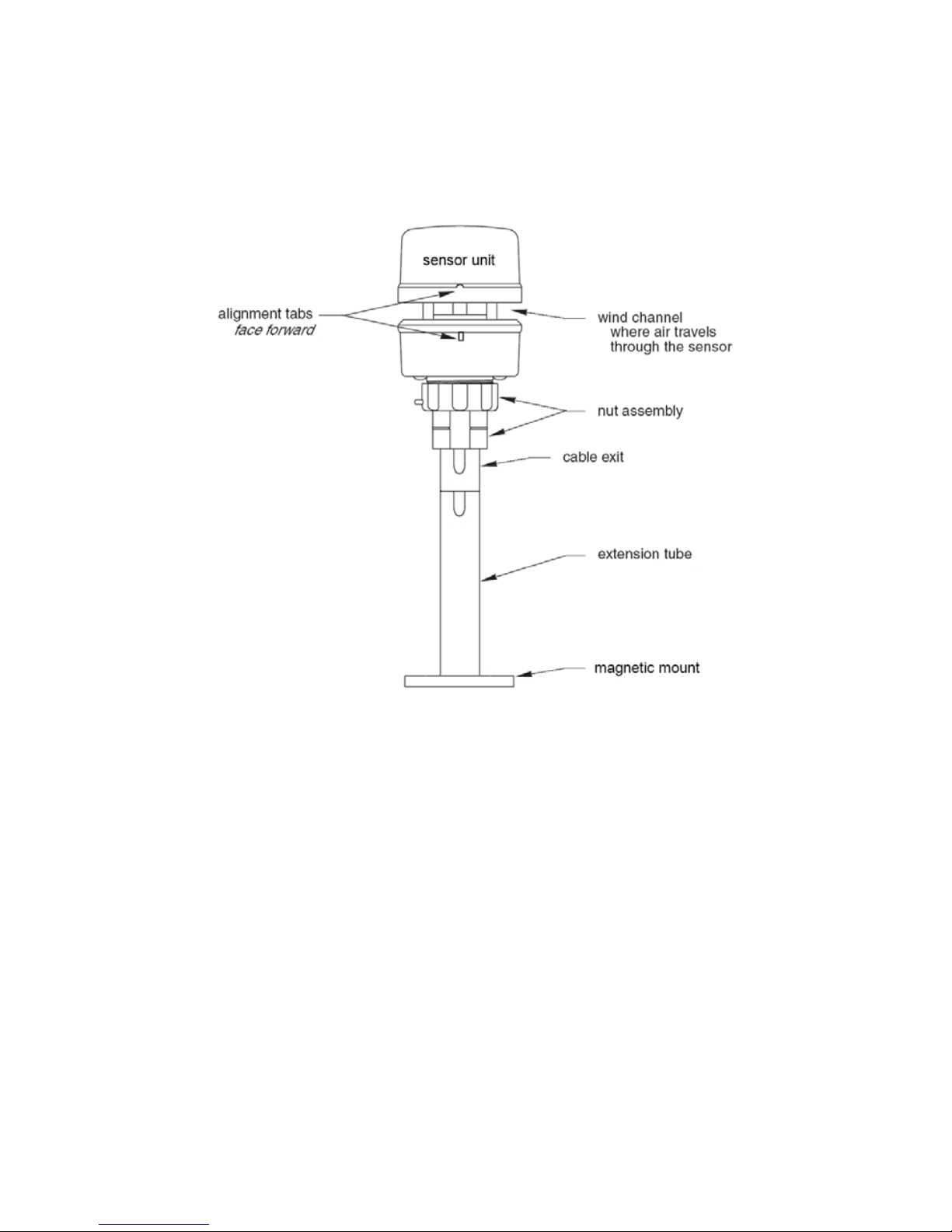

• Sensor Unit

• Mounting Post

• Cable Assembly

• Vehicle Power Adapter

• Hook & Loop Fastener Strips (2)

• SpecWare Mobile CD

• User Guide

Page 4

Installing

the Station

Caution: The blue metal plate and the blue film found in

the wind channel of the Sensor Unit are essential to its

operation. Be careful not to scratch the plate, puncture

the film, or damage them in any way.

Choosing the Mounting Location

The Sensor Unit must be mounted in “clear air”—away

from obstructions in any direction that will interfere with

air flowing through the unit. Ideally, this would be on the

roof of the cab or the tank. If the Sensor Unit is not the

highest point, be sure to mount it far enough from any obstruction so there is no interference with the air flow.

Page 5

Because the Sensor Unit has an electronic compass, it

should be at least 3' (1 m) away from strong magnetic

fields from equipment such as radio transmitters. Since it

has a GPS, be sure it is as far as possible from highpowered transmitting antennas to avoid mutual interference. Similarly, mount the Sensor Unit far enough from

an existing GPS unit to avoid interference, and to keep the

Sensor Unit from blocking the GPS unit’s view of the sky.

The Sensor Unit must be installed vertically—NOT tilted

to one side. Tilting the unit will introduce an error in the

compass reading.

If you are using the magnetic mount, remember that you

must have a steel surface to attract the magnet. With a

fiberglass roof, this usually requires applying an adhesive

steel plate, as is used to provide a mounting point for GPS

units. The magnetic mount can also be removed, and a

standard ¼” bolt can be used to attach the mounting post

to the vehicle.

Once you have decided on a location, note which direction

you want the cable to travel. At this time, you may wish

to mark the front of the mounting post (the side which will

be pointing toward the front of the vehicle).

Page 6

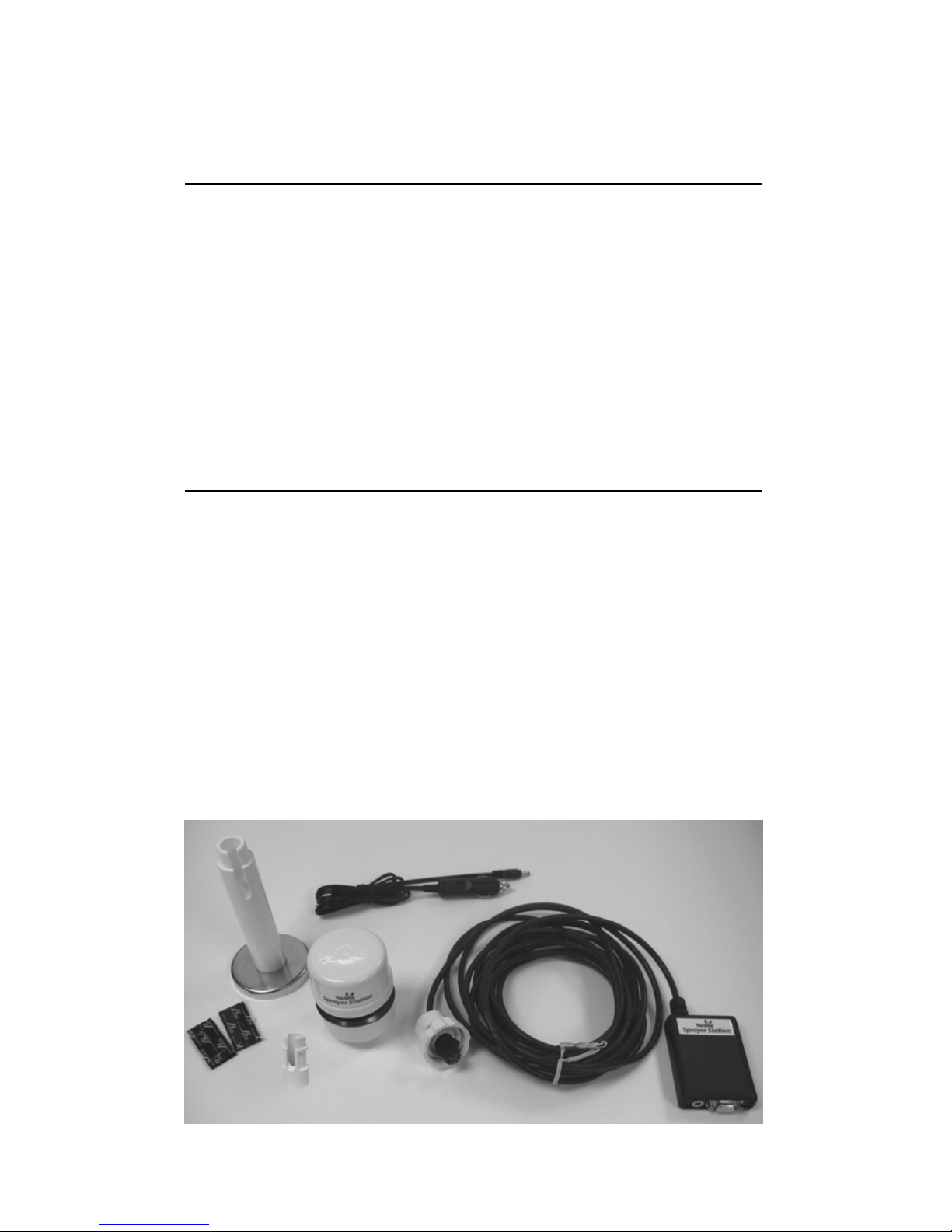

Assembling the Sensor Unit, Cable, and Mount

1. Gather the Sensor Unit, Mounting Post, and Cable Assembly.

2. With the nut assembly on the cable near the Sensor Unit

connector, slide the cable into the cable exit slot at the top

of the Mounting Tube. Leave several inches of cable

topped by the connector above the nut assembly.

3. Screw the nut assembly onto the top of the Mounting Tube.

Hand-tighten only. Do not over-tighten. Caution: If you

want to use a thread lock, use plumber’s tape. Do not use a

liquid thread lock as it may weaken the plastic, causing it to

swell and crack.

4. Remove the protective cover from the connector, and the

warning label from the bottom of the Sensor Unit. Plug the

7-pin connector into the Sensor Unit. The alignment key on

the connector fits into a notch in the base of the Sensor

Unit.

5. Be sure the alignment tabs on the Sensor Unit are facing

forward and parallel to the centerline of the vehicle. Remember to orient the front of the Mounting Post forward as

well, so the cable will exit in the correct direction. Slide

the captive nut upward and screw it onto the base of the

Sensor Unit. Hand-tighten only. Do not over-tighten. Be

Page 7

careful NOT to rotate the Sensor Unit or loosen the nut assembly from the antenna mount/extension tube. Double

check to be sure the alignment tabs are still facing forward.

Alignment

Please note that for clarity the above diagram shows the sensor

alignment tabs and the cable exit both facing forward, it is uncommon for the cable to run forward from the sensor. It would

usually run to the rear or one of the sides, and the cable exit

should be aligned accordingly. The sensor itself must face for-

Temporary Mount

For temporary mounting of the Sprayer Station, slip the cable

through an open door or window. Caution: do not damage the

cable when closing the door or window. For doors, avoid the

area near the hinges as well as near the latch. Both areas exert

extremely high forces on the cable.

Page 8

Permanent Mount

The Cable Assembly will have to be disassembled in order to

thread the cable through a hole in the wall or roof of the cab.

Although the cable will fit through a ¼” hole, a larger hole is

recommended to fit a grommet, to help ensure a watertight seal.

To disassemble the Cable Assembly:

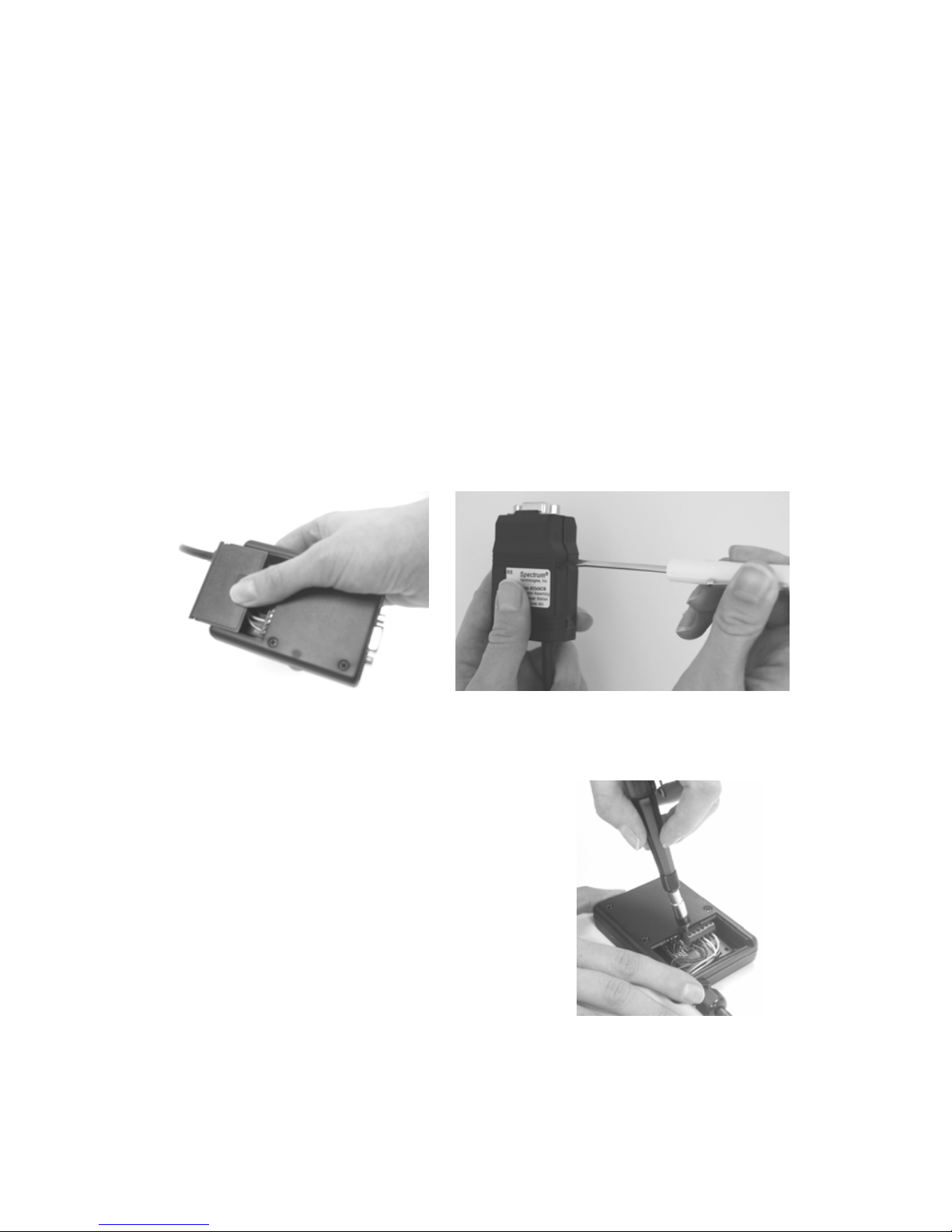

There are two versions of the connector box on the end of the

cable. The first generation box is approximately the size and

shape of a deck of cards, and has a sliding “battery cover”. The

second generation box is smaller, and is labeled as “Item

#3349CB”.

1. Open the connector box, either by sliding the “battery

cover” to remove it (first generation),

or by inserting a screwdriver in the

slots on the side and twisting to separate the top and bottom halves (second

generation).

2. Using a small screwdriver (2 mm, 2.5

mm, or 1/10” blade – a small

“electronics” screwdriver has a 1/8”

blade which will not fit), loosen the

six screws, and remove the wires from

the terminal block.

3. Loosen the outer nut on the strain relief (first generation) or

cut the wire tie holding the cable (second generation), and

pull the cable out of the connector box.

Page 9

To reassemble the Cable Assembly:

1. For a first generation box, thread the cable end through the

strain relief (it can help to remove the outer strain relief nut

completely, slipping it over the cable, and reattaching it

after the cable has been threaded through the strain relief).

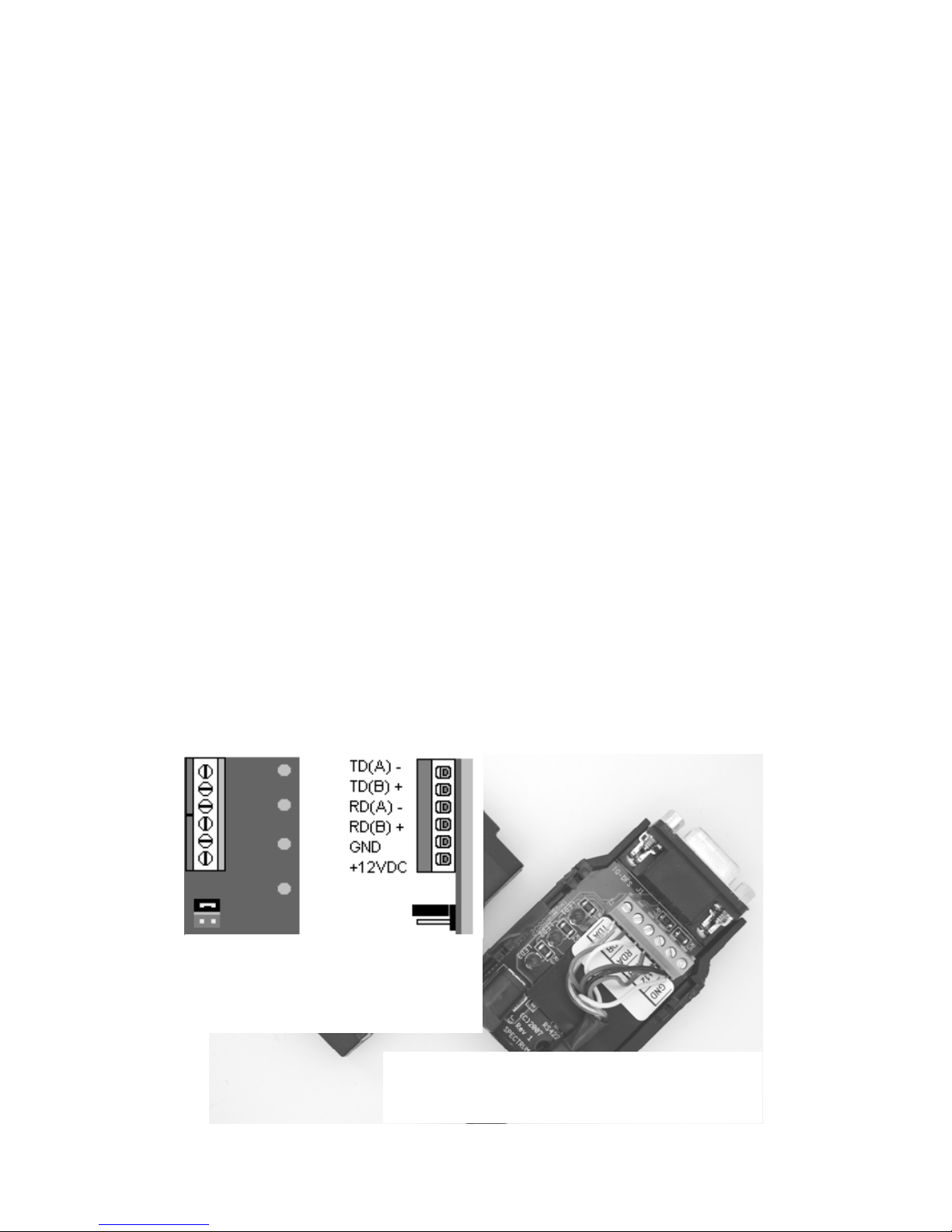

2. Thread the six wires into the holes on the side of the termi-

nal block, and tighten the screws to secure the wires. The

wire colors should be matched to the marked terminals as:

• TD(A) or TDA Yellow

• TD(B) or TDB Orange

• RD(A) or RDA White

• RD(B) or RDB Blue

• GND Black

• +12VDC or +12 Red

3. Hand-Tighten the outer strain relief nut (first generation),

or secure the cable with a wire tie through the two holes on

the circuit board (second generation).

4. Slide the “battery cover” back onto the connector box (first

generation), or press the two case halves together, making

sure the LEDs are under the holes next to the label (second

generation).

First Generation Connector

Box - Terminal Block

top view end view

Second Generation Connector Box -

Interior View (with Terminal Block)

Page 10

Connecting to your PDA or Laptop

Connect your PDA cable to the 9 pin serial connector on the

connector box. If you are using a laptop or other PC, the power

cable will prevent a direct connection. You must use either a 9

pin M-F serial extension cable, or if your laptop does not have a

serial port, a USB to Serial converter cable (available from

Spectrum Technologies as Item # 3661USB).

If your cable has anchor screws, use them to hold the cable securely to the connector box. However, Murphy’s Law states

that it is more likely that your cable will have anchor nuts, as in

the photo below.

If you encounter this situation, perform the following steps to

connect your cable securely.

For a second generation connector box, use a wrench or pliers

to unscrew the anchor nuts. No disassembly is required.

For a first generation connector box:

1. With a Phillips screwdriver, remove

the four screws from the back of the

connector box.

2. Remove the back of the connector box.

3. Using a screwdriver and a pair of pliers, remove the two nuts from the

screws holding the 9 pin serial connector .

Page 11

4. Attach your cable to the 9 pin serial connector, and tighten

the two screws to securely hold your cable.

5. Replace the back of the connector box, and secure it with

the four screws removed earlier.

Page 12

In the Cab

Attach the Vehicle Power Cable to the connector box.

Determine a location for the PDA that will provide the

best visibility and access. Next decide where the connector box will be mounted, based on the length of the PDA

cable, and the distance to the nearest power outlet. Use

the provided Hook & Loop Fastener Strips to secure the

connector box and the PDA. Coil and secure any excess

cable.

Page 13

Installing

SpecWare Mobile

Software

Insert the SpecWare Mobile installation CD in your computer’s disk drive. On most machines, the software installation will begin automatically. If it does not, run the

Setup.exe program on the CD. Follow the screen instructions to complete the installation. A desktop icon and a

Start menu entry will be created to run the PC version of

SpecWare Mobile.

Two additional menu items will be created. These will

prepare to install the the Pocket PC / Windows Mobile

2003 and the Windows Mobile 5 versions of SpecWare

Mobile for the PDA. Run whichever is appropriate for

your PDA (running the wrong install will not harm your

PDA; Windows will hold the install in anticipation of

your connecting a PDA running the other version). The

actual installation is done by ActiveSync. For those who

wish to customize the installation process, “cab” files are

placed in the SpecWare installation directory (this defaults

to “c:\SpecWare”, but can be overridden during the installation).

Once the SpecWare Mobile software is installed, you are

ready to begin using your Sprayer Station.

The current version of SpecWare Mobile software is

available on the Spectrum Technologies web site at

www.specmeters.com.

Page 14

Configuring the

WatchDog

Sprayer Station

Connect your PDA or PC/laptop to the Sprayer Station

using the cable you attached to the Connector Box earlier.

Ensure that the Sprayer Station is receiving power (there

is a pilot light on the side of the Vehicle Power Cable; the

light should be lit).

Start SpecWare Mobile using the menu or icon. There are

minor differences between the PDA and PC versions of

SpecWare Mobile. These will be pointed out as appropriate in the following instructions. All images are from the

PDA version.

The first time you run SpecWare Mobile, the following

screen will be displayed.

Page 15

The first step you must take is tell the PDA or PC where

to find the Sprayer Station. This is done by identifying

the communications (or “serial”) port the Station is

plugged into. For most PDAs, the serial port will be

“COM1”. For PDAs such as the iPaq, which do not have

a built-in serial port, a card can be added to provide a serial port. Documentation provided with these cards will

identify their port number.

If you are uncertain of the COM port on your PC, follow

the steps below.

1. If you are using a USB to Serial converter, plug it into

your PC.

2. From the Start menu, or on the Desktop, right-click

“My Computer”.

3. Select “Properties”.

4. Select the “Hardware” tab.

5. Select “Device Manager”.

6. Click on the “+” to the left of “Ports (COM & LPT)”.

A built-in serial port will be labeled “Communications

Port”. A USB converter will generally have “USB to Serial” in its name. In either case, the communications port

will be in parentheses, as in “(COM1)”.

Once you have identified the communications port you are

using, you must configure the station parameters in

SpecWare Mobile. Using your stylus, tap “Menu” in the

lower left corner. On a PC, click “Menu” in the upper left

corner. Your menu options are displayed on the next

page.

Page 16

Tap (or click) on “Configure Station”. The following

Page 17

On a PDA, a pull-down box will list the available communications ports. Select the one you are using. On a PC,

there is a text box to type in the number (without the

“COM”).

Next select the measurement system you wish to use.

English selects mph, degrees Fahrenheit, and in-Hg. Metric selects km/h or m/s, degrees Celsius, and hPa/mbar.

The Wind Alarm is set using the up/down arrows. “0”

indicates no alarm. For any other value, if the true wind

reaches or exceeds the Wind Alarm value, the wind speed

value on the main screen will have a bright yellow background (sound alarms are seldom loud enough on PDAs to

be heard over machinery).

Your Sprayer Station has been preset to send six specific

data messages to the PDA or PC. Under rare situations,

the Sprayer Station can “forget” those settings. The

“Reset Station” button is used to re-educate the Sprayer

Station.

Note: The communications ports on some PDAs were designed to omit key synchronization wires. The Sprayer

Station is so busy sending out weather data that it cannot

notice a message from the PDA or PC without those

wires. In this case, a PC would have to be used to reset

the Sprayer Station.

Tap “OK” to save your selections, and return to the main

screen.

Tap “Menu” again, and then tap “Configure Logging” to

set your data logging preferences.

Page 18

Snapshots and data logs

can be stored in one of

three locations on a

PDA (these options are

omitted from the PC

version, as “My Documents” is the only

available option).

Choosing “My Documents” places the files in the samenamed folder in the main memory of the PDA. In Microsoft ActiveSync, checking “Files” on the “Tools / Options” screen will cause ActiveSync to copy all files to a

similarly named folder in “My Documents” on your PC.

Choosing “SD Card” places the files on an Secure Digital

memory card inserted into your PDA. The SD card can be

removed and placed in a flash card reader on your PC.

Windows Explorer can be used to move the files onto

your PC.

Similarly, choosing “CF Card” places the files on an

Compact Flash memory card inserted into your PDA. The

CF card can be removed and placed in a flash card reader

on your PC. Windows Explorer can be used to move the

files onto your PC.

Some PDAs have slots for both types of flash memory

Page 19

cards, others support one type or the other. You can

change the location at any point in the future, but existing

files will not be automatically moved from the old to the

new location.

The WatchDog Sprayer Station can log location and

weather data continuously, at a specified interval. Logging is started and stopped via the “Log” button on the

main screen. If you want to disable logging, choose “No

Logging”. Otherwise select a data recording interval.

By default, all log records are written to a single file

named “Sprayer.Log.txt”. This is indicated by the “One

Log File” option.

“New Log File Each Day” places all log records in files

by day, named “Sprayer.Log.yyyymmdd.txt”.

“New File Each Log” creates a new file each time logging

is started using the “Log” button. The files are named

“Sprayer.Log.yyyymmdd.hhmm.txt”.

Checking “New Snapshot File Each Day” saves snapshots

in files named “Sprayer.Snap.yyyymmdd.txt” instead of

the default “Sprayer.Snap.txt”.

The “Log raw data” check box in the lower left corner will

activate logging of the actual weather data messages being

sent from the Sprayer Station. Most people will not want

to activate this option. It can fill all available memory in a

PDA in a short amount of time. It is provided for researchers who require the raw data, and for problem resolution.

Tap “OK” to save your selections, and return to the main

screen.

Page 20

Using the WatchDog

Sprayer Station

Start SpecWare Mobile using the menu or icon. The “No

data” screen, below, will display until the program receives weather data from the Sprayer Station Sensor Unit.

If this does not occur within 10 seconds, please refer to

the “Troubleshooting” section of this manual.

Once enough data has been received, the display will

switch to the standard display view, as shown on Page 22.

Page 21

The standard display view screen is updated once every 5

seconds, averaging the data received during that time.

The above image shows weather data without GPS information. This will be displayed until the GPS obtains a

position fix. The GPS time to first fix is one minute.

Note that a GPS fix will not be possible when there is not

a clear view of the sky, such as indoors, or in a heavily

forested location. The standard display view consists of

the following information:

Wind Direction

The wind direction is displayed in the upper left corner,

using eight compass points. If GPS data is available, the

true wind will be computed and displayed, otherwise the

apparent wind will be displayed, and the indicator

“(Apparent)” displayed below.

Apparent wind is the wind a person riding on the vehicle

would feel. True wind is the wind that would be measured if the vehicle were stationary. It is computed from

the apparent wind and the GPS-provided course and

speed.

Wind Speed

The wind speed is displayed in the upper right corner.

The units are as were specified in the Station Configuration. Either apparent or true wind speed will be displayed,

using the same rules as wind direction.

Wind Gust

The apparent or true wind gust is displayed on the first

text line.

Apparent Wind

The apparent wind direct, speed, and gust is displayed on

the second text line.

Page 22

Weather Values

The current temperature, relative humidity, and barometric pressure are displayed on the third line. Relative humidity is displayed as a percent. Temperature is displayed

in degrees Fahrenheit or Celsius, and barometric pressure

in inches or millimeters of mercury, based on whether

English or Metric units were specified in the Station Configuration.

GPS Information

GPS information is displayed on the fourth line.

Satellites

The number of GPS satellites currently being received is

displayed as a number on the right side of the fourth line.

A GPS position fix is not obtained until at least three sat-

Page 23

ellites are being received, and the more satellites, the more

accurate the position fix, and the computation of the vehicle and true wind speeds.

Monitor

On the far right of the fourth line is a small letter (a “W”

on the previous screen image). This letter should be frequently changing during normal operation. Each of the

six data messages sent by the Sprayer Station Sensor Unit

is assigned a letter which is displayed as it is received by

SpecWare Mobile. The data sentences are sent individually at one second intervals, and at times different letters

may be followed by a larger break, and therefore be easier

to see.

Page 24

Control Buttons

The control buttons are large enough to be pressed by a

fingertip. The stylus should only be needed when configuring SpecWare Mobile.

View Button

Pressing the View button cycles between the standard display, a GPS-oriented display, and a record count display

(which is used for problem resolution).

Log Button

Pressing the Log button will start and stop the logging

function. The logging interval is set in the Logging Configuration. The log button will appear different when the

logging function is active.

SnapShot Button

The SnapShot button records a snapshot of the currently

displayed wind, weather, and GPS information.

Ok Button

The “ok” button in the upper right exits SpecWare Mobile

(Use the red “X” button for the PC version).

Page 25

Logging Weather

and GPS Data

SpecWare Mobile stores logged data in one of three locations, as specified in the Logging Configuration. These

are “My Documents”, “SD Card”, and “CF Card”. See

the Configuration section for more details on these options.

Regardless of which location is specified, a folder will be

created with a name of “SprayerStation”. This folder will

contain the three types of log files. These files will be

added to until they are deleted or renamed, and then a new

file will be created.

Sprayer.Log.txt

When a log interval has been specified in Logging Configuration, and logging is activated using the Log button,

records are written to a “Sprayer.Log.txt” file. The file is

in text format, with tabs separating the values. This format can be easily imported into Excel (using the text import wizard) or other programs. The first record of the file

is a header record, identifying the columns.

By default, all log records are written to a single file

named “Sprayer.Log.txt”. This is indicated by the “One

Log File” option in “Configure Logging”. If you want to

have a separate file for each field application with full

control of the file names, stop SpecWare Mobile, and use

File (or Windows) Explorer to rename the file. Restarting

logging will create a new log file.

Alternatively, selecting “New Log File Each Day” in

“Configure Logging” places all log records in files by day,

Page 26

named “Sprayer.Log.yyyymmdd.txt”.

Similarly, the “Configure Logging” option “New File

Each Log” creates a new file each time logging is started

using the “Log” button. The files are named

“Sprayer.Log.yyyymmdd.hhmm.txt”.

Sprayer.Snap.txt

When the SnapShot button is pressed, a record is written

to the “Sprayer.Snap.txt” file. The format is the same as

the Log file.

Similar to the Log files, checking “New Snapshot File

Each Day” in “Configure Logging” saves any snapshots

in daily files named “Sprayer.Snap.yyyymmdd.txt”.

Sprayer.Raw.txt

If the “Log raw data” box is checked in “Configure Logging”, NMEA 0183 sentences from the Sensor Unit will

be written to the “Sprayer.Raw.txt” file. Most people will

not want to activate this option. It can fill all available

memory in a PDA in a short amount of time. It is provided for researchers who require the raw data, and for

problem resolution.

Page 27

Log File Format

The Log and SnapShot files contain the following data

values, separated by tabs.

Date and Time

Temperature

Relative Humidity

Dew Point

Barometric Pressure

Apparent Wind Direction

Apparent Wind Speed

Apparent Wind Gust

If a GPS position fix is available, the records will also

contain:

True Wind Direction

True Wind Speed

True Wind Gust

Satellite Count

UTC

Latitude

Longitude

Course

Speed

Page 28

Troubleshooting

If the station does not seem to be working at all

(the display shows “No data” unless the view is changed, or the

temperature, wind, etc., do not change from “0”):

1. Check that the pilot light is lit on the Power Adapter.

2. If you have a second generation connector box, confirm

that the “PWR” LED is lit.

3. Check that all connections are tight.

4. Verify that you are using the correct COM port for the station. If you are using a PDA, the most likely ports are

COM1 (for the built-in connector) or COM4 (for a CF serial card). If you are using PC with a USB-to-serial

adapter, and are uncertain of the COM port number, follow

the steps below.

• From the Start menu, select Control Panels.

• Select the System option.

• Select the Hardware tab.

• Select Device Manager.

• Select Ports.

• Look for a COM port which includes “USB” in its

name.

5. If you have a second generation connector box, ensure that

the “RX” light is blinking (this is the signal from the sensor

module). Otherwise, open the “battery cover” on the connector box and check the screw terminals with a voltmeter

to confirm that:

• “+12VDC” to “GND” is +12VDC (nominal).

• “RD(B)” to “RD(A)” cycles once per second between

+4.5VDC and 0VDC (this is the signal from the sensor

module).

5. For further investigation, reference the diagram on the next

page.

• If the prior checks show power, but not signal, remove

the sensor module from the cable and check that hole 1

(marked with a small dot) to hole 2 (clockwise next to

hole 1) reads +12VDC (nominal).

Page 29

• Disconnect the power cable from the connector box,

and use a continuity tester to check that all wires are

intact between the sensor module connector and the

screw terminals in the connector box.

If Step 4 above shows that signal is present, but it is not appearing on the PDA screen:

6. Use the PC program on a laptop to see if the problem is

with your PDA or cable.

7. Use Windows HyperTerminal on a laptop to eliminate Spec

Mobile as a problem:

IMPORTANT: Before starting HyperTerminal, note the

COM Port number that the Sprayer Station is connected to.

IMPORTANT: You must close Spec Mobile to use Hyper-

Terminal with the Sprayer Station.

1. From the Start menu, select All Programs, Accessories,

Communications. Click HyperTerminal.

2. Enter an area code if prompted.

3. Select File, then New Connection.

4. Name the connection, then click OK.

5. Select the particular COM port that the Sprayer Station

is connected to, then click OK.

6. Set the bits-per-second to 4800. Do not change any

other selection. Click OK.

7. You should see the data sentences from the Sprayer

Station scrolling on the screen, similar to the following

example.

Page 30

If a GPS position fix is not made after several minutes:

1. Ensure you are outdoors with a clear view of most of the

sky. Being able to see some sky through the trees is usually not enough.

2. Use menu option “View Station Counts”. All six record

types should have counts within one of each other. If one

or more types have counts of 0, or double the usual number,

then the Sensor Unit needs to be reset using the “Reset Station” button in Station Configuration.

If “Reset Station” doesn’t reset the station:

1. If you have a second generation connector box, watch the

“TX” LED after you click “Reset Station”. It should blink

about once per second as commands are sent to the station.

2. Some PDAs do not have the necessary wire connections to

get the attention of the Sensor Unit. Use the PC program

on a laptop instead.

Page 31

How the Sprayer

Station Works

About the Ultrasonic Wind Sensor

The ultrasonic wind sensor (an ultrasonic anemometer) measures apparent wind speed and direction. The Sprayer Station contains four

ultrasonic transducers, visible through the four holes in the top of the

sensor’s wind channel. These transducers operate in pairs—one transducer injects a pulse into the air, and the other (directly opposite to it)

listens for the arrival of that pulse. Each pulse bounces off the metal

plate at the bottom of the wind channel and is carried by the wind to

arrive at the opposing transducer a short time later.

When there is no wind, the pulse travels at the speed of so und from

the sender to the receiver. Whenever the wind is blowing in that direction, the pulse will arrive sooner than if the air is still. Similarly,

whenever the wind is blowing in the opposite direction, the pulse will

arrive later than if the air is still. The four transducers take turns in

sending and receiving pulses to cover all possible wind directions.

A microprocessor within the Sprayer Station then combines the measurements from all four transducers to calculate the resultant wind

speed and direction. Throughout this process, the sensor monitors the

air temperature, to compensate for the fact that the speed of sound in

air changes with temperature.

Understanding True and Apparent Wind

The Sprayer Station has the unique ability to display both true and

apparent wind. True wind is the actual motion of the air relative to the

earth. Apparent wind is the wind which an observ er expe riences wh ile

moving. It is the result of two motions—the actual motion of the air

(the true wind) and the motion of the vehicle. If the vehicle is not

moving, then the true and apparent wind will be the same.

There are two components to any wind measurement: speed and direction. By convention, the wind direction is an angle representing the

direction from which the wind is blowing.

Page 32

Consider the case of a vehicle proceeding at a speed of 15 mph in

calm air. An observer on board would experience a wind of 15 mph

from dead ahead. This apparent wind would be due solely to the motion of the vehicle. If a true wind of 15 mph was blowing from the

rear, an observer would experience dead calm—no apparent wind.

That is because the vehicle is moving at the same speed and in the

same direction as the surrounding air.

Now, consider the more complicated situation of a vehicle proceeding

at 15 mph with a true wind of 15 mph blowing from the side. To an

observer on board, the apparent wind would be 21.2 mph blowing

from an angle 45º off the front.

In order to calculate the true wind speed and direction when on board

a moving vehicle, it is necessary to know the apparent wind speed and

direction, the speed and course over ground of the vehicle, the compass heading, and the local magnetic variation. Note that heading and

course are not the same thing: heading is the direction the vehicle is

pointing, while course is the direction the vehicle is traveling. On

land, heading and course differ only when the vehicle is stationary.

The Sprayer Station can provide true wind speed and direction only if

all of the data is available. The speed and course over ground must be

provided by a GPS receiver––either built-in or networked. The heading may be provided by either the built-in electronic compass or b y an

external networked compass.

Because true wind is calculated using the data from several sensors,

its accuracy depends on the accuracy of all the raw data used in the

calculation. For instance, if the electronic compass is located near iron

or a similar magnetic disturbance, the heading will be incorrect, and

the true wind calculation will therefore be in error, perhaps by quite a

bit. In another example, the speed and course over ground (SOG and

COG) provided by the GPS receiver are averaged over time. If the

vehicle is performing maneuvers, changing speed and/or direction,

then it will take a few seconds for the SOG and COG values to "catch

up". The reported true wind values will therefore also be incorrect

until the vehicle reaches a steady-state condition, traveling in a

straight line at a constant speed.

About the Electronic Compass

The Sprayer Station includes a pair of magnetoinductive sensors that

measure magnetic field strength in two axes on the horizontal plane of

Page 33

the Sprayer Station. From these measurements, it calculates the resultant magnetic heading angle, thereby providing a built-in electronic

compass.

Like all magnetic compasses, the Sprayer Station compass will be

affected by any ferrous or magnetic materials in the vicinity, such as

metal structures, motors, speakers, etc. It will also be affected by

nearby electric fields, such as the wiring for lights. These nearby

sources of magnetic interference will distort the magnetic field and

produce errors in the compass heading. These errors are known as

magnetic deviation.

Although the Sprayer Station compass is a 2-axis device, the earth's

magnetic field occurs in three dimensions. That is, part of the earth's

magnetic field is oriented in the vertical direction. The closer one's

location is to the north or south pole, the stronger this vertical component becomes in comparison to the horizontal components. The effect

this has on the Sprayer Station is to introduce an error in the compass

reading if the Sprayer Station is tilted from the horizontal plane.

Therefore, it is important when installing the Sprayer Station to ensure the support pole is mounted vertically, and not tilted to one side.

Also, keep in mind that when your vehicle experiences pitch and roll,

the compass heading will be affected accordingly.

Because the compass heading is used in the calculations for true wind,

any errors in the compass heading will also produce errors in the reported true wind speed and direction. This is adjusted for in the

Sprayer Station by using the GPS-sourced course over ground when

the vehicle is moving.

About Magnetic Variation and True Heading

The earth acts like a giant magnet, with a magnetic north pole and a

magnetic south pole. The axis of the magnetic poles is offset approximately 11.5° from the axis of the earth's rotation. Therefore, the

earth's magnetic north and south poles are in different locations than

the earth's geographic north and south poles. In addition, the earth's

magnetic field is non-uniform, and changes over time. Magnetic

variation, also known as magnetic declination, is the angle between

magnetic north and true (or geographic) north, at the observer's current location.

A magnetic compass measures heading with respect to magnetic

Page 34

north. To convert this magnetic heading to true heading (that is, heading with respect to true north), the magnetic variation must be added

to the measured magnetic heading value.

Because magnetic variation changes with location and gradually over

time, it is necessary to calculate the magnetic variation using the

user's present position and the current date. Therefore it is necessary

to have a GPS with a fix in order to provide magnetic variation and

heading with respect to true north.

About the Air Temperature Sensor

The Sprayer Station includes a built-in negative-temperaturecoefficient thermistor that measures the ambient air temperature. This

NTC thermistor is located in a thermally isolated region of the

Sprayer Station housing that is open to the outside air.

About the Relative Humidity Sensor

The Sprayer Station contains a capacitive cell humidity sensor that

measures the relative humidity of the air. Humidity refers to the

amount of water vapor in the air. Relative humidity is the percentage

of saturation of the water vapor in the air. It is the ratio of the moisture content of the air to the saturated moisture level at th e same temperature and pressure.

About the Barometric Pressure Sensor

The Sprayer Station contains a temperature-compensated, silicon,

piezoresistive, pressure sensor. It measures atmospheric pressure for

use as a digital barometer

About the GPS

The Sprayer Station has a built-in Global Positioning System with its

own antenna, receiver, and position determining electronics. The GPS

receiver receives radio signals from a constellation of orbiting satellites maintained by the U.S. government. By accurately measuring the

time it takes for a transmission to travel from each satellite to the receiver, the unit is able to determine the distance between the satellite

and the receiver. When the distance is known to three satellites, the

unit is able to calculate the latitude and longitud e of the receiver. This

is known as a 2D (2 dimensional) fix. If the distance is known to four

Page 35

or more satellites, then the unit is additionally able to calculate the

altitude of the receiver. This is known as a 3D, or 3 dimensional fix.

On average, the GPS receiver in the Sprayer Station takes approximately one minute to achieve a position fix after power is first applied. This is known as the "time to first fix." The GPS receiver has

16 channels to track satellites, and will use u p to 12 satellites in co mputing a position fix.

The GPS receiver synchronizes itself to the atomic clocks on board

each satellite. This allows the GPS receiver to accurately determine

the date and time as well.

If the GPS receiver is mounted on a moving vehicle, its changing position over time allows the speed and course over ground to be calculated. The course reported by a GPS is always with respect to true

north.

The ability of the Sprayer Station to calculate true wind speed and

direction depends on the presence of a GPS fix. If the GPS receiver is

not tracking at least three satellites, then the Sprayer Station will be

unable to provide true wind data. (Apparent wind data should always

be available, regardless of the status of the GPS receiver.)

Specifications

Wind Speed Range 0.6 – 114 mph (1 to 185 km/h)

Wind Speed Resolution 0.1 mph (0.2 km/h)

Wind Speed Accuracy ±1.1 mph (±1.9 km/h) or ±4%

Wind Direction Resolution 1º

Wind Direction Sensitivity ±1.5º

Temperature Range -22 – 122ºF (-30ºC – 50ºC) *

Temperature Accuracy ±2.7ºF (±1.5ºC) *

Compass Sensing ±1º typically

Barometric Pressure Range 25 – 34 in-Hg (850 – 1150hPa)

Barometric Pressure Accuracy ±1.5%

Relative Humidity Range 10 – 95% RH

Relative Humidity Accuracy ±5% RH *

Supply Voltage 10-16VDC (nominal 12VDC)

Supply Current 0.5 amp

* Note: The Sprayer Station’s accuracy can degrade below 32ºF (0º C).

Temperature and Humidity accuracy are with wind above 2.3 mph (3.7 km/h).

Page 36

This equipment has been manufactured for

Spectrum Technologies, Inc.

12360 S. Industrial Dr. East

Plainfield, IL 60585 USA

The Manufacturer’s DECLARATION OF CONFORMITY is on file at the above

address, and certifies conformity to the following:

Model Number: 3349SS

Description: WatchDog Sprayer Station

Directive: EN 60945:1997-EMC Art 3.1b 00/05/CE

Maritime Navigation and Radiocommunication Equipment and Systems

Clauses: 9.2 Conducted Emissions

9.3 Radiated Emissions

10.2 Conducted Low Frequency Interference

10.3 Conducted Radio Frequency Interference

10.4 Radiated Interferences

10.5 Fast Transients of Signal and Control Lines

10.8 Immunity to Power Supply Failure

10.9 Immunit y to Electrostatic Discharge

Warr anty

This product is warranted to be free from defects in material

or workmanship for one year from the date of purchase. During the warranty period Spectrum will, at its option, either repair or replace products that prove to be defective. This warranty does not cover damage due to improper installation or use, lightning, negligence, accident, or

unauthorized modifications, or to incidental or consequential damages beyond the Spectrum product. Before returning a failed unit, you must obtain a Returned Materials Au-

12360 S. Industrial Dr. E

(800) 248-8873 or (815) 436-4440

E-Mail: info@specmeters.com

Plainfield IL 60585

Fax (815) 436-4460

www.specmeters.com

Loading...

Loading...