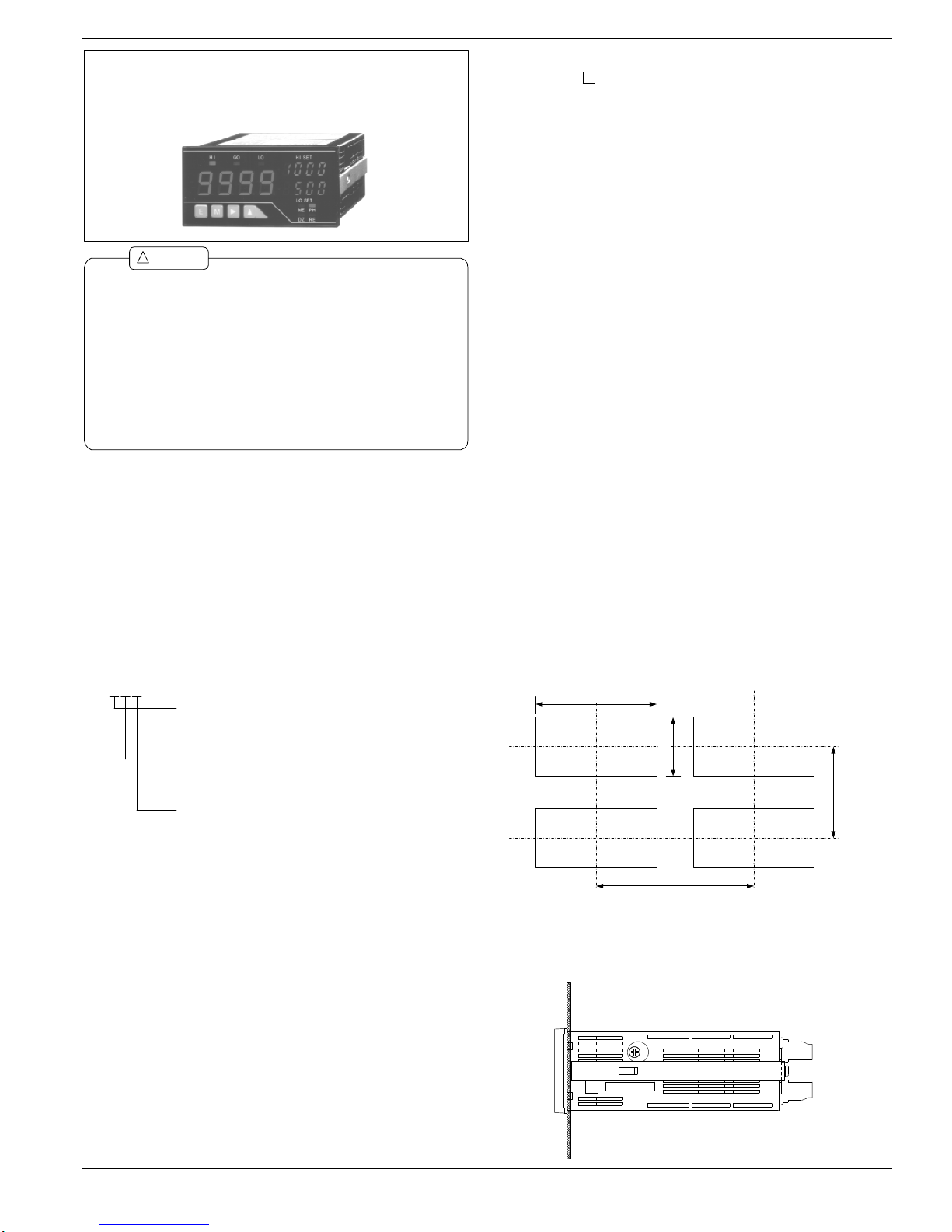

WATANABE A5000 Series Instruction Manual

1.Before Using the Product

Thank you for purchasing the A5000 series. This manual should be passed on to

the person who operates the product. Examine the product for damage caused by

transportation or any other defects. If you find any damage or defects, contact the

sales agent from which you purchased the product or Watanabe Electric

Industry Co., Ltd.

1.1.Model Codes

The model lineup of the A5000 series is shown below. Check that the model

code and specifications of your product match those you specified when

ordering.

2.Mounting the Product

2.1.Dimensions for Cutting Panel

Cut the panel for mounting according to the following dimensions.

2.2.Mounting the Product to the Panel

To mount the A5000 to the panel, remove its fittings and insert it through the

hole in the front of the panel. From the back of the panel, fix the product to the

panel with the fittings.

Instruction Manual for A5000 Series 1/12

UU-33554t

2015.12

MODEL A5000 SERIES

INSTRUCTION MANUAL

(1) Do not apply a voltage or current exceeding the maximum allowable

value; otherwise, it may damage the equipment.

(2)

Use a power voltage within the operation range; otherwise, it may result

in a fire, electrical shock, or malfunction.

(3) The contents of this manual are subject to change without notice.

Although the contents of this manual have been prepared with extra

care, if you have any questions, or find errors or missing information,

contact the sales agent from which you purchased the product or

Watanabe Electric Industry Co.,Ltd.

(4)

After reading this manual thoroughly, keep it in a convenient place for

future reference.

(5)

Caution

!

The mark on a label shows the measurement tail range of the input

specification of 8.1. clause.

(6)

01: DC voltage measuring unit

03: DC current measuring unit

02: DC voltage measuring unit

04: AC voltage measuring unit (average rms)

(range 11: ±99.99 mV)

(range 12: ±999.9 mV ; range 13: ±9.999 V)

(range 23: ±9.999 mA; range 24: ±99.99 mA)

(range 11: 99.99 mV; range 12: 999.9 mV)

05: AC voltage measuring unit (average rms)

(range 14: 99.99 V; range 15: 600 V)

06: AC voltage measuring unit (true rms)

(range 11: 99.99 mV; range 12: 999.9 mV)

07: AC voltage measuring unit (true rms)

(range 14: 99.99 V; range 15: 600 V)

08: AC current measuring unit (average rms)

(range 23: 9.999 mA; range 24: 99.99 mA)

09: AC current measuring unit (average rms)

(range 23: 9.999 mA; range 24: 99.99 mA)

10: AC current measuring unit (true rms)

(range 26: 5 A)

11: AC current measuring unit (true rms)

12: Resistance measuring unit

13: Temperature measuring unit (TC)

14: Temperature measuring unit (RTD)

15: Frequency measuring unit

(inputs: open collector, logic, and magnet)

16: Frequency measuring unit(input: 50 to 500 Vrms)

17: Strain gauze input unit (load cell)

(range 14:±99.99 V ; range 15: ±600 V)

18: Process signal measuring unit (4 to 20 mA or 1 to 5 V)

Input unit

(range 25: ±999.9 mA)

A 5 X X X - X X

(range 13: 9.999 V)

(range 13: 9.999 V)

(range 25: 999.9 mA)

(range 25: 999.9 mA)

(range 26: 5 A)

92

+0.8

-0

45

+0.6

-0

70 mm min.

120 mm min.

WATANABE ELECTRIC INDUSTRY CO., LTD.

0: None

Output unit

1: Comparison

2: Analog

3: RS-232C

4: RS-485

5: Comparison and analog

6: Comparison, analog, and RS-232C

Display unit

1: Single display

2: Multi display

Power unit

1: 100 to 240 V AC ±10%

7: Comparison, analog, and RS-485

A 5 X X X - X X

2: 9 to 60 V DC

3. Terminal Arrangement

3.1.Power

3.2.External Controls

3.3.Input Signals

3.3.1 DC Voltage Measuring Unit (Range 11)

3.3.2.DC Voltage Measuring Unit (Range 12)

3.3.3. DC Current Measuring Unit

3.3.4. AC Voltage Measuring Unit (Ranges 11 to 13)

3.3.5. AC Voltage Measuring Unit (Ranges 14 and 15)

3.3.6. AC Current Measuring Unit (Ranges 23 to 25)

3.3.7. AC Current Measuring Unit (Range 26)

3.3.8.Resistance Measuring Unit

Instruction Manual for A5000 Series 2/12

(1) Mount the product to a panel that is strong enough to hold the product.

If the panel is not strong enough or the product is not fixed tightly, it

may fall down and cause injury.

(2) The A5000 does not have a power switch, and will thus be immediately

ready for operation upon connecting it to a power supply.

(3) If the product is installed inside other equipment, provide sufficient heat

dissipation to ensure that the temperature inside the equipment does

not exceed 50℃.

Caution

!

External

control

Power

connector

Input (the shape depends on the unit.)

Comparison

output

Serial

communication

Analog output

6 7 8 9 10

1

1

12 13 14 15 16 17 18 19

20

2

1

22

2

3

24 25 26

No. Name Description

10 POWER

Power terminal without polarity for both

DC and AC

11 POWER

Power terminal without polarity for both

DC and AC

10 11

Name Description

6 HOLD

Control for hold function. Enabled when

short-circuited or at the same potential as

COM.

7 DZ

Control for digital zero function. Enabled

when short-circuited or at the same

potential as COM.

6 7 8 9

89PH

COM

No.

Control for peak hold function. Enabled

when short-circuited or at the same

potential as COM.

Common for all external control terminals.

1 2 3

Name Description

1 HI Positive input terminal

2 NC Do not connect this terminal.

3 LO

No.

Negative input terminal

Name Description

1 12

Positive input terminal for range 12

(±999.9 mV)

2 13

3 14

No.

1 2 3 4 5

4 15

5 LO Negative input terminal

Positive input terminal for range 13

(±9.999 V)

Positive input terminal for range 14

(±99.99 V)

Positive input terminal for range 15 (±600

V)

1 2 3 4 5

Name Description

1 23

Positive input terminal for range 23

(±9.999 mA)

2 24

3 25

No.

4

LO5Negative input terminal

Positive input terminal for range 24

(±99.99 mA)

Positive input terminal for range 25

(±999.9 mA)

1 2 3

Name Description

1 11-12

Positive input terminal for ranges 11

(99.99 mV) and 12(999.9 mV)

2 13

3

No.

LO

Positive input terminal for range 13 (9.999 V)

Common input terminal

1 2 3

Name Description

1 14

Positive input terminal for range 14 (99.99 V)

2 15

3

No.

LO

Positive input terminal for range 15 (600 V)

Common input terminal

1 2 3 4 5

Name Description

1 23

Positive input terminal for range 23 (9.999

mA)

2 24

3 25

No.

4

LO5Negative input terminal

Positive input terminal for range 24 (99.99

mA)

Positive input terminal for range 25 (999.9

mA)

5.8

mm

min.

5.8

mm

min.

Applicable solderless terminals

1 2

Name DescriptionNo.

1 HI Input terminal

2 LO Input terminal

1 2 3 4 5

Name Description

1 HI Input terminal for all ranges

2 LO

3 +S

No.

4

COM5

Common terminal (grounding terminal for

input circuit)

Input terminal for all ranges

Constant current for four-wire resistance

measurement(positive)

-S

Constant current for four-wire resistance

measurement(negative)

※Set to the 4-wire system when shipped.

When changing to the 2-wire system, locate

the ST1 socket on the resistance measurement

unit to the “2” positions.

4-wire

2-wire

3.3.9. Temperature Measuring Unit (TC)

3.3.10. Temperature Measuring Unit (RTD)

3.3.11. Frequency Measuring Unit (Open collector, logic, and

magnet)

3.3.12.Frequency Measuring Unit (500 Vrms)

3.3.13. Strain Gauge Input Unit (Load cell)

3.3.14. Process Signal Measuring Unit

3.4. Comparison Output

3.5. Analog Output

3.6. Serial Communication

4. Components and their Functions

The front panel design of the A5000 series of unit meters differs depending on the

display unit selected. The names and functions of each unit are as shown below.

4.1.Multi-display Unit

Instruction Manual for A5000 Series 3/12

1 2 3

Name Description

1 + Positive terminal for thermocouple

2 NC

3

No.

-

Do not connect this terminal.

Negative terminal for thermocouple

Connection of three-wire sensor

1 2 3

Name Description

1 A Resistance sensor wire

2 B

3

No.

C Elimination of wire resistance

Resistance sensor wire

The analog output at the time of a burnout becomes + side

at the time of A or B disconnection, and is set to 0V or 1V,

and 4mA at the time of C disconnection.

When A or B is disconnection, it is displayed as OL, and when

C is disconnection, it is displayed as ----.

1 2 3 4 5

Name Description

1 HI Positive input terminal

2 LO

3 +15V

No.

4

COM5

Common terminal (grounding terminal for

input circuit)

Negative input terminal

Power output for sensor (positive)

0V Power output for sensor (negative)

1 2 3

Name Description

1 HI Input terminal

2 NC

3

No.

LO

Do not connect this terminal.

Input terminal

1 2 3 4 5

Name Description

1 +SIG Positive input terminal

2 -SIG

3 +EXC

No.

4

COM5

Common terminal (grounding terminal for

input circuit)

Negative input terminal

Power output for sensor (positive)

-EXC Power output for sensor (negative)

1 2 3

Name Description

1 V-IN Positive input terminal for 1 to 5 V range

2 A-IN

3

No.

LO

Positive input terminal for 4 to 20 mA range

Negative input terminal

12 13 14 15 16 17 18 19

Name Description

12 LO-b LO output terminal (b contact)

13 LO-c

14

No.

LO-a

Common terminal for LO output

LO output terminal (a contact)

15 GO-c Common terminal for GO output

16 GO-a

17 HI-b

GO output terminal (a contact)

HI output terminal (b contact)

18 HI-c

19 HI-a

Common terminal for HI output

HI output terminal (a contact)

24 25 26

Name Description

24 COM Common terminal for analog output

25 A-OUT

26

No.

V-OUT

Current output terminal (4 to 20 mA)

Voltage output terminal (1 to 5 V, 0 to 1 V,

and 0 to 10 V)

202122 23

Name Description

20 RXD(+)

RS-232C: transmission;

RS-485: Non-reverse output

21 TXD(-)

22

No.

NC

RS-232C: reception;

RS-485: Reverse output

Do not connect this terminal.

23 SG Common terminal for communications

(2)(3)(4)(5)

Modular jack:

RJ-14(6P 4C)

(1) Use 12 to 28 AWG wire for the power, input (except for range 26),

external control, and comparison output connectors.

(2) Tighten the screws for the power, input (except for range 26), external

control, and comparison output connectors to a torque of 0.5 to 0.6 Nm.

(3) Use 16 to 28 AWG wire for the analog output connector.

Tighten the screws of analog output connector to a torque of 0.22 to

0.25 Nm.

(4)

Caution

!

Each wiring except a power supply is given as under full-length 30m.

(5)

If 30m is exceeded, it will become out of the scope of EN/IEC standard.

(1)

(2)

(3)

(4)

(6) (7) (8) (9)

(5)

No. Name

Main Functions

During measurement During parameter setup

(1) Main display Indicates the measured value.

IIndicates information on the

parameter to be set.

Judgment

indicators

HI

(2) GO

LO

Indicates the result of judgment and

turns on if the measured value > HI

judgment value.

Indicates the result of judgment and

turns on if LO judgment value ≦ the

measured value ≦ HI judgment value.

Indicates the result of judgment and

turns on if the measured value < LO

judgment value.

(3)

Function

indicators

ME Turns on if “digital zero backup” is on.

PH

Turns on if “peak hold/valley

hold/peak - valley hold” is on.

Turns on if “digital zero” is on.DZ

RE

Turns on if remote control is being

performed through RS-232C or RS485 interface.

(4) Sub-display 1

Indicates the HI side judgment value.

Indicates the item in the

maximum/minimum/(maximumminimum)/input value monitoring mode.

Indicates the LO side judgment value.

Sub-display 2(5)

Indicates information on the item in

the maximum/minimum/(maximumminimum)/input value monitoring mode.

Indicates the item to be set.

(6) Enter key

Pressing the Enter and Mode keys

together changes to the parameter

setting mode.

Pressing the Enter and Increment keys

together changes to the

maximum/minimum/(maximumminimum)/input value monitoring mode.

Switches from the

maximum/minimum/(maximummaximum/minimum/(maximumminimum)/input value monitoring mode to

the comparative judgment reading mode.

Returns to the measurement

mode.

4.2. Single Display Unit

5. Parameter Setup

5.1. Differences between Display Units

5.1.1.Multi-display Unit

Note: Pressing the Mode key displays the next parameter.

5.1.2.Single Display Unit

Note 1: Pressing the mode key with the parameter name shown changes the

display to the parameter information indication. If there is no key

operation for about one second when the parameter name is shown, the

display automatically changes to the parameter information indication

(however, this change does not automatically occur for parameters

PH/S-HI/FSC, etc., right after COND/COM/MET is indicated).

Note 2: Pressing the Mode key when the parameter information indication is

shown results in the next parameter being displayed.

Note 3: If there is no key operation for about 8 seconds with the parameter

information indication shown, the display returns to the parameter

name indication.

Mode key(7)

Pressing the Mode and Enter keys

together changes to the parameter

setting mode.

Selects the item to be set.

Pressing the Mode and Shift keys

together changes to the shift function

setup mode.

Pressing the Mode and Incremental

keys together turns on/off the “Digital

zero” indicator.

(8) Shift key

Pressing the Shift and Mode keys

together changes to the shift function

setup mode.

Selects from items in the

maximum/minimum/(maximumminimum)/input value monitoring mode.

(Hold down the key for about one second.)

Increment key(9)

Pressing the Increment and Mode keys

together turns on/off the “Digital

zero” indicator.

Pressing the Increment and Enter keys

changes to the

maximum/minimum/(maximumminimum)/input value monitoring mode.

Resets the

maximum/minimum/(maximumminimum)/input value monitoring mode.

(Hold down the key for about one second.)

Changes the value or content

of a selected digit.

(Increments the value)

(3) (1) (3)

(6) (7) (8) (9)

No. Name

Main Functions

During measurement During parameter setup

(1) Main display

Indicates the measured value.

IIndicates information on the

parameter to be set.

Indicates information on the item in

the maximum/minimum/(maximumminimum)/input value monitoring mode.

Judgment

indicators

HI

(2) GO

LO

Indicates the result of judgment and

turns on if the measured value > HI

judgment value.

Indicates the result of judgment and

turns on if LO judgment value ≦ the

measured value ≦ HI judgment value.

Indicates the result of judgment and

turns on if the measured value < LO

judgment value.

(3)

Function

indicators

ME Turns on if “digital zero backup” is on.

PH

Turns on if “peak hold/valley

hold/peak - valley hold” is on.

Turns on if “digital zero” is on.

DZ

RE

Turns on if remote control is being

performed through RS-232C or RS485 interface.

Flashes when linearization data output

values are set.

Flashes when linearization data input

values are set.

(6) Enter key

Pressing the Mode and Enter keys

together changes to the parameter

setting mode.

Pressing the Enter and Increment keys

together changes to the

maximum/minimum/(maximumminimum)/input value monitoring mode.

Switches from the

maximum/minimum/(maximummaximum/minimum/(maximumminimum)/input value monitoring mode to

the comparative judgment reading mode.

Returns to the measurement

mode.

Mode key(7)

Pressing the Mode and Enter keys

together changes to the parameter

setting mode.

Selects the item to be set.

Pressing the Mode and Shift keys

together changes to the shift function

setup mode.

Pressing the Mode and Incremental

keys together turns on/off the “Digital

zero” indicator.

(1)(2)

(6) (7) (8) (9)

Setup contents Parameter name

Setup contents and parameter name

(8) Shift key

Pressing the Shift and Mode keys

together changes to the shift function

setup mode.

Selects from items in the

maximum/minimum/(maximumminimum)/input value monitoring mode.

(Hold down the key for about one second.)

Holding down the Shift key for about

one second moves to the HI judgment

value indicator.

Increment key(9)

Pressing the Increment and Mode keys

together turns on/off the “Digital

zero” indicator.

Pressing the Increment and Enter keys

changes to the

maximum/minimum/(maximumminimum)/input value monitoring mode.

Resets the

maximum/minimum/(maximumminimum)/input value monitoring mode.

(Hold down the key for about one second.)

Changes the value or content

of a selected digit.

(Increments the value)

Holding down the Increment key for

about one second moves to the LO

judgment value indicator.

Instruction Manual for A5000 Series 4/12

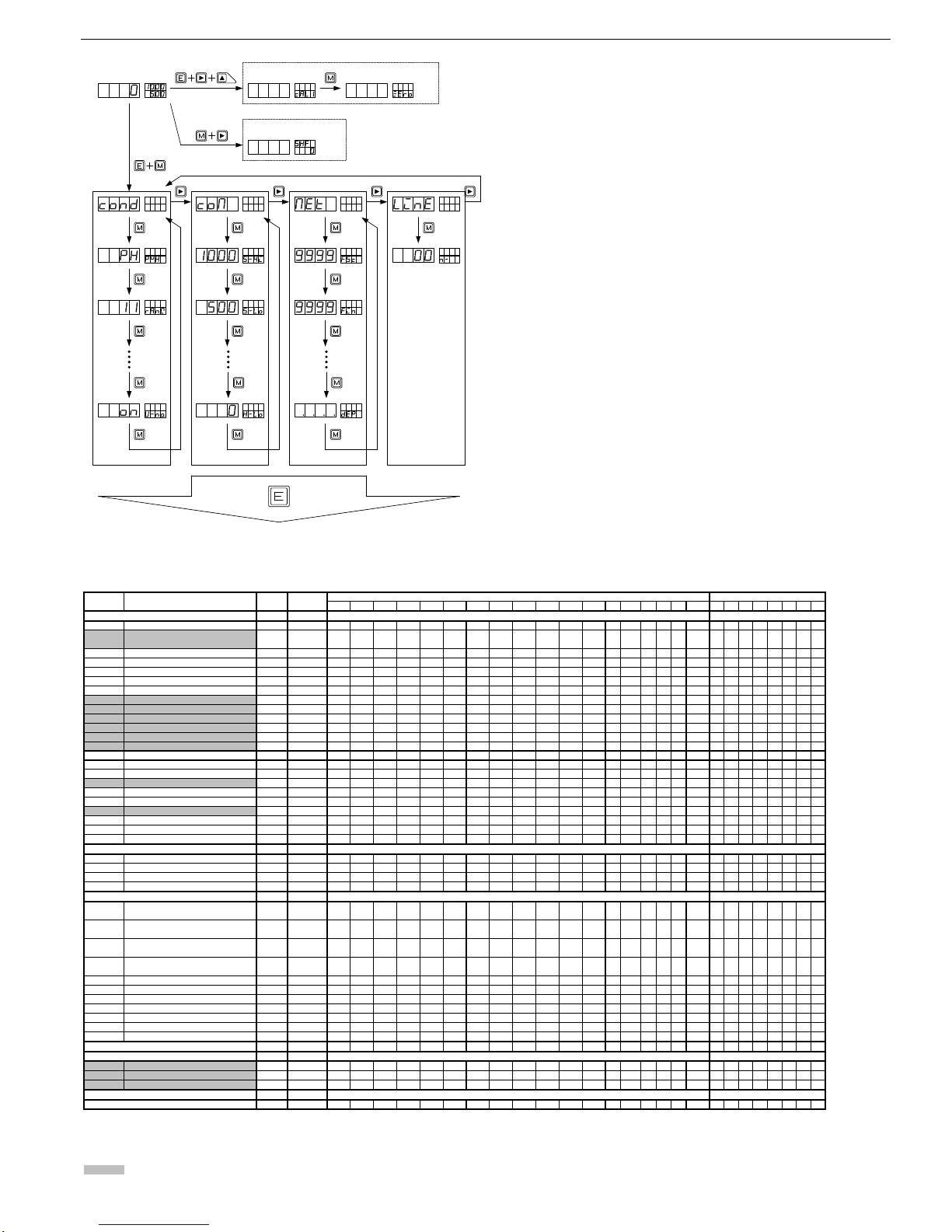

5.2. Moving to the Parameter Setup Mode

5.3. Data Lists and Default Settings

Condition data Comparator data Scaling data Linearization data

Measurement

Pressing the ENTER key saves the data and returns to the measurement mode.

Calibration data

Shift data

(Data are backed up with EEPROM even when the power is turned off.)

Instruction Manual for A5000 Series 5/12

Default Equipped

Indication Name value as 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 0 1 2 3 4 5 6 7

PVH Peak hold setup PH ○

RANG Measurement range setup *1 × ○ ○ ○ ○ ○ ○ ○ × ○ × ○ ○ ○ ○ ○ × ○

11 15 25 13 15 13 15 25 26 25 26 14 B JPB 14 14 2A

AVG Number of averaging 1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ × × ○ ○

MAV Number of moving averaging setup OFF ○

S.UD Step wide setup 1 ○

BLNK Indication blank setup OFF ○

UNIT Unit setup C × × × × × × × × × × × × ○ ○ × × × ×

BAUD Baud rate setup 9600 × × × ○ ○ × ○ ○

DATA Data length setup 7 × × × ○ ○ × ○ ○

P.BIT Parity bit setup E × × × ○ ○ × ○ ○

S.BIT Stop bit setup 2 × × × ○ ○ × ○ ○

T- Delimiter setup CR.LF × × × ○ ○ × ○ ○

ADR Equipment ID setup 00 × × × × ○ × × ○

A.OUT Analog output setup OFF × × ○ × × ○ ○ ○

B.UP Digital zero backup setup OFF ○

LINE Linearization setup CLR ○

I.SEL Input selection OC × × × × × × × × × × × × × × ○ × × ×

TR T Tracking zeroing time setup 00

○

× ×

TR V Tracking zeroing width setup *2 01

○

× ×

SNSR Sensor power setup 5 × × × × × × × × × × × × × × × × ○ ×

PON Power-on delay setup OFF ○

PRO Protect setup OFF ○

U-NO. Unit number Indication setup ON ○

S-HI HI side judgment value setup 1000 × ○ × × × ○ ○ ○

S-LO LO side judgment value setup 500 × ○ × × × ○ ○ ○

H-HI HI side hysteresis setup 0 × ○ × × × ○ ○ ○

H-LO LO side hysteresis setup 0 × ○ × × × ○ ○ ○

FSC Full scale Indication value setup *1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ × × × × × ○

9999 9999 9999 9999 9999 9999 9999 9999 9999 9999 9999 9999 9999

FIN Full scale input value setup *1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ × × × × × ○

9999 9999 9999 9999 9999 9999 9999 9999 5000 9999 5000 9999 *3

OFS Offset indication value setup *1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ × × × × × ○

0 0 0 0 0 0 0 0 0 0 0 0 0

OIN Offset input value setup *1 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ × × × × × ○

0 0 0 0 0 0 0 0 0 0 0 0 *4

PS Pre-scaling value setup 1 × × × × × × × × × × × × × × ○ ○ × ×

PPR Frequency division setup 1 × × × × × × × × × × × × × × ○ ○ × ×

DLHI Digital limiter HI value setup 9999 × × × × × × × ×

DLLO Digital limiter LO value setup -9999 × × × × × × × ×

AOHI Analog output HI indication setup 9999 × × ○ × × ○ ○ ○

AOLO Analog output LO indication setup 0 × × ○ × × ○ ○ ○

DEP Decimal point position setup None ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ × × ○ ○ ○ ○

*5 ○

ZERO Zero input value *6 0 × × × × × × × × × × × × × × × × ○ ×

SPIN Span input value *6 2000 × × × × × × × × × × × × × × × × ○ ×

SPAN Span indication 9000 × × × × × × × × × × × × × × × × ○ ×

SHF Shift data setup 0 ○

*1 Each value in the lower part of a cell in the columns on the right is the default value.

*2 Tracking zero width setup parameter is not indicated if the tracking time is set to OFF(0).

*3 5000 for 1 V range and 2000 for 2 A range

*4 1000 for 1 V range and 400 for 2 A range

*5 Linearization data are not set up for the default values.

*6 This value is not indicated if calibration is done using an actual load.

The shaded parts show the parameters that must be set for each unit.

Shift data

Input unit number Output unit number

Linearization data

Calibration data

Condition data

Comparator data

Scaling data

○○○

○

○○○

○

× × × × × × × × × × ×

× × × × × × × × × × ×

5.4. Information on Each Parameter

5.4.1Method of Setting Condition Data

This section shows a typical example of setting the peak hold parameter.

The same method applies to other parameters.

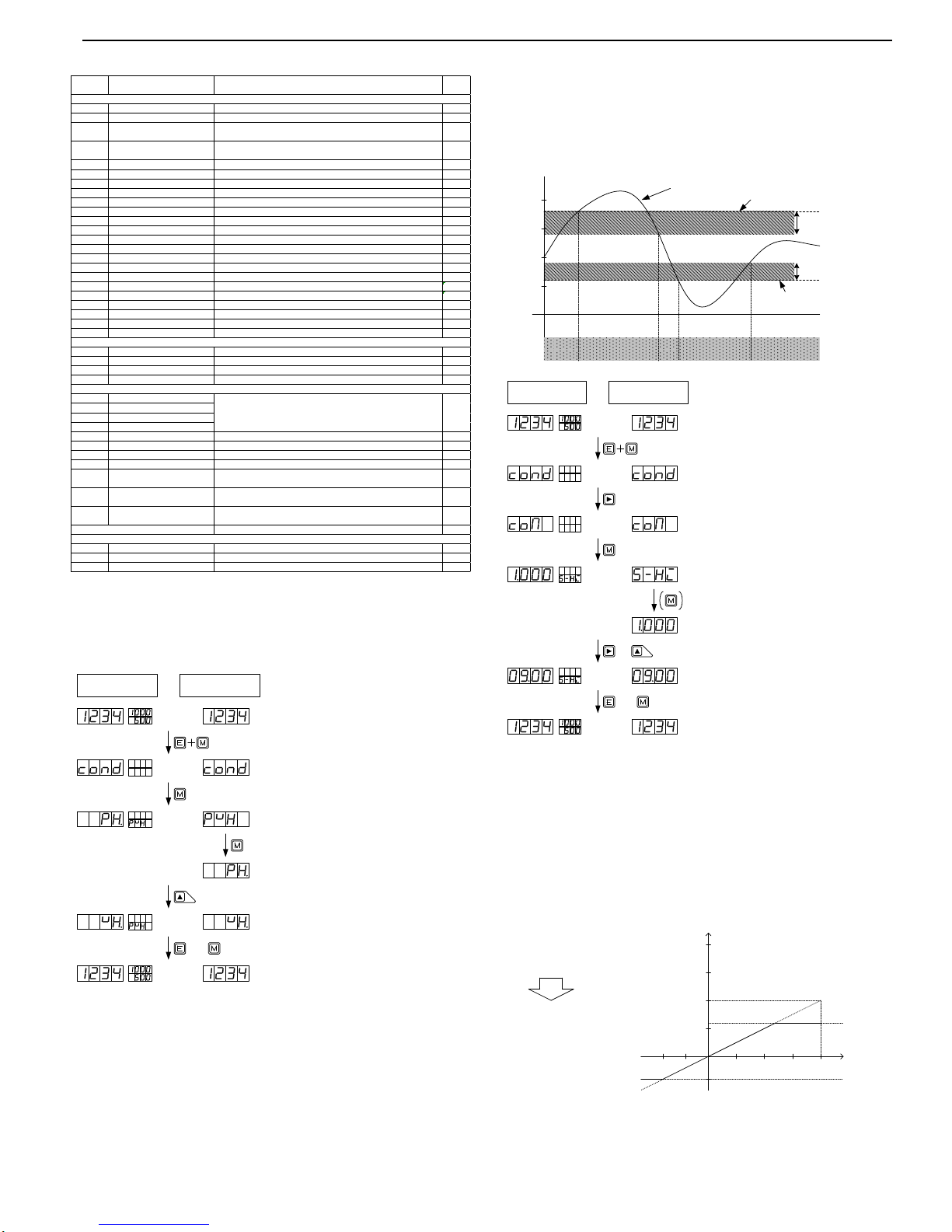

5.4.2 Method of Setting Comparator Data

This section explains comparator data and shows a typical example of setting

the HI side judgment value. The same method applies to all other parameters.

Note: The setup conditions are HI side judgment value > LO side judgment

value, HI side judgment value ³ LO side judgment value + LO side

hysteresis, and LO side judgment value £ HI side judgment value-HI

side hysteresis. If these conditions are not satisfied, an error indication

appears and the display returns to the HI side judgment value setup.

5.4.3 Method of Setting Scaling Data

This section explains comparator data and shows a typical example of setting

the full scale indication parameter. The same method applies to all other

parameters.

Note: For the Digital limiter, values larger than the DLHI setpoint are not

indicated even if signals greater that the value set in the DLHI

parameter are input (for DLLO parameter, values smaller than the

DLLO setpoint are not indicated).

Indication Name Setup options

Default

value

PVH Peak hold setup PH (peak hold)/VH (valley hold)/PVH (peak-valley hold) PH

RANG Measurement range setup *1 *1

AVG

Number of averaging operations

setup

1/2/4/8/10/20/40/80 1

MAV

Number of moving average

operations setup

OFF/2/4/8/16/32 OFF

S.UD Step width setup 1(1digit)/2(2digit)/5(5digit)/0(10digit) 1

BLNK Indication blank setup OFF/B-3/B-2/B-1/ON OFF

UNIT Unit setup C/F C

BAUD Baud rate setup 9600/4800/2400/384(38400)/192(19200) 9600

DATA Data length setup 7(7bit)/8(8bit) 7bit

P.BIT Parity bit setup E (even number), O (odd number), N (none) E

S.BIT Stop bit setup 2(2bit)/1(1bit) 2

T- Delimiter setup CR.LF(CR+LF)/CR CRLF

ADR Equipment ID setup 01 to 99 00

A.OUT Analog output setup OFF/0-1(0 to 1V)/0-10(0 to 10V)/1-5(1 to 5V)/4-20(4 to 20mA) OFF

B.UP Digital zero backup setup OFF/ON OFF

LINE Linearization setup OFF/ON CLR

I.SEL Input selection OC (open collector)/LGC (logic)/MAG (magnet) O.C

TR T Tracking zeroing time setup 00 to 99 00

TR V Tracking zeroing width setup *2 00 to 99 01

SNSR Sensor power setup 10(10V)/5(5V) 5

PON Power on delay time setup OFF/ON OFF

PRO Protect setup OFF/1 to 30 OFF

U-NO. Unit number indication setup OFF/ON ON

S-HI HI side judgment value setup -9999 to 9999 1000

S-LO LO side judgment value setup -9999 to 9999 500

H-HI HI side hysteresis setup 0 to 999 0

H-LO LO side hysteresis setup 0 to 999 0

FSC Full scale indication value setup -9999 to 9999

FIN Full scale input value setup *In the case of AC input, please use it by "+" setting by all means.

OFS Offset indication value setup It is not displayed normally when I use it by "-" setting.

OIN Offset input value setup

PS Pre-scaling value setup 0.001 to 5.000 1.000

PPR Frequency division setup 1 to 100 1

DLHI Digital limiter HI value setup -9999 to 9999 9999

DLLO Digital limiter LO value setup -9999 to 9999 -9999

AOHI

Analog output HI indication

setup

-9999 to 9999 9999

AOLO

Analog output LO indication

setup

-9999 to 9999 0

DEP

Decimal point indication position

setup

None/place of 100/place of 101/place of 102/place of 10

3

None

*2 *2

ZERO Zero input value -0.300 to 2.000 0.000

SPIN Span input value 1.000 to 3.000 2.000

SPAN Span indication 0 to 9999 9000

Condition data

Comparator data

Scaling data

Calibration data

Linearization data

*1

Multi-display unit Single display unit

or

(1) Press the Mode and Enter keys together during

measurement.

(2) Press the Mode key to change to the peak hold

setup mode.

(3) For a single display unit, press the Mode key to

change to the parameter information indication.

(The display automatically changes to this

indication in about 1 second, except right after

COND is indicated.)

(4) Press the Increment key a few times to set to

Valley Hold.

(5) Press the Enter key to return to measurement

mode. (Pressing the Mode key changes to the next

parameter).

HIGO GO LO GO

HI side hysteresis

range

Indicated value

HI side judgment value

LO side judgment value

LO side hysteresis

range

Judgment

900

500

0

1000

300

150

200

HI side judgment value

: 900

HI side hysteresis value

200:

: 300

150:

LO side hysteresis value

LO side judgment value

Multi-display unit Single display unit

or

(1) Press the Mode and Enter keys together during

measurement.

(2) Press the Shift key a few times to display the

comparator data menu.

(6) Press the Enter key to return to the

measurement mode (Pressing the Mode key

changes to the next parameter).

(5) Press the Shift key (change digit) and press the

Increment key (change numeric value) to set to 10.

&

Note:The decimal point in the selected digit

flashes.

(3) Press the Mode key a few times to display the

parameter to be set.

(4) For a single display unit, press the Mode key to

change to the parameter information indication.

(The display automatically changes to this

indication in about 1 second, except for parameter

S-HI right after COM is indicated.)

Indication

Input

5000

10V

Input voltage

: 0 to 10V

0 to 5.000:

Indication

F S C : 5000

F I N : 9999

O F S : 0

O I N : 0

DL H I : 3000

DLLO : -2000

D E P :

The place of 103 is lit.

0

DLLO

DLHI3000

-2000

Instruction Manual for A5000 Series 6/12

Loading...

Loading...