Waste King SS8000TC, SS5000TC Installation

FOOD WASTE DISPOSER

OWNER’S GUIDE

See insert for specific information about your new disposer

NOTE: This Food Waste Disposer has been designed to operate on 110-120 Volt, 60 Hz exclusively.

Using any other voltage or Hz adversely affects performance.

IMPORTANT: Read all instructions thoroughly. Keep this guide for future reference.

CAUTION: Be sure to review SAFETY INSTRUCTIONS FIRST PERTAINING TO A RISK OF FIRE, ELECTRI-

CAL SHOCK OR INJURY TO PERSONS before using disposer.

4240 E. La Palma Avenue • Anaheim, CA 92807 • www.anaheimmfg.com 560C485P01 REV A

Record important disposer information here

Model Number* Serial Number*

*Above information appears on the label affixed to bottom of the disposer. For your convenience,

write down the model and serial numbers prior to installation.

Bill of sale, sales slip, cancelled check or other purchase record should be kept to verify the original purchase

date for warranty purposes.

Call our toll free Help Line with any questions

800-854-3229

PIPE WRENCH

HACKSAW

POWER CORD

DISHWASHER CONNECTOR KIT

HAMMER DOWEL OR

STEEL PUNCH

STRAIN RELIEF

PLUMBER’S PUTTY

Tools and materials you may need

PHILLIPS & FLATBLADE

SCREWDRIVER

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO

PERSONS. SAVE THESE INSTRUCTIONS.

WARNING – When using electrical appliances, basic

precautions should always be followed, including the

following:

1. Read all instructions before using the appliance.

2. To reduce the risk of injury, close supervision is

necessary when an appliance is used near children.

3. Do not put fingers or hands into a waste disposer.

4. Turn the power switch to the off position before

attempting to clear a jam or remove an object

from the disposer.

5. When attempting to loosen a jam in a waste disposer, use a long wooden object such as a wooden

spoon or the wooden handle of a broom or mop.

6. When attempting to remove objects from a waste

disposer use long-handled tongs or pliers. If the

disposer is magnetically actuated, non-magnetic

tools should be used.

7. To reduce the risk of injury by materials that may

be expelled by a waste disposer, do not put the

following into a disposer: clam or oyster shells;

caustic drain cleaners or similar products; glass,

china or plastic; large whole bones; metal, such as

bottle caps, tin cans, aluminum foil or utensils;

hot grease or other hot liquids; whole cornhusks.

8. When not operating a disposer, leave the stopper

in place to reduce the risk of objects falling into

the disposer.

9. DO NOT operate disposer unless splash guard is

in place. (Does not apply to the Top

Control/Batch Feed units.)

10. For proper grounding instructions see the ELECTRICAL CONNECTION portion of this manual.

Before starting this step, turn off electrical power at

the circuit breaker or fuse box.

If your old mount is the same as the mount on your

new disposer, just reverse the assembly instructions

found in section 3. If your new mount system is different, follow these instructions:

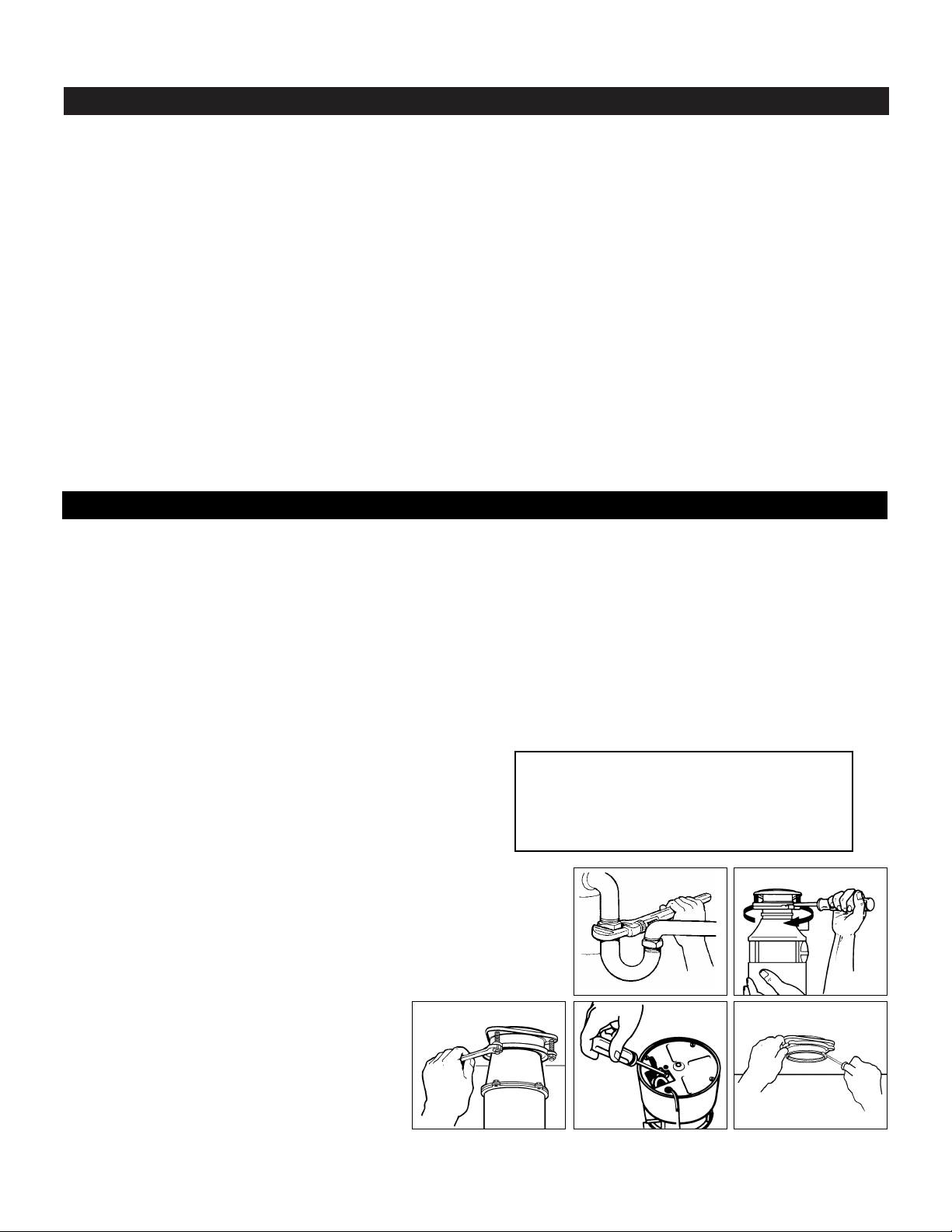

A. Use a pipe wrench to disconnect drain line where

it attaches to disposer discharge tube (see 1A).

B. Remove disposer from sink flange by turning

mount ring to the left clockwise (see 1B). If you

are unable to turn the mount ring, tap on one of

the extensions from the ring with a hammer.

Some mounting systems have tubular extensions.

Inserting a screwdriver into one tube will provide

additional leverage for turning the mount ring

(see 1B). Some disposers may require the removal

or loosening of nuts from the mount screws (see

1C). Some disposers may require the removal of a

clamp.

Caution: Be sure to support the disposer

while performing this step or it may fall

when the mounting ring is disconnected

from the mounting assembly. If your disposer is hard wired (metal shielded cable

not utilizing a wall plug), complete

steps C and D. If you utilize a plugin cord, go on to step E.

C. When disposer is removed, turn up side

down and remove electrical cover plate

(see 1D).

D. Use screwdriver to remove green ground

wire. Remove wire nuts from black and

white power wires and separate disposer wires

from power cable wires. Loosen screws on cable

clamp and separate cable from disposer.

E. To remove remaining mount system from the

sink, loosen mount screws, push mount ring up.

Under it is the snap ring. Use screwdriver to pop

off ring (see 1E). Remove mount ring, protector

ring and gasket from sink flange. Some mounts

will require the unscrewing of a large ring holding

the sink flange in place. Pull sink flange up

through sink and clean off old putty from sink.

IMPORTANT: Unless you have a new

home, this is a good time to clean out the

trap and drain lines by running a drain

auger or plumber’s snake before installing

your new disposer.

1. REMOVAL OF OLD UNIT

TYPICAL INSTRUCTIONS, YOUR MODEL MAY VARY.

1A 1B

1C 1D 1E

2. DISHWASHER CONNECTION

If you are utilizing a dishwasher, complete the following procedure. If dishwasher is not to be connected

go on to section 3.

A. Using a blunt instrument (steel punch or wooden

dowel), knock out entire plug (see 2A). Do not

use a screwdriver or sharp instrument. When

knockout plug falls into disposer, you may

remove it or simply grind it up when the disposer

is used. This will not damage the disposer in any

way, but may take some time to grind, over the

course of several uses. Go to Section 3.

B. Connect dishwasher hose using hose clamp. If

hose size is different, you will need a Dishwasher

Connector Kit (see 2B). Make sure all plumbing

connections are tight and in accordance with all

plumbing codes and ordinances. Run water and

check for leaks.

KNOCK

OUT PLUG

2B

DISHWASHER

HOSE

RUBBER

HOSE

*

AIR GAP

DISPOSER

*Air gap may not be required

for all installations. Check local

plumbing codes.

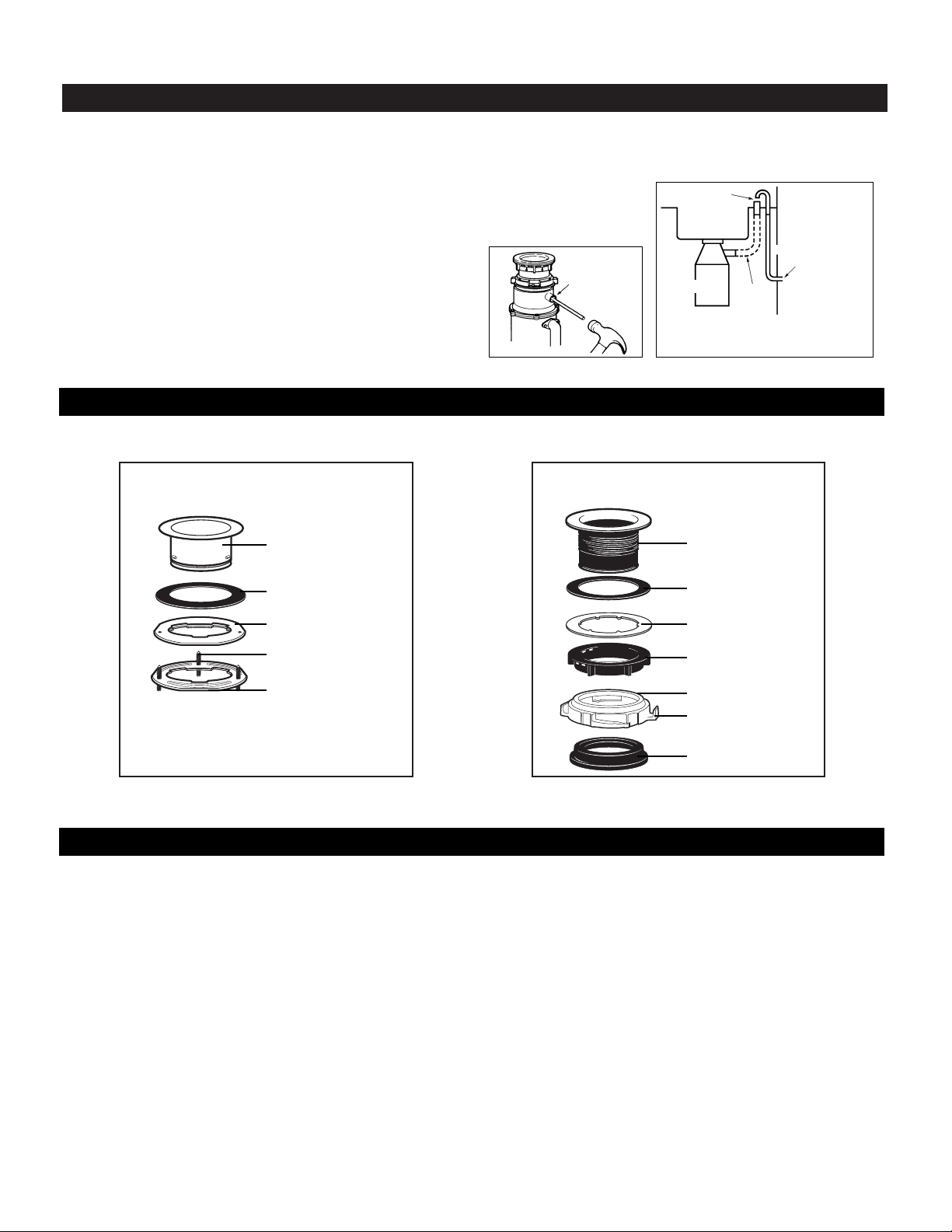

3. INSTALLATION OF MOUNTING ASSEMBLY

YOUR DISPOSER COMES WITH ONE OF THE FOLLOWING MOUNT SYSTEMS

Proceed to the instructions for your type of mount system.

3-Bolt Mount System EZ Mount System

SINK FLANGE

SINK FLANGE GASKET

PROTECTOR RING

FIBER GASKET

SINK MOUNT RING

MOUNTING SCREWS (3)

SUPPORT RING

MOUNT RING

TIGHTENING EARS

CUSHION MOUNT

SINK FLANGE*

SINK FLANGE GASKET

* An extended sink flange (Item # 3140) is

available for deep-well, cast iron sinks. (For

3-bolt mount only.)

2A

NOTE: Pay close attention to the order of mount

assembly parts, as they have been correctly assembled

by the factory. (See 3A and 3B.)

A. Disassemble the mounting assembly, as it has

been shipped, by turning the sink flange until the

projections align with the notches in the mount

ring and allow you to pull the sink flange up and

out of the remaining mount assembly. Note the

sequence of these parts as they are stacked and

refer to 3A and 3B to identify each part. Unpack

the 3 mount screws and screw them half way

through the mount ring (notice “THIS SIDE UP”

is imprinted on top of the mount ring).

Next, stack the rubber gasket on top of the protector ring and sit them on top of the pointed

ends of the mount screws.

B. Keep these assembled parts together and set aside.

Before you connect the disposer to the mount

assembly under the sink, you may want to practice engaging the groove of the Hush Cushion®

to the ridge at the bottom of the sink flange (see

3A and read Sec. 6).

C. Be sure your sink is clean. Pack the underside rim

of the sink flange with plumber’s putty (see 3C).

Position the sink flange so it is centered and readable as you look into your sink. Push the sink

3-Bolt Mount System

READ COMPLETELY BEFORE STARTING

Loading...

Loading...