Waste King 3200, 3200-000 Installation Manual

Warranty on SHURflo Macerator Pumps

napkins.

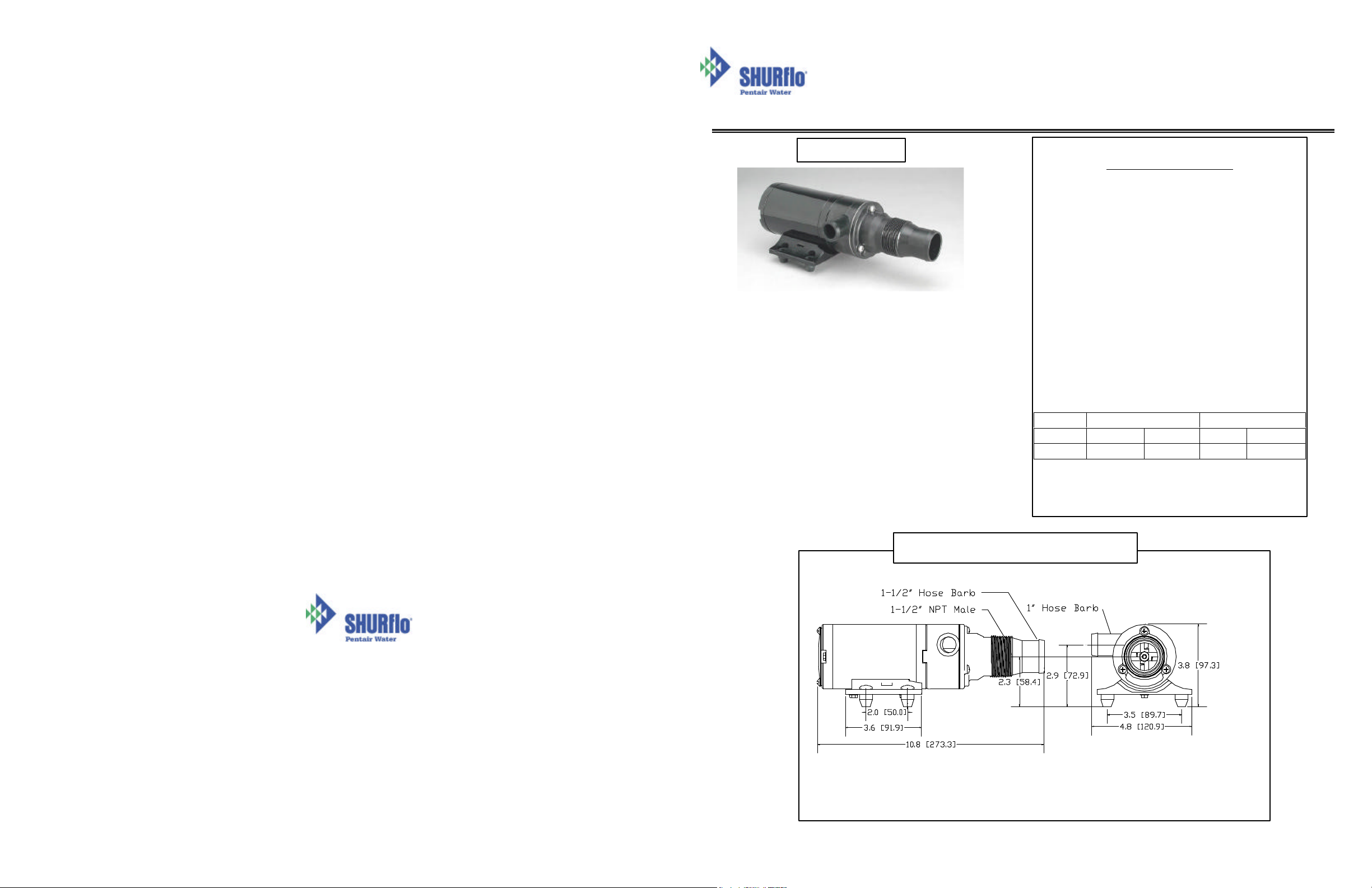

Dimensional Drawing

Typical Pump

DO NOT SHIP MACERATOR PUMPS TO SHURFLO PUMP MANUFACTURING COMPANY! Under no

circumstance will Macerator Pump returns be accepted at SHURflo Pump Co., Cypress, Elkhart or Sussex,

England for any reason. All returns must be taken to an authorized SHURflo dealer/marine store for replacement.

SHURflo warrants to the original purchaser of its products (the “Purchaser”) that such products will be free from

defects in material and workmanship under normal use for the period of one (1) year for all products except:

accessories will be free from defects in material and workmanship under normal use for the period of ninety (90)

days.

“Normal use” does not include use in excess of recommended pressures, vacuums and temperatures, or use

requiring handling of fluids not compatible with component materials, as noted in SHURflo product catalogs,

technical literature, and instructions. This warranty does not cover freight damage, freezing damage, normal wear

and tear, or damage caused by misapplication, fault, negligence, alterations, or repair that affects the performance

or reliability of the product.

THIS WARRANTY IS EXCLUSIVE. SHURflo MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

THIS IS THE EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY. IN NO EVENT SHALL SHURflo BE

LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND, WHETHER FOR BREACH

OF ANY WARRANTY, FOR NEGLIGENCE, ON THE BASIS OF STRICT LIABILITY, OR OTHERWISE.

SHURflo reserves the right to request a Material Safety Data sheet from the Purchaser for any pump or product

SHURflo deems necessary. SHURflo reserves the right to “disposition as scrap” pumps or products returned which

contain unknown substances, or to charge for any and all costs incurred for chemical testing and proper disposal

of components containing unknown substances. SHURflo requests this in order to protect the environment and

personnel from the hazards of handling unknown substances.

SHURflo may request additional information, and may require a sketch to illustrate the problem.

Contact the closest factory with questions.

SHURFLO reserves the right to update specifications, prices, or make substitutions.

Model 3200 Macerator Pump

Installation, Operation & Repair Manual

SHURflo’s macerator pump is designed to

empty marine and RV holding tanks of normal

waste. It is also an excellent choice for

emptying fish boxes of scales and residual

waste. A flow rate of up to 13 gallons per

minute conveniently empties any tank in

minutes. The unique dual-cut blade design

ensures waste is ground up thoroughly. The

pump is self-priming to a five foot lift when

impeller is wet, four foot lift when impeller is

dry, but for optimum performance and life, it

should be mounted as close to the tank as

possible. Marine pump out must be in

proper discharge zones only. This macerator

will not handle hard objects, rags, or feminine

Product Specifications

Motor: Seamless can motor, 1/8 hp

Thermally protected

Lead wires: 14 GA

Fuse: See motor label for fuse size

Pump Type: Flexible impeller

Duty Cycle: Intermittent duty only

Ports: Inlet: 1-1/2” hose barb &

1-1/2” NPT Male

Outlet: 1” hose barb

Impeller: Polyurethane

Blade: 316 stainless “Double-cut”

Dimensions: See drawing

Weight: 5 lbs.

Approvals: Ignition protected, ISO 8846

CE, and CSA, models available

Typical Flow: Dependent on fluid viscosity

Chart below based on water

Head Flow gpm[lpm] Max DC Amps

Ft [m] 12 V 24V 12V 24V

0 [0] 13 [49] 13 [49] 17 9

Maximum Operating Head = 30 feet

SHURflo, LLC Headquarters

5900 Katella Avenue

Cypress, California 90630

Phone (562) 795-5200 Ÿ Toll Free (800) 854-3218

Fax (562) 795-7564

911-566 Rev-J Page 4 of 4

©2008 SHURflo, LLC All Rights Reserved

SHURflo, LLC East

52748 Park Six Court

Elkhart, Indiana 46514-5427

Phone (562) 795-5200 Ÿ Toll Free (800) 854-3218

Fax (574) 264-2169

www.shurflo.com

SHURflo Europe, Middle East, Africa

Pentair Water Belgium bvba,

Industriepark Wolfstee, Toekomstlaan 30

B-2200 Herentals, Belgium

Phone +32-14-283500 Ÿ Fax +32-14-283505

Eco #: 16135 page 1 of 4

Electrical Connections

1 2 4 5 3 7 14

11

19 8 12 10 9 6 18 13 15 16

17

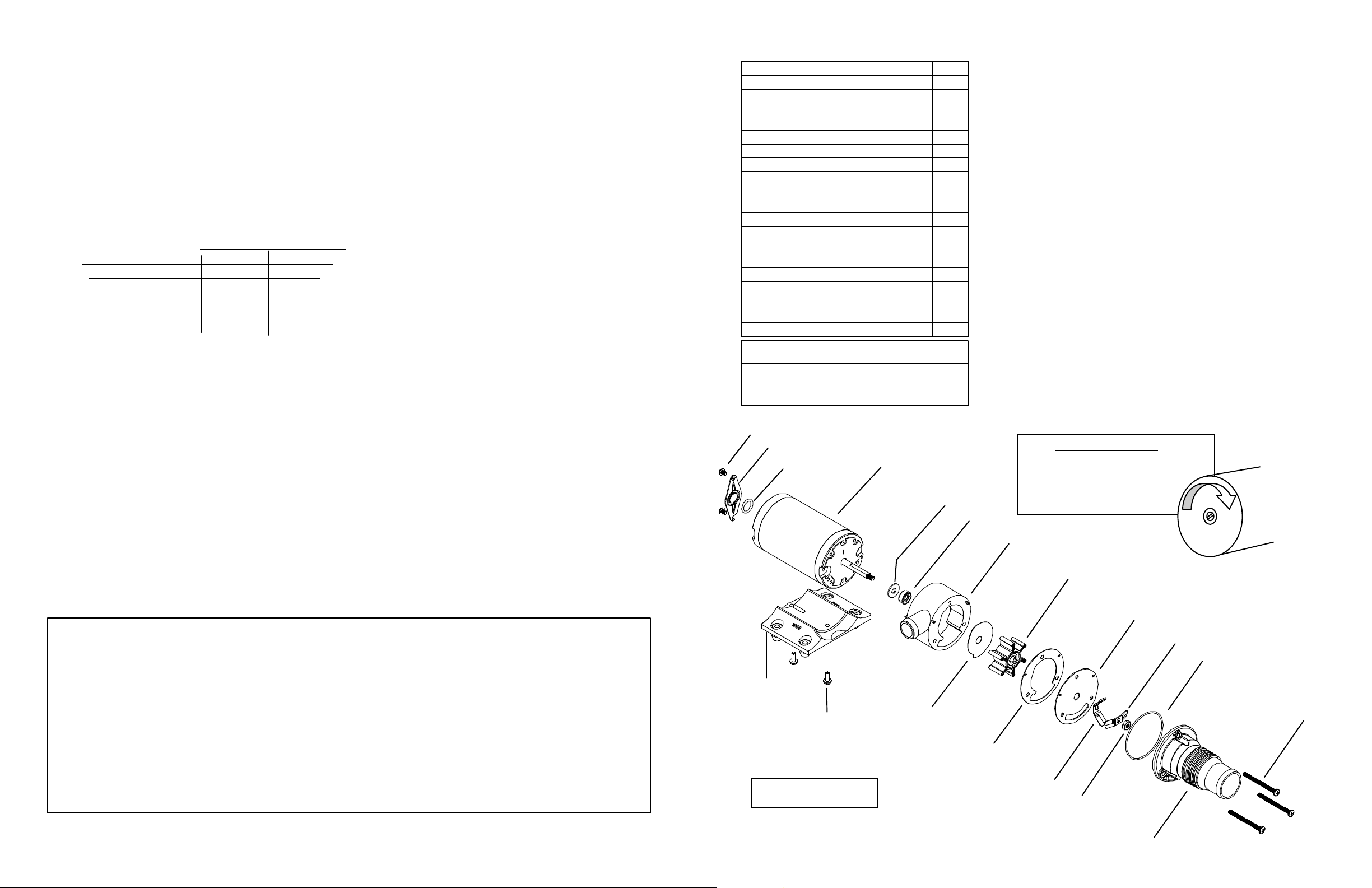

Exploded View

page 3 of 4

page 2 of 4

WARNING: If the pump is operated in an area containing flammable vapors, the wire leads must be joined by

insulated mechanical locking connectors. Loose or inadequate wire connections can spark, resulting in an

explosion resulting in property damage, injury, or death. All electrical installations should be done by a qualified

electrician.

Pump must be protected with proper size fuse as specified on the motor label.

Pump should be operated on a separate circuit.

Pump should be connected to properly sized momentary switch. This prevents pump from damage due to long

periods of dry run condition.

Switch should be near pump. This will allow operator to hear change in pump sound when tank is empty.

NOTE: For proper operation motor must rotate counterclockwise when viewed from pump end.

12 Volt System Min. Wire Size (20 Amps)

Total Wire Length * 3% Drop 10% Drop

feet [m] GA GA

1-10 [.3-3] #10 #16

11-20 [3.3-6] #8 #14

21-30 [6.4-9.1] #6 #12

30-60 [9.1-18.2] #4 #10

*length from power source to motor

and back to ground.

Electrical Installation Checklist

v Separate circuit from power source

v Proper size momentary switch mounted near pump

v Proper wire size to length

v Proper fuse size and type

v Insulated wire connectors

Plumbing Connections

Pump should be mounted as near as possible to tank to minimize dry run. Pump is self -priming to a five-foot lift

when impeller is wet, four foot lift when impeller is dry. Pump is more efficient if mounted near the holding tank.

Installations should be done by qualified marine tech.

INLET: Always install pump with a shut-off valve between pump and holding tank.

Hose: Use 1-1/2” ID [non-collapsible vacuum rated] hose on inlet [suction] side. Use stainless steel hose

clamps on all sanitation connections.

Flange: To mount to 1-1/2” female flange, inlet barb must be cut off just before threads. Seal threads and

hand tighten.

Warning: Any air leak on inlet side can cause pump to run dry and can damage

impeller and impeller housing. Check all inlet side connections, even

those on deck plates. All runs should be smooth with no kinks or sharp

Part and Kit Lists

Item

1 Cover Screw 3

2 Cutter Housing 1

3 O-Ring 1

4 Hex Nut 1

5 Top Cutter Blade 1

6 Bottom Cutter Blade 1

7 Top Wear Plate 1

8 Gasket 1

9 Impeller 1

10 Bottom Wear Plate 1

11 Impeller Housing 1

12 Shaft Seal 1

13 Slinger 1

14 Motor Assembly 1

15 O-Ring 1

16 Rear End Shaft Cover 1

17 End Cap Screw 2

18 Baseplate Assembly 1

19 Hex Bolt 2

Kit Name Kit # Kit Items

Impeller 94-571-00 8, 9

Pump Head 94-570-00 3, 7 - 13

Description Qty.

Maintenance: Turn off all power!

Rear end cap/ motor shaft slot access:

Loosen end cap screws (17). Rotate shaft cover (16) to access

slot on motor shaft.

Pump disassembly:

Remove 3 cover screws (1). Remove cutter housing (2) and oring (3). Remove hex nut (4) and cutter blades (5) & (6). It

may be necessary to hold the motor shaft steady. Insert a

screwdriver into slot on motor shaft (see slot access above),

or slip a thin wrench (9/32” [7mm]) behind blades onto flat of

motor shaft. Remove top wear plate (7), gasket (8), impeller

(9) and bottom wear plate (10). Remove impeller housing

(11) and shaft seal (12). It is not necessary to remove slinger

(13).

Pump reassembly:

Make sure slinger (13) is on shaft. Make sure shaft seal (12)

is inserted properly into rear of impeller housing (11). Slide

impeller housing (11) onto motor shaft. Seat bottom wear

plate (10) into housing. Twist impeller (9) onto shaft and

into housing with a counterclockwise motion. Install gasket

(8) and top wear plate (7). Install cutter blades (6) & (5) with

tab on bottom blade aligned with motor shaft flat. Secure

motor shaft with screwdriver or wrench (9/32”) [7mm] and

tighten hex nut (4). Position o-ring (3) and cutter housing (2)

in place, and install cover screws (1).

A Maintenance Tip!

Loosen stuck impeller by turning

motor shaft clockwise from rear

with a flat-tipped screwdriver.

OUTLET: Use 1” minimum ID hose on discharge side of pump. Connect to thru-hull fitting above highest

Operation: INTERMITTENT DUTY ONLY!

Pump switch must be near pump and tank so operator can hear pump running.

Make sure shut-off valve to pump and dump valve [if equipped] are both open. Turn on momentary switch

and pump out tank. When tank is empty, pump will get louder with a high pitch sound. Immediately turn

pump off, or damage to impeller and housing will occur. Do not run pump dry for more than 15 – 20

seconds. Flush tank and pump with water after each use. This macerator will handle normal waste,

tissues, cigarettes, fish scales, etc. It is not designed to handle large hard objects such as large bones or

fruit pits.

Periodic Maintenance and Storage: Flush with water after each use. Check wire connections

occasionally. After periods of non-use, impeller can stick. To loosen, open rear shaft cover and turn motor

shaft clockwise with a flat tip screwdriver. Then replace shaft cover. For extended periods of non-use,

pump impeller can be lubricated by running a small amount of mineral oil through holding tank system.

angles.

heeled point above waterline. Vented loop installations must vent at least 10” above highest

heeled point above waterline. Use stainless steel hose clamps on all sanitation connections.

Loading...

Loading...