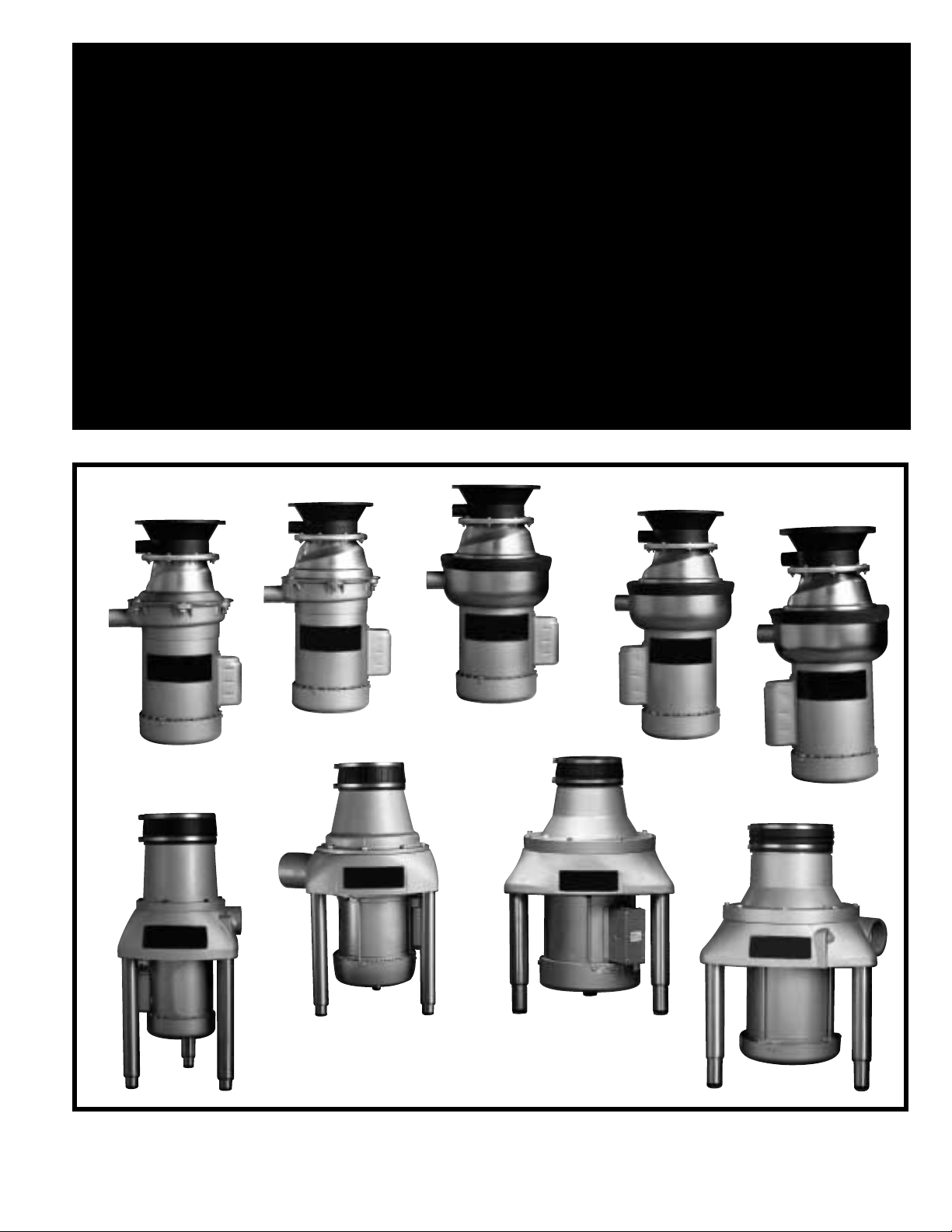

Waste King 1 1-2HP Service Manual

COMMERCIAL

FOOD WASTE

DISPOSERS

SERVICE MANUAL

1/2 HP

3/4 HP

1 1/2 HP

1 HP

1 1/4 HP

3 HP

5 HP

10 HP

2 HP

560P455P01 REV A

1. INSTALLATION INSTRUCTIONS

1/2 HP, 3/4 HP, 1 HP, 11/4 HP, and 11/2 HP Models 1-4

2 HP, 3 HP, 5 HP, and 10 HP Models 5-8

2. SINK MOUNTED MODELS DISASSEMBLY PROCEDURE 9

3. TRIPOD MOUNTED MODELS DISASSEMBLY PROCEDURE

AND GENERAL DATA

Upper Housing Disassembly 10

Grind Ring Disassembly 10

Tur ntable Disassembly 11

Tur ntable and Grind Ring Information 12

Seal Disassembly and Replacement 13

Motor Removal from Tripod 14

Small and Mid-sized Models Bearing Removal 14

Disassembly Procedure for Stator and Rotor 15

Disassembly of the Upper Motor 15

Motor Data for Models 16

Stator and Cooling Fan Removal 17

Rotor and Bearing Removal 17

End Shield Removal 18

Stator and Overload Protector Information 18

Overload Protector Terminals 19

Electrical Description and Terminals 19

Testing and Capacitor on Models 1/2 HP through 2 HP 20

Impeller Replacement 20

Cutter Blade Replacement for Models 1/2 HP through 1 HP 21

Boot Seal Replacement for Models 1/2 HP through 1 HP 21

Disassembly of Tr ipod Legs 22

4. WIRING DIAGRAM FOR ONE PHASE MOTORS 23

5. WIRING DIAGRAM FOR THREE PHASE WYE MOTORS 24

6. COMMERCIAL DISPOSER TROUBLESHOOTING CHART 25

TABLE OF CONTENTS

1

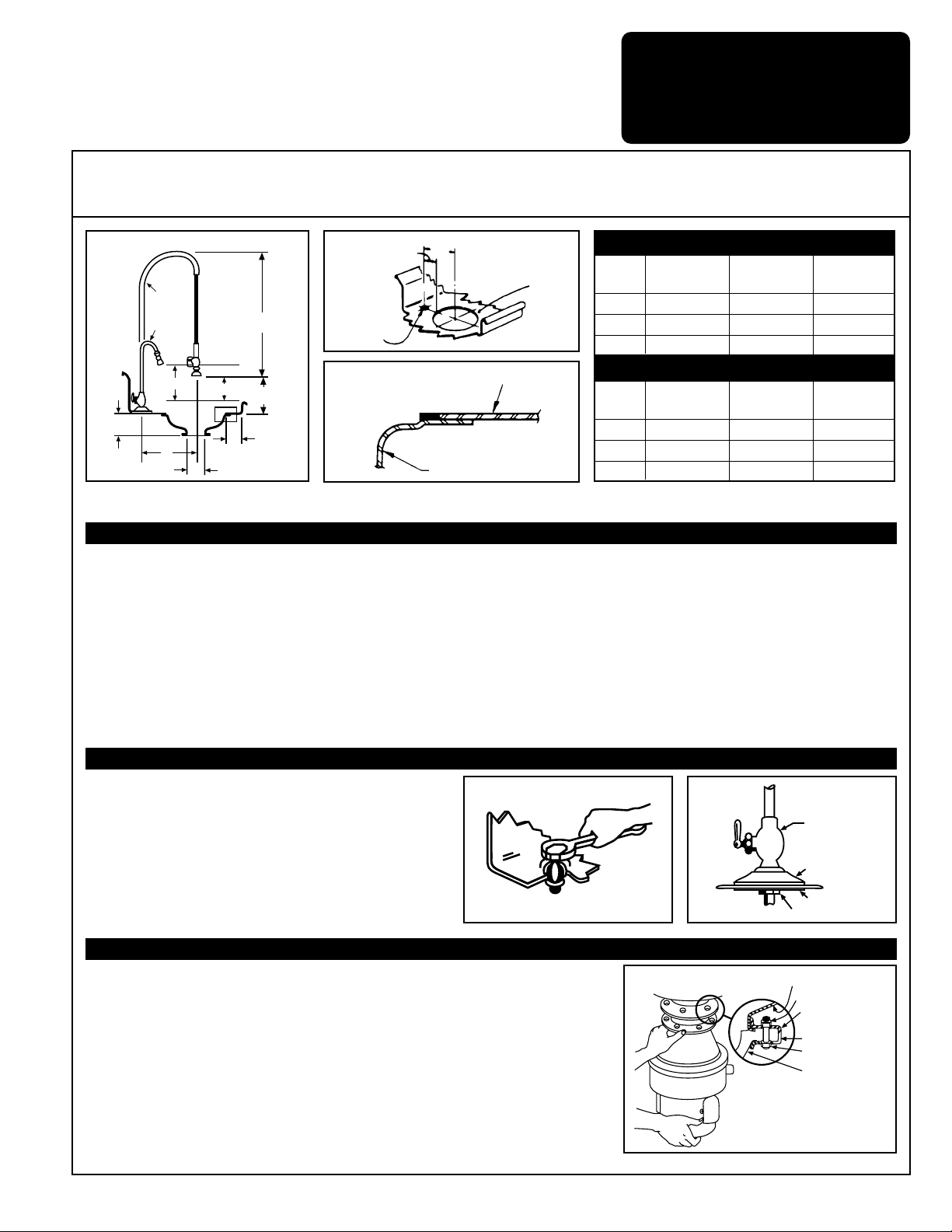

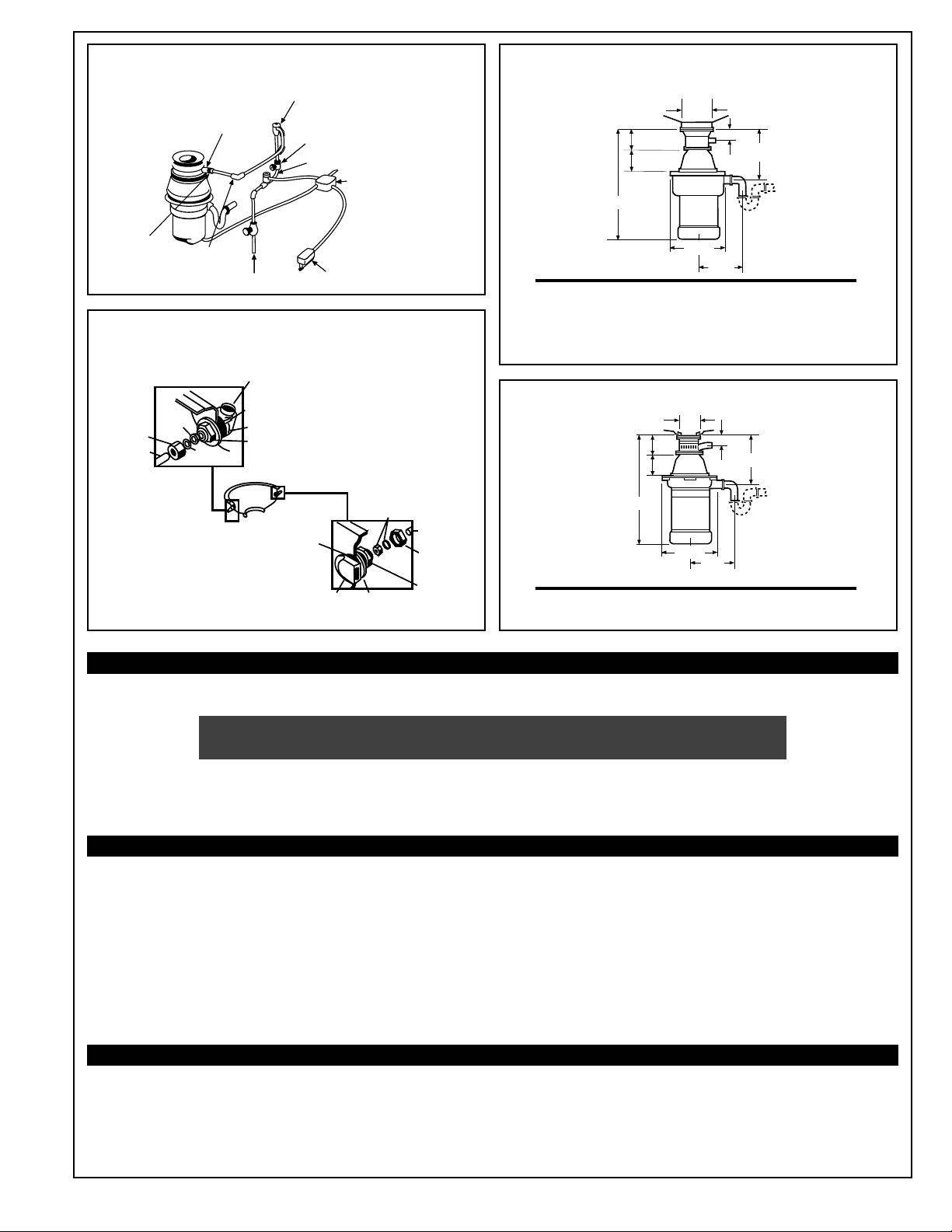

INSTALLATION OF CONE SINK INTO DISH OR WORKTABLE

1. (See Figures 1 and 2.) Locate hole center as shown on Figure 2. Cut a “C” (Figure 2) diameter hole in dish or work table, a minimum of 2”

from the inside front edge (operator’s side).Hole can be cut with a “nibbler” after a knockout hole 1-1/2” diameter has been punched.

2. Lift cone to underside of table with cone flange overlapping all around (Figures 1 and 3).

3. Check alignment of cone spray fittings to be sure they are in the proper position.For 15” and 18” cones, position such that holes are located

to right and left side of operator.(See Figure 7 for location.)

4. Tack weld, spot weld, bolt, or rivet flange of cone sink to underside of dish or work table. If bolted or riveted, smooth top surface and washsolder around bolt or rivet heads and sand smooth.

5. Bead weld or solder and wash-solder all around where the table joins flange of cone sink for a clean, watertight, sanitary installation.

6. The cone sink has been designed with the step, as shown in Figure 3.In the welding or soldering operation required to assemble the cone

sink to the dish or work table, every attempt should be made to keep the recessed, flat portion of the cone free of the welded or solder

material.This will minimize the clean-up time required and provide a smooth, flat surface for any cover.

SPRAY-RINSE INSTALLATION

1. Locate center (Figures 1 and 2).

2. Drill 7/16” diameter hole through center.

3. Assemble 7/8” punch and tighten bolt head, as shown in

Fig. 4, until the die pierces the stainless steel, leaving a

clean opening of 7/8”.

4. Place body valve and base in position, assemble washer

and locknut as shown in Figure 5.

5. Attach vol-temp assembly to the projecting nipple, as

shown in Figure 7.

MOUNTING DISPOSER

For models to be installed in sink with 3-1/2” outlet,

see separate sheet enclosed for mounting instructions.

1. Clamp ring taped to top side of Hush Cushion®should be placed on underside of

top flange of Hush Cushion®. Line up holes in clamp ring with holes in Hush Cushion

®

and insert six screws also contained in plastic bag. Insert through clamp r ing and

Hush Cushion®from the underside.

2. Line up holes in loose steel clamp ring on cone sink with screws in Hush Cushion

®

and raise disposer into position with screws matching holes in clamp ring in approximate

position with plumbing drain outlet.

3. To manually raise the disposer into position, lift the unit by grasping the disposer with

one hand from the bottom of the motor, and with the other hand around the Hush

Cushion

®

, guide the unit into position, as shown in Figure 6.

COMMERCIAL

DISPOSER MODELS

1

/2 HP, 3/4 HP, 1 HP,

1

1

/4 HP, 11/2 HP

INSTALLATION

INSTRUCTIONS

BEFORE INSTALLING, READ ENTIRE INSTRUCTIONS CAREFULLY.

RISK OF INJURY TO PERSONS FROM HAZARDOUS MOVING PARTS. SERIOUS INJURY POSSIBLE IF

NOT PROPERLY INSTALLED WITH A HOPPER OR A CONE SPECIFIED IN THE INSTRUCTION MANUAL.

IF YOU ARE REPLACING AN OLD DISPOSER GO TO

MOUNTING DISPOSER

MODEL 6T

2216 2215 2211

12” CONE 15” CONE 18” CONE

A 101/

4”11

3

/

4”13

1

/

4”

B 3

1

/2”3

1

/2”3

1

/2”

C 13

1

/2”16

1

/2”19

1

/2”

MODEL 9T

2216 2215 2211

12” CONE 15” CONE 18” CONE

A 127/8”12

7

/8”12

7

/8”

B 6

1

/8

”4

5

/8

”3

1

/8

”

C 13

1

/2”16

1

/2”19

1

/2”

FIG. 1 FIG. 2

FIG. 4 FIG. 5

FIG. 3

CO

N

FIG. 6

CONE SINK

NUT

CLAMP RING

CLAMP RING

MOUNT SCREW

HUSH CUSHION

BODY VALVE

7/8” PUNCH

BASE

WASHER

LOCKNUT

DISH TABLE

CONE SINK

APPROX.

30”

APPROX.14”

9” MIN.

6” MIN.

2” TO 4”

6”

A

6-5/8”

No.9T

SPRAY

RINSE

No.6T

SINK

HOLE

C DIA.

SPRAY

RINSE

HOLE

A

B

LOCKNUT

2

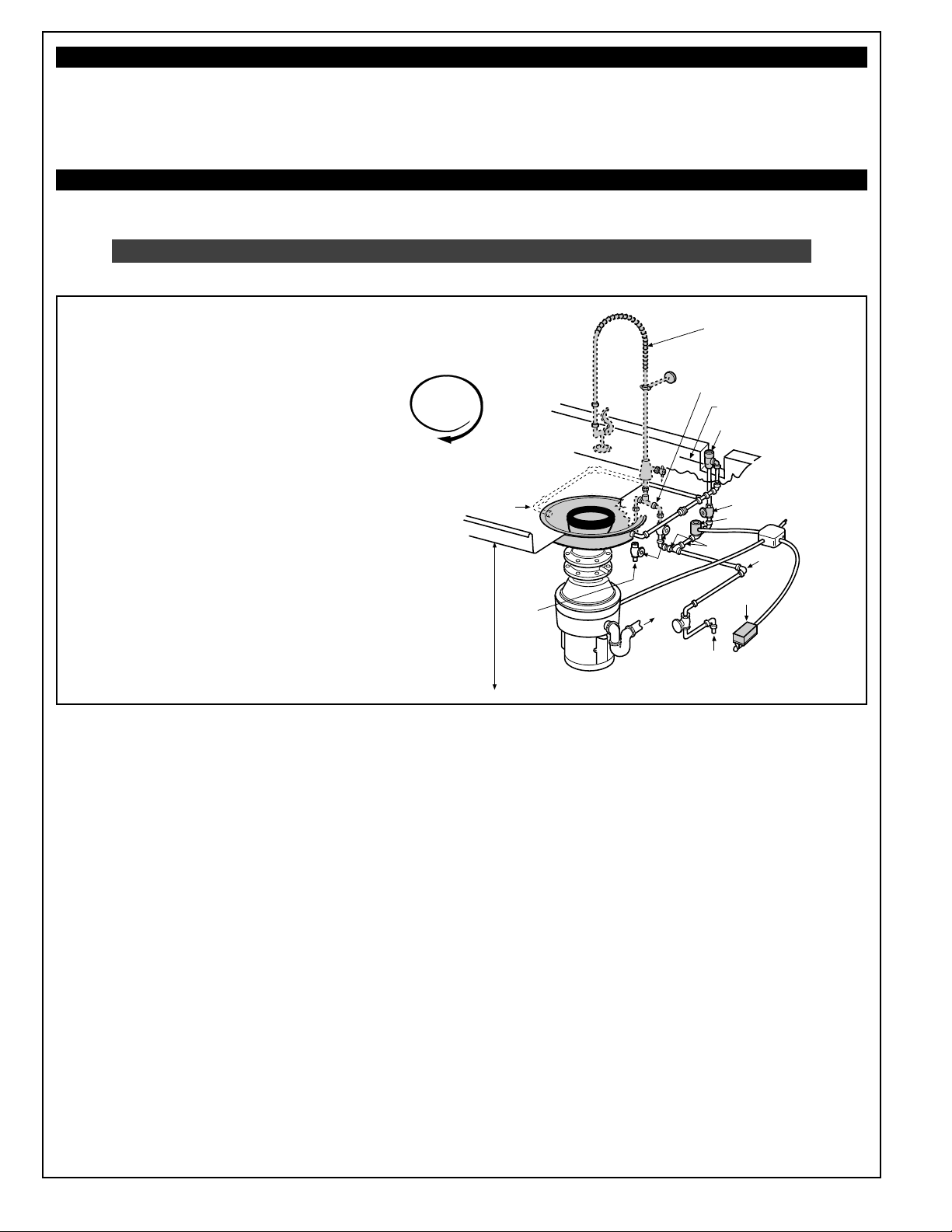

MOUNTING DISPOSER –

Continued (Refer to Figure 6)

4. Attach a nut by two or three threads to screw and then attach another nut to screw on the opposite side of disposer.Finger-tighten two

screws to hold unit in place.Attach remaining four nuts to screws and finger-tighten evenly.

5. Check alignment with plumbing. Adjustment in alignment to plumbing can be made by rotating the unit carefully before tightening the nuts.

To assist in rotating unit, raise the unit from the bottom of the motor to relieve weight.

6. With the unit in its proper position, proceed to tighten six nuts evenly.

PLUMBING INSTALLATION

IMPORTANT! Before installing the disposer, the connecting waste line must be cleaned out to the

connecting sewer main.

MAKE ALL PLUMBING AND ELECTRICAL CONNECTIONS ACCORDING TO LOCAL CODES.

Recessed thread fittings must be used throughout and all pipe ends should be carefully reamed.

1. For spray-rinse with vol-temp, run a 1/2” hot water line to point indicated in Figure 7. Connect to spray-rinse globe valve, hot water side.

At no time should hot water be connected directly to disposer or cone sink.

2. Run a 1/2” cold water connection to point indicated in Figure 7.

3. Install solenoid valve in line, in upright (coil side up) position as shown in Figure 7, with arrow on side pointing in direction of water flow.

4. Install syphon breaker as in Figure 7. CHECK LOCAL CODE.

5. Make connection to water inlet fitting of cone sink.See Figure 7.

6. Make 1/2” cold water connection to spray-rinse globe valve, cold water side.This must be separate cold water line. Do not tee off of line to

cone unless a 3/4” line is furnished to assembly location. See Figure 7.

7. Assemble swirl spray(s) as shown in Figure 9.The assembly method for the swirl spray(s) is the same for all models. Other combinations

of convertible and fixed swirl spray(s) are optional.The outlet hole of the fixed swirl spray should be horizontal to promote vortex action in

the cone.

NOTE:The convertible spray should be easily adjustable by the operator to function as a swirl spray or as a dish-washing flume.Avoid

excessive tightening of nut or locknut.

8. Connect 1/2” pipe to swirl spray as shown in Figure 7.

9. The disposer is equipped with a drain outlet designed for a slip-joint connection to a conventional 11/2” trap (not furnished). Connect the trap

with a branch waste line running directly into the sewage connection (Figure 7).Do not connect into a grease trap. A minimum slope of 1/4”

per foot of run of waste line is recommended. Limit 11/

2” drain line to a 15-foot run, free of turns. A minimum number of elbows, tees, etc.,

reduce the possibility of plumbing stoppages. If unusual sewer conditions exist (too many bends, main too long, low water pressure resulting

in low flow rate*, or if a high percentage of food waste is leafy and/or paper), the use of a time delay relay and water injector into sewer is

suggested. Under such conditions, additionally, a larger size cold water line, larger solenoid valves and larger syphon breakers should be

used to overcome potential stoppages.(Parts and data available from factory.)

*Minimum cold water flow rate used with Models

1

/2 HP through 11/2 HP: 5 gallons per minute or enough to push waste through pipeline

into the sewer.

TIP: Water volume adjustment:The top of the swirling water should occasionally crest to the body of the swirl water inlet.

10. To use the optional supplementary water connection, see Figure 8.

FIG. 7 CONE ASSEMBLY (Typical Installation)

NOTE:

A globe valve, if used for metering flow, must

be installed between solenoid valve and disposer.

See metering valve Fig.7. Any valve ahead of the

solenoid valve must be opened and cause no

restrictions.

IMPORTANT! Do not test or run disposer

without minimum water flow (see Plumbing

Installation) as this will damage the seal and

void the warranty.

MINIMUM WATER FLOW RATE

5 GALLONS PER MINUTE WHILE IN USE

NOTE:

BASE UNIT INCLUDES DISPOSER, MOUNTINGS,

AND DRAIN OUTLET. OTHER ITEMS SHOWN IN

GRAY IN FIGURE 7 ARE AVAILABLE IN

EQUIPMENT GROUPS ORDERED SEPARATELY.

Looking from top.

#9 SPRAY RINSE (OPTIONAL)

VOL-TEMP ASSEMBLY

(included with 9T)

CLOCKWISE

ROTATION

SPRAY CONE

FITTINGS

GLOBE

VALVE

1/2" HOT

WATER

SUPPLY

DISHTABLE OR

DRAIN BOARD

RIM TO FLOOR

STANDARD 34"

1-1/2"

WASTE

LINE

1" MIN. ABOVE TABLE RIM

CHECK CODE

1/2" SYPHON BREAKER

1/2" GLOBE VALVE

(for metering flow)

1/2" SOLENOID VALVE

1/2"

3/4"

SWITCH

3/4" COLD

WATER SUPPLY

3

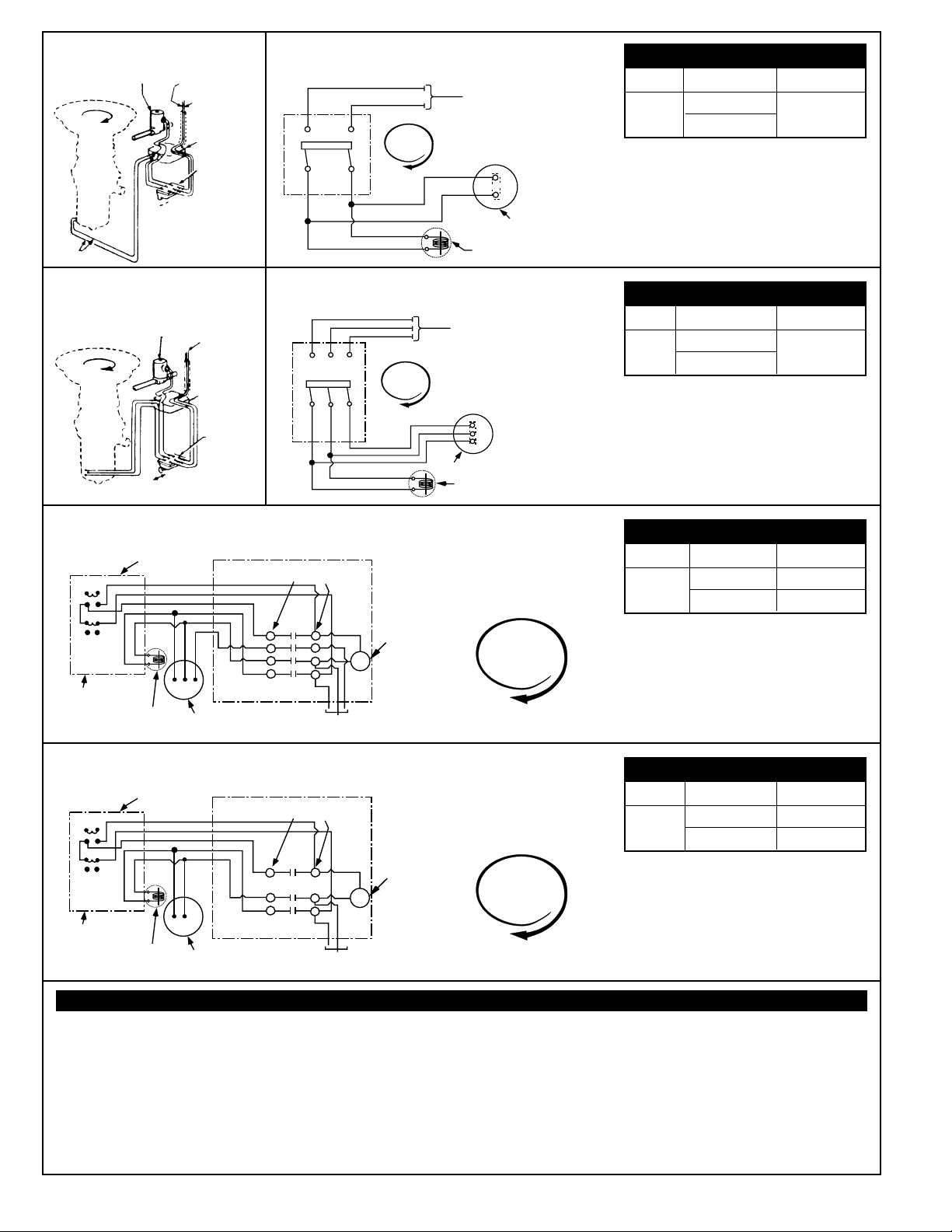

ELECTRICAL CONNECTIONS

All electrical connections must be made in accordance with local wiring codes Flexible BX cable should be used in making electrical

connections to motor to avoid transmission of noise. Be careful not to pinch wires when replacing terminal box.

IMPORTANT! THE DISPOSER MUST BE CAREFULLY AND PERMANENTLY

GROUNDED. GROUND SCREW IS PROVIDED.

Overload Protection: Reset button overload provided on all standard models.

IMPORTANT NOTE: Disposer motor phase, single or three phase, must be the same as power source and line phase.

Disposer wiring connection voltage must be the same as the voltage of power source.

ALL SINGLE PHASE MOTORS

3-Pole, 20 Amp., heavy duty switch encased in waterproof receptacle.Two poles of switch control motor and third pole controls solenoid,

isolating the two circuits to prevent solenoid kickback when switch is turned off.Refer to Figures 12 and 13 for recommended wiring installation.

SINGLE PHASE 1/2 HP

Factory Wired for 110-120-V A.C. unless otherwise specified. To connect for 220-240-V A.C. refer to information on inside face of

terminal box cover.

SINGLE PHASE 3/4 HP, 1HP, 11/4 HP, and 11/2 HP

Factory Wired for 220-240 volts.To reconnect for 110-120 volts refer to information on inside face of terminal box cover.

NOTE: After installation, be sure turntable rotates clockwise.

CAUTION:When making field changes for voltage, be certain to change all other related electrical circuits such as solenoid valves, relays, etc.

ALL THREE PHASE MOTORS

3-Pole, 20 Amp., heavy duty switch encased in waterproof receptacle.Tap off any two leads for the solenoid valve. Refer to Fig. 14 and 15 for

typical wiring installation.

THREE PHASE 3/4 HP, 1HP, 11/4 HP, and 11/2 HP

All three phase motors are factory wired for 208-240-V A.C.AFTER INSTALLATION BE SURE TURNTABLE ROTATES CLOCKWISE. If not,

interchange any two of the three wires.To reconnect for 460 volts, refer to information shown on inside face of terminal box cover.

FIG. 8 OPTIONAL SUPPLEMENTARY

WATER CONNECTION

FIG. 10 INSTALLATION DIMENSIONS AND

DRAINLINE CONNECTIONS

FIG. 9 SWIRL SPRAY(S) ASSEMBLY

FIG. 11 SINK MOUNTED MODELS (SM)

FLOOR LINE

FLOOR LINE

TOGGLE SWITCH

1/2” ELBOW

CLAMP

1” I.D.

FLEXIBLE

HOSE

1/2” GLOBE VALVE

SYPHON BREAKER MUST be above

Table Floor Level.Check

local code for confirmation.

1/2” SOLENOID VALVE

1/2” COLD WATER SUPPLY

JUNCTION BOX

AERATOR SPRAY

SPRAY GASKETS

STEEL WASHER

CONICAL –

BRASS WASHERS

NUT

LOCK

NUT

TUBING

LOCK

NUT

TUBING

NUT

STEEL WASHERSPRAY HEAD

BRASS

WASHERS

SPRAY HEAD

GASKET

21/2”

31/2

”

81/2”

A

73/4”

815/16”

1

1

/8”

SLOPE =

1

/4

” PER FOOT

3

9

/16”

3”

6”

81/2”

A

73/4”

815/16”

2

5

/32”

SLOPE =

1

/4” PER FOOT

3

9

/16

”

CONICAL

WASHER

1/2-1 = 187/16 1 1/4-1 = 1911/16

3/4-1 = 1815/16

1 1/4-3 = 18

15

/16

3/4-3 = 187/16 1 1/2-1 = 1911/16

1-1 = 1815/16 1 1/2-3 = 1815/16

1-3 = 187/16

1/2 HP-1SM = 1711/16 3/4 HP-1SM= 183/16

3/4 HP-3SM = 1711/16

{

{

A

A

4

TESTING –

IMPORTANT! Do not test or run disposer dry as this will damage the seal and void the warranty.

1. Test assembly for leaks: a.where cone sink joins table b. where disposer joins cone c. all piping connections d. “Swir l Spray” fittings

2. After plumbing and electrical connections are made, turn on disposer to be sure all parts are in working order and that the disposer tur ntable

rotates clockwise when viewed from above. Open valve in vacuum breaker line, and using valves in plumbing assembly (Fig.7), adjust so

that water swirls around just below the rim of the cone sink. Leave valves in these positions.These combinations provide a flow of

approximately 8 gallons of water per minute.

3. Replace cover, retest for leaks and turn unit off.

4. Unit is now ready for operation.

MANUAL SWITCH

MODEL VOLTS PART NO.

1/2 HP–

110-120

2420

1-1/2 HP

220-240

FIG. 12 SINGLE PHASE FIG. 13 WIRING FOR SINGLE PHASE

UNITS WITH MANUAL SWITCH

FIG. 14 THREE PHASE FIG. 15 WIRING FOR THREE PHASE

UNITS WITH MANUAL SWITCH

FIG. 16 WIRING FOR THREE PHASE UNITS WITH MAGNETIC SWITCH

FIG. 17 WIRING FOR SINGLE PHASE UNITS WITH MAGNETIC SWITCH

NOTES:

1. Motor wired at Factory for 220-240

volts except for 1/2 HP. For 110-120

volts, connect motor wires as shown

inside of motor junction box cover.

MANUAL SWITCH

MODEL VOLTS PART NO.

1/2 HP–

208-240

2420

1-1/2HP

460

NOTES:

1. Motor wired at Factory for 208-240 volts.

For 460 volts, connect motor wires as

shown inside of motor junction box cover.

2. Interchange T1 and T3 to reverse

rotation.

MAGNETIC SWITCH

MODEL VOLTS PART NO.

3/4 HP –

208-240 2416

1-1/2 HP

460 2417

NOTES:

1. Motor wired at Factory for 208-240 volts.

For 460 volts, connect motor wires as

shown inside of motor junction box cover.

2. Interchange T1 and T3 to reverse rotation.

3. No heaters used with magnetic switch.

MAGNETIC SWITCH

MODEL VOLTS PART NO.

1/2 HP –

110-120 2414

1 1/2 HP

220-240 2415

NOTES:

1. Motor wired at Factory for 220-240

volts except for 1/2 HP. For 110-120

volts, connect motor wires as shown

inside of motor junction box cover.

2. No heaters used with magnetic switch

CLOCKWISE

ROTATION

WHITE WIRE

HOT WIRE

POWER “IN”

SOLENOID

VALVE

ON / OFF

POWER SUPPLY FUSE PER

LOCAL CODE

SOLENOID RATED VOLTAGE

TO MATCH LINE VOLTAGE

MOTOR JUNCTION BOX

TURNTABLE ROTATION

AS VIEWED FROM THE TOP

POWER SUPPLY FUSE PER

LOCAL CODE

SOLENOID RATED VOLTAGE

TO MATCH LINE VOLTAGE

MOTOR JUNCTION BOX

TURNTABLE ROTATION

AS VIEWED FROM THE TOP

TURNTABLE

ROTATION

AS VIEWED

FROM THE TOP

TURNTABLE

ROTATION

AS VIEWED

FROM THE TOP

CLOCKWISE

ROTATION

3 PHASE

POWER

LINE

JUNCTION

BOX

3 POLE

SWITCH

SOLENOID

VALVE

ON / OFF

L1 L2

T1 T2

L1 L2 L3

T1 T2 T3

SWITCH START - STOP

(MOUNT NEAR UNIT)

COIL RATED

VOLTAGE TO

MATCH LINE

VOLTAGE

POWER SUPPLY - FUSE PER LOCAL CODE.

MOTOR:CONSULT CHART FOR

CORRECT MAGNETIC SWITCH

SOLENOID-RATED

VOLTAGE TO MATCH

LINE VOLTAGE

SWITCH BOX ON

FRONT OF UNIT

START

STOP

SWITCH START - STOP

(MOUNT NEAR UNIT)

COIL RATED

VOLTAGE TO

MATCH LINE

VOLTAGE

POWER SUPPLY - FUSE PER LOCAL CODE.

MOTOR:CONSULT CHART FOR

CORRECT MAGNETIC SWITCH

SOLENOID-RATED

VOLTAGE TO MATCH

LINE VOLTAGE

SWITCH BOX ON

FRONT OF UNIT

START

STOP

JUNCTION

BOX

SWITCH

BOX AND

COVER

ALL VOLTAGES – DO NOT USE L3 OR

T3 FOR SINGLE PHASE APPLICATION

L-1 L-2

T-1 T-2

CLOCKWISE

ROTATION

L-1 L-2

T-2

T-1

L-3

CLOCKWISE

ROTATION

T-3

THESE TERMINALS MAY BE

LABELED T4 OR L4

32

T-3

T-2 L-2

T-1

L-3

L-1

CLOCKWISE

ROTATION

THESE TERMINALS MAY BE

LABELED T4 OR L4

32

T-2 L-2

T-1

L-1

CLOCKWISE

ROTATION

5

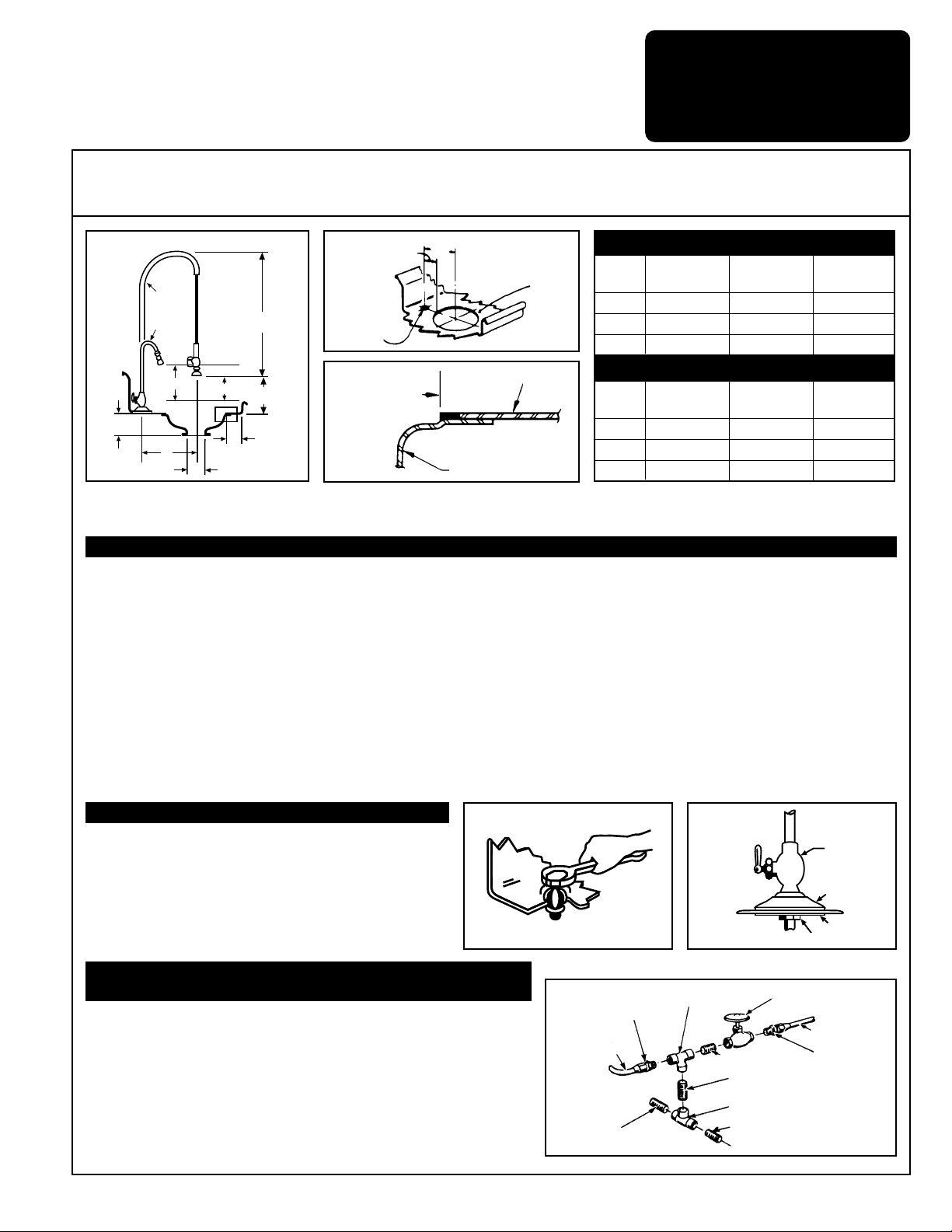

INSTALLATION OF CONE SINK INTO DISH OR WORKTABLE

1. (See Figures 1 and 2.) Locate hole center as shown on Figure 2. Cut a “C” (Figure 2) diameter hole in dish or work table, a minimum of 2”

from the inside front edge (operator’s side).Hole can be cut with a “nibbler” after a knockout hole 11/2” diameter has been punched.

2. Lift cone to underside of table with cone flange overlapping all around (Figures 1 and 3).

3. Check alignment of cone spray fittings to be sure they are in the proper position.For 15” and 18” cones, position such that holes are located

to right and left side of operator.(See Figure 7 for location.)

4. Tack weld, spot weld, bolt, or rivet flange of cone sink to underside of dish or work table. If bolted or riveted, smooth top surface and washsolder around bolt or rivet heads and sand smooth.

5. Bead weld or solder and wash-solder all around where the table joins flange of cone sink for a clean, watertight, sanitary installation.

6. The cone sink has been designed with the step, as shown in Figure 3.In the welding or soldering operation required to assemble the cone

sink to the dish or work table, every attempt should be made to keep the recessed, flat portion of the cone free of the weld or solder

material.This will minimize the clean-up time required and provide a smooth, flat surface for any cover.

7. Minimum installation criteria:

• Minimum clearance between left and right side of waste disposer and side wall: 18 inches.

• Minimum clearance to back wall: 10 inches.

• No front panel/door between waste disposer installation cavity under a sink/dish table and room.

SPRAY-RINSE INSTALLATION

1. Locate center (Figures 1 and 2).

2. Drill 7/16” diameter hole through center.

3. Assemble 7/8” punch and tighten bolt head, as illustrated,

until the die pierces the stainless steel, leaving a clean

opening of 7/8”.

4. Place body valve and base in position, assemble washer

and locknut as shown in Figure 5.

5. Attach vol-temp assembly to the projecting nipple.

POSITIONING AND INSTALLATION

OF COMMERCIAL DISPOSER

1. Subassemble plumbing for swirl sprays as shown in detail in Figure 6,

and as shown assembled on final unit in Figure 7.

2. Slide Hush Cushion

®

up over edge of flange on cone sink.The inner

edge of this Hush Cushion®is chamfered to facilitate this operation.

3. Slide one clamp ring over Hush Cushion

®

, place between two upper beads

and tighten, this firmly attaches the Hush Cushion®to the cone sinks.

NOTE: On the six inch opening only to make certain that the Hush Cushion

®

is not mounted upside down, look down into the cone sink from above the

work table and check that the wording is readable on the center plug on the

Hush Cushion®.This reads, “Remove before using”.

COMMERCIAL

DISPOSER MODELS

2 HP, 3 HP, 5HP

AND 10HP

INSTALLATION

INSTRUCTIONS

BEFORE INSTALLING, READ ENTIRE INSTRUCTIONS CAREFULLY.

RISK OF INJURY TO PERSONS FROM HAZARDOUS MOVING PARTS. SERIOUS INJURY POSSIBLE IF

NOT PROPERLY INSTALLED WITH A HOPPER OR A CONE SPECIFIED IN THE INSTRUCTION MANUAL.

IF YOU ARE REPLACING AN OLD DISPOSER GO TO

POSITIONING AND

INSTALLATION OF COMMERCIAL DISPOSER

MODEL 6T

2216 2215 2211

12” CONE 15” CONE 18” CONE

A 101/4” 113/4” 131/4”

B 3

1

/2” 31/2” 31/2”

C 13

1

/2” 161/2” 191/2”

MODEL 9T

2216 2215 2211

12” CONE 15” CONE 18” CONE

A 127/8” 127/8” 127/8”

B 6

1

/8

” 4

5

/8

” 3

1

/8

”

C 13

1

/2” 161/2” 191/2”

FIG. 1 FIG. 2

FIG. 4 FIG. 5

FIG. 3

FIG. 6

BODY

VALVE

7/8” PUNCH

BASE

WASHER

DISH TABLE

CONE SINK

APPROX.

30”

APPROX.14”

9” MIN.

6” MIN.

2” TO 4”

6”

A

6-5/8”

No.9T

SPRAY

RINSE

No.6T

SINK

HOLE

C DIA.

SPRAY

RINSE

HOLE

A

B

LOCKNUT

FLAT PORTION

OF CONE SINK

GLOBE VALVE 1/2”

1/2” COPPER

TUBING

1/2” COPPER

TUBING

1/2” TUBE

FITTING

1/2” TUBE

FITTING

1/2” CLOSE

NIPPLE

NIPPLE 1/2” X 6”

1/2” X 4” NIPPLE

1/2”“T”

1/2”“T”

1/2” CLOSE NIPPLE

SPRAY RINSE

6

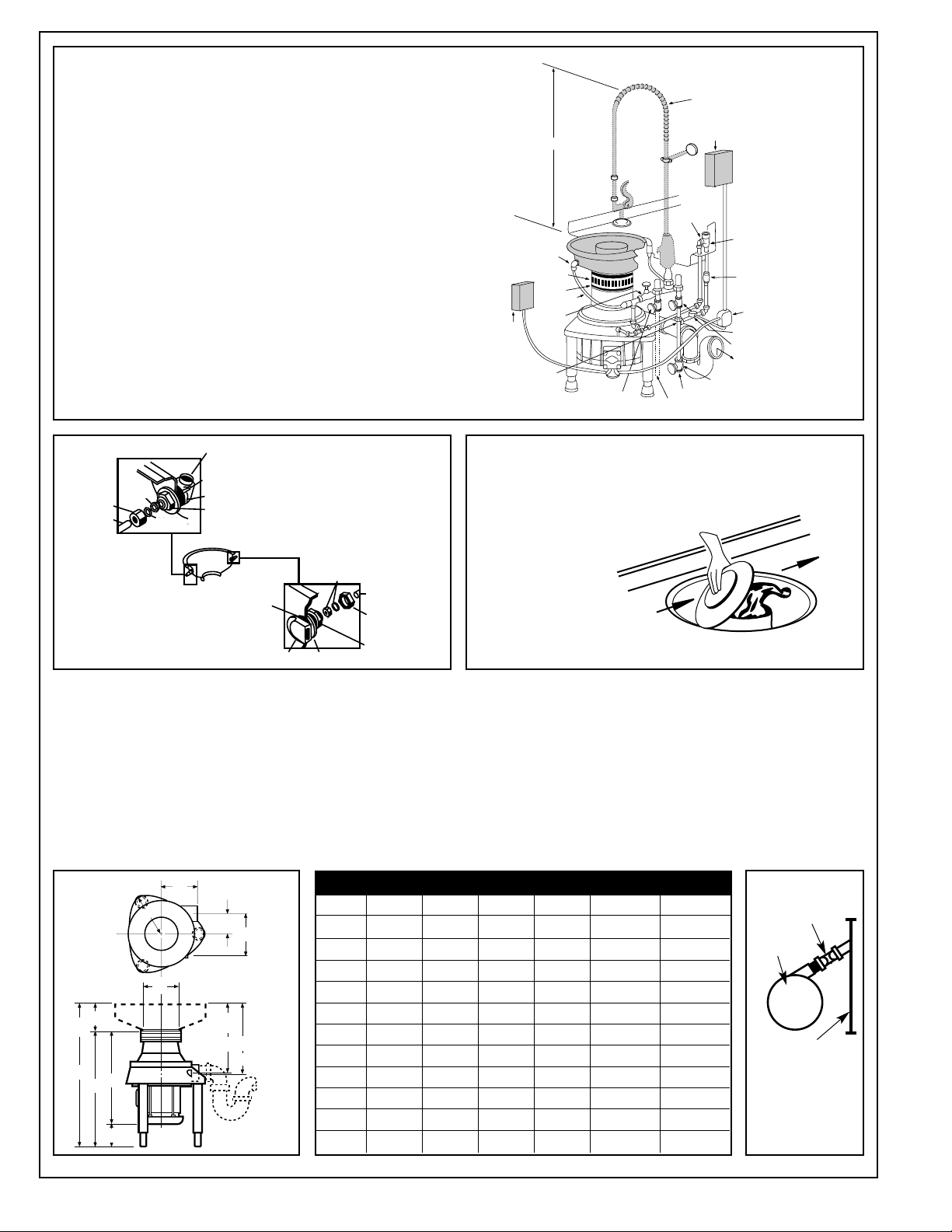

4. Slide second clamp ring loosely over Hush Cushion®and up to previously tightened clamp ring. Do not tighten.

5. Unscrew legs until there is a space of approximately 1/4” between the top of the upper housing and the Hush Cushion®. Raise disposer until

the upper housing slides into the Hush Cushion®.

Slide the loose clamp ring between the two lower beads on the Hush Cushion®and tighten.

6. Assemble swirl spray or swirl sprays as shown in Figure 8.The method of assembly of the swirl sprays is typical. Other combinations of

convertible and fixed swirl sprays are available.The outlet hole of fixed spray head should be horizontal to promote swirling action in cone

sink. (convertible spray see Figure 9.)

7. Connect copper tube or tubes to swirl sprays and bend in gradual curve to connect to fittings in valves.See Figure 7.

8. Thread special nipple into drain outlet, slide hush connector over pipe and assemble and tighten clamp ring in two grooves.

NOTE: ALL PLUMBING AND ELECTRICAL CONNECTIONS SHOULD BE MADE ACCORDING TO LOCAL CODES.

INSTALLATION DIMENSIONS AND DRAINLINE CONNECTIONS

FIG. 7

NOTE:

A globe valve used for metering flow to prevent solenoid

hammering must be installed between solenoid valve and

disposer.See Fig.7. Any valve ahead of the solenoid valve

must be opened and cause no restrictions.

IMPORTANT! Do not test or run disposer without

minimum water flow (see Plumbing Installation) as this

will damage the seal and void the warranty.

NOTE:

Disposer assembly includes disposer, outlet, nipple, Hush

Cushion

®

, clamps and supporting legs. Other items must be

purchased separately. Items shown in gray in Figure 7 are

available in equipment groups ordered separately.

FIG. 8 FIG. 9 CONVERTIBLE SPRAY

AERATOR SPRAY

SPRAY GASKETS

STEEL WASHER

CONICAL –

BRASS WASHERS

NUT

LOCK

NUT

CONICAL

WASHER

TUBING

LOCK

NUT

TUBING

NUT

STEEL WASHERSPRAY HEAD

BRASS

WASHERS

SPRAY HEAD

GASKET

The convertible spray

should be located

opposite the direction

of travel of dishes in

scrapping operation.

FIG. 10 FIG. 11

DIMENSIONS

2HP-1 2HP-3 3HP-3 5HP-3 5HP-38 10HP-3

A

323/8 - 351/8 323/8 - 351/8 323/8 - 351/8 327/8 - 353/8 3261/64 - 3529/64 3261/64 - 3529/64

B 215/16 209/16 2215/32 221/2 2237/64 2337/64

C 65/8 65/8 65/8 65/8 65/8 65/8

D 6666 8 8

E 161/4 161/4 1715/16 1719/64 173/8 173/8

F 16 16 161/8 165/8 1623/32 1623/32

G

253/

4 - 28

1

/

2 25

3

/

4 - 28

1

/

2 25

3

/

4 - 28

1

/

2 26

1

/

4 - 28

3

/

4 26

21

/

64 - 28

53

/

64 26

21

/

64 - 28

53

/

64

H 51/8 51/8 67/8 87/16 87/16 87/16

J 53/4 53/4 87/8 88 8

K 25/8 25/8 33/8 43/4 43/4 43/4

L 67/16 67/16 713/16 1013/16 1013/16 1013/16

*

*

TRAP

WALL

DISPOSER

If space between

disposer and wall is

insufficient to allow

for installation of trap,

waste line may have

to be at an angle to

the wall as shown.

J

K

H

E

F

A*

G*

B

C

G minus B

D

Water

Inlet

Drain

Slope =

1/4” Per

Foot

L

Sink

Flange

*

Legs are adjustable beyond the minimum shown in the screw adjustment. 2” clearance must be maintained beneath unit for proper ventilation.

MANUAL

SWITCH

APPROX. 40"

ELBOW

TUBE FITTING

HUSH CUSHION

1/2" GLOVE

VALVE

SEE FIG. 11

CLAMP

RING

¤

TUBE

GATE VALVE

1/2" HOT WATER

#9T SPRAY RINSE

(Dotted Outline Illustates 9T Rinse)

MAGNETIC SWITCH

AND REMOTE

PUSH BUTTON

STATION

SYPHON

BREAKER

(Check Local

Code)

3/4" COLD WATER

HOT WATER

1" MIN.

ABOVE

TABLE RIM

1/2" GLOBE

VALVE FOR

METERING*

SOLENOID VALVE

1/2" GLOBE VALVE

WASTE LINE

GATE VALVE

POWER

SUPPLY

7

PLUMBING INSTALLATION

NOTE: Refer to FIgure 10 for installation dimensions and drainline connections.

1. Plumb unit using valves and fittings as shown typically in Figure 7.

NOTE: Syphon breaker, available as option item, is approved in most areas.Check local code to be sure it conforms in your area.

2. When overhead spray rinse is used, split the incoming 3/4”cold water into two 1/2”lines and connect one to the 1/2”“T” at the bottom of the

unit and the other to the globe valve on the cold water side of the spray rinse. Connect one 1/2” hot water line to the globe valve on the hot

water side of the spray rinse.

3. On models 3 HP, 5 HP, and 10 HP connect 3” drain to the hush connector. Drain line must have a minimum of bends.The unit is equipped

with a drain outlet designed for a connection to a conventional 3” trap. For model 2 HP drain line and trap will be 2”.

IMPORTANT! Before installing the disposer, the connecting waste line must be cleaned out all the way to the connecting sewer main.

DO NOT CONNECT INTO GREASY TRAP.

The trap may be connected to a 3” branch waste line running directly into the stack.For model 2 HP, branch waste line can be 2”.A minimum

slope of 1/4” per foot of run of waste line is recommended. Limit the horizontal drain line to a 15 foot run free of turns; then, using a long 45°

“Y”, connect to a 3”or 4” horizontal line or stack. Recessed thread fittings must be used throughout and all pipe ends should be carefully

reamed. A minimum number of elbows, tees, etc., reduce the possibility of plumbing stoppages.Water is injected to underside of table

chamber through a control that allows approximately 4 gallons per minute flow.Do not restrict or alter this control as it is necessary to

properly clean the inside of the unit.

IMPORTANT: If unusual sewer conditions exist (too many bends or too long to main), if the water pressure is low for application resulting in low

water flow rate, or if high percentage of leafy and/or paper material is included in food waste, serious consideration should be given to the use of

a time delay and water injector into the sewer to overcome stoppages.Under such conditions a larger size cold water line should be used along

with larger solenoid valves and syphon breakers. (Parts and data available from factory.)

*Minimum Water Flow RATE Used with Model: 2 HP and 3 HP – 10 gallons per minute. 5 HP and 10 HP – 14 gallons per minute.

TESTING

IMPORTANT! Do not test or run disposer without minimum water flow (see Plumbing Installation) as this

will damage the seal and void the warranty.

1. Test assembly for leaks: a.Where cone sink joins table

b.Where disposer joins cone sink

c. At all piping connections

d.Where swirl spray fittings connect

2. After plumbing and electrical connections are made, turn on disposer to be sure all parts are in working order and that the disposer tur ntable

rotates clockwise when viewed from above. Open valve in vacuum breaker line and, using globe valves in plumbing assembly (Refer to

Figure 6), adjust so that water swirls around just below the rim of the cone sink. Leave valves open in these positions.

NOTE: When the convertible swirl spray is used to remove food waste from dishes, adjust the flow to provide a convenient combination of

anti-splash and high flow volume characteristics (top of flume approximately 3”above cone sink).These combinations provide a flow of

approximately 8 gallons of water per minute.

3. Replace cover, retest for leaks and turn unit off.

4. Unit is now ready for operation.

OPERATING INSTRUCTIONS

IMPORTANT! Do not test or run disposer without minimum water flow (see Plumbing Installation) as this

will damage the seal and void the warranty.

1. Push “start” button. Be sure unit is running and water is flowing before any waste is fed into the disposer. Do not pack food waste into unit.

Do not dump garbage can loads directly into unit. Feed waste in gradually.

2. DO NOT ALLOW GLASS, METAL OR CROCKERY TO ENTER. IF THIS OCCURS, STOP THE UNIT AND REMOVE SUCH MATERIAL.

3. IF THE MOTOR STOPS, push stop button. Remove any waste material which caused stoppage.Check the turntable to see that it will turn

freely.Wait three minutes, push red reset button firmly (LOCATED ON JUNCTION BOX OF MOTOR).Then push “start” button.

4. If the motor hums and the turntable does not rotate freely, there is usually a jamming obstruction, such as metal. STOP UNIT.With a suitable

bar or stick, pry against one of the impellers and rotate the turntable in a counterclockwise direction.When the turntable is free, REMOVE

THE BAR AND THE OBSTRUCTION MATERIAL BEFORE RESTARTING UNIT.CAUTION – LOSS OF ONE PHASE IN THREE PHASE

UNITS (if one fuse blows while running) WILL CAUSE MOTOR TO LABOR AND HEAT. PROLONGED OPERATION WILL DAMAGE THE

MOTOR.

5. If the motor remains silent after resetting the overload protector (as instructed in item 3 above) and the turntable rotates freely, check the

electric fuses and complete electrical circuit.

6. ALWAYS ALLOW THE DISPOSER AND THE WATER TO RUN FOR THREE MINUTES AFTER EACH OPERATION to keep the unit clean

and to flush all food waste out of the drain lines.THIS IS IMPORTANT!

CAUTION:ALWAYS TURN THE DISPOSER OFF AND LET IT COME TO A STANDSTILL BEFORE PUTTING YOUR HAND INTO THE

HOPPER OR NEAR THE GRINDING CHAMBER.DO NOT LOOK FOR CAUSE UNTIL STARTING CONTROL IS TURNED OFF.

ELECTRICAL INSTALLATION

1. Use waterproof conduit and make all electrical connections according to local codes.

2. Wire three phase units using manual switches as shown in wiring diagram, Figure 12.

Loading...

Loading...