Waste King 10000-3 User Manual

FEATURES

•1/2HP disposer, dual voltage

• Fan cooled motor with ball bearing construction, and

integral overload protection

• Dynamically balanced for smooth, long wearing operation

• Hush Cushion®mounting connection for 6” cone or sink opening includes

an auxiliary water inlet

• Stainless steel grind chamber

• Corrosion proof, glass reinforced polyester exit chamber

•5

3

/8" Diameter stainless steel turntable

• 2 Jam resistant, hardened stainless steel swivel impellers

• Stainless steel undercutter blade

• Hard, tough, cast alloy grind ring with dual stage grinding action

• Lifetime particle size control by non-wearing exit slots

WASTE KING®EXCLUSIVES

• Stainless Steel Swivel Impellers swivel and retract if they are jammed so that

they return to the grinding position during revolution, reducing motor

overloading and costly jams. Waste King’s stainless steel swivel impellers

eliminate the need for reversing

switches and special ”de-jamming“ wrenches.

• Stainless Steel Undercutter Blade located beneath the grind ring snips fibrous

and stringy waste into small particles making them less likely to clog drain lines.

• Hush-Cushions®isolate the unit from metal to metal contact, significantly

reducing noise level. Hush-Cushions®are specially compounded and designed

to withstand vibration and tension, and have a built-in safety splash guard.

MOUNTING SYSTEMS

Basic Cone

Assembly (B)

• 12", 15", or 18" Cone

with Swirl Sprays

All-Purpose Cone

Assembly (AP)

• 12", 15", or 18" Cone

with Swirl Sprays

• Silver Guard

• Scrap Ring

Dish Table Cone

Assembly (DT)

• 12", 15", or 18" Cone

with Swirl Sprays

• 12", 15", or 18"

Cone Cover

• Scrap Ring

Trough Mount

Assembly (TM)

• #2536 6” Weld-in

flange for models

with 6” throat

Sink Mount

Assembly (SM)

• #2539 31/2" Bolt-in

adapter for suspended

models with 6” throat

COMMERCIAL FOOD WASTE DISPOSER SPECIFICATIONS

500-1

1

/2HP • Single Phase

APPLICATION

SMALL CHURCHES, ELEMENTARY SCHOOLS AND

SNACK BARS WHERE FOOD WASTE VOLUME IS LIGHT.

Add desired Waste King water controls, switch or panel control box to complete your package. (See catalog)

®

4240 E. La Palma Avenue • Anaheim, California 92807 • (800) 454-4423

www.wasteking.com

WKC-1154

MOTOR DATA

500-1 & 500-1SM (special order ONLY)

• 60 cycle

• 1 Phase

•1/2HP

• 1725 RPM

• 110-120/220-240 volts

• 9.2/4.6 Amps

Bearing permanently lubricated.

Manual reset overload protection in motor.

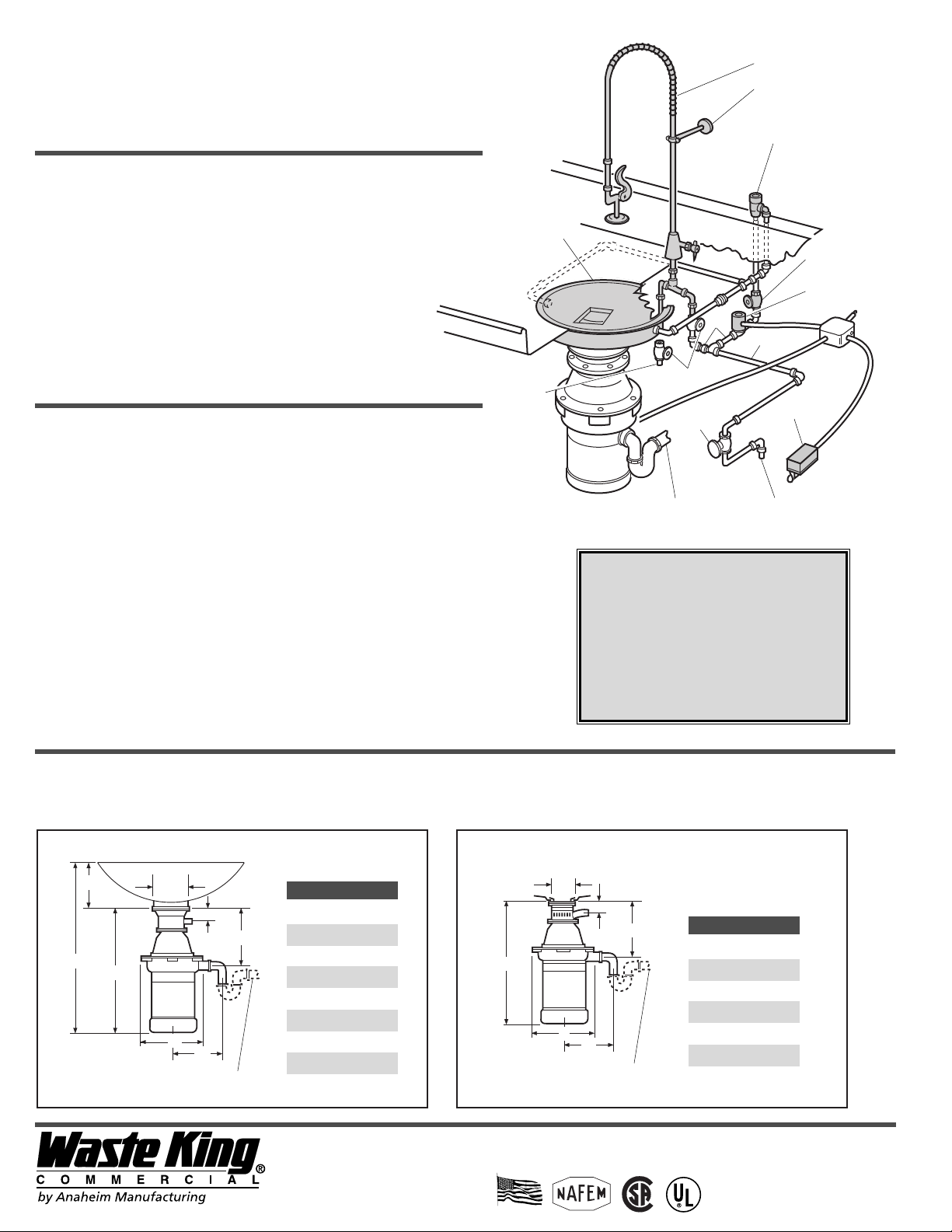

Cone Mounted Models

Sink Mounted Models with #2539 Sink Mount Installation

Special Order ONLY

NOTE:

1. Disposer assembly includes disposer, mountings,

and drain outlet. Other items shown in gray are

available in mounting systems or ordered separately.

2. Installation should be made in accordance with

local codes.

4. All specifications subject to change without notice.

3. Assembly should be installed in accordance with

Waste King’s printed installation instructions.

*

Items available through Waste King

PLUMBING

1

/2HP models are equipped

with a drain outlet for connection

to a conventional 11/2" trap. The trap may be connected to a 2" branch

waste line running directly into a waste stack. We recommend a slope in

the waste line of not less than 1/4" per foot. Connect directly to waste

line, not through a grease interceptor.

ROUGH-IN DIMENSIONS

WITH DRAIN LINE

CONNECTIONS

TO SPECIFIERS

So that you may

be assured of

receiving the fine quality you expect when you specify a WASTE KING

®

FOOD WASTE REMOVAL SYSTEM, we include the following sample

specification for your convenience:

• Food waste disposer shall be 1/2HP, 60 cycle, I Phase with 110-120/220-

240 volts.

• There shall be a rubber Hush Cushion®between the disposer and

the cone or sink to eliminate metal to metal contact.

• Turntable shall be of stainless steel with jam-resistant swivel impellers

of stainless steel and stainless steel cutting blade rotating below the

exit slots.

• Grind ring shall be precision ground on all cutting surfaces and shall

have non-wearing, size controlled exit slots.

• Disposer shall have a totally enclosed, continuous duty, fan cooled motor

with integral overload protection.

• Unit shall be Waste King

®

model 500-1.

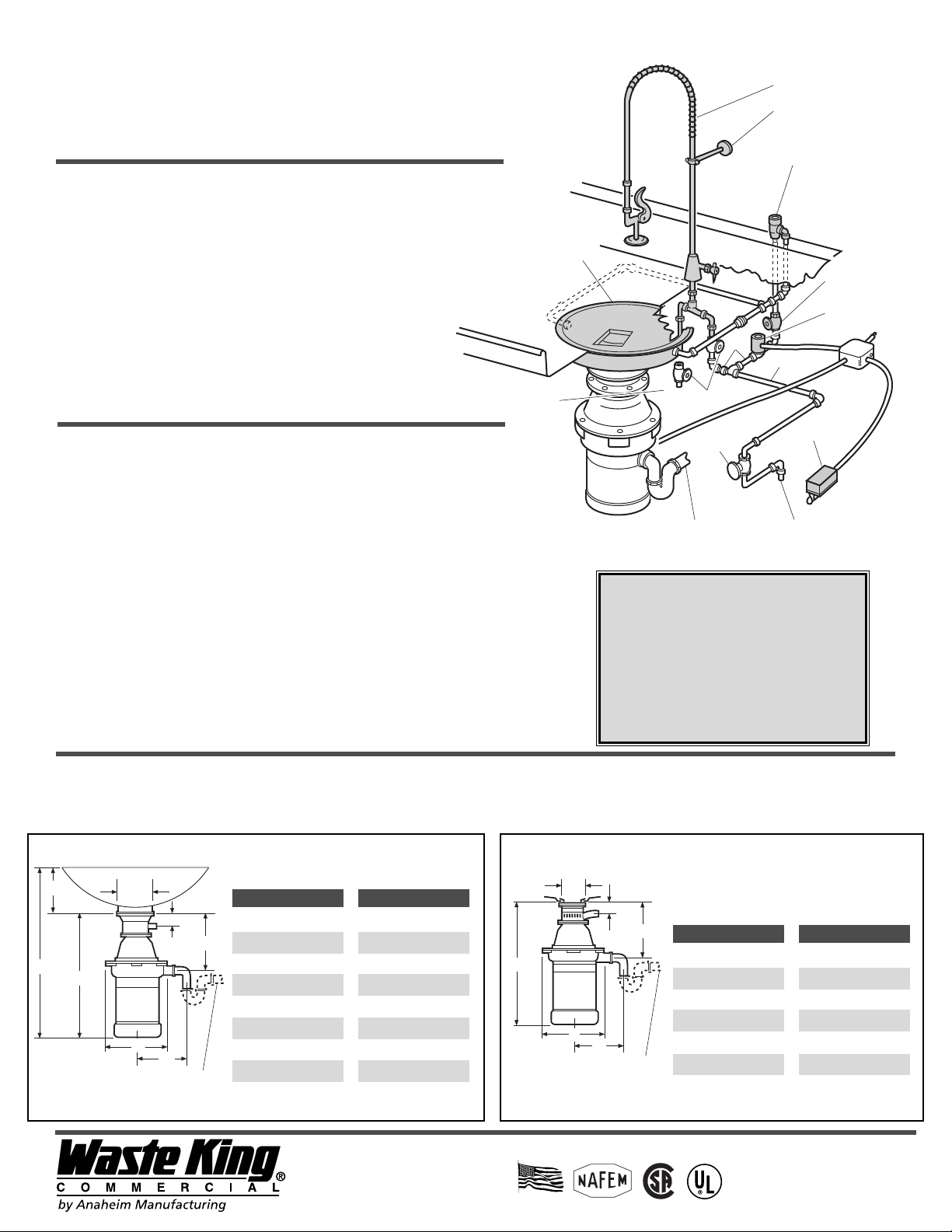

#9 Spray Rinse

*

Wall Bracket

*

1

/2" Syphon Breaker

*

1

/2" Flow

Control Valve

*

1

/2" Solenoid Valve

*

DT Cone Assembly shown

*

1

/2" Hot Water Valve

Globe Valve

1

/2"

3

/4"

11/2" Waste Line

3

/4" Gate

Valve

3

/4" Gate Valve

Switch

*

Proudly made

in the USA

F

O

O

D

E

Q

U

I

P

M

E

N

T

M

A

N

U

F

A

C

T

U

R

E

R

S

N

A

T

I

O

N

A

L

A

S

S

O

C

I

A

T

I

O

N

O

F

500-1 with

#2539 Sink

Mount Installation

IN CM

A 19 48.2

B 9 22.7

C 8

1

/221.6

D 3

1

/28.9

E 2

3

/85.9

F 7

3

/419.7

500-1

IN CM

A 25

1

/1663.7

B 6

5

/816.8

C 18

7

/1646.8

D 6 15.2

E 2

1

/85.4

F 8 20.3

G 9 22.7

H 7

3

/419.7

Slope = 1/4”p/ft.

D

C

F

E

A

B

A

B

C

D

H

G

E

F

Slope = 1/4”p/ft.

Cone Flange

®

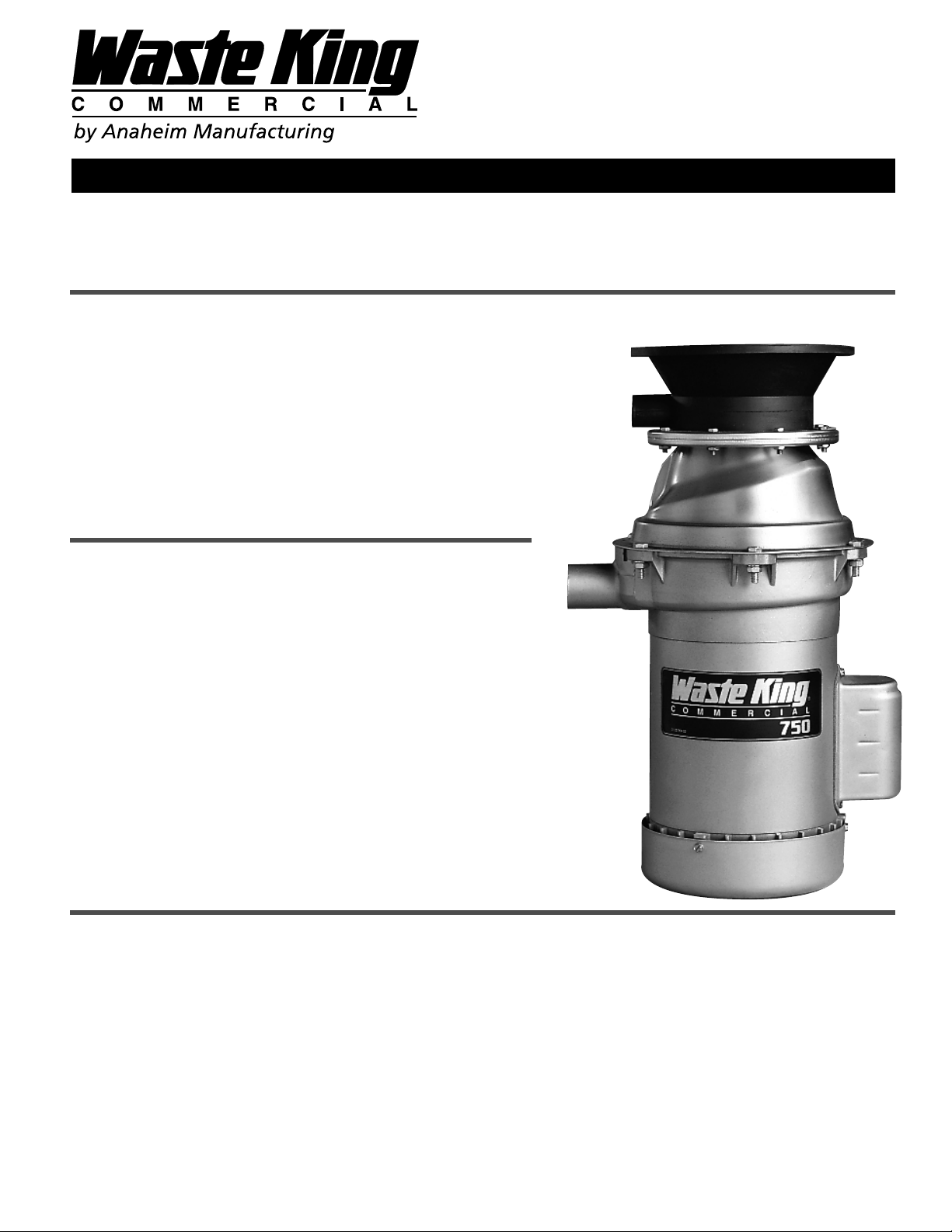

FEATURES

•3/4HP disposer, dual voltage

• Fan cooled motor with ball bearing construction, and

integral overload protection

• Dynamically balanced for smooth, long wearing operation

• Hush Cushion®mounting connection for 6” cone or sink opening includes

an auxiliary water inlet

• Stainless steel grind chamber

• Corrosion proof, glass reinforced polyester exit chamber

•61/4" Diameter stainless steel turntable

• Ripper bar integrated with turntable

• 2 Jam resistant, hardened stainless steel swivel impellers

• Stainless steel undercutter blade

• Hard, tough, cast alloy grind ring with dual stage grinding action

• Lifetime particle size control by non-wearing exit slots

WASTE KING®EXCLUSIVES

• Stainless Steel Swivel Impellers swivel and retract if they are jammed so that

they return to the grinding position during revolution, reducing motor

overloading and costly jams. Waste King’s stainless steel swivel impellers

eliminate the need for reversing

switches and special ”de-jamming“ wrenches.

• Stainless Steel Undercutter Blade located beneath the grind ring snips fibrous

and stringy waste into small particles making them less likely to clog drain lines.

• Hush-Cushions®isolate the unit from metal to metal contact, significantly

reducing noise level. Hush-Cushions®are specially compounded and designed

to withstand vibration and tension, and have a built-in safety splash guard.

MOUNTING SYSTEMS

COMMERCIAL FOOD WASTE DISPOSER SPECIFICATIONS

750-1

3

/

4

HP • Single Phase

750-3

3

/

4

HP • 3 Phase

APPLICATION

SCHOOL CAFETERIAS, SMALL

COFFEE SHOPS, HOSPITALS, CLINICS,

AND SHORT ORDER CAFES WHERE VOLUME IS AVERAGE.

®

Basic Cone

Assembly (B)

• 12", 15", or 18" Cone

with Swirl Sprays

All-Purpose Cone

Assembly (AP)

• 12", 15", or 18" Cone

with Swirl Sprays

• Silver Guard

• Scrap Ring

Dish Table Cone

Assembly (DT)

• 12", 15", or 18" Cone

with Swirl Sprays

• 12", 15", or 18"

Cone Cover

• Scrap Ring

Trough Mount

Assembly (TM)

• #2536 6” Weld-in

flange for models

with 6” throat

Sink Mount

Assembly (SM)

• #2539 31/2" Bolt-in

adapter for suspended

models with 6” throat

Add desired Waste King water controls, switch or panel control box to complete your package. (See catalog)

MOTOR DATA

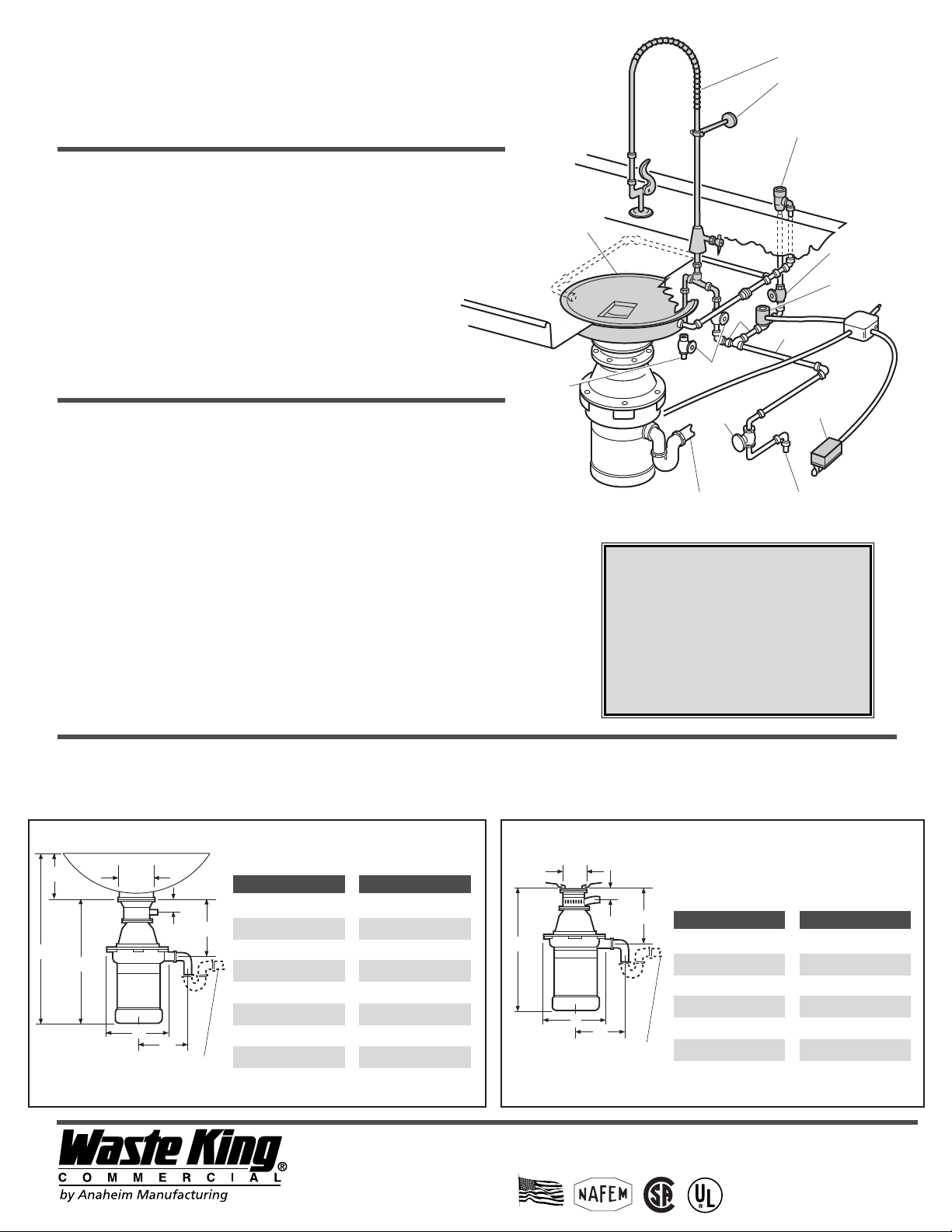

Sink Mounted Models with #2539 Sink Mount Installation

Special Order ONLY

PLUMBING

Models 750-1 and 750-3 are equipped

with a drain outlet for connection

to a conventional 1

1

/2" trap. The trap may be connected to a 2" branch

waste line running directly into a waste stack. We recommend a slope in

the waste line of not less than 1/4" per foot. Connect directly to waste line,

not through a grease interceptor.

WITH DRAIN LINE

CONNECTIONS

750-3

• 60 cycle

• 3 Phase

•3/4HP

• 1725 RPM

• 208-240/460 volts

• 2.8/1.4 amps

750-1 with

#2539 Sink

Mount Installation

IN CM

A 19

1

/249.5

B 9 22.7

C 8

1

/221.6

D 3

1

/28.9

E 2

3

/85.9

F 7

3

/419.7

750-3 with

#2539 Sink

Mount Installation

IN CM

A 19 48.2

B 9 22.7

C 8

1

/221.6

D 3

1

/28.9

E 2

3

/85.9

F 7

3

/419.7

D

C

F

E

B

NOTE:

1. Disposer assembly includes disposer, mountings,

and drain outlet. Other items shown in gray are

available in mounting systems or ordered separately.

2. Installation should be made in accordance with

local codes.

4. All specifications subject to change without notice.

3. Assembly should be installed in accordance with

Waste King’s printed installation instructions.

*

Items available through Waste King

#9 Spray Rinse

*

Wall Bracket

*

1

/2" Syphon Breaker

*

1

/2" Flow

Control Valve

*

1

/2" Solenoid Valve

*

DT Cone Assembly shown

*

1

/2" Hot Water Valve

Globe Valve

1

/2"

3

/4"

11/2" Waste Line

3

/4" Gate

Valve

3

/4" Gate Valve

Switch

*

Bearing permanently lubricated.

Manual reset overload protection in motor.

TO SPECIFIERS

So that you may

be assured of

receiving the fine quality you expect when you specify a WASTE KING

®

FOOD WASTE REMOVAL SYSTEM, we include the following sample

specification for your convenience:

• Food waste disposer shall be 3/4HP, 60 cycle, 1 Phase with 110-120/220240 volts or 3 Phase with 208-240/460 volts.

• There shall be a rubber Hush Cushion®between the disposer and

the cone or sink to eliminate metal to metal contact.

• Turntable shall be of stainless steel with jam-resistant swivel impellers of

stainless steel and stainless steel cutting blade rotating below the exit slots.

• Grind ring shall be precision ground on all cutting surfaces and shall have

non-wearing, size controlled exit slots.

• Disposer shall have a totally enclosed, continuous duty, fan cooled

motor with integral overload protection.

• Unit shall be Waste King

®

model 750-1 or 750-3.

Cone Mounted Models

ROUGH-IN DIMENSIONS

A

B

C

D

H

G

E

F

Slope = 1/4”p/ft.

Cone Flange

750-1

IN CM

A 25

5

/865.1

B 6

5

/816.8

C 19 48.2

D 6 15.2

E 2

1

/85.4

F 8 20.3

G 9 22.7

H 7

3

/419.7

750-3

IN CM

A 25

1

/1663.7

B 6

5

/816.8

C 18

7

/1646.8

D 6 15.2

E 2

1

/85.4

F 8 20.3

G 9 22.7

H 7

3

/419.7

Slope = 1/4”p/ft.

A

750-1

• 60 cycle

• 1 Phase

•3/4HP

• 1725 RPM

• 110-120/220-240 volts

• 10.6/5.3 amps

4240 E. La Palma Avenue • Anaheim, California 92807 • (800) 454-4423

www.wasteking.com

WKC-1155

Proudly made

in the USA

F

O

O

D

E

Q

U

I

P

M

E

N

T

M

A

N

U

F

A

C

T

U

R

E

R

S

N

A

T

I

O

N

A

L

A

S

S

O

C

I

A

T

I

O

N

O

F

®

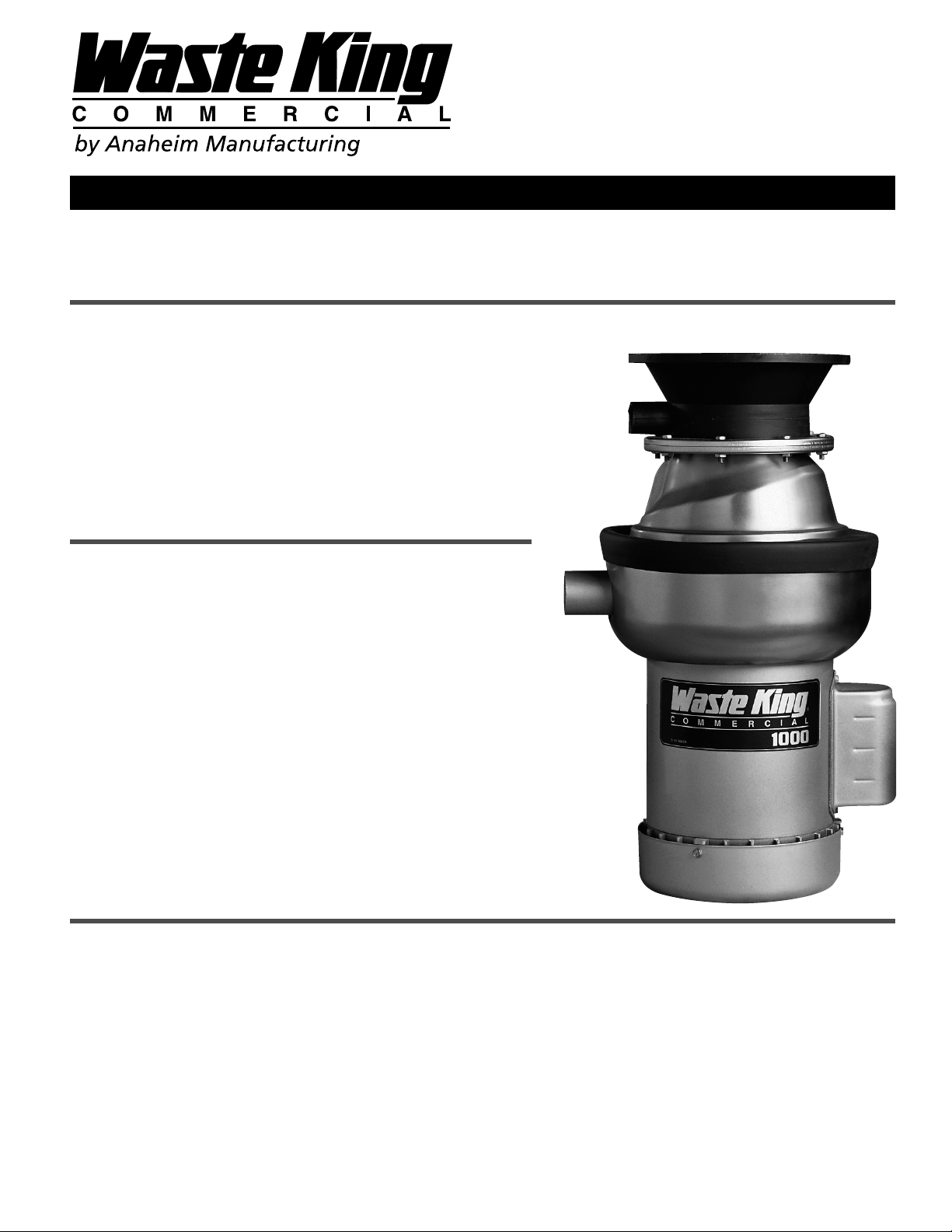

FEATURES

• 1 HP disposer, dual voltage

• Fan cooled motor with ball bearing construction and integral

overload protection

• Dynamically balanced for smooth, long wearing operation

• Hush Cushion

®

mounting connection for 6” cone or sink opening includes

an auxiliary water inlet

• Stainless steel grind chamber

• Corrosion proof, glass reinforced polyester exit chamber

•61/4" Diameter stainless steel turntable

• Ripper bar integrated with turntable

• 2 Jam resistant, hardened stainless steel swivel impellers

• 3 Stainless steel undercutter blades

• Hard, tough, cast alloy grind ring with dual stage grinding action

• Lifetime particle size control by non-wearing exit slots

WASTE KING®EXCLUSIVES

• Stainless Steel Swivel Impellers swivel and retract if they are jammed so that

they return to the grinding position during revolution, reducing motor

overloading and costly jams. Waste King’s stainless steel swivel impellers

eliminate the need for reversing

switches and special ”de-jamming“ wrenches.

• Stainless Steel Undercutter Blade located beneath the grind ring snips fibrous

and stringy waste into small particles making them less likely to clog drain lines.

• Hush-Cushions®isolate the unit from metal to metal contact, significantly

reducing noise level. Hush-Cushions®are specially compounded and designed

to withstand vibration and tension, and have a built-in safety splash guard.

COMMERCIAL FOOD WASTE DISPOSER SPECIFICATIONS

10 0 0-1

1 HP • Single Phase

10 0 0-3

1 HP • 3 Phase

APPLICATION

SCHOOL CAFETERIAS, HOSPITALS, CLINICS,

SMALL TO MEDIUM SIZE RESTAURANTS WITH SOME

DIFFICULT FOOD WASTE. WHERE VOLUME IS MEDIUM TO HEAVY.

MOUNTING SYSTEMS

®

Basic Cone

Assembly (B)

• 12", 15", or 18" Cone

with Swirl Sprays

All-Purpose Cone

Assembly (AP)

• 12", 15", or 18" Cone

with Swirl Sprays

• Silver Guard

• Scrap Ring

Dish Table Cone

Assembly (DT)

• 12", 15", or 18" Cone

with Swirl Sprays

• 12", 15", or 18"

Cone Cover

• Scrap Ring

Trough Mount

Assembly (TM)

• #2536 6” Weld-in

flange for models

with 6” throat

Sink Mount

Assembly (SM)

• #2539 31/2" Bolt-in

adapter for suspended

models with 6” throat

Add desired Waste King water controls, switch or panel control box to complete your package. (See catalog)

MOTOR DATA

1000-1

• 60 cycle

• 1 Phase

• 1 HP

• 1725 RPM

• 110-120/220-240 volts

• 12.0/6.0 amps

PLUMBING

Models 1000-1 and 1000-3 are

equipped with a drain outlet for

connection to a conventional 11/2" trap. The trap may be connected to a

2" branch waste line running directly into a waste stack. We recommend

a slope in the waste line of not less than 1/4" per foot. Connect directly to

waste line, not through a grease interceptor.

1000-3

• 60 cycle

• 3 Phase

• 1 HP

• 1725 RPM

• 208-240/460 volts

• 3.2/1.6 amps

NOTE:

1. Disposer assembly includes disposer, mountings,

and drain outlet. Other items shown in gray are

available in mounting systems or ordered separately.

2. Installation should be made in accordance with

local codes.

4. All specifications subject to change without notice.

3. Assembly should be installed in accordance with

Waste King’s printed installation instructions.

*

Items available through Waste King

#9 Spray Rinse

*

Wall Bracket

*

1

/2" Syphon Breaker

*

1

/2" Flow

Control Valve

*

1

/2" Solenoid Valve

*

DT Cone Assembly shown

*

1

/2" Hot Water Valve

Globe Valve

1

/2"

3

/4"

11/2" Waste Line

3

/4" Gate

Valve

3

/4" Gate Valve

Switch

*

Sink Mounted Models with #2539 Sink Mount Installation

Special Order ONLY

WITH DRAIN LINE

CONNECTIONS

1000-1

IN CM

A 25

5

/865.1

B 6

5

/816.8

C 19 48.2

D 6 15.2

E 2

1

/85.4

F 8 20.3

G 9 22.7

H 7

3

/419.7

1000-3

IN CM

A 25

1

/663.7

B 6

5

/816.8

C 18

7

/1646.8

D 6 15.2

E 2

1

/85.4

F 8 20.3

G 9 22.7

H 7

3

/419.7

1000-1 with

#2539 Sink

Mount Installation

IN CM

A 19

1

/249.5

B 9 22.7

C 8

1

/221.6

D 3

1

/28.9

E 2

3

/85.9

F 7

3

/419.7

1000-3 with

#2539 Sink

Mount Installation

IN CM

A 19 48.2

B 9 22.7

C 8

1

/221.6

D 3

1

/28.9

E 2

3

/85.9

F 7

3

/419.7

D

C

F

E

A

B

Bearing permanently lubricated.

Manual reset overload protection in motor.

TO SPECIFIERS

So that you may

be assured of

receiving the fine quality you expect when you specify a WASTE KING

®

FOOD WASTE REMOVAL SYSTEM, we include the following sample

specification for your convenience:

• Food waste disposer shall be 1 HP, 60 cycle, 1 Phase with 110-120/220240 volts or 3 Phase with 208-240/460 volts.

• There shall be a rubber Hush Cushion®between the disposer and

the cone or sink to eliminate metal to metal contact.

• Turntable shall be of stainless steel with jam-resistant swivel impellers of

stainless steel and stainless steel cutting blade rotating below the exit slots.

• Grind ring shall be precision ground on all cutting surfaces and shall have

non-wearing, size controlled exit slots.

• Disposer shall have a totally enclosed, continuous duty, fan cooled motor

with integral overload protection.

• Unit shall be Waste King

®

model 1000-1 or 1000-3.

Cone Mounted Models

ROUGH-IN DIMENSIONS

A

B

C

D

H

G

E

F

Slope = 1/4”p/ft.

Cone Flange

Slope = 1/4”p/ft.

4240 E. La Palma Avenue • Anaheim, California 92807 • (800) 454-4423

www.wasteking.com

WKC-1156

Proudly made

in the USA

F

O

O

D

E

Q

U

I

P

M

E

N

T

M

A

N

U

F

A

C

T

U

R

E

R

S

N

A

T

I

O

N

A

L

A

S

S

O

C

I

A

T

I

O

N

O

F

®

Loading...

Loading...