Waste king 1000 User Manual

INSTALLATION OF CONE SINK INTO DISH OR WORKTABLE

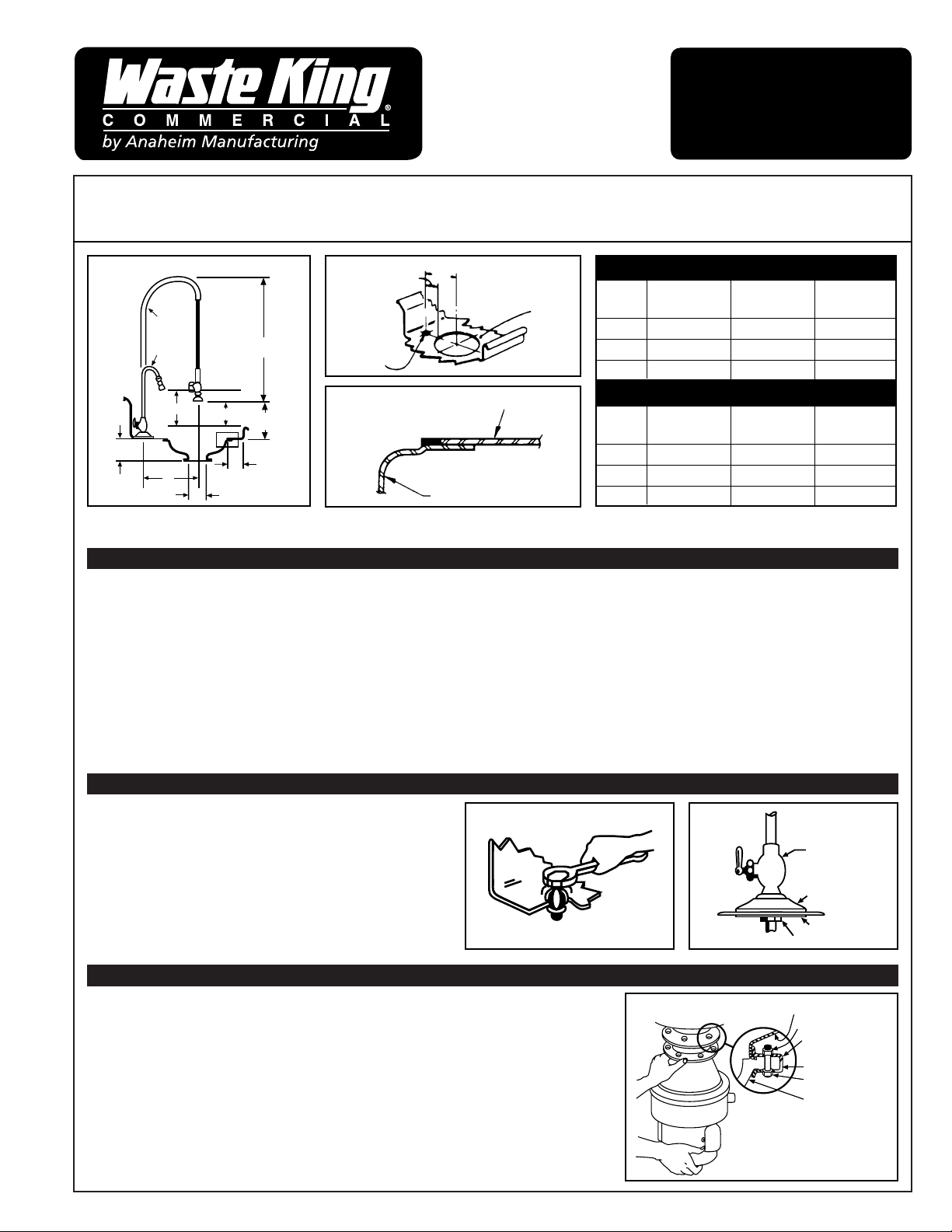

1. (See Figures 1 and 2.) Locate hole center as shown on Figure 2. Cut a “C” (Figure 2) diameter hole in dish or work table, a minimum of 2”

from the inside front edge (operator’s side). Hole can be cut with a “nibbler” after a knockout hole 1-1/2” diameter has been punched.

2. Lift cone to underside of table with cone flange overlapping all around (Figures 1 and 3).

3. Check alignment of cone spray fittings to be sure they are in the proper position. For 15” and 18” cones, position such that holes are located

to right and left side of operator. (See Figure 7 for location.)

4. Tack weld, spot weld, bolt, or rivet flange of cone sink to underside of dish or work table. If bolted or riveted, smooth top surface and washsolder around bolt or rivet heads and sand smooth.

5. Bead weld or solder and wash-solder all around where the table joins flange of cone sink for a clean, watertight, sanitary installation.

6. The cone sink has been designed with the step, as shown in Figure 3. In the welding or soldering operation required to assemble the cone

sink to the dish or work table, every attempt should be made to keep the recessed, flat portion of the cone free of the welded or solder material. This will minimize the clean-up time required and provide a smooth, flat surface for any cover.

SPRAY-RINSE INSTALLATION

1. Locate center (Figures 1 and 2).

2. Drill 7/16” diameter hole through center.

3. Assemble 7/8” punch and tighten bolt head, as shown in

Fig. 4, until the die pierces the stainless steel, leaving a

clean opening of 7/8”.

4. Place body valve and base in position, assemble washer

and locknut as shown in Figure 5.

5. Attach vol-temp assembly to the projecting nipple, as

shown in Figure 7.

MOUNTING DISPOSER

For models to be installed in sink with 3-1/2” outlet,

see separate sheet enclosed for mounting instructions.

1. Clamp ring taped to top side of Hush Cushion®should be placed on underside of

top flange of Hush Cushion®. Line up holes in clamp ring with holes in Hush Cushion

®

and insert six screws also contained in plastic bag. Insert through clamp ring and

Hush Cushion®from the underside.

2. Line up holes in loose steel clamp ring on cone sink with screws in Hush Cushion

®

and raise disposer into position with screws matching holes in clamp ring in approximate

position with plumbing drain outlet.

3. To manually raise the disposer into position, lift the unit by grasping the disposer with

one hand from the bottom of the motor, and with the other hand around the Hush

Cushion®, guide the unit into position, as shown in Figure 6.

COMMERCIAL

DISPOSER MODELS

500, 750, 1000,

1250, 1500

INSTALLATION

INSTRUCTIONS

BEFORE INSTALLING, READ ENTIRE INSTRUCTIONS CAREFULLY.

RISK OF INJURY TO PERSONS FROM HAZARDOUS MOVING PARTS. SERIOUS INJURY POSSIBLE IF

NOT PROPERLY INSTALLED WITH A HOPPER OR A CONE SPECIFIED IN THE INSTRUCTION MANUAL.

IF YOU ARE REPLACING AN OLD DISPOSER GO TO

MOUNTING DISPOSER

MODEL 6T

2216 2215 2211

12” CONE 15” CONE 18” CONE

A 101/4”11

3

/4”13

1

/4”

B 3

1

/2”3

1

/2”3

1

/2”

C 13

1

/2

”16

1

/2

”19

1

/2

”

MODEL 9T

2216 2215 2211

12” CONE 15” CONE 18” CONE

A 127/8

”12

7

/8

”12

7

/8

”

B 6

1

/8”4

5

/8”3

1

/8”

C 13

1

/2”16

1

/2”19

1

/2”

FIG. 1 FIG. 2

FIG. 4 FIG. 5

FIG. 3

CO

N

FIG. 6

CONE SINK

NUT

CLAMP RING

CLAMP RING

MOUNT SCREW

HUSH CUSHION

BODY VALVE

7/8” PUNCH

BASE

WASHER

LOCKNUT

DISH TABLE

CONE SINK

APPROX.

30”

APPROX. 14”

9” MIN.

6” MIN.

2” TO 4”

6”

A

6-5/8”

No. 9T

SPRAY

RINSE

No. 6T

SINK

HOLE

C DIA.

SPRAY

RINSE

HOLE

A

B

LOCKNUT

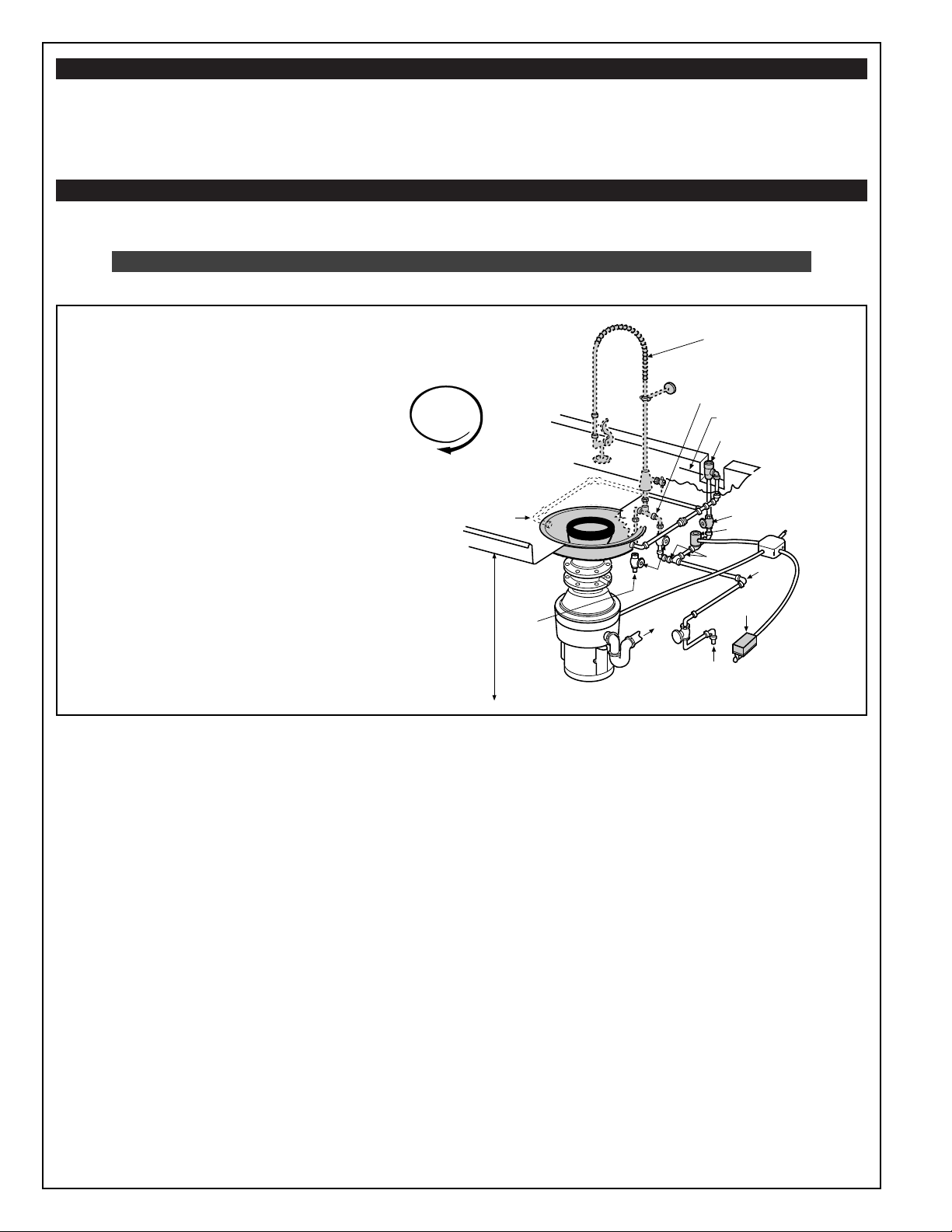

MOUNTING DISPOSER –

Continued (Refer to Figure 6)

4. Attach a nut by two or three threads to screw and then attach another nut to screw on the opposite side of disposer. Finger-tighten two

screws to hold unit in place. Attach remaining four nuts to screws and finger-tighten evenly.

5. Check alignment with plumbing. Adjustment in alignment to plumbing can be made by rotating the unit carefully before tightening the nuts.

To assist in rotating unit, raise the unit from the bottom of the motor to relieve weight.

6. With the unit in its proper position, proceed to tighten six nuts evenly.

PLUMBING INSTALLATION

IMPORTANT! Before installing the Waste King disposer, the connecting waste line must be cleaned out to

the connecting sewer main.

MAKE ALL PLUMBING AND ELECTRICAL CONNECTIONS ACCORDING TO LOCAL CODES.

Recessed thread fittings must be used throughout and all pipe ends should be carefully reamed.

1. For spray-rinse with vol-temp, run a 1/2” hot water line to point indicated in Figure 7. Connect to spray-rinse globe valve, hot water side.

At no time should hot water be connected directly to disposer or cone sink.

2. Run a 1/2” cold water connection to point indicated in Figure 7.

3. Install solenoid valve in line, in upright (coil side up) position as shown in Figure 7, with arrow on side pointing in direction of water flow.

4. Install syphon breaker as in Figure 7. CHECK LOCAL CODE.

5. Make connection to water inlet fitting of cone sink. See Figure 7.

6. Make 1/2” cold water connection to spray-rinse globe valve, cold water side. This must be separate cold water line. Do not tee off of line to

cone unless a 3/4” line is furnished to assembly location. See Figure 7.

7. Assemble swirl spray(s) as shown in Figure 9. The assembly method for the swirl spray(s) is the same for all models. Other combinations

of convertible and fixed swirl spray(s) are optional. The outlet hole of the fixed swirl spray should be horizontal to promote vortex action in

the cone.

NOTE: The convertible spray should be easily adjustable by the operator to function as a swirl spray or as a dish-washing flume. Avoid

excessive tightening of nut or lock nut.

8. Connect 1/2” pipe to swirl spray as shown in Figure 7.

9. The disposer is equipped with a drain outlet designed for a slip-joint connection to a conventional 11/

2” trap (not furnished). Connect the trap

with a branch waste line running directly into the sewage connection (Figure 7). Do not connect into a grease trap. A minimum slope of

1

/4”

per foot of run of waste line is recommended. Limit 11/2” drain line to a 15-foot run, free of turns. A minimum number of elbows, tees, etc.,

reduce the possibility of plumbing stoppages. If unusual sewer conditions exist (too many bends, main too long, low water pressure resulting

in low flow rate*, or if a high percentage of food waste is leafy and/or paper), the use of a time delay relay and water injector into sewer is

suggested. Under such conditions, additionally, a larger size cold water line, larger solenoid valves and larger syphon breakers should be

used to overcome potential stoppages. (Parts and data available from factory.)

*Minimum cold water flow rate used with Models 500 through 1500: 5 gallons per minute or enough to push waste through pipeline

into the sewer.

TIP: Water volume adjustment: The top of the swirling water should occasionally crest to the body of the swirl water inlet.

10. To use the optional supplementary water connection, see Figure 8.

FIG. 7 CONE ASSEMBLY (Typical Installation)

NOTE:

A globe valve, if used for metering flow, must

be installed between solenoid valve and disposer.

See metering valve Fig. 7. Any valve ahead of the

solenoid valve must be opened and cause no

restrictions.

IMPORTANT! Do not test or run disposer

without minimum water flow (see Plumbing

Installation) as this will damage the seal and

void the warranty.

MINIMUM WATER FLOW RATE

5 GALLONS PER MINUTE WHILE IN USE

NOTE:

BASE UNIT INCLUDES DISPOSER, MOUNTINGS,

AND DRAIN OUTLET. OTHER ITEMS SHOWN IN

GRAY IN FIGURE 7 ARE AVAILABLE IN EQUIPMENT GROUPS ORDERED SEPARATELY.

Looking from top.

#9 SPRAY RINSE (OPTIONAL)

CLOCKWISE

ROTATION

SPRAY CONE

FITTINGS

DISHTABLE OR

DRAIN BOARD

RIM TO FLOOR

STANDARD 34"

1/2" HOT

WATER

SUPPLY

VOL-TEMP ASSEMBLY

(included with 9T)

1" MIN. ABOVE TABLE RIM

CHECK CODE

1/2" SYPHON BREAKER

1/2" GLOBE VALVE

(for metering flow)

1/2" SOLENOID VALVE

1/2"

GLOBE

VALV E

1-1/2"

WASTE

LINE

3/4" COLD

WATER SUPPLY

3/4"

SWITCH

Loading...

Loading...