Page 1

W3 POLE INSTALLATION MANUAL

V1.0

Page 2

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

WASSP W3P INSTALLATION MANUAL

The WASSP W3P is an integrated wireless unit for real-time tender mapping within a

portable bracket mounted unit.

The integrated solution, provides transducer, processor, transmitter, position sensors, wifi

and bracket mounted pole in a fully contained and eye catching product.

With a simple bracket mounted attachment, the W3P only requires a power connection

and external PC/Tablet to allow real-time 3D bathymetry mapping of the sea floor from a

vessel which can optionally be transmitted back in real-time to a mothership at distances

up to 2 Nm.

DOCUMENT REVISION HISTORY

W3 POLE INSTALLATION MANUAL

General Notices

WASSP Ltd. reserves the right to change the contents of this manual and any system

specifications without notice.

Contact WASSP Ltd. regarding copying or reproducing this manual.

Support information

If you require maintenance or repair, contact your local dealer. You can also contact

WASSP Ltd. using the following address: wassp.com/support/.

If you need information about WASSP products, visit wassp.com.

On the website you will also find a list of WASSP dealers and distributors.

Warnings, Cautions, and Notes

Warnings, cautions, and notes are indicated by the following icons throughout this

manual:

REVISION DATE REASON FOR CHANGE VERSION

October 2021 Product Release 1.0

RELATED DOCUMENTS

» WASSP DRX Installation Manual – For the latest version of this manual go to

wassp.com

» WASSP Transducer Installation Manual – Installation manual for specific transducers

supported by DRX.

» WASSP CDX Operators Manual – User manual for the WASSP CDX application for

control, visualisation and data post processing of DRX data.

» 3rd Party Application Manuals – 3rd Party Applications that interface with DRX

» Sensor Installation and Operation Manuals – Sensors supported by DRX.

» WASSP DRX ICD – Interface documentation for DRX and associated DRX SDK/API

documentation.

» Sensor Box Installation Manual - Installation Manual for the WASSP Sensor package

Further documentation and updated specifications and DRX installation manual can be

found at wassp.com

CAUTION indicates that if the instruction is not heeded, the action may result

in equipment damage or software corruption.

NOTE indicates a TIP or additional information that could be helpful while

performing a procedure.

»

» 3rd Party Application Manuals – 3rd Party Applications that interface with DRX

» Sensor Installation and Operation Manuals – Sensors supported by DRX.

» WASSP DRX ICD – Interface documentation for DRX and associated DRX SDK/API

documentation.

» Sensor Box Installation Manual - Installation Manual for the WASSP Sensor package

Further documentation and updated specifications and DRX installation manual can be

found at wassp.com

Page 2 of 40 Page 3 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 3

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

CONTENTS

1 INTRODUCTION 6

1.1. Main Features 6

2 SYSTEM CONFIGURATION 7

2.1. Tender 7

2.2. Mothership 8

3 PART LIST 9

3.1. Standard Supply 9

3.2. Mothership WIFI Equipment WSP-W3-ANT-KIT-MS 9

3.3. Optional Supply 9

3.4. Optional Licenses 10

4 INSTALLATION 11

4.1. Installation Considerations 11

4.1.1. Connect to a Distribution Switchboard 11

4.1.2. Location 11

6.3. Connecting to the W3P via fixed ethernet Cable 20

6.4. Connecting to the W3P via Built in Wifi Router 21

6.5. Networking overview 21

7 INITIAL SETUP - OPERATION 22

7.1. Initial Setup W3P 22

7.1.1. Osets 22

7.1.2. Tide Oset 22

7.1.3. Transducer Draft oset 25

7.1.4. Sound Velocity 26

7.1.5. Roll Oset 27

7.2. Datamanager Overview 27

7.3. Initial Setup Mothership PC 27

8 MAINTENANCE & TROUBLESHOOTING 29

8.1. Maintenance 29

8.2. Replacement of Fuse 30

8.3. Trouble shooting 31

4.2. Installation of the W3P Mounting bracket 12

4.2.1. Installation on a Swim Platform (deck mount) 12

4.2.2. Installation Directly to a Transom 14

5 WIRING 16

5.1. Tender / W3P Pole Side 16

5.1.1. Power Requirement 16

5.1.2. Network Cable Connection 16

5.1.3. PC 16

5.2. Wiring Mothership Side 16

5.2.1. Power Requirement 16

5.2.2. Antenna Mounting 16

5.2.3. Antenna Cabling 17

5.2.4. Bullet Mounting 17

6 INITIAL SETUP - CONNECTING TO SYSTEM 18

6.1. Check Points After Installation 18

6.1.1. Mechanical Checks 18

6.1.2. Turning the Power on and Initial Setup 18

6.2. LED STATUS 18

6.2.1. Startup sequence 19

6.2.2. Normal Operation LED Indications 20

9 NMEA SUPPORTED SENTENCES 32

10 SPECIFICATIONS OF W3P 33

10.1. Outline Drawings 34

10.2. Base Plate Drawings 35

10.3. Bracket Drawings 36

10.4. Interconnection Diagram 38

11 APPENDIX: PRODUCT REGISTRATION, SUPPORT AND RESOURCES 39

FIGURES

Figure 1. System Configuration Tender 7

Figure 2. System Configuration Mothership 8

Figure 3. Mount on transom 13

Figure 4. W3 unit on mount, on transom 13

Figure 5. Bracket showing set angles 15

Figure 6. Loop cable and tie loop with cable ties. 15

Figure 7. Startup Sequence 19

Figure 8. Normal Operation LED Indications 20

Page 4 of 40 Page 5 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 4

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

1 INTRODUCTION

The WASSP W3P is a ‘All in one’ portable multibeam mapping solution that includes all

the components to make a complete the WASSP Multibeam Sounder System (sans PC).

Conveniently housed in one pole mounted system – this includes DRX processor, Wi-Fi

units (for local and remote access) IMU motion sensor and Satellite compass.

The supplied bracket allows for transom or duck board mounting, and can easily be

set to various angles and heights to accommodate dierent transoms and installation

requirements.

The WASSP W3P system can be configured to operate in various modes, typically using a

wide-angle sonar transducer to profile the water column and seafloor in high resolution.

The WASSP W3P can be configured to be suitable for operations such as Exploration,

survey and mapping, search and rescue and many more.

Actual data types output to client applications, such as WASSP CDX, will be determined

by:

» Data types enabled in DRX, as determined by the licensing model

» Data types the client application supports and queries for

» If the client application is using raw, processed or post processed data

2 SYSTEM CONFIGURATION

NOTE: ALL EQUIPMENT CASES TO BE EARTHED

NOTE: ALL CABLES TO BE SCREENED

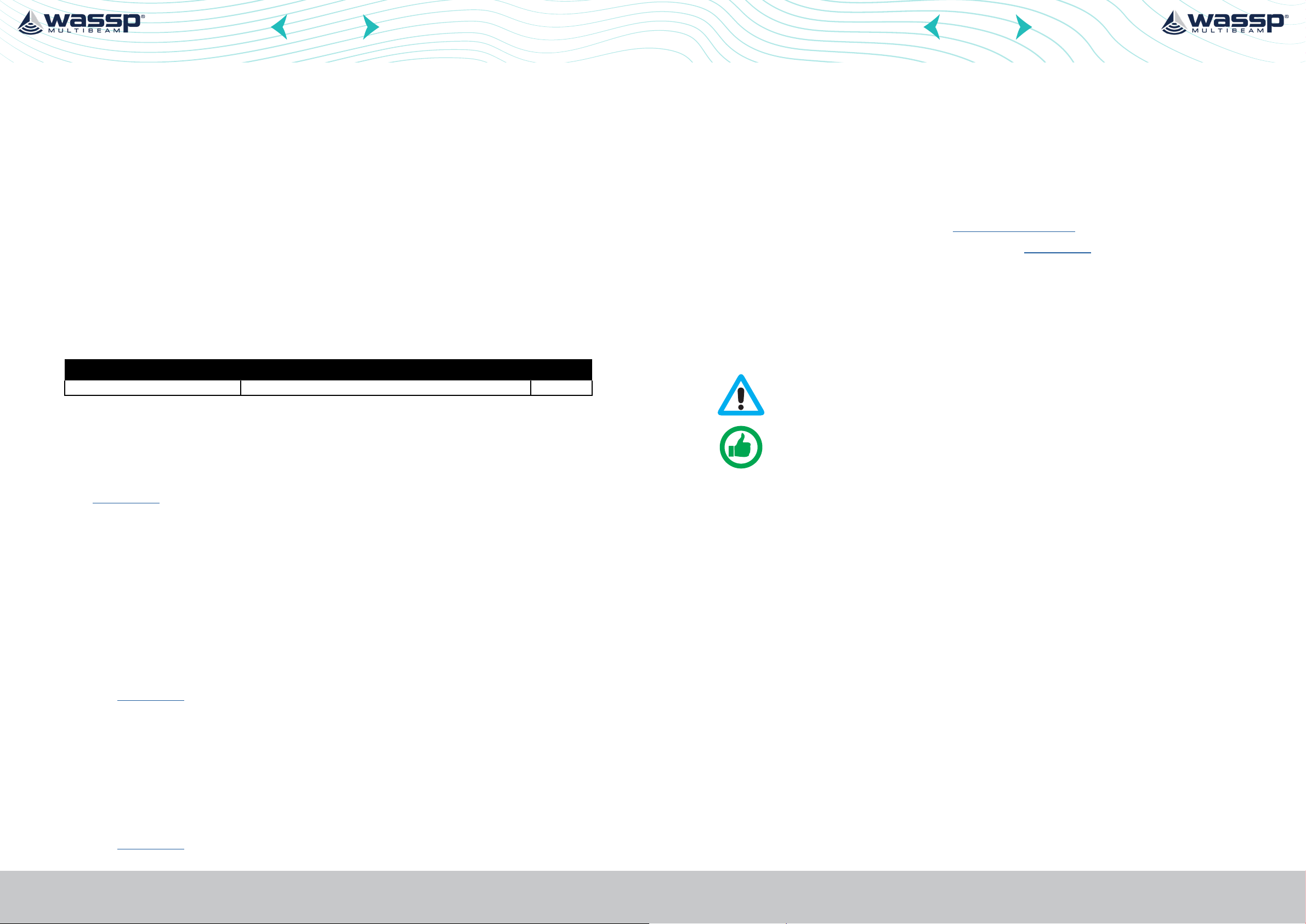

2.1. TENDER

» Data types that are supported will increase through continual product development

and DRX upgrades

The WASSP W3P functionality is defined by the software installed, the data types enabled.

1.1. MAIN FEATURES

The main features of WASSP in a multibeam configuration will depend on the model as

follows:

» 120° Swath coverage

» Up to 2Nm realtime mapping (coverage dependent)

» Designed for (max 15knots) high speed quick deployment mapping

» Store and forward mapping technology for out of range data gathering

» Rugged all in one pole mount design

» 12/24VDC operation

» Control via CDX SW on remote on board PC or Windows tablet

» Depth capability is configuration and environment dependent. Typical numbers are

DRX-32 with WASSP Wideband Fairing Transducer; 1 to 400m

» WMB Fairing Transducer 90-190 khz operation

Figure 1. System Configuration Tender

» WSP IMU038 0.2° pitch/roll accuracy static, .25°dynamic, 5cm or 5% heave

» WSP V200 Sat Compass 0.75° heading accuracy

» Internal 5ghz Wi-Fi router

Page 6 of 40 Page 7 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 5

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

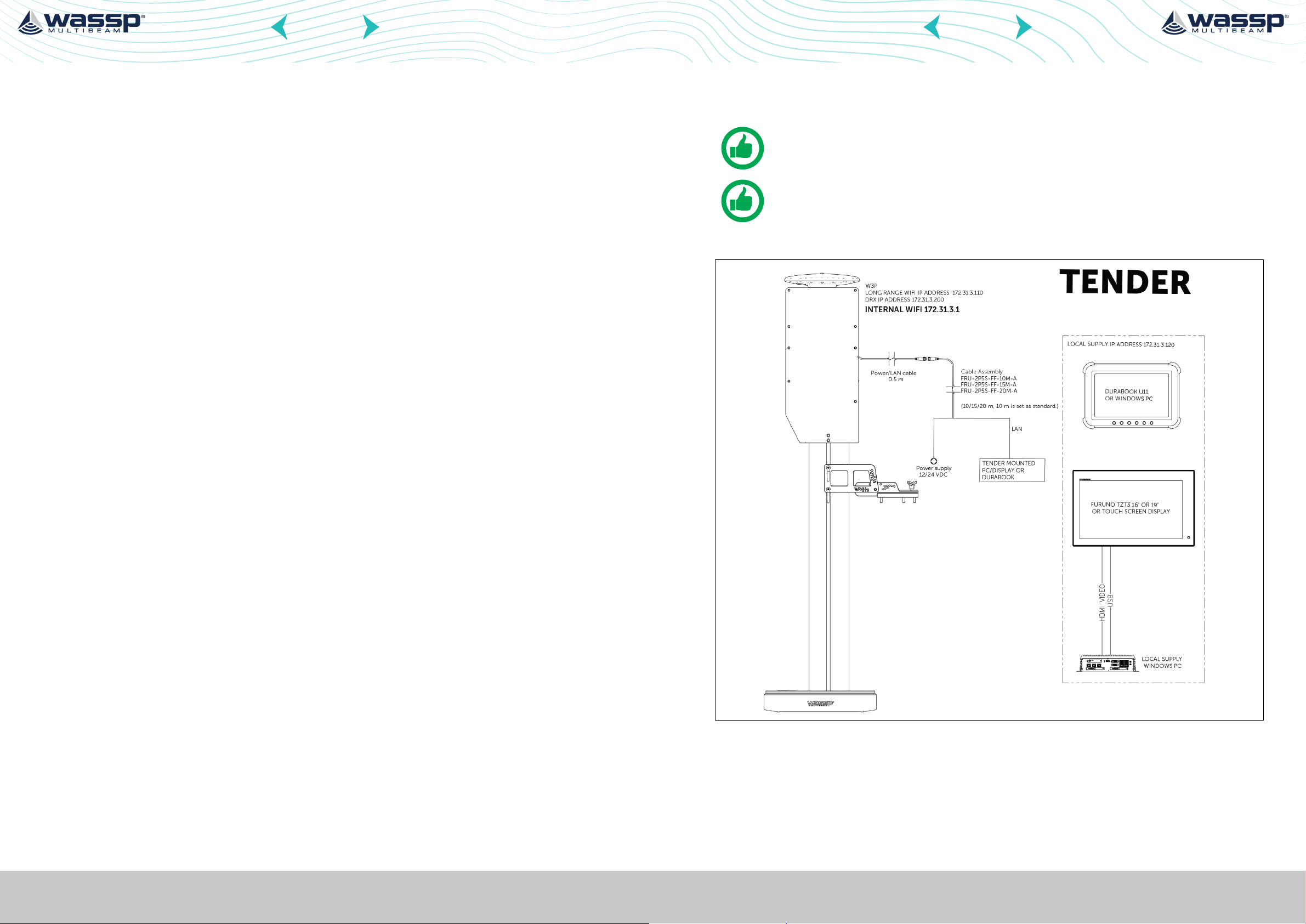

2.2. MOTHERSHIP

3 PART LIST

3.1. STANDARD SUPPLY

WASSP P/N Qty Name Type Remarks

WFT1320W3P90-190-2.5 1 WASSP W3 POLE W3P

WSP-400-952 1 BRACKET ASSEMBLED W3P BRACKET

WSP-400-912 6 HANDLES

WSP-400-901 1 DECK PLATE

WSP-400-904 2 T SLOT ADAPTER

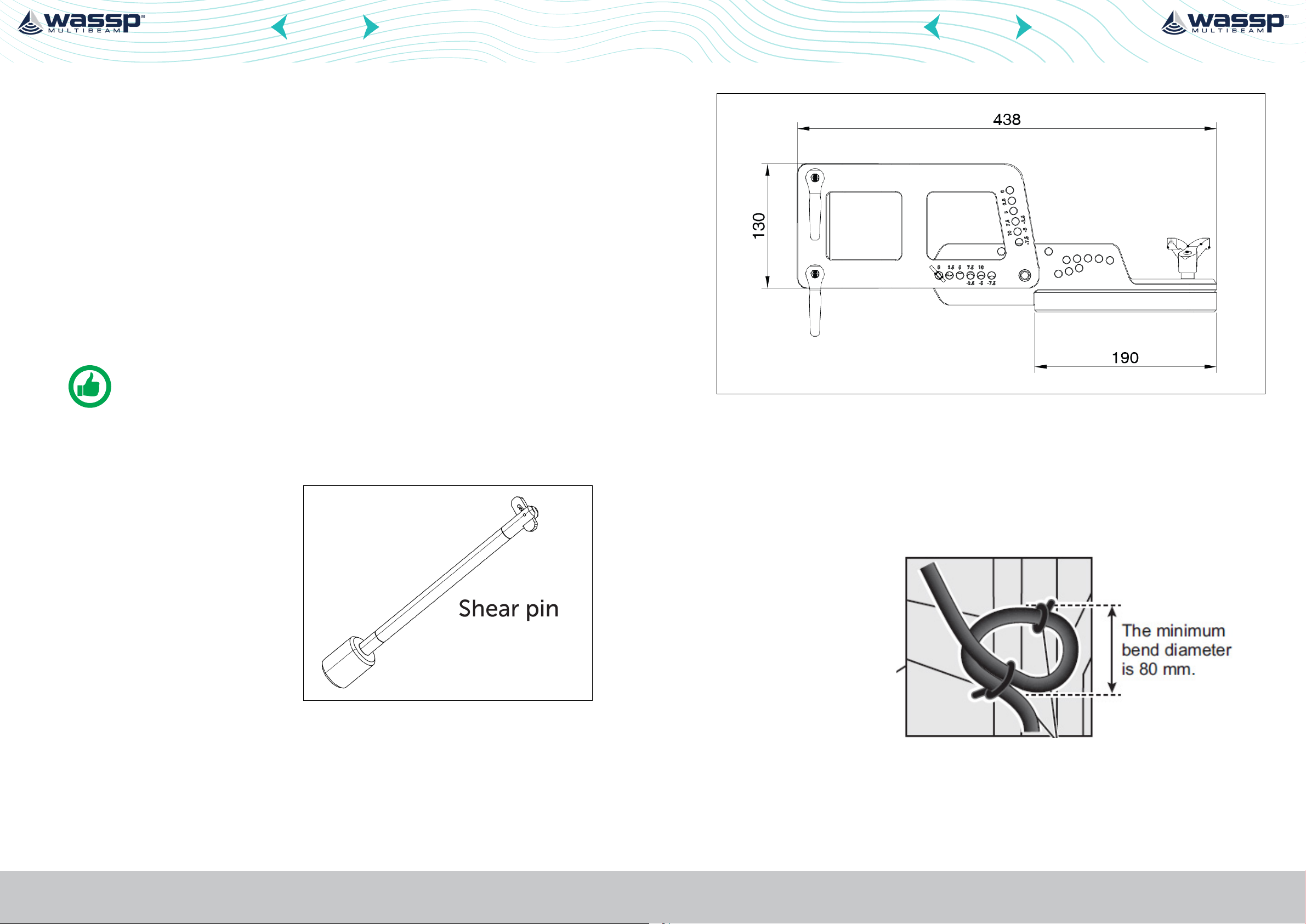

WSP-400-951 1 BREAKAWAY PIN SHEER PIN FOR BRACKET CONSUMABLE ITEM

001-512-600-00 1 POWER CABLE

WSP-002-216 CDX license WASSP CDX License

WSP-002-210 WASSP License Module Time Zero Interface

CLAMP LEVERS FOR DECK

AND POLE MOUNT

DECK/TRANSOM MOUNT

PLATE

STAINLESS T SLOT FOR

BRACKET TO POLE MOUNT

COMBINED POWER /

ETHERNET CABLE 10M

Required for operation

choose one

Required for operation

choose one’

Figure 2. System Configuration Mothership

3.2. MOTHERSHIP WIFI EQUIPMENT WSP-W3-ANT-KIT-MS

WASSP P/N Qty Name Type Remarks

M2 HP 1 WiFI Bullet

CEL24 1 Wifi Antenna

E180F 1 ANTENNA MOUNT

P51 1 ANTENNA CABLE

POE-24-12W 1

MOTHERSHIP AC POE

INJECTOR

802.11b/g/n 600mW

Outdoor AP/Bridge

Omnidirectional Antenna

c/w N240F N-female

Connector (2310-2485 MHz)

Stainless Steel Deck Mount

Flange - 1 1/4" - 11 TPI

N-Male to N-Female 500cm

LLC400 Pig-tail

POE-24-12W 0.5A

airGateway Compatible POE

3.3. OPTIONAL SUPPLY

WASSP P/N Qty Name Type Remarks

001-512-620-00 POWER CABLE COMBINED POWER/

ETHERNET CABLE 15M

001-512-640-00 POWER CABLE COMBINED POWER/

ETHERNET CABLE 20M

Page 8 of 40 Page 9 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 6

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

3.4. OPTIONAL LICENSES

WASSP P/N Qty Name Type Remarks

WSP-002-210 TZ License TimeZero Pro Inter-face

WSP-002-200 Backscatter License Backscatter License

WSP-002-201 Water Column target

License

WSP-002-202 Side Scan License Side Scan License for tender

WSP-002-300 XYZ Data Format export Datamanager XYZ export

WSP-002-301 GSF Data Format export Datamanager GSF export

WSP-002-209 Survey License Survey functionality, Provides

Fish targets dis-played on

tender only

only

license

license

connection to 3rd party

clients like Hypack, Eiva, &

QPS that require uncorrected

data Included in S3.

Please note Survey

license WSP-002209 must be used in

conjunction

4 INSTALLATION

4.1. INSTALLATION CONSIDERATIONS

4.1.1. Connect to a Distribution Switchboard

» The W3P has a power switch, and should be connected to a fused power switch

board of either 12/24v DC

4.1.2. Location

» Install the pole in a vertical position,

with power cable in the forward

orientation.

Page 10 of 40 Page 11 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

» Install the W3P in a position on the transom the vessel, the pole can be mounted

on to a suitably strong swim platform (or duckboard) the mount can accommodate

fore/aft angles of up to 15° by selecting a location for the shear pin.

Alternatively, the bracket can be rotated to be and mounted against the transom of

the vessel again the bracket can accommodate angles up to 15° for aft.

The mount should be strong enough to not cause the pole to wobble while

underway, or cause damage to the vessel under normal operation, or while kicking

up on the event of striking an object

» The unit should be mounted were the transducer can be lowered into a clean flow

of water away from electrically noisy systems, or items on the vessel that create

turbulent water (i.e water inlets/outlets, engine intakes or exhausts

» The unit should not interfere or come in contact with the vessels drive units (i.e

outboards or sterndrives) and should not be subjected to thrust or forces from the

drive unit (i.e a jet drive)

» Install the pole where the GPS satellite compass on top of the unit has an

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 7

CONTENTS CONTENTS

22

W3 POLE INSTALLATION MANUAL

unobstructed view of the sky, and is away from VHF transmitters and RADAR

systems that may cause interference

» Install the system where the long range Wi-Fi antenna (mounted inside the case

under the satellite compass at the rear of the unit) is not blocked by metallic object

that could interrupt transmission

» Ensure that the pole can be raised and lowered.

NOTE: The W3P pole is designed with a shear pin that will break if excessive

force is applied to the pole – this is to try to protect the pole in case it strikes

an object. The pole will rotate forward in this instance and it should be in a

position that it will not cause harm to anyone on board.

NOTE: Maximum Speed warning: the unit is designed to be used at a speed

up to 15knots in calm seas, operating at speeds above this could cause

damage or death to persons on board the vessel, damage to the unit, or

damage to the vessel.

W3 POLE INSTALLATION MANUAL

4.2. INSTALLATION OF THE W3P MOUNTING BRACKET

Determine the suitability of the mounting location BEFORE permanently mounting the

sensor.

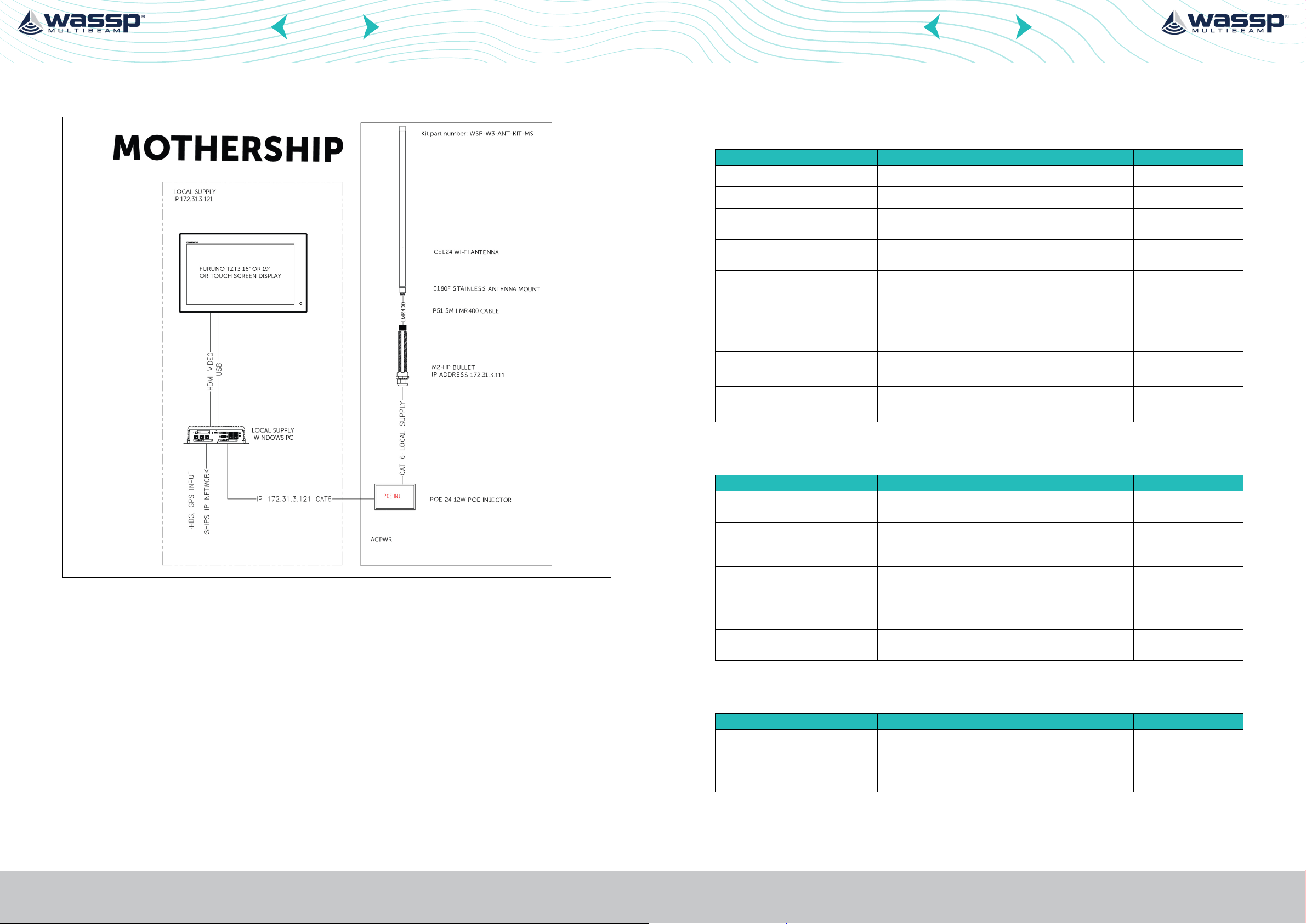

4.2.1. Installation on a Swim Platform (deck mount)

Mount the deck mount plate WSP-400-901 so the bracket can easily be slid on or o the

transom of the vessel. Use 4 x M10 socket capscrews with suitable washer and nyloc nut,

ensure all surfaces are covered in a corrosion inhibitor such a tef-gel to prevent to metal

to metal corrosion.

The bracket of the W3P can be bolted down to the plate using the supplied Clamp levers

(M8 x 1.25 thread) ensure threads are covered in a corrosion inhibitor such as tef-gel, and

that excessive torque is not applied to the clamp levers. This could damage the threads in

the aluminium mount.

Figure 3. Mount on transom

100

Page 12 of 40 Page 13 of 40Doc: W3 Pole Installation Manual

190

wassp.com wassp.com

Version: 1.0 October 2021

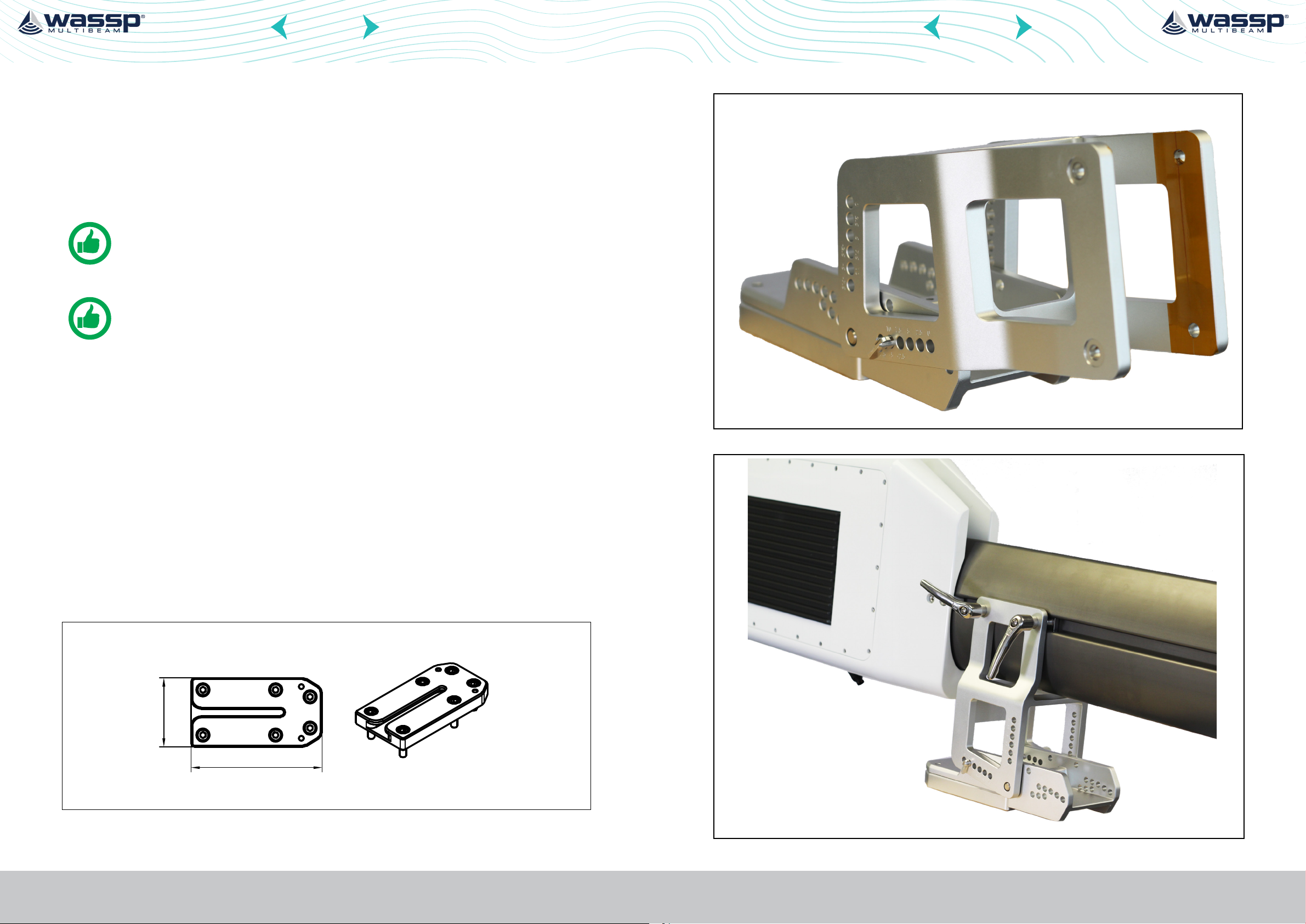

Figure 4. W3 unit on mount, on transom

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 8

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

4.2.2. Installation Directly to a Transom

» Mount the deck mount plate WSP-400-901 so the opening on the bracket is facing

up.

» Ensure the pole easily be slid on or o the transom of the vessel.

» Use 4 x M10 socket capscrews with suitable washer and nyloc nut, ensure all

surfaces are covered in a corrosion inhibitor such a tef-gel to prevent to metal to

metal corrosion.

» The bracket of the W3P can be bolted down to the plate using the supplied Clamp

levers (M8 x 1.25 thread), alternatively locally sourced bolts may be used.

» Ensure threads are covered in a corrosion inhibitor such as tef-gel, and that

excessive torque is not applied to the clamp levers/bolts. This could damage the

threads in the aluminium mount.

1. Use the supplied plate as a template to the mounting location, then drill four fixing

holes in the mounting location.

W3 POLE INSTALLATION MANUAL

NOTE: The holes must be parallel with the fore and aft line.

2. Put the plate on the platform and ensure that is lined up parallel with the ship’s bow.

3. Use customer furnished bolts, flat washers, spring washer to secure the plate to the

platform/transom. The torque for the bolts is 19.6 to 24.5 N*m

4. Use the bracket shear pin inserted

into a suitable hole so that the

transducer is mounted level on

the transom when at rest.

Figure 5. Bracket showing set angles

5. Connect the power/LAN cable to the cable assembly.

Follow these guidelines for laying the power/LAN cable:

• The connectors must not strike any part of the vessel due to wind, etc.

• Do not apply any load to the connectors

• The cable must

be located where

no tension is

applied to the

connectors. To

prevent tension,

create a loop in

the cable close

to the sensor and

tie the loop with

cable ties

Page 14 of 40 Page 15 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Figure 6. Loop cable and tie loop with cable ties.

• Ensure that either end of the cable when disconnected cannot be dropped

into water. Cover connector when disconnected and not in use to ensure

that water cannot ingress and cause corrosion.

6. Connect the cable assembly to the power source and display unit. See “5 Wiring” on

page 16.

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 9

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

5 WIRING

5.1. TENDER / W3P POLE SIDE

5.1.1. Power Requirement

The W3P requires either 12 VDC or 24 VDC power.

» Connect the red cable to the positive terminal of ship’s battery

» Connect the blue cable to the negative terminal

» The black cable is a shielding cable for grounding

5.1.2. Network Cable Connection

Connect the network cable to the ships furnished windows PC or ships network. See

“Figure 1. System Configuration Tender” on page 7 and “6.3. Connecting to the W3P

via fixed ethernet Cable” on page 20.

If using the internal Wifi directly to the pole (i.e using a Durabook to wirelessly connect

to the pole), please ensure the cable is sealed with self amalgamating rubber tape, and

insulation tape and left in a dry location. See “6.4. Connecting to the W3P via Built in Wifi

Router” on page 21 for connection information.

NOTE: For best performance we recommend using the network cable to

communicate with the DRX.

5.2.3. Antenna Cabling

See “Figure 2. System Configuration Mothership” on page 8.

» Screw the supplied 5m coaxial cable to the N type fitting on the bottom of the

CEL24 antenna, and pass the cable through antenna mount.

» Using the overlocking nut (N239F) and O ring Secure the antenna onto the E180F

base.

NOTE: Wifi performance will be degraded by a long antenna run or poor

cable connection, where possible keep the antenna cable as short as

possible and extend the Ethernet cable to the Wifi bullet.

5.2.4. Bullet Mounting

1. Mount the M2 Bullet HP in a cool dry location. Screw the other end of the coaxial

cable to the Ntype connector.

2. Connect the Cat6 cable (user supplied) into the bottom of the Bullet unit.

3. Connect the Cat6 connected to the bullet to the POE labelled output on the POE

injector. Connect the AC power cable to the POE injector and connect to a local AC

power supply. Connect the second CAT6 cable directly to the ethernet port for the

mothership PC .

4. Set the IP address of the Mothership PC to 172.31.3.121 Subnet 255.255.0.0

5.1.3. PC

Connect PC as per manufactures instructions and Install the WASSP CDX SW (refer CDX

user Manual).

5.2. WIRING MOTHERSHIP SIDE

5.2.1. Power Requirement

The Wireless antenna bullet is designed to powered by the supplied AC powered POE

injector, however it can be powered by a DC powered version or suitable POE network

switch (local supply).

5.2.2. Antenna Mounting

Mount the antenna base with a clear view forward of the vessel, the higher the antenna

the greater the range of the antenna, however if it is too high, the tender may not be able

to connect to the mothership when the are along side. Consideration of high powered

transmitters that may interfere with the wireless access point (other Wifi, VHF, SSB,

RADARS and VSAT/SATCOMMS) should be taken into account, mount the unit away from

sources of interference – consult your dealer for more information.

5. Install the CDX software as per the CDX user manual.

Page 16 of 40 Page 17 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 10

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

6 INITIAL SETUP - CONNECTING TO SYSTEM

6.1. CHECK POINTS AFTER INSTALLATION

Before using the product, carry out the following:

» Mechanical checks

» Turning the power on and initial setup

6.1.1. Mechanical Checks

Check below points before switching on the W3P.

» All washers are in place and bolts are fully fastened.

» All connections are secure and network cable is connected to the multi function

display

» All connecting cables and wires are secured. See “5 Wiring” on page 16.

6.1.2. Turning the Power on and Initial Setup

Use the information in this manual and the manual for CDX software to power the sensor

and to proceed with initial setup.

» Briefly press the power button on the W3P, all the LEDS will initially turn on.

» To turn OFF the W3P, press and hold the power key for more than 4 seconds. All

LEDs will turn o, indicating that power has been turned o

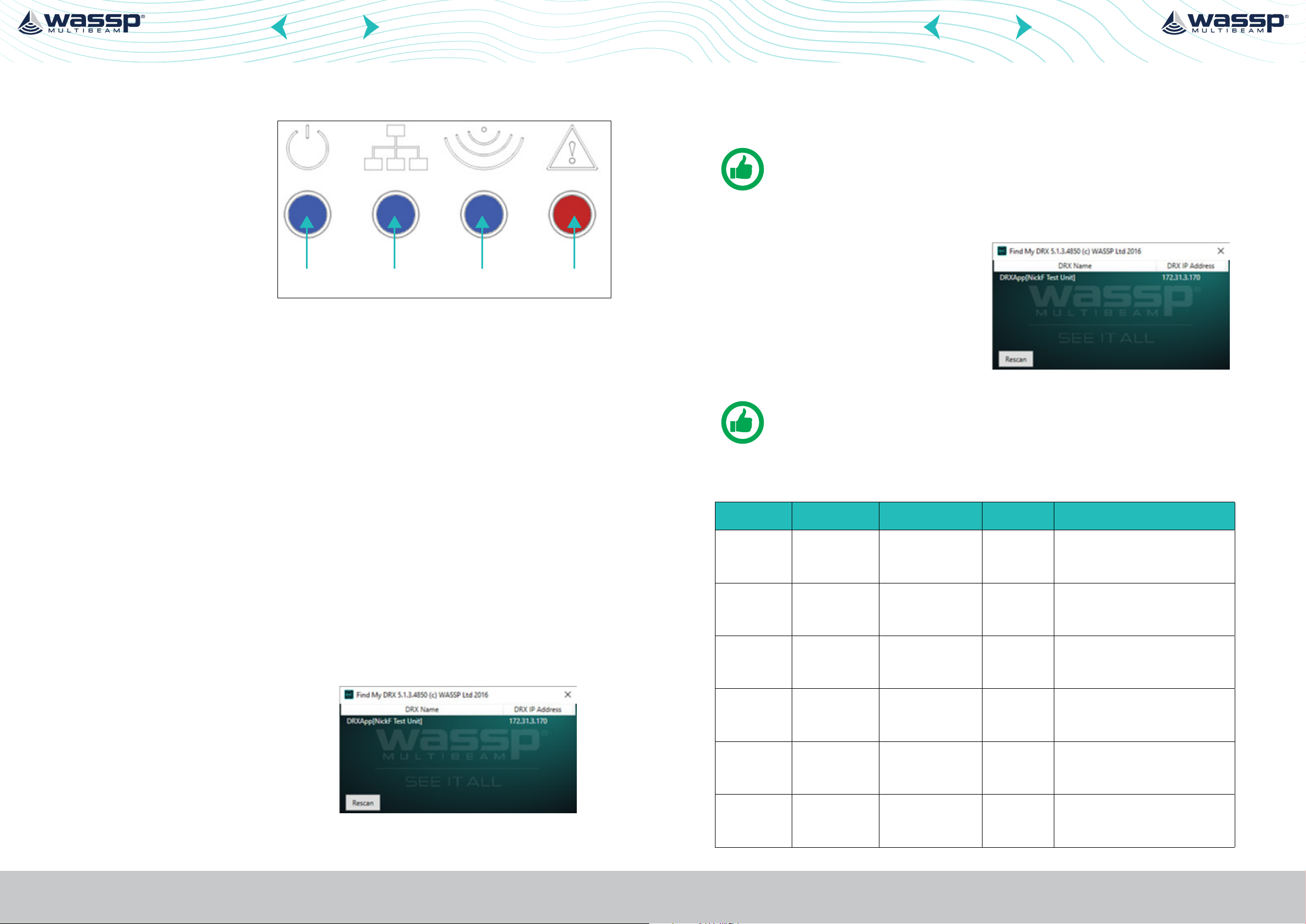

The DRX features 4 LEDS next to the power button which give a quick indication of the

status of the DRX system.

6.2.1. Startup sequence

The boot sequence is as below:

Power on

Booting

Power Network Ping Error

Starting

Process

6.2. LED STATUS

Normal

Operation

Figure 7. Startup Sequence

Page 18 of 40 Page 19 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 11

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

6.2.2. Normal Operation LED Indications

Power LED:

O = Power OFF

On Solid = DRXApp is running

Network LED:

O: No Link (cable not connected)

Solid: Link/Link Established

Blinking: Tx or RX trac

Ping LED:

O: Not pinging

Blinking: Pinging with frequency relative to ping rate (not actual ping rate).

Error LED:

Power Network Ping Error

Figure 8. Normal Operation LED Indications

6.4. CONNECTING TO THE W3P VIA BUILT IN WIFI ROUTER

1. Scan on the available wireless networks for WASSP_LOCAL

NOTE: This is preset to USA frequencies on the 5ghz band.

2. The Password is WASSP123 (case sensitive).

3. Open the Find My DRX program (refer

CDX operation manual).

4. If connected correctly and powered

on the unit will be found as per the

screenshot.

NOTE: The Built in router will provide an IP address in the correct range,

however we recommend to FIX the IP address to 172.31.3.199 subnet

255.255.0.0

O: Normal operation

On: (While booting) system is booting

On: (After booting) Indicates an error state. All LED states should be noted and reported

to WASSP Support. See “11 Appendix: Product Registration, Support and Resources” on

page 39.

6.3. CONNECTING TO THE W3P VIA FIXED ETHERNET CABLE

Power on the Windows PC or Tablet used on the tender to connect to the W3P pole.

1. Plug in the Rj45 connector to the PC connection.

2. Set the fixed IP address of the LAN port used to talk to the W3P to a Class B IP address

– Suggested address is 172.31.3.120 subnet 255.255.0.0

3. Open the Find My DRX program (refer

CDX operation manual)

4. If connected correctly and powered

on the unit will be found as per the

screenshot.

6.5. NETWORKING OVERVIEW

Code Name Type IP/subnet Remarks

RUTX10 WASSP_LOCAL 5ghz Inbuilt to W3P 172.31.3.1

255.255.0.0

Bullet M2 WASSP_TENDER 2.4ghz long range

inbuilt into W3P

Bullet M2 MOTHERSHIP 2.4ghz long range

unit – installed on

mothership

DRX1 Wassp DRX 172.31.3.120

User Furnished Tender PC PC mounted on

tender

172.31.3.110

255.255.0.0

172.31.3.111

255.255.0.0

/255.255.0.0

172.31.3.122

255.255.0.0

WASSP_Local password: WASSP123

System Username:admin

Password:Wassp123

WPA PSK : WASSP123

System Username:ubnt

Password:WASSP123

WPA PSK : WASSP123

System Username:ubnt

Password:WASSP123

Either connected via ethernet power

cable to pole, uses own router or via

Wifi inbuilt into W3P

5. Click on the text to open the DRX configuration page

Page 20 of 40 Page 21 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

User Furnished Mothership PC PC mounted on

Mothership

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

172.31.3.121

255.255.0.0

Either connected directly to bullet M2

On Mothership

Page 12

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

7 INITIAL SETUP - OPERATION

7.1. INITIAL SETUP W3P

Turn on the PC display device, and do the initial setup for the DRX (see “6 Initial setup -

Connecting To System” on page 18).

7.1.1. Osets

The unit is factory calibrated to work right out of the box, however you will need to add

the draft oset (depth of the transducer) for correct mapping.

1. From the HOME bar, under

CONFIGURATION select DRX

PROCESSING.

2. Select TIDES.

1. From the HOME bar, under

CONFIGURATION select DRX

PROCESSING.

2. Select TIDES.

NOTE: NAVIONICS (AUTO), HARMONIC (AUTO) and MANUAL (STATION)

require appropriate cartography containing tidal station information. Use a

Navionics SD card to use these modes.

When TIDE CONTROL is disabled DRX tidal

data is not updated by CDX. On initially

setting TIDE CONTROL to OFF the DRX

tide value will be set to zero.

3. Select TIDE CONTROL on, TIDE MODE

to NAVIONICS AUTO and set the local

UTC OFFSET time.

7.1.2. Tide Oset

The Tide Oset is used in conjunction with the local tide oset to display the depth

corrected to chart datum.

Incorrect tide/draft osets will result in incorrect depths being recorded and poor

mapping results.

It is necessary to select your current UTC oset (+/-14 hours) and to select the database

to use for tide corrections. In either case using the Harmonic (built in) tides or Navionics

Tides (from installed chart) you have the option of automatic tide station selection, or

manually select the tide station. In auto mode the system will select the closest tide

station, but this may not necessarily be the correct tide station to use i.e if the tide station

is on another coast/inlet.

Tidal height oset can be configured to be applied as a depth correction in the DRX. This

will depend on the tide option set in the TIDES menu.

When TIDE CONTROL is enabled CDX will

set the DRX tidal level as per the options

below.

TIDE MODE will provide you with the

following options: DISABLED, MANUAL

(OFFSET), RTK, NAVIONICS (AUTO),

NAVIONICS (MANUAL), HARMONIC

(AUTO) or HARMONIC (MANUAL).

UTC OFFSET is used to correct UTC time

to local time. The Oset should include any

daylight savings.

Page 22 of 40 Page 23 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 13

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

7.1.2.3. Tide Mode Disabled

No tidal oset will be applied as a

correction to seafloor data in the DRX.

7.1.2.4. Tide Mode Manual (Oset)

The manually set tidal oset will be applied

to the DRX.

7.1.2.5. Tide Mode RTK

RTK tide calculates the tide based on RTK corrected GPS information. It is in general

significantly more accurate than conventional tide predictions, as it is based on a realtime GPS height measurement.

It does require the RTK tide DRX license and an RTK corrected satellite compass via PPP

or online RTK subscription.

7.1.2.7. Tide Mode Navionics

(Manual) or Harmonic (Manual)

Tidal oset will be applied based on a

manually selected tide station. The value

will be applied to the DRX periodically.

UTC OFFSET should entered to apply

correct local time for the tide station.

NOTE: TIDE VALUE will give the tide value currently being applied to the DRX.

NOTE: If UTC OFFSET for local time is incorrect, this will result in incorrect

tidal height being calculated.

7.1.3. Transducer Draft oset

Enter the depth of the transducer below the water line to correct the recorded depth of

the soundings.

It is recommended that a mark is put on the W3P and ensure that the pole is lowered

to the same position each time – if using on a dierent vessel it may be necessary to

change this value.

7.1.2.6. Tide Mode Navionics (Auto)

or Harmonic (Auto)

Tidal oset will be selected based on

local tide station using time and position

data. The value will be applied to the DRX

periodically.

UTC OFFSET should entered to apply

correct local time for the tide station.

1. From the HOME bar, under

CONFIGURATION select DRX

PROCESSING.

2. Select TIDES.

Page 24 of 40 Page 25 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 14

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

3. At the bottom of page enter the

TRANSDUCER DRAFT – this is in meters,

and the number is a positive value.

In this example the measured draft is 75cm

below the waterline:

7.1.5. Roll Oset

The W3P is factory calibrated for pitch and roll, and should not require correction,

however if correction is required please use the PATCH TEST app included with the CDX

SW to recalculate the roll correction.

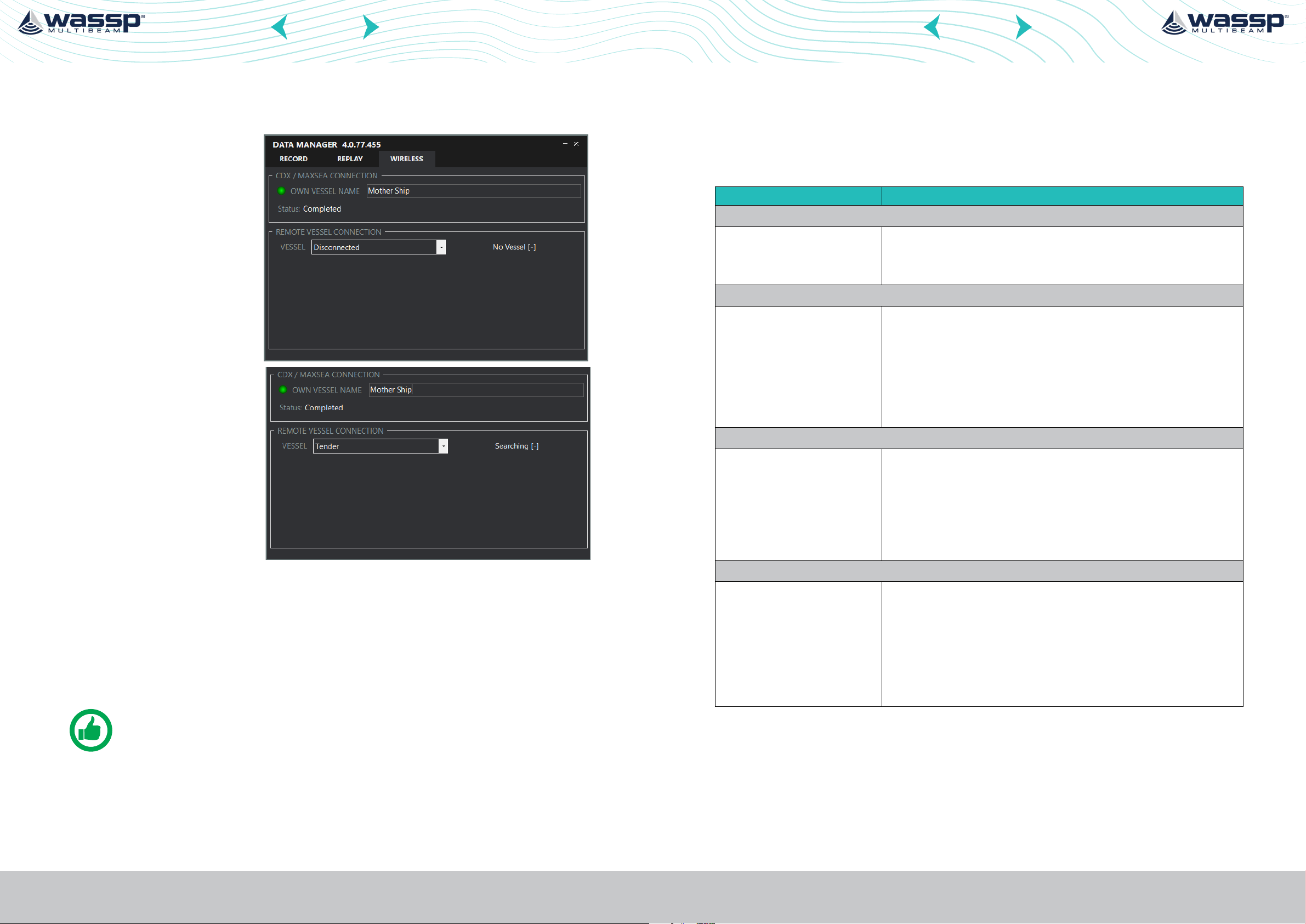

7.2. DATAMANAGER OVERVIEW

Run DATAMANAGER on the WIRELESS SERVER and it will automatically connect to the

DRX. The WIRELESS tab will be available if the Wireless license is installed.

1. Enter the nominated name

of the WIRELESS SERVER

under VESSEL NAME. This

will be used to identify

the vessel for all wireless

operations and will be the

name used to identify the

vessel by WIRELESS CLIENT

vessels. The name selected

here is ‘Tender’.

7.1.4. Sound Velocity

Sound velocity input is required to compensate for range inaccuracies caused by sound

speed variations. These changes can occur both seasonally and with geographical areas

especially in coastal areas where sound velocity will be impacted by both temperature

and water salinity dierences.

Sound velocity in water is aected by both temperature and salinity and can either be

measured directly or derived from temperature and salinity. This value should be adjusted

regularly, depending on the operating environment, as it will have a direct impact on

mapping accuracy.

The sound velocity control allows for both direct and derived values. Sound velocity

compensation can be calculated using appropriate sound velocity, sound velocity profile

or temperature and salinity sensors. The more accurate the sound velocity the more

accurate the mapping.

The visual eect of incorrect sound velocity is that a flat seafloor will either curve up or

curve down. This representation will indicate soundings that are too shallow or too deep

with the aect being accentuated toward the edges of the swath.

Sound velocity measurements can be manually reckoned using the sonar display. For

further details, refer to the CDX Operators Manual.

2. WIRELESS VESSEL is typically

not used for the WIRELESS

SERVER.

3. SCAN and connect to the

DRX using the RECORD Tab.

For further details, refer to

the CDX Operators Manual.

NOTE: WIRELESS does not require pressing the RECORD button, however the

DRX should be connected on the RECORD TAB.

7.3. INITIAL SETUP MOTHERSHIP PC

CDX software requires a GPS and Heading input to display the mothership position

relative to the Tender and the mapped chart.

Connection will typically be using a serial connection either directly or using a serial to

USB adapter connected to the CDX PC.

Once the connection between the sensor and PC is established configure the port(s)

under the WIRELESS SERVER section.

CDX supports 2 ports for own vessel data. CDX will automatically connect to the position

and heading data from the serial ports and display Own Vessel Position.

Page 26 of 40 Page 27 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 15

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

Run DATAMANAGER on the WIRELESS CLIENT. The WIRELESS tab will be available if the

Wireless license is installed.

1. Enter the nominated name of

the WIRELESS CLIENT vessel

under VESSEL NAME. This

will be used to identify the

vessel for wireless operation.

The vessel name selected

here is ‘Mother Ship’.

2. Select the name of the

WIRELESS SERVER from

the drop-down list under

WIRELESS VESSEL. In this

case ‘Tender’ is selected as

the active server.

All available WIRELESS

SERVERS on the network will

be visible and available for

selection.

8 MAINTENANCE & TROUBLESHOOTING

8.1. MAINTENANCE

Regular maintenance is important for good performance. Check the points mentioned

below every before use to keep the unit in good working order.

Checkpoint Action

Fixing bolts

» Corrosion

» If they are tightened

Top Box

» Cracks

» Foreign material

Bracket / Mount

» Replace corroded bolts.

» Tighten loosened bolts.

» Coat new bolts with marine sealant.

» If a crack is found, repair it with a small amount of

sealing compound or adhesive

» Remove foreign material with a freshwater-moistened

cloth. Do not use commercial cleaners to clean

the sensor; they can remove paint and markings or

deform the plastic.

» Replace corroded bolts.

» Tighten loosened bolts.

» Coat new bolts with marine sealant.

» Check for damage, bending or cracks, replace parts as

necessary

WIRELESS VESSEL STATUS will show as:

» NO VESSEL; No vessel available for connection.

» SEARCHING; Searching for vessel.

» SYNCING; Vessels synchronising connection.

» CONNECTED; Connection established.

» READY TO CONNECT; Connection available but not connected.

» OUT OF RANGE; Connection was established but subsequently lost.

NOTE: The number in brackets is the number of packets received from the

wireless vessel.

Page 28 of 40 Page 29 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Complete Unit

» Cleaning

» Storage

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

» For long life it is recommended to wash the unit with a

low pressure hose and a mild detergent after each use.

» Store the unit is clean location in the upright position.

Dry unit before storing away

» Ensure that any cables left disconnected are covered

in a waterproof way to stop corrosion

Page 16

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

8.2. REPLACEMENT OF FUSE

The 5A fuse (Type: FRU-2P5S-FU-5A-A, Code No.: 000-168-869-10) in the fuse holder

on the cable assembly protects the W3P sensor from overcurrent and equipment fault.

If you cannot turn on the power, check the fuse to see if it has blown. If the fuse has

blown, find the reason before you replace the fuse. If the fuse blows again after the

replacement, contact your dealer for advice.

8.3. TROUBLE SHOOTING

The table below provides simple troubleshooting procedures to restore normal

operation.

If you cannot restore normal operation, contact your dealer for advice.

Trouble Remedy

The unit will not power on » Check Power supply

» Check Fuse

» Check Connection to W3P to Power cable

I Cannot connect the DRX » Check IP address of PC

» Check W3P is powered on (LED light

sequence)

CDX software does not map » Check mapping is enabled

» Check Nav data bar to ensure all data is

received (GPS / HDG / itch /Roll / Heave) –

all are required to map

» Check Datamanager is running

Data is not received on mothership » Check datamanger is running on both tender

and mothership

» Check Datamanager on mothership is set to

receive data from the selected tender

Tender and Mothership are not

connected

» Check mothership IP address

» Ping tender bullet – open command prompt

on windows PC and type “ping 172.31.3.110”

– if data is being received check windows

firewall/antivirus is turned o

» Check POE injector

» Check Wireless connection is made via

webpage HTTPS://172.31.3.111

» Check W3P is powered on

» Check Tender PC is powered on

Page 30 of 40 Page 31 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 17

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

9 NMEA SUPPORTED SENTENCES

NMEA 0183 and serial sentences supported:

NMEA / Serial

Sentence

GGA GPS Position Fix and related data

GLL Position, Latitude/Longitude

GNS GNSS position fix data and related data

PTNL GGK Trimble Geographic Position

RMC

ZDA Time and date

HDG Magnetic Heading

HDT True Heading

Description

Navigation Information;

Position, Track Made Good and Speed Over Ground

10 SPECIFICATIONS OF W3P

TRANSCEIVER TYPE INTEGRATED DRX-32

CURRENT TRANSDUCER SUPPORT WIDEBAND FAIRING TRANSDUCER

MINIMUM DEPTH/M 1M

TYPICAL DEPTH 1/M (90° OR 2:1) 300M

MAX DEPTH 2/M (53° OR 1:1) 350M

SOUNDER DEPTH 3/M (NADIR) 400M

SWATHE COVERAGE (UP TO) 120°

DETECTION POINTS 224 (0.54° OVER 120°)

SIGNAL TYPE FM/CW

DEFAULT CENTRE FREQUENCY 160KHZ

CENTRE FREQUENCY RANGE 120-160Khz

MAXIMUM CHIRP FREQUENCY RANGE +/-30KHZ

HDM Heading Magnetic

PFEC ATT True heading (Furuno proprietary sentence), optionally pitch and roll

PFEC HVE Heave (Furuno proprietary sentence)

TSS1 Roll, pitch, heave

PASHR Roll, pitch, heave, heading

VTG Track Made Good and Ground Speed

MTW Water Temperature

FREQUENCY FROM 90-190KHZ

BANDWIDTH (UP TO) 60KHZ

RANGE RESOLUTION (MAX) 2CM

BEAM WIDTH PORT/STARBOARD 4.5° (3.6° @200KHZ)

BEAM WIDTH FORE/AFT 3.2° (2.6° @200KHZ)

SOUNDER BEAMS CONFIGURABLE 5-60°

DC INPUT 9-32V

WIRELESS ANTENNA KIT INTEGRATED

POWER CONSUMPTION (MAX) 60w

DATA CONNECTION GBE

OPERATING TEMPERATURE 0° TO 50°

ENVIRONMENTAL STANDARDS IEC60945, MIL-STD-901

MAX OPERATION SPEED 15 KNOTS

Page 32 of 40 Page 33 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

For Packing list see “3.1. Standard Supply” on page 9.

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 18

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

10.1. OUTLINE DRAWINGS 10.2. BASE PLATE DRAWINGS

Page 34 of 40 Page 35 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 19

10.3. BRACKET DRAWINGS

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

Page 36 of 40 Page 37 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 20

CONTENTS CONTENTS

W3 POLE INSTALLATION MANUAL

W3 POLE INSTALLATION MANUAL

10.4. INTERCONNECTION DIAGRAM

11 APPENDIX: PRODUCT REGISTRATION, SUPPORT AND RESOURCES

WARRANTY

DRX products are covered with a one year limited warranty. In order to be covered by

the warranty, the WASSP DRX must be registered with WASSP Ltd. The product warranty

registration form can be filled in online by going to:

http://wassp.com/product-warranty-registration/

TECHNICAL SUPPORT

If you require maintenance and/or repair contact your local dealer. A list of WASSP dealers

and distributors is available at wassp.com.

DRX technical support is available directly through:

» Online: http://wassp.com/support/ and click on ‘Request Support’

LATEST RESOURCES

» For the latest version of manuals: http://wassp.com/support/ and click on ‘Manuals’

» For software updates and release notes: http://wassp.com/support/ and click on

‘Request Support’

» For Knowledge Base: http://support.wassp.com:8095/display/KB/

» For System drawings, mechanical drawings and declarations of conformity:

http://wassp.com/support/ and click on ‘Request Support’

Page 38 of 40 Page 39 of 40Doc: W3 Pole Installation Manual

wassp.com wassp.com

Version: 1.0 October 2021

Doc: W3 Pole Installation Manual

Version: 1.0 October 2021

Page 21

Loading...

Loading...