Wasp WPL608, WPL610 Quick Start Manual

Media Sensor Calibration

This utility is used to calibrate the sensitivity of

the media sensor. The media sensor should be

calibrated whenever changing the label media

or after printer initialization. Please follow the

steps below to calibrate the media sensor.

Method 1:

1. Make sure the ribbon and label media are

installed properly as described above.

2. Press the

button to enter the

main menu.

3. Press

and buttons to

select the "Setup" option and press

button to enter this option. And

enter the "Sensor"option.

4. When enter this option, the sensor type in

the right side of ">" icon is the current

sensor setting. Press the

and

to select the sensor type, and

press the button to calibrate

the media sensor.

Method 2:

1. Make sure the ribbon and label media are

installed properly as described above.

2. Turn off the printer power.

3. Hold down the

button and

turn on the printer power.

4. Do not release the buttons until printer

LCD shows "Calibrating...".

Printer Initialization

Printer Initialization will restore printer settings

to defaults. Please follow the steps below to

initialize the printer.

Method 1:

1. Press the button to enter the

main menu.

2. Press

and buttons to

select the "Service" option and press

button to enter this option.

3. And press

and buttons

to scroll the cursor to "Initialization"

option and press button to

restore printer settings to defaults.

Method 2:

1. Turn off the printer power.

2. Press and hold

and

button at the same time then

turns on the printer’s power.

3. Do not release the buttons until printer

LCD shows "Initializing...".

Remove Used Ribbon

1. Break the ribbon between ribbon guide

plate and the ribbon rewind spindle.

2. Push the ribbon release button to release

the ribbon on the ribbon rewind spindle.

3. Then, slide off the ribbon from ribbon

rewind spindle.

© 2008 Wasp Technologies

Wasp 610/608

Quick Start Guide

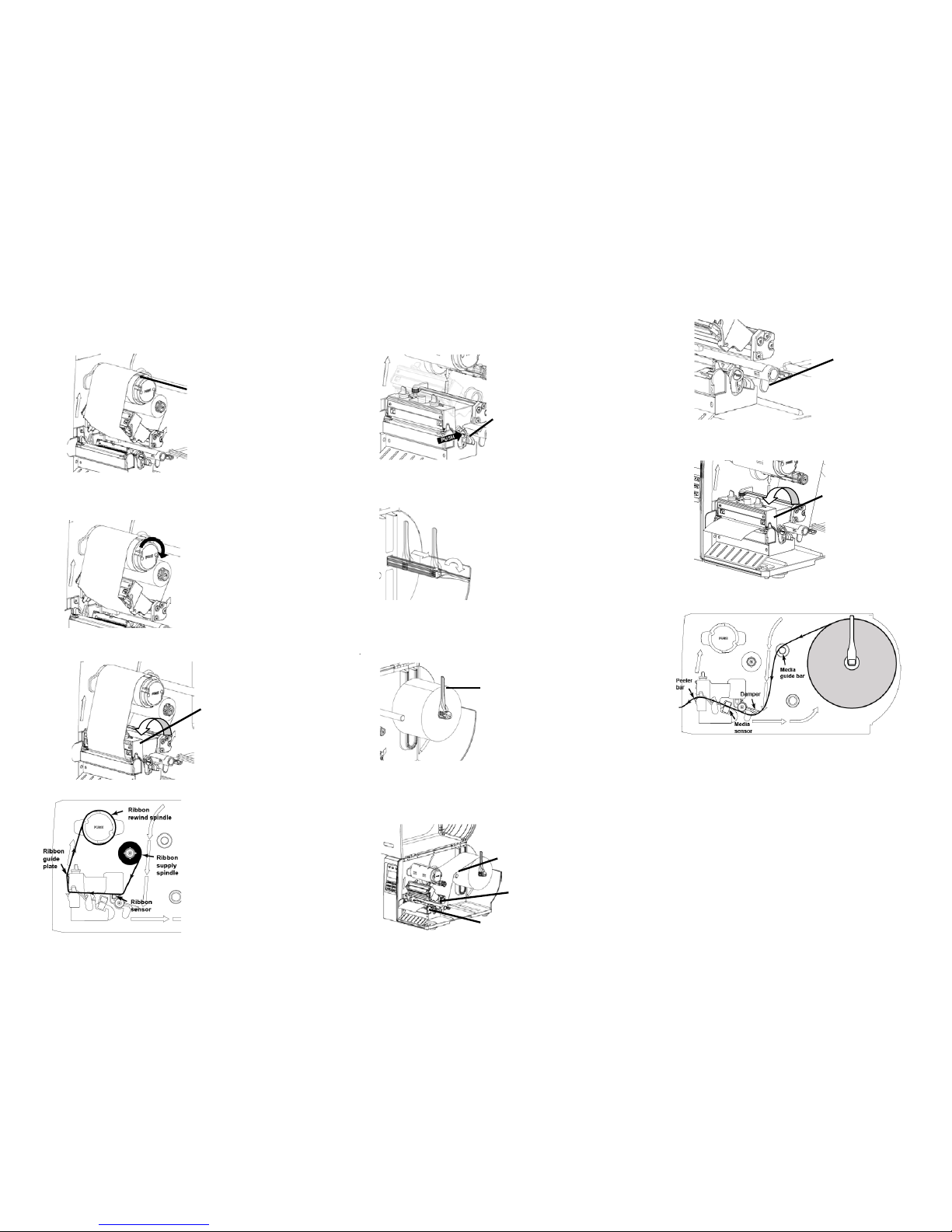

Loading Ribbon

1. Lift open printer right side cover. Push the

print head release lever to open the print

head mechanism.

2. Install the ribbon onto the ribbon supply

spindle. Thread the ribbon through the ribbon

sensor slot and then through the open space

in between print head and platen.

Print head

release lever

Ribbon Supply

Spindle

Print head

Platen

3. Wrap the ribbon onto the ribbon rewind

spindle. Keeping the ribbon flat and without

wrinkles.

4. Wind the ribbon clockwise about 3~5

rotations onto the ribbon rewind spindle until it

is smooth and properly stretched.

5. Close the print head mechanism making sure

the latches are engaged properly.

Loading path for ribbon

Loading Media

1. Lift open printer right side cover. Push the

print head release lever to open the print

head mechanism.

2. Move the label roll guard horizontally to the

end of label spindle then flip down the label

roll guard.

3. Place the roll of media on the label supply

spindle. Flip up the label roll guard. Move the

label roll guard horizontally to gently fit the

width of label roll.

4. Pull label roll leading edge forward through

the media guide bar, damper, media sensor

and place the label

leading edge onto the

platen roller.

5. Adjust the label guide to fit the width of the

label.

6. Close the print head mechanism making

sure the latches are engaged properly.

Loading path for media

7. Using the front display panel, set the

media sensor type and calibrate the

selected sensor.

Note: Please calibrate the gap/black mark

sensor when changing media.

Ribbon rewind

spindle

Print head

mechanism

Print head

release lever

Flip up label roll

guard.

Platen roller

Media guide bar

Media sensor

Print head

mechanism

Label guide

Loading...

Loading...