Wasp WPL308 Quick Start Manual

Printer Overview

Feed / Pause

button

WPL308 Quick Start Guide

LED indicator

Power jack

socket

Fan-fold paper

entrance chute

USB host

Centronics

interface

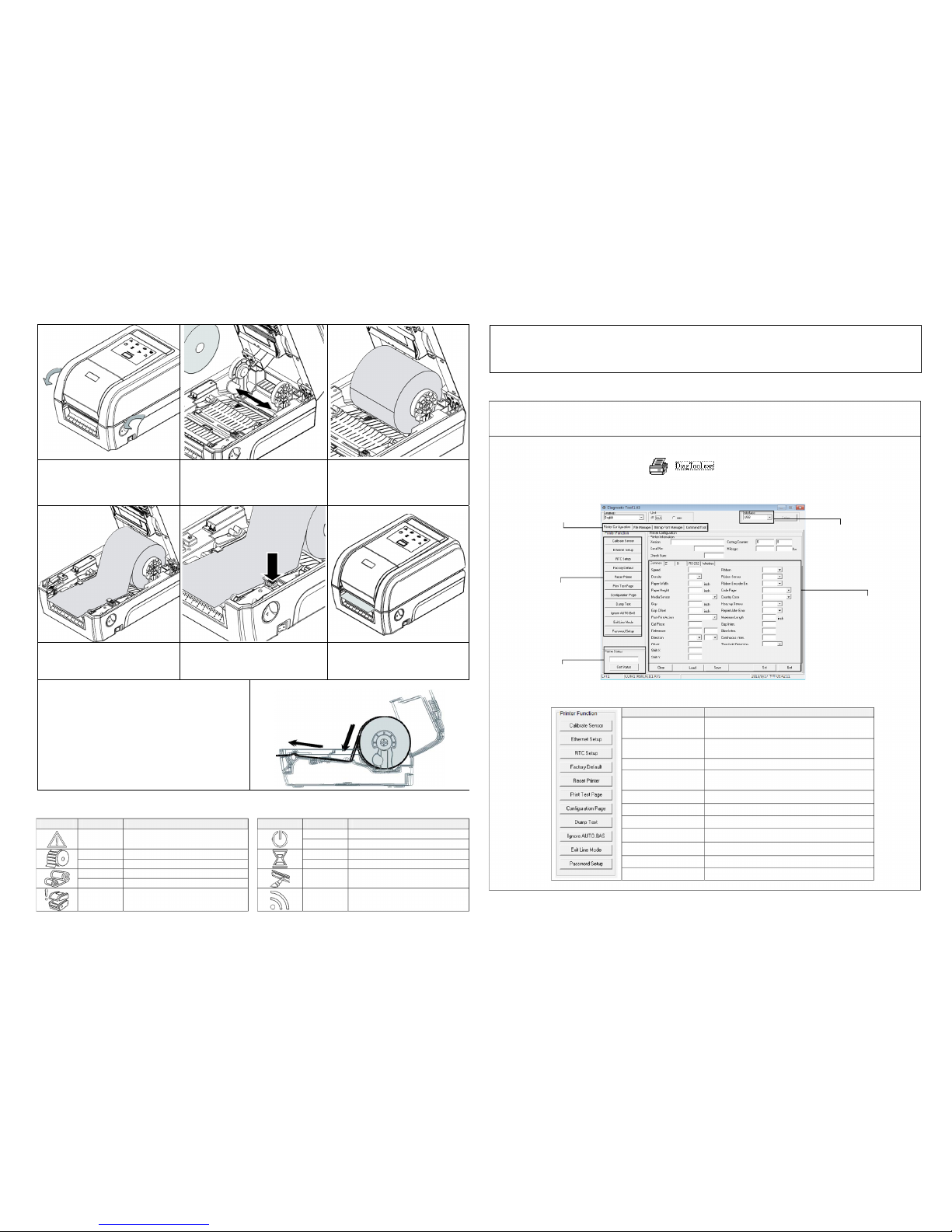

Loading the Ribbon

Top cover

Power

RS-232C

Ethernet

Micro SD

USB

open lever

switch

interface

interface

card socket

interface

Note: The interface picture here is for reference only. Please refer to the product specification for the interfaces

availability.

Ribbon access

cover

Ribbon

rewind hub

Ribbon

rewind gear

Top cover

Ribbon

supply hub

Print head

Gap sensor

(receiver)

Media cover

Gap sensor

(transmitter)

Media holder

Media holder

locking switch

Media guide

adjustment button

Black mark

sensor

Platen roller

Media guides

Page 1 of 2

(1) Open the printer’s top cover by

pulling the top cover open levers

located on each side of the printer

and lifting the top cover to the

maximum open angle.

(2) Open the ribbon access cover and

the media cover.

(3) Insert the ribbon spindle into the

ribbon core.

(4) Install the ribbon right side onto the

supply hub first then align the

notches on the left side and mount

onto the spokes.

Note: The yellow part of spindle is in

left side.

(5) Insert the rewind spindle into the

paper core.

(6) Install the paper core right side

onto the rewind hub first then

align the notches on the left side

and mount onto the spokes.

Note: The yellow part of spindle is

in left side.

* Loading Path for Ribbon

(7) Stick the ribbon onto the ribbon

rewind paper core.

(8) Turn the ribbon rewind gear until

the ribbon plastic leader is

thoroughly wound. Close the ribbon

access cover and the top cover.

Loading the Media

Button Functions

Diagnostic Tool

The Diagnostic Utility is a toolbox that allows users to explore the printer's settings and status; change printer settings;

download graphics, fonts, and firmware; create printer bitmap fonts; and to send additional commands to the printer.

Using this convenient tool, you can explore the printer status and settings and troubleshoot the printer.

Start the Diagnostic Tool:

(1)

Double click on the Diagnostic tool icon to start the software.

(2)

There are four features (Printer Configuration, File Manager, Bitmap Font Manager, Command Tool) included in the

Diagnostic utility.

Features tab

Interface

Printer functions

Printer setup

Printer Status

(3)

The detail functions in the Printer Function Group are listed as below.

Function Description

Calibrate Sensor

Calibrate the sensor specified in the Printer

Setup group media sensor field

Ethernet Setup

Setup the IP address, subnet mask, gateway

for the on board Ethernet

RTC Setup Synchronize printer Real Time Clock with PC

Initialize the printer and restore the settings

Factory Default

to factory default

LED Indicators

LED Status Indication LED Status Indication

On Other errors

On Printer is ready

Blinking Pause

On Out of paper On Erasing memory

Blinking Paper jam Blinking Downloading file

On Out of ribbon

Blinking Need to clear print head

Blinking Ribbon near end

On Print head open Blinking RF communication

Reset Printer Reboot printer

Print Test Page Print a test page

Configuration Page Print printer configuration

Dump Text To activate the printer dump mode

Ignore AUTO.BAS Ignore the downloaded AUTO.BAS program

Exit Line Mode Exit line mode

Password Setup Set the password to protect the settings

*

For more information and features about this printer, please refer to the User’s Manual inside the CD disk.

*

Specifications, accessories, parts and programs are subject to change without notice.

Page 2 of 2

(1)

Feed labels

When the printer is ready, press the button to feed one label to the beginning of next label.

(2)

Pause the printing job

When the printer is printing, press the button to pause a print job. When the printer is paused the power LED will blink

green. Press the button again to continue the printing job.

(1) Open the printer top cover by

pulling the tabs located on each

side towards the front of the printer,

then lift the top cover to the

maximum open angle.

(2) Separate and hold open the media

holders.

(3) Place the roll between the holders

and close them onto the core.

PUSH

(4) Place the paper, printing side face

up, through the media sensor and

place the label leading edge onto

the platen roller.

(5) Move the media guides to fit the label

width by pushing the media guide

adjustment button.

(6) Close the top cover gently.

(7) Use “Diagnostic Tool” to set the media sensor type and

calibrate the selected sensor. (Start the “Diagnostic tool”

Select the “Printer Configuration” tab Click the

“Calibrate Sensor” button ) Please refer to the

diagnostic utility quick start guide for more information.

Note:

Please calibrate the gap/black mark sensor when

changing the media.

* Loading Path for Media

Loading...

Loading...