Wasp WPL305 User Manual

WPL305 Thermal Label Printer

User’s Guide

For Wasp Technologies

DT/TT Printer

Copyright Wasp Bar Code Technologies 2004.

All rights reserved.

No part of this publication may be reproduced or transmitted in any

form or by any means without the written permission of Wasp Bar

Code Technologies. The information contained in this document is

subject to change without notice.

Wasp is a trademark of Wasp Bar Code Technologies. All other trademarks are the property of their

respective owners.

i

Contents

1. Introduction.........................................................................................1

2. Getting Started....................................................................................1

2.1 Unpacking and Inspection............................................ 1

2.2 Equipment Checklist..................................................... 1

2.3 Printer Parts................................................................... 2

3. Setup.................................................................................................... 2

3.1 Setting Up the Printer ................................................... 2

3.2 Loading the Ribbon....................................................... 3

3.3 Loading Label Stock ..................................................... 4

3.7 Top Cover Operation..................................................... 6

4. Power on Utilities................................................................................8

4.1 Initialization ...................................................................8

4.2 Ribbon Sensor Calibration ...........................................9

4.3 Gap/Black Mark Calibration.......................................... 9

5. Maintenance...................................................................................... 12

5.1 Cleaning ....................................................................... 12

6. Troubleshooting................................................................................12

6.1 LED Status ................................................................... 12

6.2 Print Quality................................................................. 13

7. Specifications ...................................................................................14

7.1 Printer Specifications .................................................14

7.2 Label Stock Specifications......................................... 15

7.3 Ribbon Specifications................................................. 15

7.4. LED and Button Operation ........................................15

8. Product Support ...............................................................................16

9. Warranty Information........................................................................16

Revised Date: 7/26/2004

ii

1. Introduction

Thank you for purchasing the W305 Thermal Transfer and Direct Thermal Bar

Code Printer. Although the printer takes only a small amount of space, it

delivers reliable, superior performance.

This printer provides both thermal transfer and direct thermal printing at user

selectable speed of: 2.0, 3.0, 4.0 or 5.0ips. It accepts roll feed, die-cut, and

fan-fold labels for both thermal transfer and direct thermal printing. All common

bar codes formats are available. Fonts and bar codes can be printed in 4

directions, 8 different alphanumeric bitmap fonts and a build-in true type font

capability. You will enjoy high throughput for printing labels with this printer.

2. Getting Started

2.1 Unpacking and Inspection

This printer has been specially packaged to withstand damage during shipping.

Please carefully inspect the packaging and printer upon receipt. Please retain

the packaging materials in case you need to reship the printer.

2.2 Equipment Checklist

Printer

Software CD disk

Sample ribbon roll

Sample label roll

Label spindle (1 inch diameter core)

2 Label spindle fixed tabs with 1.5” core adapters

Paper core

2 Ribbon supply/rewind spindles

Parallel / Centronics cable

Auto switching power supply

Power cord

Quick start guide

To unpack the unit, remove the packaging material and parts carefully from the

box. Remove and discard the tape holding the two halves of the printer and the

media door. Open the media door and remove the Styrofoam. Open the printer

and remove the two cushioning pads from the mouth of the printer. Remove

the protective covers over the media door and back viewing door.

2.3 Printer Parts

Ribbon Access Window

Top Cover Open Lever

Feed Button

Printer Top Cover

LED Indicator

Figure 1: Top front view

3. Setup

3.1 Setting Up the Printer

1. Place the printer on a flat, secure surface.

2. Make sure the power switch is off.

3. Connect the printer to the computer with the Centronics or USB cable.

4. Plug the power cord into the power supply connector at the rear of the

printer, and then plug the power cord into a properly grounded

receptable.

Rear Paper Guides

Wall

Plug

Power Supply

Figure 2: Back of Printer Parts

Centronics

/ Parallel

RS-23

USB

Power

Power Switch

2

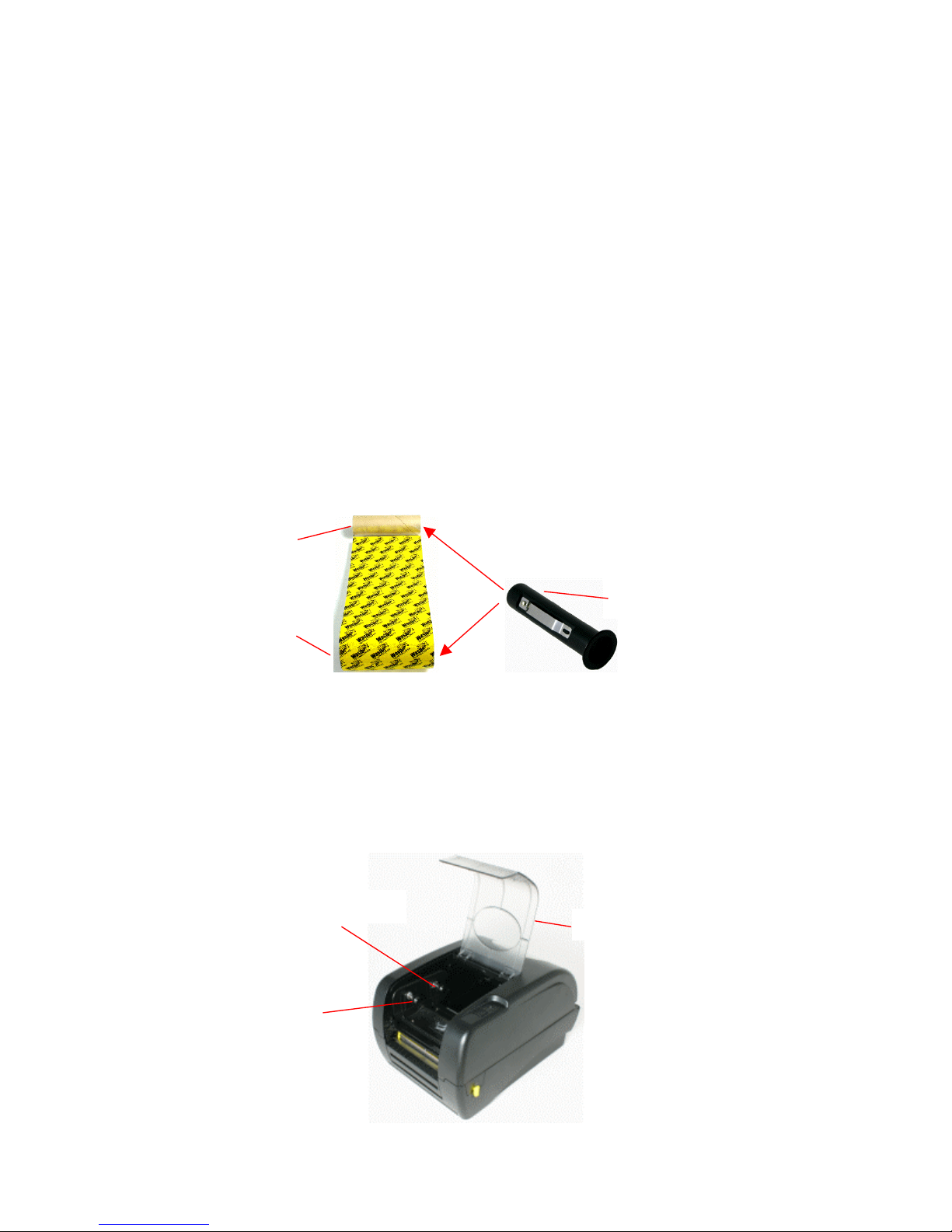

3.2 Loading the Ribbon

The printer automatically detects if a ribbon is installed after power on and will

switch to thermal transfer or direct thermal printing mode. If printer does not

detect the ribbon, the motor that drives the ribbon rewind spindle will be turned

off. In case the ribbon is installed but the printer does not detect the ribbon,

please refer to the ribbon calibration procedure to calibrate the ribbon sensor.

NOTE: If you are using direct thermal labels you should not load a ribbon.

1. Push down on the ribbon access window to unlock and open the cover.

2. Wasp Ribbons come with the cardboard rewind core already attached to

the ribbon for ease of accurate installation. Arrange the ribbon and core as

seen in the picture below so that the core is rolled out about 4 inches and

the dull side of the printer ribbon is facing toward you. On Wasp Ribbons

the Wasp logo should face you.

3. Put the two spindles into the two cores from the right. Make sure the right

side of the spindle is flush with the core after insertion.

4. Pull the cover access lever to open the printer

5. Hold the ribbon with the wide end of the spindle on the right and lower the

rewind core through the back of the ribbon compartment

Back Hub

Ribbon Core

Rewind Core

Spindle

Ribbon Access Window

Front Hub

3

Figure 3: Ribbon installation

6. Attach the ribbon spindle to the Back Hub by placing the left side of the

spindle against the knob with the spring on it and compressing with the

ribbon spindle. Slide the right side down over the other knob. The ribbon

spindle should not be able to be removed without re-compressing the

spring. You may have to turn the ribbon until the grooves on the spindle

align and it clicks into place.

7. Reach between the two halves of the printer and gently pull the rewind

spindle and core under and around the print head and mount it on the Front

Hub as above.

8. Rotate the ribbon rewind core away from you until the black ribbon is on the

rewind core.

9. Close the ribbon access window and press down to lock it.

Make sure both the ribbon access window and the printer top cover are closed

when powering up the printer.

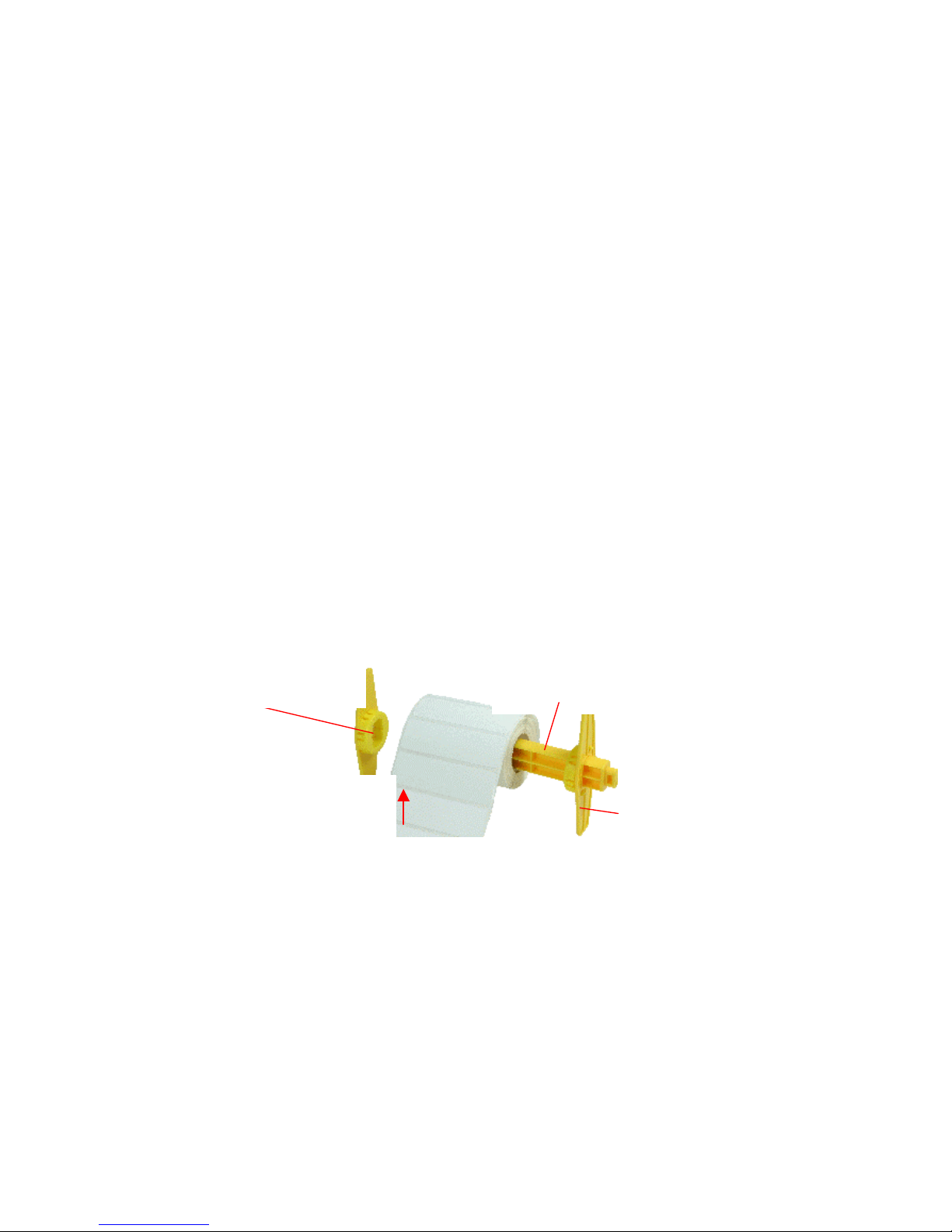

3.3 Loading Label Stock

1. Insert a 1” label spindle into the label roll. If your paper core is 1 inch, you

can remove the 1.5” core adapters from the centering tab. If the label width

is 4 inches wide, the two centering tabs are not required.

1.5” Core Adapter

1” Label Spindle

Printing Side

Face Up

Centering Tab

Figure 4: Label Roll Installation

2. Open the printer’s top cover by pulling the yellow top cover open levers

located on each side of the printer and lifting the top cover. A top cover

support at the rear of the printer will hold the printer top cover open.

4

Loading...

Loading...