Page 1

W-300 Thermal Label Printer

User’s Guide

for Wasp Bar Code Technologies

®

DT/TT Printer

Page 2

© Copyright Wasp Bar Code Technologies 2001.

All rights reserved.

No part of this publication may be reproduced or transmitted in any for m

or by any means without the written permission of Wasp Bar Code

Technologies.The information contained in this document is subject to

change without notice.

Wasp is a trademark of Wasp Bar Code Technologies. All other trademarks or registered trademarks

are the property of their respective owners.

Page 3

Table of Contents

Quick Setup Guide

Inspecting the Printer ..............................................................1

Connection Diagram................................................................2

Connecting the Printer ............................................................3

Loading the Ribbon..............................................................4-8

Loading the Media..............................................................9-13

Calibrating the Printer............................................................14

Chapter 1 Operator Controls..................................................................15

Chapter 2 Resetting the Printer..............................................................16

Chapter 3 Printer Driver..........................................................................17

Chapter 4 Setting Printer Properties ................................................18-19

Chapter 5 Troubleshooting................................................................20-22

Chapter 6 Printer Maintenance ..............................................................23

Chapter 7 Technical Specifications ........................................................24

Chapter 8 Product Support & Warranty Information ..............................25

Page 4

Page 5

1

Quick Setup Guide

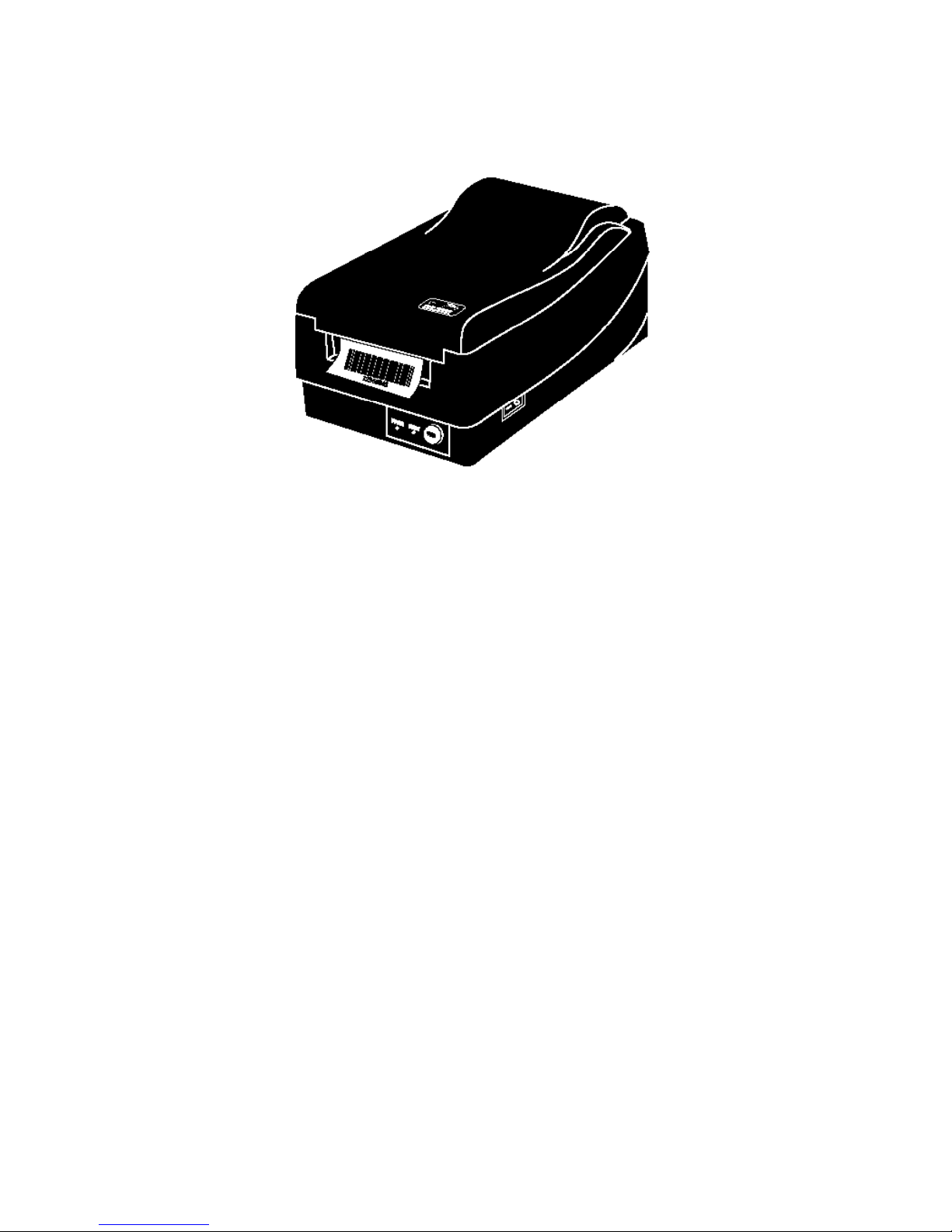

Inspecting the Printer

After removing the printer from the packaging material, check the contents of

the package.The following items should be included:

• Wasp Bar Code Printer

• AC Power Supply

• CD Rom Disk

• Sample Media

• Sample Ribbon

• Parallel Printer Cable

Inspecting the Printer

Printer

AC Power Supply

Sample Media

Centronics

DB25

Sample Ribbon

CD Rom Disk

Page 6

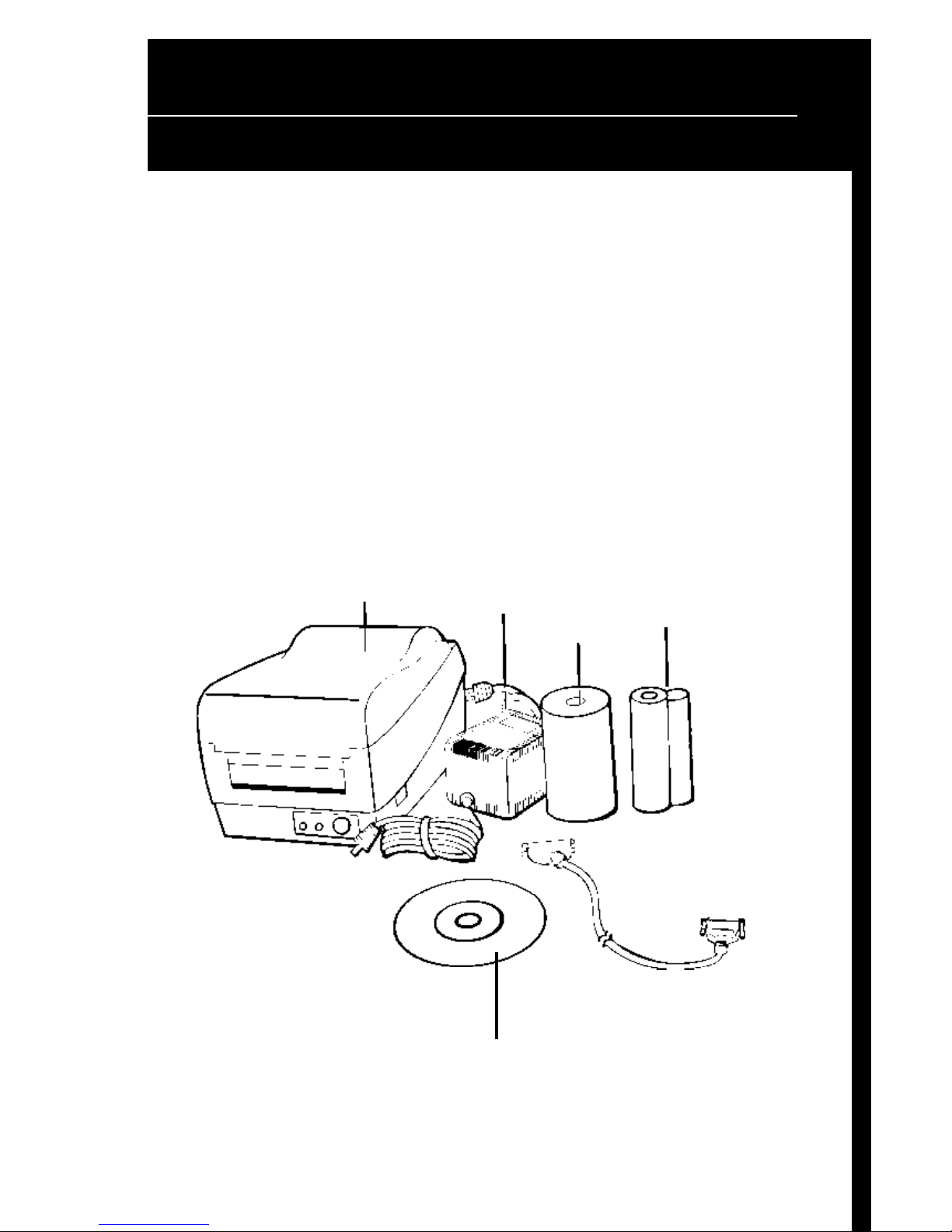

2

Quick Setup Guide

Connection Diagram

AC Electrical Outlet

Power Adapter

To PC

Barrel Connector

Power Jack

Power Switch

Parallel Port

Page 7

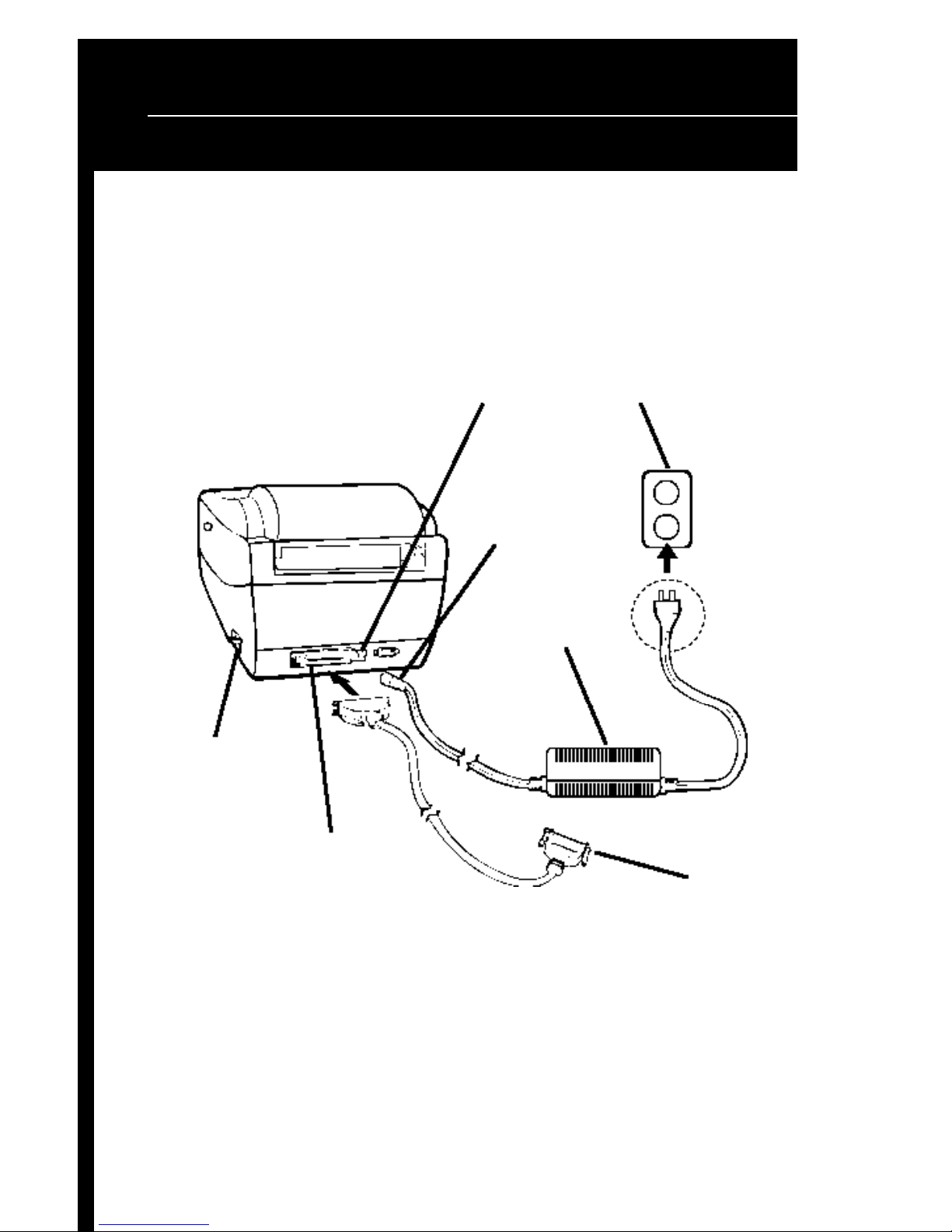

3

Power Supply

Quick Setup Guide

Connecting the Printer

Note: The power supply must be connected into the back of the printer before

connecting the communication cables.

1. The Power Adapter has a barrel connector on one end that must be inserted

into the power jack on the back of the printer.

2. Plug the other end of the cord into an appropriate 120V AC electrical outlet.

Parallel Interface Requirements

Note: This printer complies with FCC “Rules and Regulations”, Part 15, for

Class B Equipment, using fully shielded six-foot data cables. Use of longer

cables or unshielded cables may increase radiated emissions above the

Class B limits.

The included cable (IEE 1284-compliant) has a standard 36-pin parallel connector

on one end, which is plugged into the parallel port located on the back of the

printer.The other end of the parallel interface cable connects to the parallel port

on the host computer.

Data cables must be of fully shielded construction and fitted with metal or

metalized connector shells. Shielded cables and connectors are required to

prevent radiation and reception of electrical noise.

To minimize electric noise pickup in the cable:

1. Keep data cables as short as possible (6 feet recommended).

2. Do not tightly bundle the data cables with power cords.

3. Do not tie the data cables to power wire conduits.

Page 8

4

Note:

This section is not applicable to Direct Thermal (DT) printing.

Quick Setup Guide

Loading the Ribbon

Loading the Ribbon

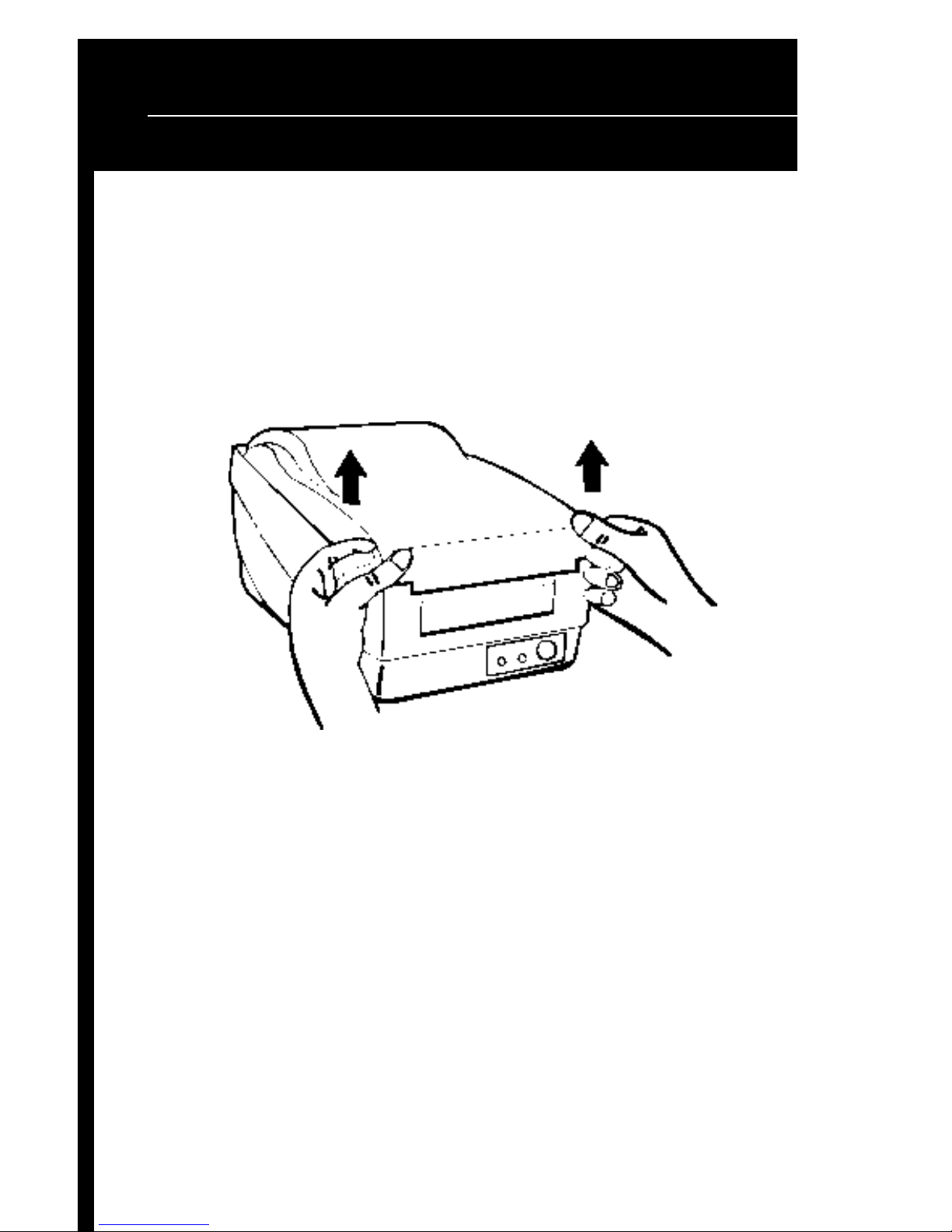

1. Lift the top cover to expose the media compartment.

Page 9

5

Loading the Ribbon

Quick Setup Guide

Loading the Ribbon

Media Compartment

Print Head Module

Release Lever

Release Lever

Ribbon Supply Holder

2. Unlatch the print head module by pushing the two white release levers on

the sides of the print head module.

3. Turn over the print head module to expose the ribbon supply holder.

Page 10

6

Quick Setup Guide

Loading the Ribbon

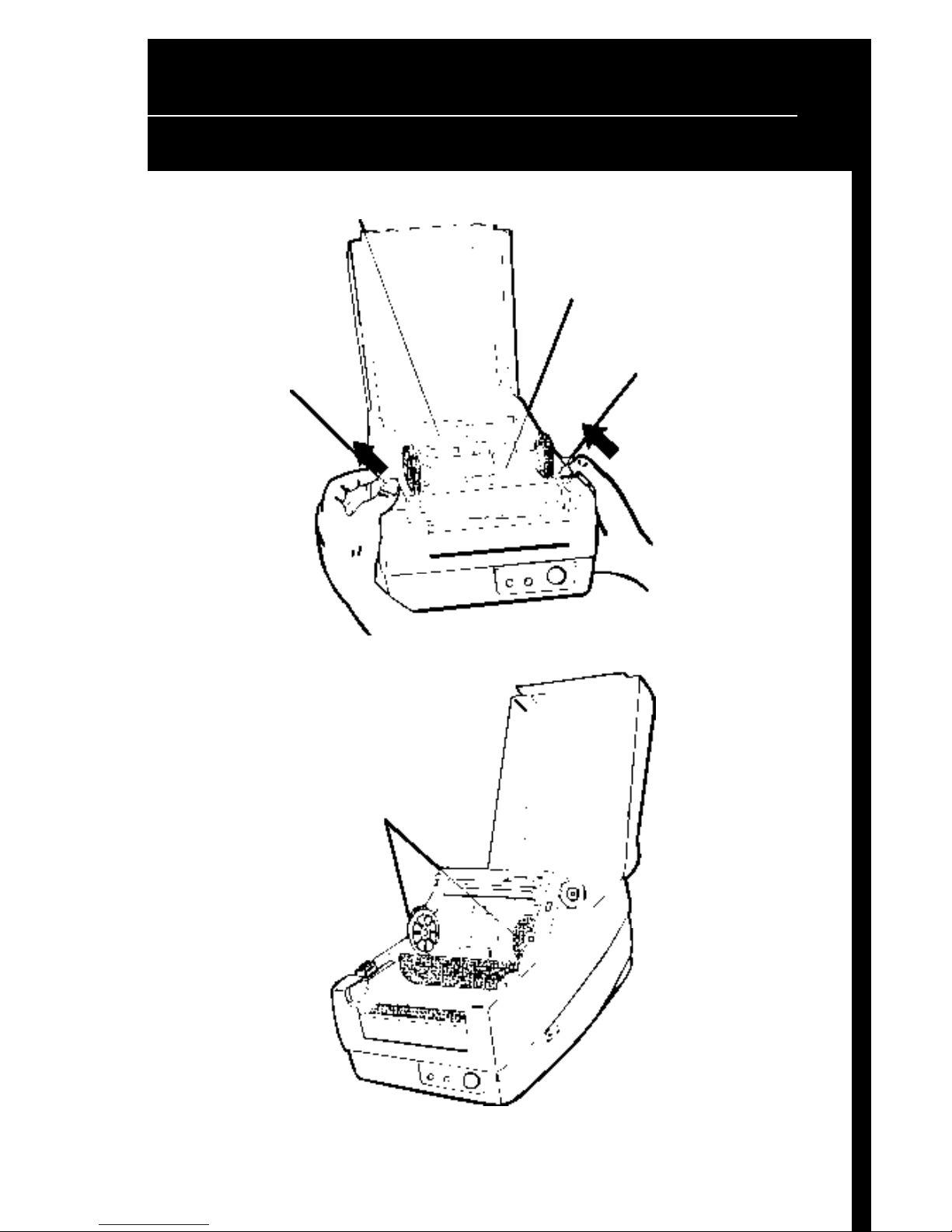

4. Unwrap the ribbon package and separate the ribbon roll and the empty core.

Ribbon Supply Holder

Ribbon Roll

Notch

Ribbon

Empty Core

Empty Core

5. Insert ribbon into the internal ribbon supply holder. (First snap in left side by

aligning notches in the core to the notches on supply wheel.Then snap in

right side.)

Page 11

7

Quick Setup Guide

Loading the RIbbon

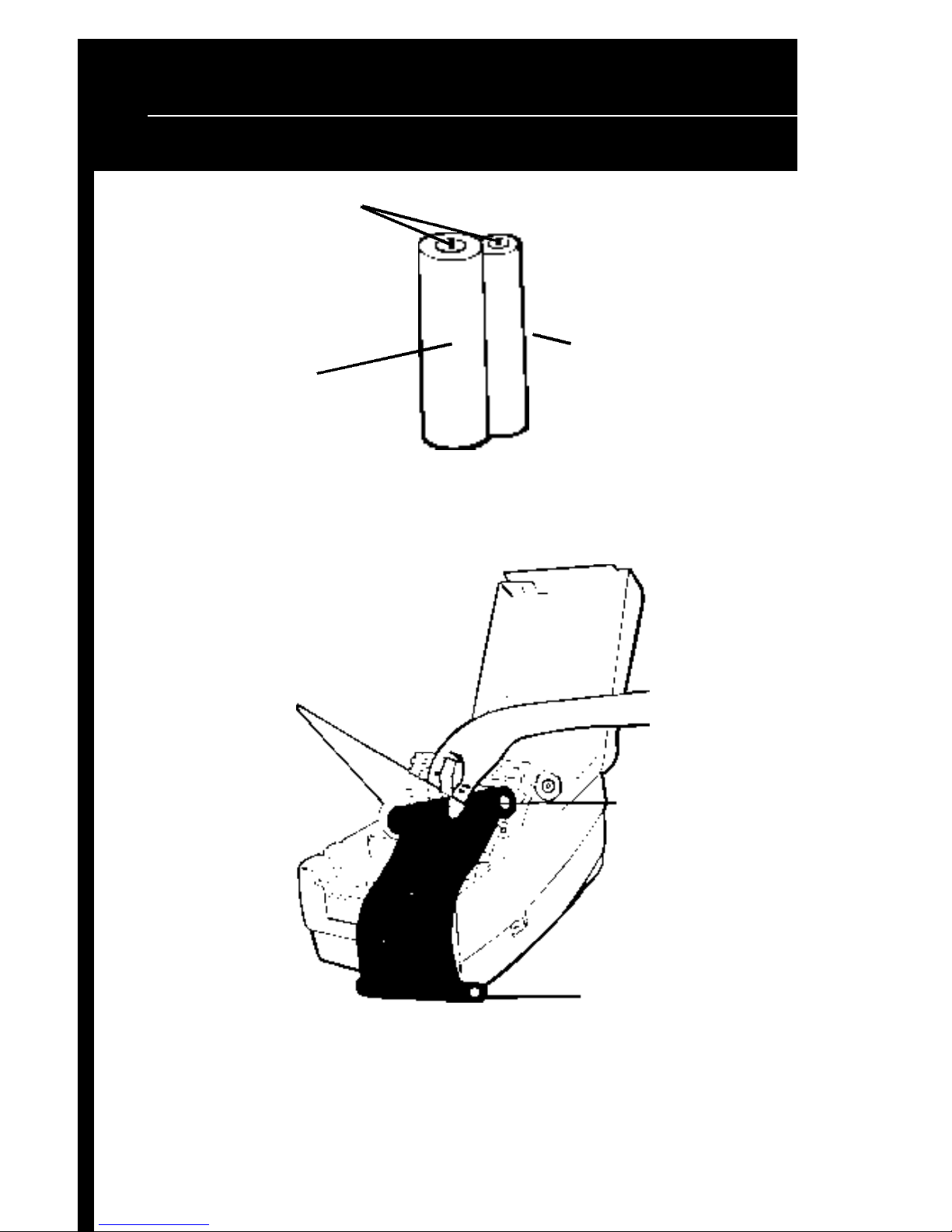

6. Insert empty core into the outer ribbon supply take-up holder. (First snap in

left side by aligning notches in the core to the notches on the take-up

wheel.Then snap in the right side.)

Ribbon Take-up Holder

Empty Core

Page 12

8

Quick Setup Guide

Loading the Ribbon

7. Turn the take-up wheel forward and rewind the excess ribbon.

Wheel

Page 13

9

Quick Setup Guide

Loading the Media

Standard Mode - (Direct Thermal and Thermal Transfer)

1. Lift the top cover to expose the media compartment.

Page 14

10

Quick Setup Guide

Loading the Media

3. Load the media roll onto the holder from the left.

Media Compartment

Media Holder

Media Holder

Media Roll

2. Remove the media holder.

Page 15

11

Quick Setup Guide

Loading the Media

4. Place the media holder back to the media compartment.

5. Move the media roll to the left end of the holder.

6. Slide the shield snug against the media.

Media Compartment

Media Roll Shield

Page 16

12

Quick Setup Guide

Loading the Media

7. Hold the print head module upright with one hand to allow the media to pass

under it.Lead the media through the media guides with the other hand. Right

side slides in and out.

8. Lead the media over the platen roller

Print Head Module

Media Guides

Platen Roller

Page 17

13

Quick Setup Guide

Loading the Media

10. Close the top cover and turn on the printer or press the feed button if the

printer is already on.

Print Head Module

Feed Button

9. Press down firmly on the outside edges of the supply holder to securely lock

into place.You will hear it “click” shut

Page 18

14

Performing Calibration

Note: This step is very important and must always be carried out whenever

media is being changed. Failure to do so will result in mis-detection of

the label size.

1. Press and hold the feed button while turning on the power until the printing

motor becomes activated.

2. The calibration is complete when the printer automatically feeds the

label stock.

3. Press feed button one more time to line label up for printing.

Printing Configuration Repor t

1. Press and hold the feed button while turning on the power.

2. Continue holding down the feed button.The printer will begin to feed

approximately 12” of blank media. The printer will then print a configuration

report.This report states the firmware version, ROM checksum, RS232,

thermal transfer/direct thermal settings, hardware configuration and font types.

Quick Setup Guide

Calibrating the Printer

Page 19

15

Chapter 1

Operator Controls

Operator Controls

Power Switch - Controls printer power

On - normal operation

Off - the power should be turned off before connecting or disconnecting the

communication cables and power cables

Feed Button - Advances the media to the printing position

Press - to advance a label

Press - takes the printer out of a “pause” condition

Press and hold while turning on the power to print out the configuration profile

Ready Indicator - Shows the printer status

Green - printer is ready to operate

Blinking - printer is paused

Power Indicator - Shows the power and error status

Off - printer power off

Green - printer power on

Blinking - error

Top Cover

Power Indicator

Ready Indicator

Feed Button

Power Switch

Page 20

16

Chapter 2

Resetting the Printer

Resetting the Printer to Factory

Default Settings

1. Turn on the printer and wait for approximately 5 seconds .

2. Press the “Feed” button for 10 seconds.The “Ready” indicator and

“Power” indicator will go off in order.

3. When the two indicators become lit again, release the feed button.

4. At this moment, the printer will feed 12 inches of label stock, and will reset

itself to the factory default settings.

Note: All settings are stored in non-volatile EPROM and cannot be erased when

the printer is turned off.

Page 21

17

Chapter 3

Printer Driver

Printer Driver

The bundled printer driver is compatible with Windows 2000/ME/9x, and Windows

NT. Through this driver you may print using any Windows software application that

supports Windows printing.

Installing Driver

1. Click the Start, point to Settings, click

Printers, and then double-click Add Printer.

2. Click Network or Local and then click Next.

3. Click Have Disk, click the pull-down menu to select CD ROM (or floppy

disk) drive path.

4. Click Browse.

5. Select the proper operating system for installation:

–WIN95

–WIN98

–WIN2000

–NT4.0

6. The driver name will appear in the “List of Printers,” click Next.

7. Select the communication port for the label printer. For parallel port, select

“LPT1:”, “LPT2:” or “LPT3:”, for serial port, select “COM1:” or “COM2:”.

8. After the related files have been copied to your system, the installation is

complete.

Page 22

18

Chapter 4

Setting Printer Properties

Setting Printer Properties

After installing the driver, follow the steps below to modify the printer properties:

1. Click Start, point to Settings, and then click Printers.

2. Right-click the icon for the printer you are using and then click Properties.

The properties include:

Ports

Select the IO port you are printing to.This port may be parallel (LPT), serial

(COM), network port or file.

Paper Size

Select your label size from the menu. If your size is not listed, select “Custom” to

define your paper size.

Orientation

Set portrait or landscape according to the print direction.

Paper source (Media type)

T/T stands for Thermal Transfer (ribbon) mode and D/T for Direct Thermal mode

(without ribbon).

Page 23

19

Chapter 4

Setting Printer Properties (cont.)

Media choice (Darkness)

Some printing applications require changes to the darkness setting.This setting

actually controls the heat intensity of the printhead.The lowest setting is 0; the

highest intensity setting is 15.

Note: In most cases, direct thermal media requires a higher printhead heat than

thermal transfer printing.

Note: Use the lowest intensity setting possible for your application.Printing at the

lowest intensity will reduce the printhead wear.

Copies

This function designates the number of printed copies of each page.

Device options (Speed)

Use the pull down menu to choose the appropriate speed for your printing

application. Speed is measured in inches per second from 1.0 ips to 3.0 ips.

Note: Speed will directly affect print quality:the slower the speed the longer the

media will travel under the print head. For example, direct thermal media is

heat activated; therefore, the label will be more reactive the longer the

print head makes contact with the media.

Note: In most cases, use the slowest speed to achieve the highest print quality.

Page 24

Troubleshooting

Normally, when the printer has an error, the “Power” or the “Ready” LED will blink.

To understand the problem, please check both LEDs first:

A. Power and Ready LEDs blink at the same time

Possible Solutions Refer to Pages

Problems

Mis-detected • Check the label path 10-14

the label gap. • Check the label sensor

Label stock • Reload labels 10-14

empty

Label stock • Reinstall the label roll 10-14

not installed

properly

Label jam • Check media path and 10-14

print head for possible

media errors

20

Chapter 5

Troubleshooting

Page 25

21

Chapter 5

Troubleshooting

B. Power and Ready LEDs blink alternately

Possible Solutions Refer to Pages

Problems

Ribbon empty • Reload ribbon 5-9

Ribbon jam • Reload labels 5-9

• Check media and ribbon

Ribbon sensor • Call tech support N/A

error

C. Only the Power LED blinks

Possible Solutions

Problems

Serial IO error • Check the baud rate

Memory full • Close all applications

that are not needed

for printing

Hardware error • Call tech support

Page 26

22

Chapter 5

Troubleshooting

D. Miscellaneous

The PC says “Printer Time Out”

1. Make sure the communications cable (parallel or serial) is connected

securely to the parallel or serial port on the PC and the printer.

2. Make sure the printer power is turned on.

If the data has been sent, but here is no output from the printer

Check the active printer driver and make sure the label printer has been

selected.

Vertical streaks in the printout usually indicate a dirty or faulty print head

Example:

Clean the print head first. If the lines still persist, then the print head may need

to be replaced.

Poor print quality

1. Adjust the Darkness (heat temperature)

in the Windows printer driver.

2. Slow down the print speed.

3. Refer to the next chapter and clean

the related spare parts.

Page 27

23

Chapter 6

Printer Maintenance

Clean the following areas of the printer after 8 rolls of labels have been used. In

each case, use a cotton swab dampened with alcohol.Do not soak the cotton

swab excessively. These supplies can be purchased from Wasp Bar Code

Technologies. Please call 214-547-4100 for details.

Note: Always switch off the power before cleaning.

Cleaning

Thermal Print Head

Thermal paper stock and ribbons will release debris on the print head and

degrade printing quality.Clean the print head with methanol or isopropyl

alcohol with a cotton swab. Do not touch the heater element with your fingers.

Paper Sensor

Debris or dirt on the paper sensor will cause a mis-read or incorrect detection

of the label gap. Clean with a cotton swab dampened with alcohol.

Print Head

Page 28

24

Chapter 7

Technical Specifications

Model W-300 Thermal Transfer Printer

Print Method Direct Thermal or Thermal Transfer

Resolution 203 DPI

Print Width Up to 4”

Maximum Length 45”

Print Speed 3 IPS (Inches Per Second)

Memory 512K Standard

Dimensions 7.3” W x 10.9” D x 6.0” H

Weight 3.74 lbs

Electrical FCC Class B, 19 VAC, 24 DC

(2.5 A) 50/60 Hz

(E, UL and CU Approved)

Operating Temperature 40ºF – 100ºF (4ºC – 38ºC)

Storage Temperature 40ºF – 140ºF (4ºC – 60ºC)

Humidity 15 – 85% RH

Ribbons Wax, Wax Resin, and Resin

Labels Direct Thermal and Thermal Transfer (various)

Page 29

25

Chapter 8

Product Support & Warranty Information

Wasp W-300 Printer is wa r ranted against defects in wo rkmanship and materi a l s

for a period of one year from the date of shipment, provided that the product

remains unmodified and is operated under normal and proper conditions.

Note: W-300 print heads are warranted for 90 days against defect in

workmanship. Print heads will be replaced during the 90 day period

once it is determined that the print head is defective.

This warranty is limited to repair or replacement at Wasp Technologies’ option,

with reasonable promptness after being notified. These provisions do not

prolong the original warranty term for any product which has been repaired or

replaced by Wasp Technologies.

This warranty applies to the original owner and does not extend to any product

which has been subject to misuse, neglect, accidental damage, unauthorized

repair, or tampering.

No other express warranty is given. The replacement or repair of a product is

your exclusive remedy. Any other implied warranty of merchantability or fitness

is limited to the duration of this written warranty. Some states, provinces, and

countries do not allow how long an implied warranty lasts, so the above

limitation may not apply to you.

In no event shall Wasp Technologies be liable for consequential damages.Some

s t a t e s, prov i n c e s, and countries do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitations may not apply to yo u .

Warranty Information

Product Support

If you experience any problems with your Wasp W-300 Printer that you are

unable to resolve, call for technical assistance at (214) 547-4100, Monday

through Friday, 8:00 AM - 5:00 PM Central Standard Time. Our web site is

www.waspbarcode.com

You may also contact us in writing at:

Wasp Bar Code Technologies

1400 10th Street

Plano,TX 75074

(214) 547-4100

(214) 547-4101 Fax

Page 30

Page 31

Page 32

Loading...

Loading...