PW2C

WIDE BODY FRONT LOADED WAREWASHER

C/W HEAT RECOVERY UNIT

OPERATOR MANUAL

21/11/2018 Washtech PW2C Operator Manual 2

Warnings

Before installation and commissioning, you must read the safety instructions and

warnings carefully and all the warning labels attached to the equipment.

Equipment contains dangerous voltages and can be hazardous if installed or

operated incorrectly. Non-compliance with warnings or failure to follow the

instructions contained in this manual can result in loss of life, severe personal

injury or serious damage to property.

Before installation or repair, you must read the instructions and warnings

carefully and all the warning labels attached to the equipment.

All service/repair work must be carried out by qualified personnel only and

ensure compliance with all local codes and standards including AS/NZS 3500.1.

Important Information

Failure to comply (even partially) with the instructions given in this manual will

invalidate the product warranty and relieves the manufacturer of any

responsibility.

The alteration of machine operation, design or the replacement of parts not

approved by the manufacturer may void warranties and approvals.

This machine is intended for commercial use only.

The machine is designed solely for cleaning crockery (porcelain, glass, ceramic,

temperature-resistant plastics, stainless steel or similar) from the food industry.

This machine is not intended for washing: containers that do not come into

contact with foodstuffs, animals, textiles or foodstuffs intended for further

consumption.

We have checked that the contents of this document correspond to the model described. There

may be discrepancies nevertheless, and no guarantee can be given that they are completely

identical. The information contained in this document is reviewed regularly and any necessary

changes will be included in the next edition. We welcome suggestions for improvement.

Document subject to change without prior notice.

Information supplied in this manual is copyright. No part of this work may be reproduced or

copied in any form or by any means, electronic or mechanical without the express permission of

the author / publisher.

21/11/2018 Washtech PW2C Operator Manual 3

Contents

2. Warning

3. Contents

4. Safety Instructions

5. Installation Diagram

6. Installation Instructions

8. Installation Checklist

9. Installation Troubleshooting

10. Operator Use Guide

11. Operator Troubleshooting

12. Schematic diagram

13. Accessories

14. Notes

Contents

21/11/2018 Washtech PW2C Operator Manual 4

Installation

• Use qualified, skilled personnel.

• Follow installation instructions.

• Connect to correct voltage and supply current.

• Provide fully accessible Electrical Isolation Switch & water supply valves.

Training and Supervision

• Read and Understand the Operating instructions and train all staff.

• This appliance must not be operated by children or infirm persons.

• Machine panels must only be removed by suitably qualified and trained personnel – internal

hazards include live electrics and very hot surfaces.

• No part of this appliance is not intended for use as a stepladder – do not stand on open door.

Hot Surfaces

• Some surfaces may be hot or very hot.

Chemicals

• Commercial dishwashing detergents are hazardous – handle with care.

• Read and follow the safety information found on the labels of detergent containers and

Material Safety Data Sheets.

• Use protective eyewear and clothing if decanting containers.

Hot Water

• Do not put hands in wash water which may be over 60°C and contain hazardous caustic

detergent.

• Rinse water can be over 90°C.

• Door safety switches are designed for emergency use only.

Cleaning

• Do not hose down the machine or splash water over the exterior.

• Watch for broken glass etc. when cleaning the inside of the machine.

Warnings

Equipment contains dangerous voltages and can be hazardous if installed or

operated incorrectly. Non-compliance with Warnings or failure to follow the

instructions contained in this manual can result in loss of life, severe personal

injury or serious damage to property.

Installation and servicing must be carried out by a suitably qualified person in

compliance with all local codes and standards including AS/NZS 3500.1.

Safety Instructions

21/11/2018 Washtech PW2C Operator Manual 5

Installation Diagram

PW2C Installation Diagram

• Part #: WPW20021

• Date: 25/09/2018

• Version: 3-C

21/11/2018 Washtech PW2C Operator Manual 6

Machine Positioning

• Unpack machine, check for damage and complete delivery.

• Install machine on sound waterproof self-draining floor and use adjustable feet to level

machine.

NOTE: Failure to level the machine correctly may result in leaking during the cycle,

overflowing from the door sill, poor hygiene through the wash tank not being able to

drain correctly, and/or visibly uneven door.

• Allow room for detergent to one side of machine or in adjacent cupboard. 20 litre container

requires approximately W 250mm x D 350mm x H 450 mm, but smaller containers are

available from many suppliers.

Inlet Water Operation - Cold

Incoming water should be within the following standard requirements:

• Temperature: 20°C.

• Connection: 20 mm (3/4” BSP) male – flexible hose supplied

NOTE: Flush supply line before connection. Poor quality supply or excessive water

hardness may affect performance or damage machine – filtration and/or softening is

recommended.

• Flow rate: minimum 5 litres per minute.

• Pressure: no greater than 350 kPa

NOTE: This machine is equipped with a rinse booster pump as standard and does not rely

on incoming water pressure to drive the rinse cycle.

NOTE: If above 350kPa fit pressure limiter valve (LPV). Do not use small diameter plastic

supply lines.

• Consumption: Approximately 4.0 litres per cycle.

• Backflow prevention: Atmospheric Vacuum Breaker (AVB) fitted standard.

• Watermark Certification #08603.

Inlet Water Fill - Hot

Incoming water should be within the following standard requirements:

• Temperature: 65°C.

NOTE: Excessively high temperatures may damage the solenoid which can result in

flooding should this component fail. High temperature solenoids are available and can be

retrofitted if necessary.

• Connection: 20 mm (3/4” BSP) male – flexible hose supplied

NOTE: Flush supply line before connection. Poor quality supply or excessive water

hardness may affect performance or damage machine – filtration and/or softening is

recommended.

• Flow rate: minimum 20 litres per minute.

• Pressure: no greater than 350 kPa

NOTE: If above 350kPa fit pressure limiter valve (LPV). Do not use small diameter plastic

supply lines.

• Backflow prevention: Atmospheric Vacuum Breaker (AVB) fitted standard.

• Watermark Certification #08603.

Installation Instructions

21/11/2018 Washtech PW2C Operator Manual 7

Water Quality Requirements

The incoming water should also be within the following parameters:

Hardness ppm pH

min 20 7

max 100 8

Ions Cl- SO

4

Fe Mn Cu Cl

2

Max mg/L 100 400 0.1 0.5 0.05 0.1

NOTE: Levels above or below the stated requirements can be expected to increase

component wear and reduce the expected useful life of the dishwasher. If in doubt, it is

best to consult a water specialist and have the incoming water professionally tested and

treated if necessary.

Power

• Electrical supply required is 3p/30A 415V 50Hz via switched outlet adjacent to machine.

Chemical

• This dishwasher is supplied with Detergent and Rinse Fluid injector pumps.

• To connect to chemicals, insert pump inlet hose into container of commercial low foam

detergent and rinse fluid.

NOTE: Externally adjustable chemical pumps are fitted and pre-set at an average level,

these need to be calibrated on site according to the chemical being used and site specific

conditions such as the water quality and how the machine is being used. Failure to do so

may result in excessive dosing which can result in foaming and overflowing, or

insufficient dosing which can cause inferior wash results and impact components

through a build up of grease. If in doubt, contact your chemical company for assistance.

NOTE: Commercial detergents can be hazardous – read instructions, store safely and

handle with care. Care needs to be taken when changing chemicals, ensuring that the

detergent is not accidentally connected to the rinse fluid inlet line.

NOTE: If uncertain, please consult a chemical specialist for assistance in selecting the

right chemicals and calibrating machine settings to suit this along with your unique site

conditions and requirements.

Waste

• 40 mm gravity drain – refer point B on installation diagrams – run waste directly behind the

machine or through open base.

• An S&P trap will need to be fitted at the drain waste – refer point B on the installation

diagram.

• With a standard S&P trap the drain connection height will be no less than 600mm below the

bench height on the model (or no higher than 300mm if installed in standard 900mm high

benching).

NOTE: Either copper or PVC may be used for the waste connection – PVC is more

resistant to some harsh detergents. Some authorities however suggest that copper is

required because the machine rinses at up to 90°C. It is important to note that rinse

water mixes with the 65°C wash water before discharge and then flows into the sink

trap where the water is further cooled before entering the drainage plumbing. We

recommend consulting your local authority to ensure your site remains compliant.

Installation Checklist

• Complete attached Installation Checklist to ensure machine is installed and running correctly,

and operator is familiar with operating procedures.

Installation Instructions

Check Notes

DELIVERY

SUPPLIED COMPLETE? CHECK THERE HAS NOT BEEN ANY TRANSIT DAMAGE

POSITION

LEVEL AND STABLE? ON SOUND, WATERPROOF, SELF-DRAINING FLOOR

WATER

ISOLATOR VALVE FITTED? ACCESSIBLE, ALL FITTINGS SOUND, AND NO LEAKS

TEMPERATURE CORRECT (65°C)? HIGH TEMP SOLENOID IF ABOVE RANGE

PRESSURE CORRECT (< 350 kPa)? LIMITER FITTED IF ABOVE RANGE, RINSE PUMP IF BELOW

FLOW RATE CORRECT? RINSE PUMP FITTED IF BELOW REQUIREMENT

QUALITY WITHIN REQUIREMENTS? FILTER OR SOFTENER IN PLACE IF OUTSIDE REQUIREMENTS

POWER

ISOLATING SWITCH? FITTED, FUNCTIONAL AND ACCESSIBLE

CORRECT SUPPLY (3p/30A 415V 50Hz)? VOLTAGE, CURRENT, CIRCUIT BREAKER ALL CORRECT

WASTE

40MM CONNECTION (1.5” BSP)? HARD PLUMBED, NO LEAKS

SUITABLE AIR GAP? REFER OPERATOR MANUAL.

CHEMICALS

CHEMICAL NAME CONTAINER NO LEAKS PRIMED CALIBRATED

DETERGENT

RINSE FLUID

MACHINE OPERATION

MACHINE RUNNING CORRECTLY? MULTIPLE CYCLES RUN, NO ISSUES

CHEMICAL DOSAGE CORRECT? CORRECTLY FLOWING INTO MACHINE, NO FOAMING

ALL OPERATIONS CORRECT? FILL LEVEL CORRECT, NO DRAINAGE ISSUES

OPERATOR TRAINING

ENSURE THAT THE CUSTOMER HAS BEEN GIVEN THE OPERATION MANUAL AND WALL CHART, AND IS AWARE OF THE

IMPORTANCE OF BOTH USING AND CLEANING THE MACHINE CORRECTLY.

START UP

PRE-RINSE AND RACKING BETTER TO RINSE PLATES THAN REMOVE WASTE FROM MACHINE

MACHINE USE AND CYCLE SELECTION USE LONG CYCLE WHERE POSSIBLE

DRAINING THE MACHINE DRAIN THE MACHINE DAILY

SHUT-DOWN AND DAILY CLEANING CHECK WASH ELEMENTS HAVE COOLED BEFORE CLEANING

WEEKLY MAINTENANCE FULL MACHINE CLEAN INCLUDING WASH/RINSE ARMS

PLANNED SERVICNG IMPORTANCE OF HAVING MACHINE SERVICED REGULARLY

21/11/2018 Washtech PW2C Operator Manual 8

Installation Checklist

21/11/2018 Washtech PW2C Operator Manual 9

Installation Troubleshooting

Door not closing properly

• Level the dishwasher.

Machine not starting or filling

• Ensure water supply to machine is turned on.

• Ensure power supply to machine is turned on.

• Check that the water inlet hose isn’t twisted or kinked.

Cycle taking too long

• This machine ships with Thermostop enabled, which allows a cycle to be started at any time,

even if the rinse water is not up to required temperature. To ensure a hygienic result, the

YCUJE[ENGEQPVKPWGUVQTWPWPVKNVJGTKPUGVGORGTCVWTGTGCEJGUVJGTGSWKTGFĹ%#VVJKU

stage washing will stop and the machine will begin rinsing to complete the cycle.

Poor wash results

• Check that there are adequate pre-rinse processes in place and staff use longer cycle options

for more heavily soiled items.

• Ensure high quality non-foaming commercial dishwasher detergent has been connected at

the correct dosage for your site, water quality and application. If uncertain, consult a

chemical specialist.

• Check that the wash arm is spinning freely and is not being obstructed.

• Ensure that the wash temperature is between 60°C and 65°C.

Chemical residue on items after the cycle

• Check that nothing is obstructing the wash & rinse arms from rotating

• Check the rinse fluid dosage is not too high. If uncertain, please consult a chemical specialist.

• Check detergent dosage is within the requirements.

Dishwasher is foaming

• Ensure there is no other soap being transferred into the machine from the sink.

• Ensure high quality non-foaming commercial dishwasher detergent has been connected at

the correct dosage for your site and application. If uncertain, please consult a chemical

specialist.

• #NNQYYCUJYCVGTVQJGCVVQCVNGCUVĹ%RTKQTVQUVCTVKPIVJGHKTUVE[ENGCUUQOGEQOOGTEKCN

dishwasher chemical will foam at low temperatures.

Other equipment in the kitchen has needed filters or has scale

• Due to the high temperatures in dishwashers, scale will build up in the wash tank, on the arms

and in the rinse tank. The incoming water should be treated. If uncertain, please consult a

water specialist.

• As with the combi-ovens, high chloride levels will do irreversible damage to a number of the

components inside a commercial dishwasher. The incoming water should be appropriately

treated. If uncertain, please consult a water specialist.

Cycle times not suitable for items being washed

• Some sites may require longer/shorter cycles depending on the items being washed and the

soil levels. Cycle lengths can be adjusted by a qualified service agent accessing the WI-200

Electronic timer. For adjustment instructions refer to the adjustment section of the Service

Manual for the model or the WI-200 Service Manual.

SHUT DOWN - EVERY NIGHT

• Turn Cycle Selector to 0 and turn off the power from the wall.

• Remove Scrap Trays (1) and Upstand (2) to drain the Wash Tank.

• Once the Wash Tank is fully drained remove and rinse Wash Pump Filters (3) and Scrap

Trays (1) before replacing back into the machine along with the Upstand (2).

CLEANING – AT LEAST ONCE A WEEK

Remove, rinse and replace when machine has cooled down:

Scrap Trays 1

Drain Upstand 2

Wash Pump Filters 3

Rinse Arms 4

Wash Arms 5

Inspect and clear all jets in the upper and lower

Wash/Rinse Arms using a small object such as a

toothpick where necessary to remove any

blockages prior to rinsing.

SUGGESTED BEST PRACTICE

Pre-rinse Scrape and/or rinse trays, plates & glasses in cool water.

Chemical Use a good quality non foaming commercial detergent and drying agent – do

not use domestic detergents which will cause the wash tank to foam.

21/11/2018 Washtech PW2C Operator Manual 10

Operator Use Guide

START

• Turn on at wall.

• Ensure the Upstand (2) and Wash Pump Filters (3) are

firmly in place.

• Check the Scrap Trays (1) are in place and shut door.

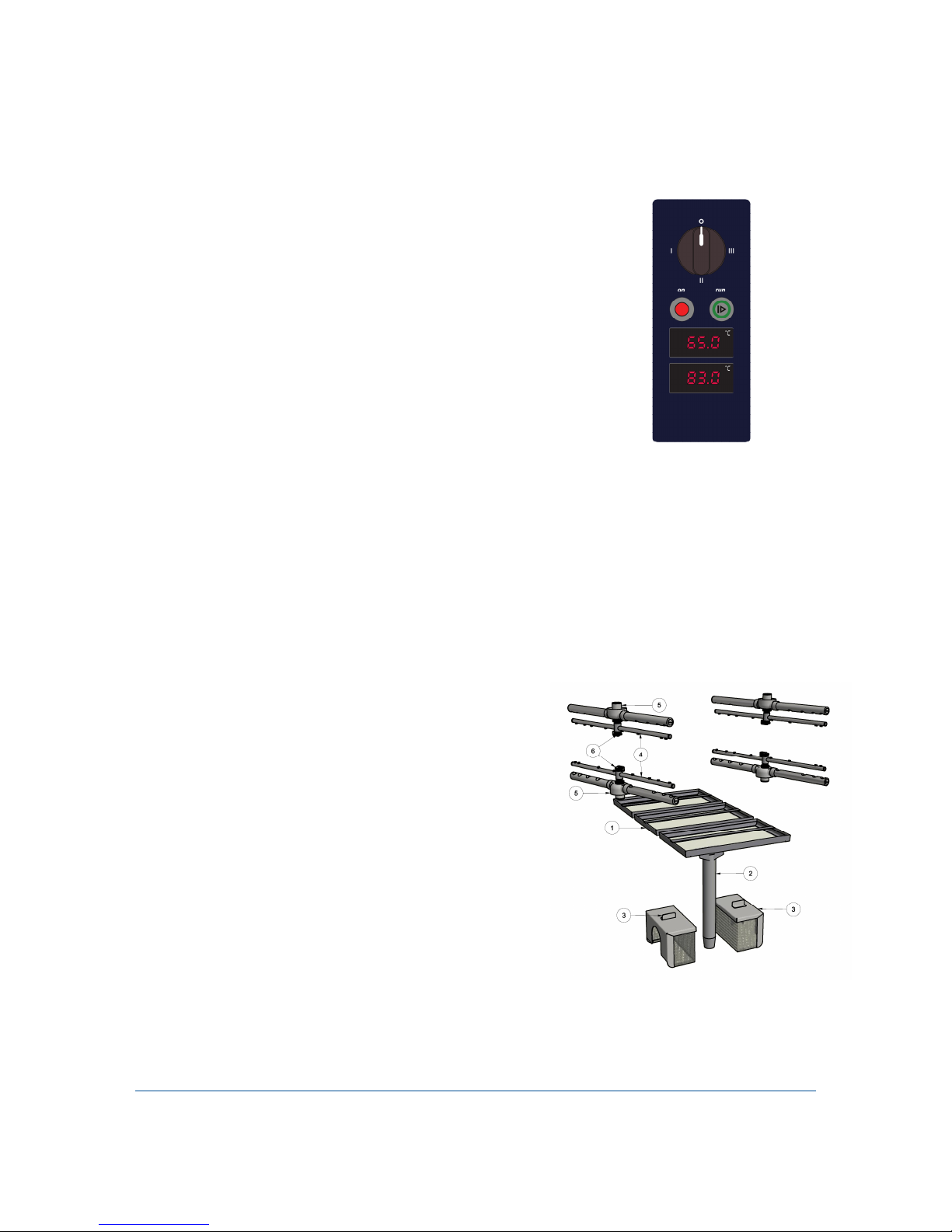

• Turn the Selector Switch to any Cycle (I, II or III).

• Power light Glows red and machine fills automatically.

• Once full, rinse heating starts.

OPERATION

• Select required Cycle of I (2.5 minutes) , II (4.5 minutes)

or III (6.5 minutes).

• Load items into the machine and shut door.

• Press Start Button to start machine.

• Start Button glows green while machine operates.

• When Start Button goes out, the cycle is complete.

NOTE: The machine may be started while the rinse water

is being heated – the machine will continue to run the

wash cycle until the rinse water is up to temperature.

Wash Temp Gauge

Start Button

Selector Switch

Rinse Temp Gauge

Power On Light

21/11/2018 Washtech PW2C Operator Manual 11

Operator Troubleshooting

Likely cause Possible cause

* For issues most likely due to incorrect chemical dosages or other chemical issues, we

recommend you consult your chemical supplier and/or a local chemical expert prior to calling

in a dishwasher technician.

** For issues that are likely due to poor water quality (scale building up, filters being required

on other kitchen equipment etc..), we recommend you consult a local water specialist prior to

calling in a dishwasher technician.

IF PROBLEMS PERSIST CONTACT MOFFAT SERVICE ON 1300 264 217

Issue Cause

POOR PRE-SCRAPING

CARRY OVER OF SOAP FROM SINK

OVERLOADING RACKS

INADEQUATE CLEANING

DRAIN UPSTAND NOT PLUGGED IN

WASH/RINSE JETS BLOCKED

WASH/RINSE ARMS NOT ROTATING

DETERGENT DOSAGE LOW/HIGH*

RINSE FLUID DOSAGE LOW/HIGH*

POOR WATER QUALITY**

DISHES NOT CLEAN

STAINING

FOAMING

PROTEIN BLOOM

DIRTY MACHINE

FOOD RESIDUE ON WARE

FILM/SPOTS ON WARE

DETERGENT RESIDUE

GREASY FILM/NO FIZZ

HIGH DETERGENT USE

HIGH RINSE FLUID USE

WET WASHWARE

SCALE BUILD UP IN MACHINE

FILTERS ON OTHER EQUIPMENT

21/11/2018 Washtech PW2C Operator Manual 12

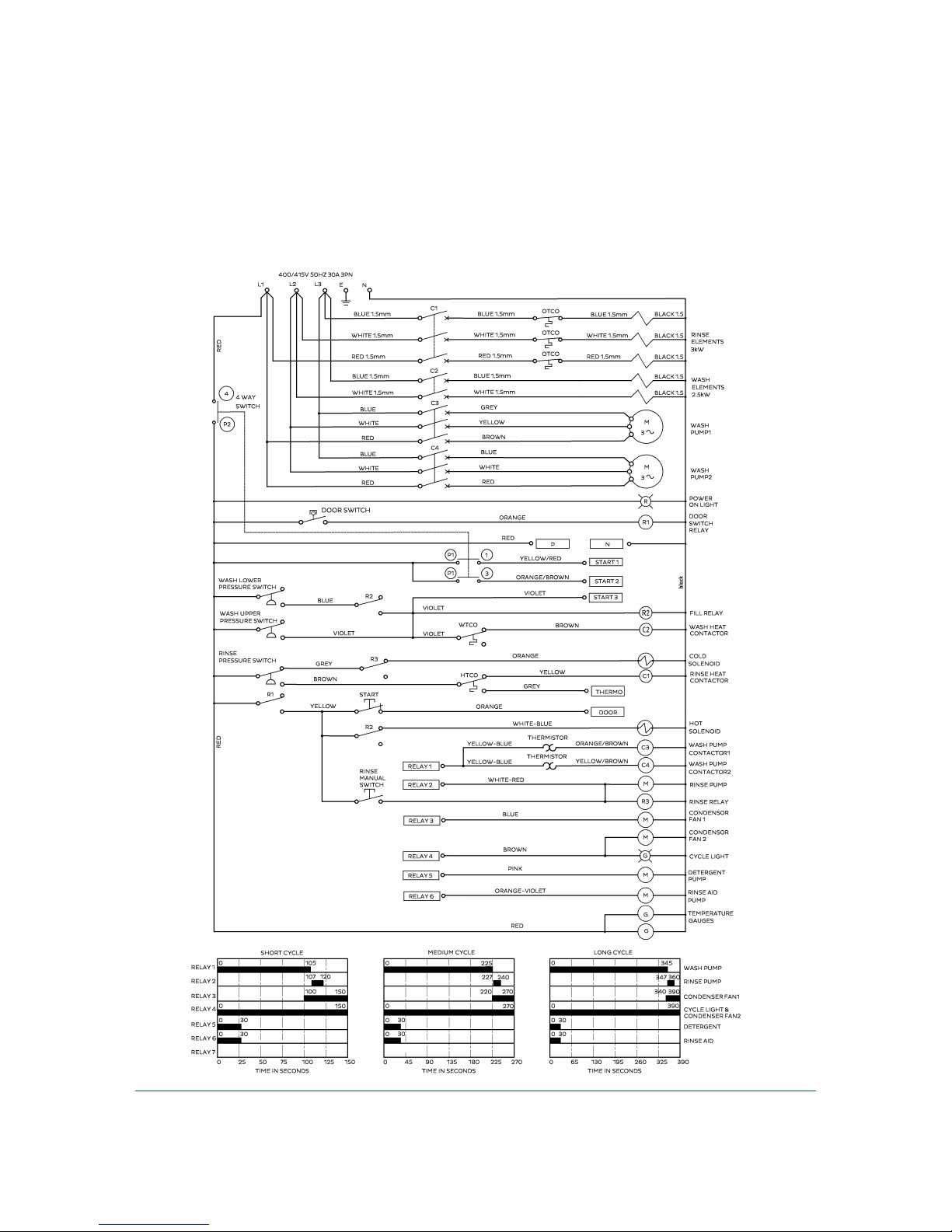

Schematic Diagram

PW2C / PW3C(S) Schematic Diagram

• Part #: 010182

• Date: 28/09/2017

• Version: 1-A

21/11/2018 Washtech PW2C Operator Manual 13

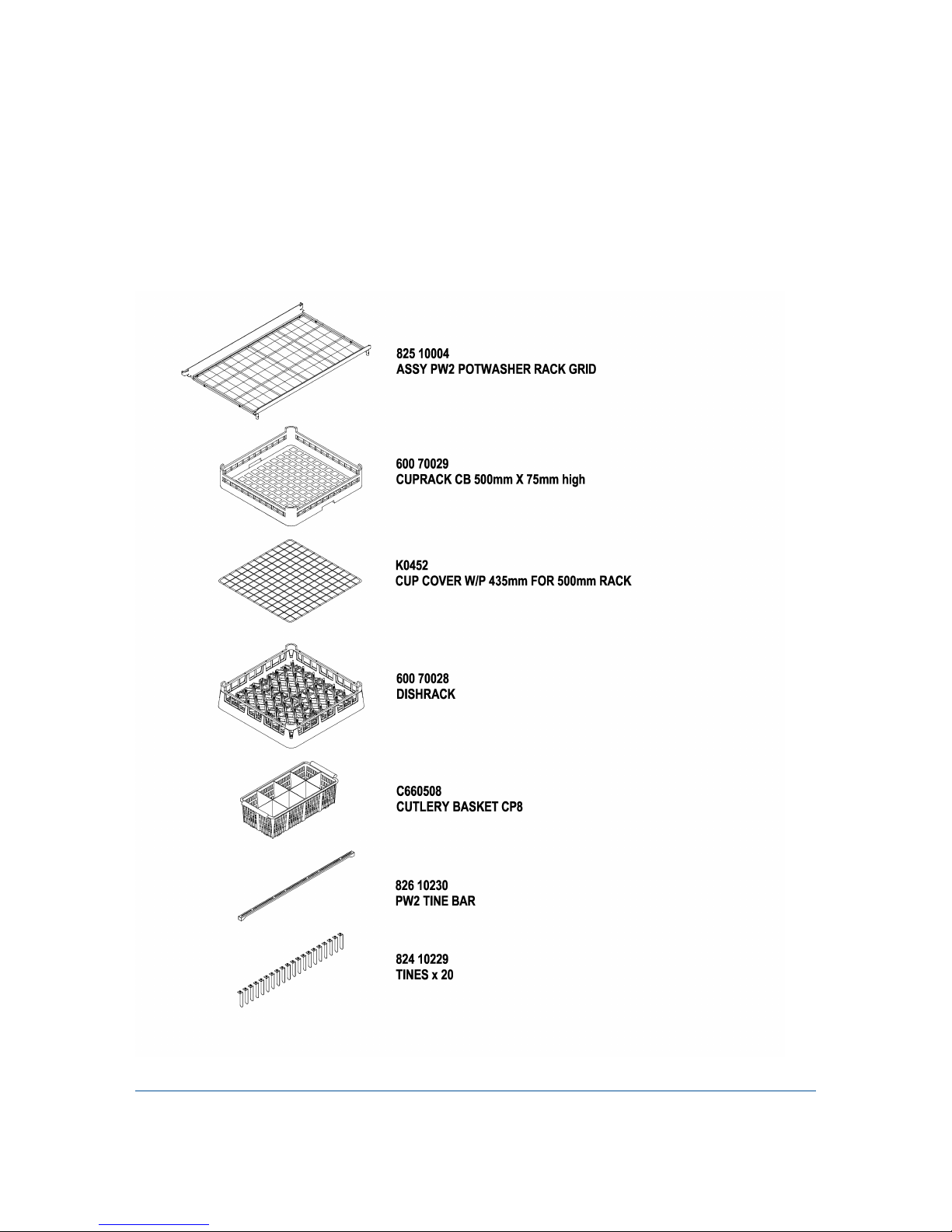

Accessories

PW2C Accessories

• Part #: PW2C ACW

• Date: 13/12/2017

• Version: 1-C

21/11/2018 Washtech PW2C Operator Manual 14

DESCRIPTION PART NO REC. STOCK

Cabinet & Door

• Control Panel Sub-Assembly 354 14008 1

• Control Panel Label 400 70204 1

• Front Panel 826 25138 1

• Left Side Panel 826 20150 1

• Right Side Panel 824 20149 1

• Lower Rear Panel 824 20153 1

• Upper Rear Panel 824 20152 1

Controls & Indicators

• Contactor 600 30337 1

• Door Reed Switch 600 30183 1

• Knob 4 Position 600 30524 1

• Power Light 600 30529 1

• Pressure Switch 600 30478 1

• Pressure Switch Wash 600 30479 1

• Relay 2 pole 240V 600 30080 1

• Relay Base 600 30081 1

• Start Button 600 30566 1

• Switch 4 Position 600 30269 1

• Temperature Gauge 600 30546 1

• Terminal Strip 6 Way 3229 -6 1

• Test Switch 3035 1

• Timer Electronic 600 30513 1

Heating Components

• Over Temperature Thermostat 600 30088 1

• Rinse Element 6 kW 600 30496 1

• Rinse Tank Assembly 400 10351 1

• Rinse Thermostat 30201 1

• Wash Element 2.5 kW 600 30159 1

• Wash Thermostat 30201 1

Hoses

• Detergent Hose 600 30148 1 roll

• Pressure Switch Hose 3067 500mm

• Rinse Hose 600 60073 2000mm

• Upper Wash Hose 6195 100mm

• Lower Wash Hose 6195 145mm

• Lower Wash Casting Hose 6195 50mm

• Left Wash Pump Inlet Hose C200359 1

• Left Wash Pump Outlet Hose 61941 140mm

• Right Wash Pump Outlet Hose 200315C 1

• Right Wash Pump inlet Hose 61942 80mm

• Break Tank Hose 400 10361 1

Spare Parts

21/11/2018 Washtech PW2C Operator Manual 15

DESCRIPTION PART NO REC. STOCK

Pumps and Solenoids

• Detergent Pump 600 30094 1

• Detergent Squeeze Tube 600 30134 1

• Rinse Aid Pump 600 30400 1

• AVB 400 0010 1

• Solenoid Valve 3342 1

• Wash Pump 3906 1

• Rinse Pump 600 30400 1

• Condenser Fan 600 30503 1

• Condenser Coil 600 90160 1

Wash Tank Components

• Drain Upstand 400 10145 1

• Rack Slide Assembly 825 10004 1

• Locknut Wash Arm 280409C 2

• Rinse Arm Assembly 815 10013 1

• Rinse Arm Bush C190624 2

• Rinse Arm Cap Screw 261004C 2

• Rinse Arm End Plug 400 30200 1

• Rinse Arm Spring Retainer Screw C450218 2

• Scrap Tray 827 12003 1

• Slip Ring AL(3) Black Acetal 400 30191 2

• Temperature Gauge Probe Clamp 400 20066 1

• Wash Arm Assembly 815 10007 1

• Wash Arm Bush 190621C 4

• Wash Arm End Screw 600 80072 4

• Wash Pump Inlet Filter 352 10026 1

• Wash Spindle AL 400 30362 1

Spare Parts

Information supplied in this manual is copyright. No

part of this work may be reproduced or copied in any

form or by any means, electronic or

mechanical without the express permission of the

author/publisher

Distributed in Australia by Moffat Pty Limited

740 Springvale Road

Mulgrave 3170

Victoria

Australia

24HR Service 1300 264 217

Parts 1300 263 107

Tel 03 9518 3888

Fax 03 9518 3818

E-mail sales@moffat.com.au

web www.moffat.com.au

ISO9001

All Washtech products are designed and

manufactured by Washtech using the

internationally recognised ISO9001 quality

management system, covering design,

manufacture and final inspection, ensuring

consistent high quality at all times.

In line with policy to continually develop and

improve its products, Washtech Ltd reserves the

right to change specifications and design without

prior notice.

Loading...

Loading...