WARNING: ALL OPERATING AND MAINTENANCE PROCEDURES SHOWN ON THE NEXT

PAGE OF THIS MANUAL MUST BE FOLLOWED DAILY FOR PROPER OPERATION OF

YOUR WASCOMAT MACHINE.

PLEASE ENTER THE FOLLOWING INFORMATION AS IT APPEARS ON THE MACHINE(S)

DATA PLATE(S).

MAKE CERTAIN TO KEEP THIS MANUAL IN A SECURE PLACE FOR FUTURE

REFERENCE.

MACHINE TYPE OR MODEL

MACHINE SERIAL NUMBER(S)

ELECTRICAL CHARACTERISTICS:________ VOLTS, _______ PHASE,_______ HZ.

OPERATING & MAINTENANCE MANUAL

EX-30 S and EX-50 S

438 9030-13/01

99.20

NOTICE TO: OWNERS, OPERATORS AND DEALERS OF WASCOMAT MACHINES

II

IMPROPER INSTALLATION AND INADEQUATE MAINTENANCE, POOR HOUSEKEEPING AND WILLFUL

NEGLECT OR BYPASSING OF SAFETY DEVICES MAY RESULT IN SERIOUS ACCIDENTS OR INJURY.

TO ASSURE THE SAFETY OF CUSTOMERS AND/OR OPERATORS OF YOUR MACHINE, THE FOLLOWING MAINTENANCE CHECKS MUST BE PERFORMED ON A DAILY BASIS.

1. Prior to operation of the machine, check to make certain that all operating instructions and

warning signs are affixed to the machine and legible. (See the following page of this manual

for description and location of the signs.) Missing or illegible ones must be replaced immediately. Be sure you have spare signs and labels available at all times. These can be obtained from your dealer or Wascomat.

2. Check the door safety interlock, as follows:

(a) OPEN THE DOOR of the machine and attempt to start in the normal manner:

For coin-operated models, select a wash cycle, insert the proper coins and press the

START button.

For manually operated models, select a wash cycle and press the START button.

THE MACHINE(S) SHOULD NOT START !

(b) CLOSE THE DOOR to start machine operation and, while it is operating, attempt to

open the door without exerting extreme force on the door handle. The door should

remain locked!

If the machine can start with the door open, or can continue to operate with the door

unlocked, the door interlock is no longer operating properly. The machine must be

placed out of order and the interlock immediately repaired or replaced.(See the door

interlock section of the manual.)

3. DO NOT UNDER ANY CIRCUMSTANCES ATTEMPT TO BYPASS OR REWIRE ANY OF

THE MACHINE SAFETY DEVICES AS THIS CAN RESULT IN SERIOUS ACCIDENTS.

4. Be sure to keep the machine(s) in proper working order: Follow all maintenance and

safety procedures. Further information regarding machine safety, service and parts can be

obtained from your dealer or from Wascomat through its Teletech Service Telephone - 516/

371-0700.

All requests for assistance must include the model, serial number and electrical characteristics as

they appear on the machine identification plate. Insert this information in the space provided on the

previous page of this manual.

5. WARNING: DO NOT OPERATE MACHINE(S) WITH SAFETY DEVICES BYPASSED, REWIRED OR

INOPERATIVE! DO NOT OPEN MACHINE DOOR UNTIL DRUM HAS STOPPED ROTATING!

CAUTION

1. Do not open washer door until cycle is completed, operating

light is off, and wash cylinder has stopped rotating.

2. Do not tamper with the door safety switch or door lock.

3. Do not attempt to open door or place hands into washer to

remove or add clothes during operation. This can cause

serious injury.

MACHINE SHOULD NOT BE USED BY CHILDREN

PRECAUCION

1. No abra la puerta de la máquina lavadora sino hasta que la

máquina haya terminado su ciclo, la luz operativa esté apaga

da y el cilindro de lavado haya completamento terminado de

girar.

2. No interferia o manipule el switch o la cerradura de la puerta.

3. No trate de abrir la puerta o meta las manos dentro de la

máquina para meter o sacar ropa mientras la máquina está

en operación, pues puede resultar seriamento herido.

LAS MÁQUINAS NO DEBEN SER USADAS POR NIÑOS

SAFETY AND WARNINGS SIGNS

Replace If Missing Or Illegible

One or more of these signs must be affixed on each machine as indicated, when not included as part of the front instruction panel.

LOCATED ON THE OPERATING INSTRUCTION SIGN OF THE MACHINE:

5

Contents

Introduction .................................................................................... 7

Technical data................................................................................ 8

Installation .................................................................................... 11

Safety rules ..................................................................................21

Operating instructions ..................................................................22

Programming................................................................................27

Wash programs............................................................................ 30

Mechanical and electrical design .................................................33

Serviceprogram............................................................................ 70

Trouble shooting .......................................................................... 73

Safety instructions

• This machine is designed for water washing only.

• This machine must not be used by children.

• All installation operations are to be carried out by qualified

personnel. Licensed personnel are necessary for all electric

power wiring.

• The interlock of the door must be checked daily for proper

operation and must not be bypased.

• All seepage in the system, due to faulty gaskets etc., must be

repaired immediately.

• All service personnel must be fully familiar with the operating

manual before attempting any repair or maintenance of the

machine.

• This machine must not be sprayed with water, otherwise short

circuiting may occur.

• Fabric softeners with volatile or inflammable fluids are not to

be used in the machine.

The manufacturer reservs the right to make changes to design and

material specifications.

EX-30 S, EX-50 S

7

4688

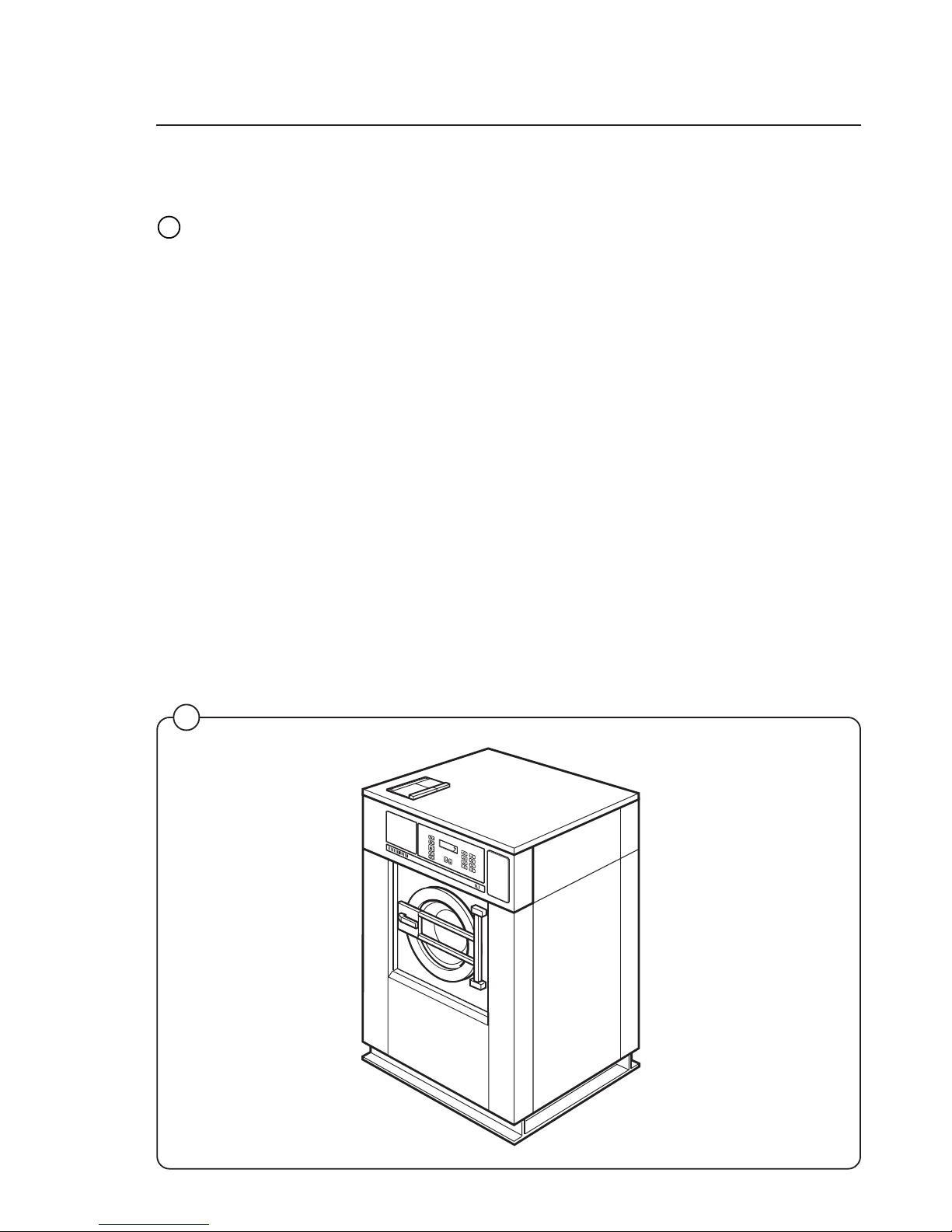

Introduction

1

Introduction

The Selecta models washer/extractor has been developed to cover the heavy

duty requirements of hotels, motels, nursing homes, hospitals, professional

laundries, restaurants, airlines, steamships, schools, colleges and all on-premises laundries where flexibility and quick formula variation, coupled with high

quality automatic washing, are required.

The machines are free-swinging, i.e., the drum is moveable and spring suspended in relation to the frame. This minimizes vibrations transferred to the frame

thus simplifying installation, as no concrete base is required.

The high speed spin gives a G factor of approximately 300, providing very

efficient water removal during the spin.

All parts of the machine which come into contact with the items being washed

are made of heavy gauge surgical stainless steel, ensuring long life and lasting

beauty, as well as full protection for no-iron fabrics. All electrical components

are made accessible for servicing by simply removing the top panel.

This manual contains a technical description of the machine and instructions for

its installation, operation and maintenance. Together with the wiring diagram

which accompanies each individual machine it should be kept in a safe place

for easy reference.

When ordering spare parts or contacting Wascomat for any purpose always

give the machine serial number, model, voltage and other electrical characteristics appearing on the nameplate at the rear of the machine.

Fig.

1

60

40

60

95

60

40

30

8

Technical data

EX 30 S

Dry load capacity up to 30 lbs

Overall dimensions Width 870 mm 34 1/4'’

Depth 790 mm

Height 1325 mm

Net weight 290 kg 639 lbs

Floor load 3.3 ± 1.1 kN 790 ± 264 lbs force

Crated dimensions Volume 1.25 m

3

44 cu.ft

Weight 315 kg 695 lbs

Inner drum Diameter 620 mm 24 7/16'’

Depth 412 mm 16 5/16'’

Volume 120 litre 4.4 cu.ft

Speed of rotation Wash 24-48 r.p.m.

Distribution 78 r.p.m

Extraction up to 950 r.p.m.

G-factor During wash 0.8

During high extract 120-310

Voltage requirements 208-240 V 1-Phase 60 Hz

Rated power

Motor system 598 W

Extraction 1900 W

Overcurrent protection 1-Phase 15 A

Water connections

Water pressure, max 10 kp/cm

2

142 psi

Recommended water pressure 2-6 kp/cm

2

25-85 psi

Hose connection, water 20 mm 3/4'’

Hose connection, drain 75 mm 3'’

9

Technical data

EX 50 S

Dry load capacity up to 50 lbs

Overall dimensions Width 1000 mm 39 3/8'’

Depth 900 mm

Height 1435 mm

Net weight 553 kg 1218 lbs

Floor load 6.0 ± 2.0 kN 1440 ± 480 lbs force

Crated Dimensions Volume 2.05 m

3

72.3 cu.ft

Weight 588 kg 1295 lbs

Inner drum Diameter 750 mm 29 1/2'’

Depth 500 mm 19 11/16'’

Volume 220 litre 7.8 cu.ft

Speed of rotation Wash 44 r.p.m.

Distribution 70 r.p.m.

Extraction up to 850 r.p.m.

G-factor During wash 0.8

During High Extract 120-300

Voltage requirements Motor system 208-240 V 1-Phase 60 Hz

Rated power Wash 756 W

Motor, extraction 3000 W

Overcurrent protection 1-Phase 20 A

Water connections

Water pressure, max 10 kp/cm

2

142 psi

Recommended water pressure 2-6 kp/cm

2

25-85 psi

Hose connection, water 20 mm 3/4'’

Hose connection, drain 75 mm 3'’

10

Technical data

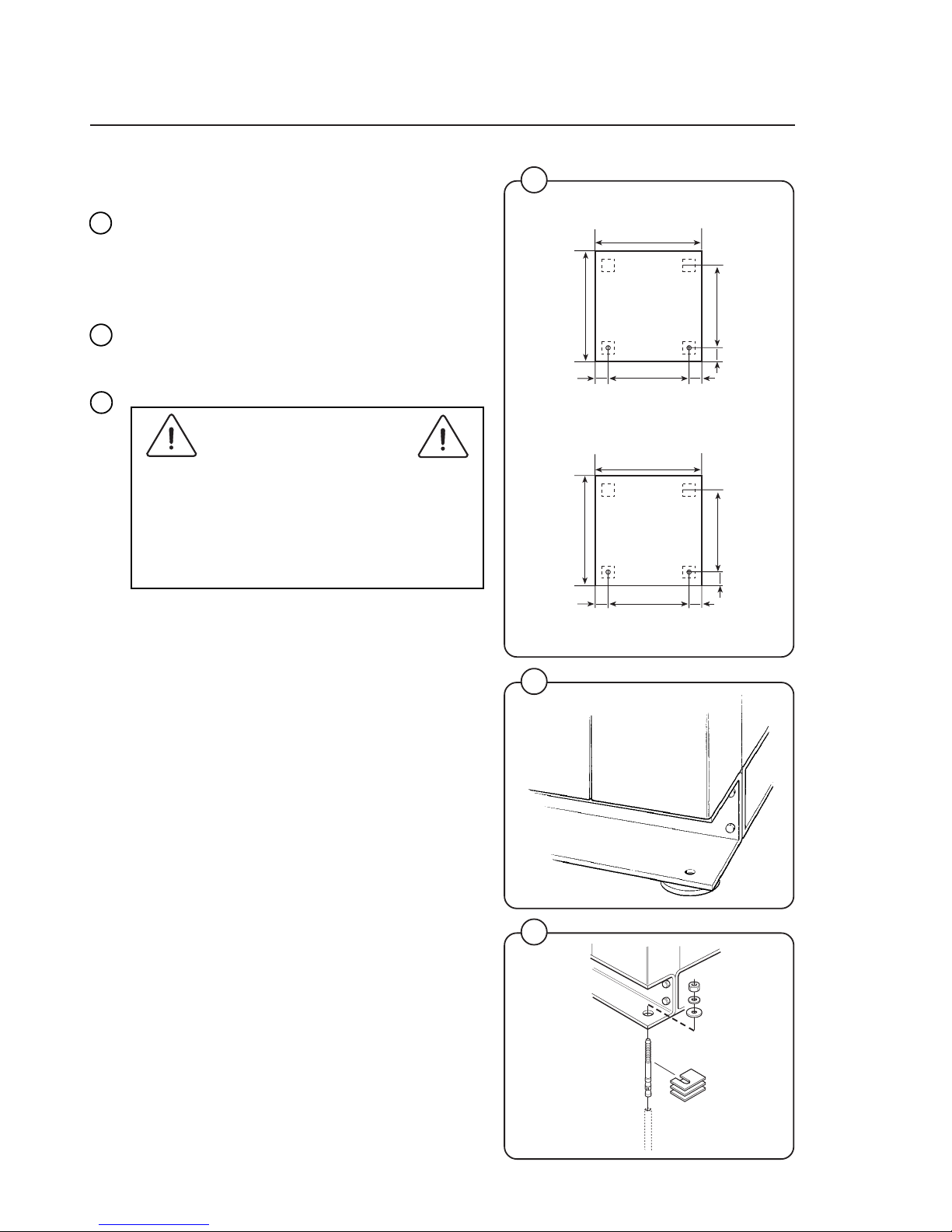

mm mm

A 870 1000

B 1325 1435

C 915 1100

D 790 900

E 125 200

F 630 615

G 570 550

H 470 600

J 1075 1170

K 200 230

L 170 170

M 110 110

N 1215 1325

O – 200

P 140 140

Q 1140 1235

R 175 175

S 305 370

T 1110 1220

U60 60

Outline and dimensions

4699

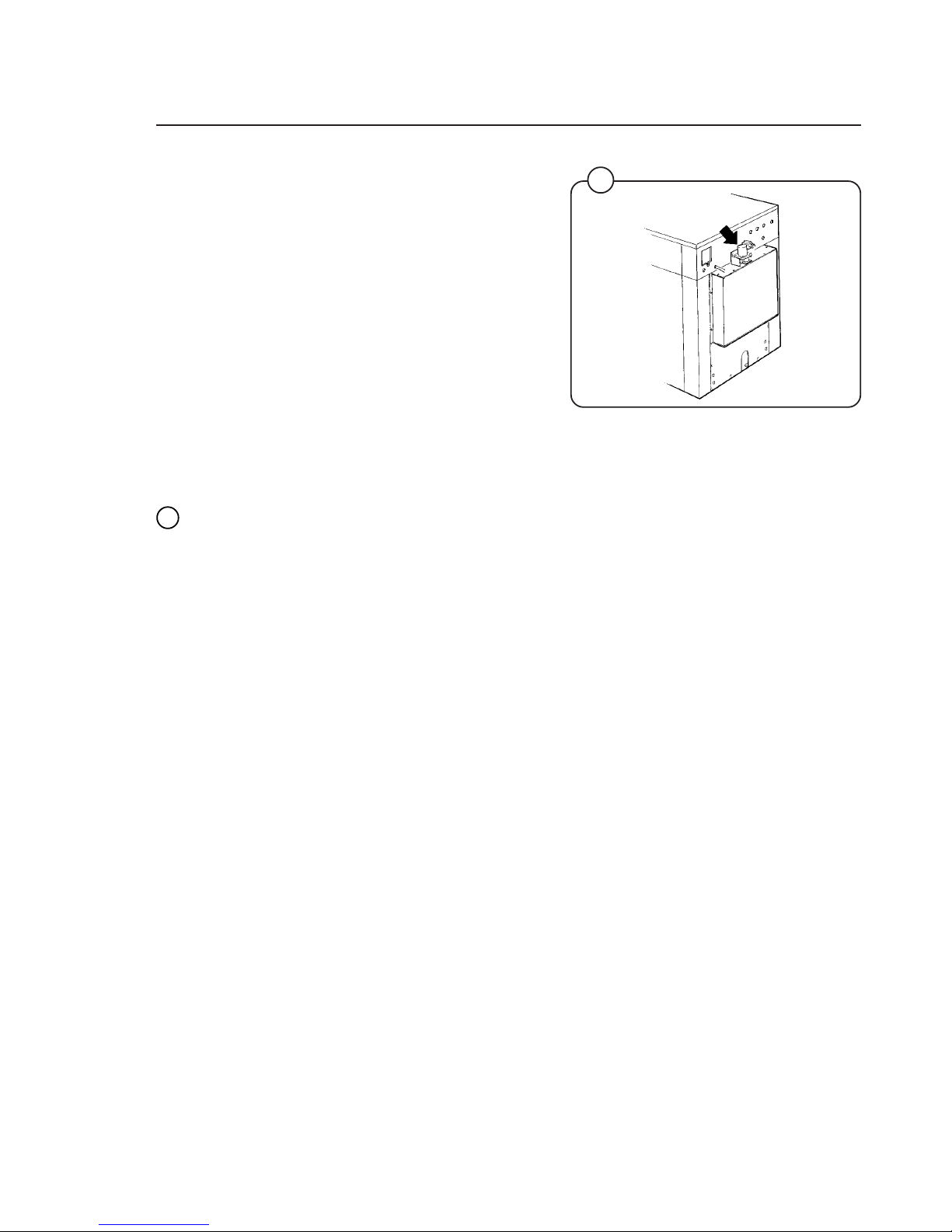

1. Opening for electrical cable connection

2. Steam connection (optional)

3. Cold water

4. Hot water

5. Hot water (only EX 50)

6. Drain outlet

7. Soap box

8. Liquid supply connections

EX 50 S

EX 30 S

6

5

G

F

B

E

C

D

T

U

4

1

2

S

R

J

Q

N

7

3

H

K

O

L

P

M

A

11

Installation

2

3

4

1247 B

1248 B

1249 B

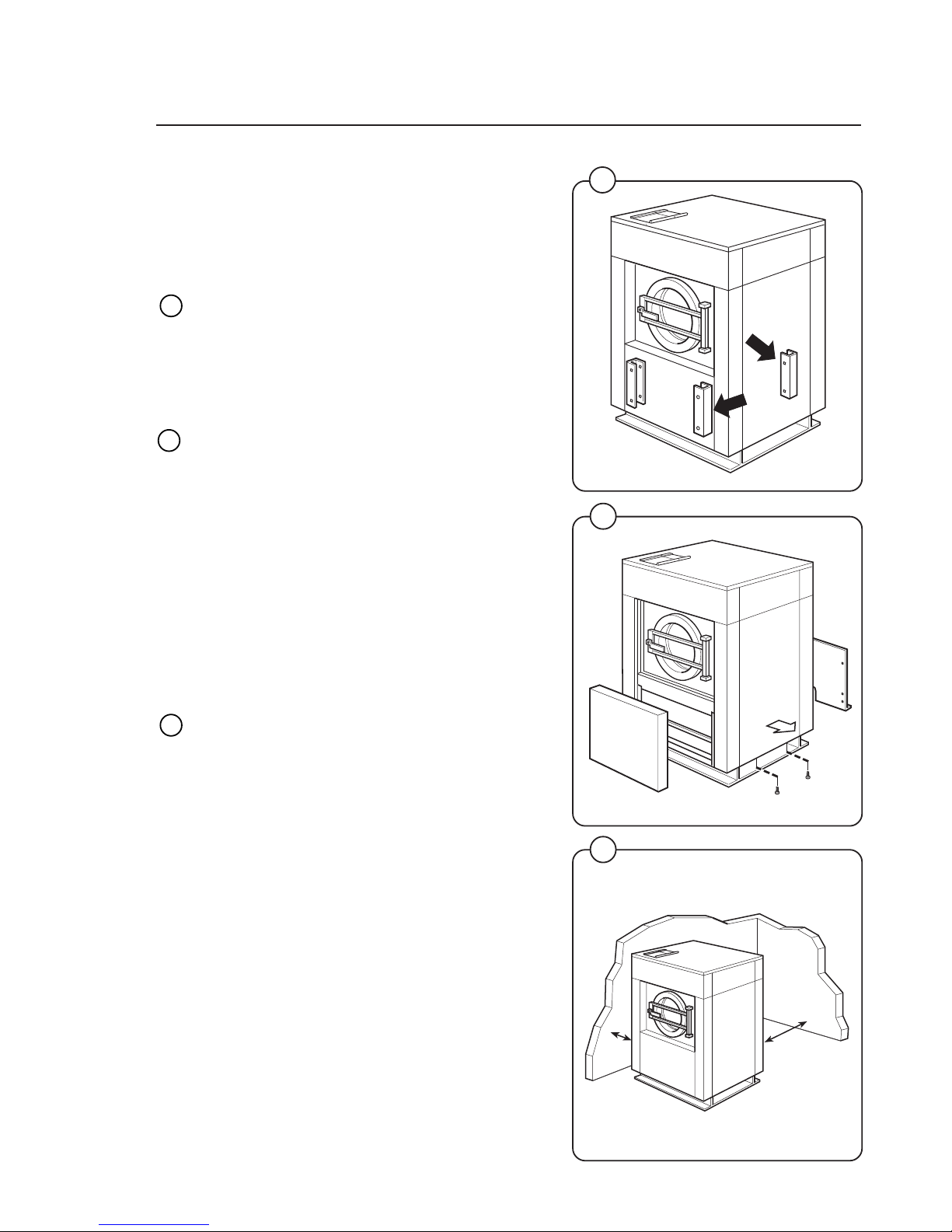

Installation

The machine is delivered with expansion bolts

and other items packed inside the drum.

Shipping securities

The machine is shipped with four large metal

brackets bolted to the four suspension legs as

well as a support between the pulley and the

back plate.

Prior to installation, follow these steps:

• Unpack the machine.

• Remove the lower front panel and the two rear

panels.

• Remove the support from the pulley at the

back of the machine.

• Remove both front brackets.

• Remove both rear brackets.

Placement

The machine should be installed close to a floor

drain or open drain to make installation, use and

service easier.

The following clearances are recommended for

ease of installation and service:

• At least 20 inches between the machine and

the wall behind it.

• At least 2 inches on each side.

The floor must be able to support a static load of

790 lbs for the EX-30 and 1440 lbs for the EX-50.

The maximum impact load at extraction is 260

lbs force for the EX-30 and 480 lbs for the EX-50.

Fig.

2

Fig.

3

Fig.

4

300 mm

1000 mm

12

Installation

5

6

7

0620

0621

Mechanical installation

• Mark and drill two holes 3/8'' in (8 mm) in

diameter and approximately 3 1/2'' in. (90 mm)

deep according to the dimensions in figure 5.

• Place the machine in position. Never lift the

machine by the door or handle.

• Check that the machine is level and steady.

Use stainless or galvanized washers between

the machine and the floor.

• Insert the expansion bolts supplied with the

machine. Fit the washers and nuts.

It is of utmost importance that the machine

is level, from side-to-side as well as frontto-rear. If the machine is not properly

levelled, it may result in out-of-balance

cutout without a real out-of-balance in the

drum.

Fig.

5

Fig.

7

Fig.

6

4811

870

780

33

4343

790

716

=

=

Front

Front

=

=

1000

910

33

4343

900

830

EX 30 S

EX 50 S

13

Installation

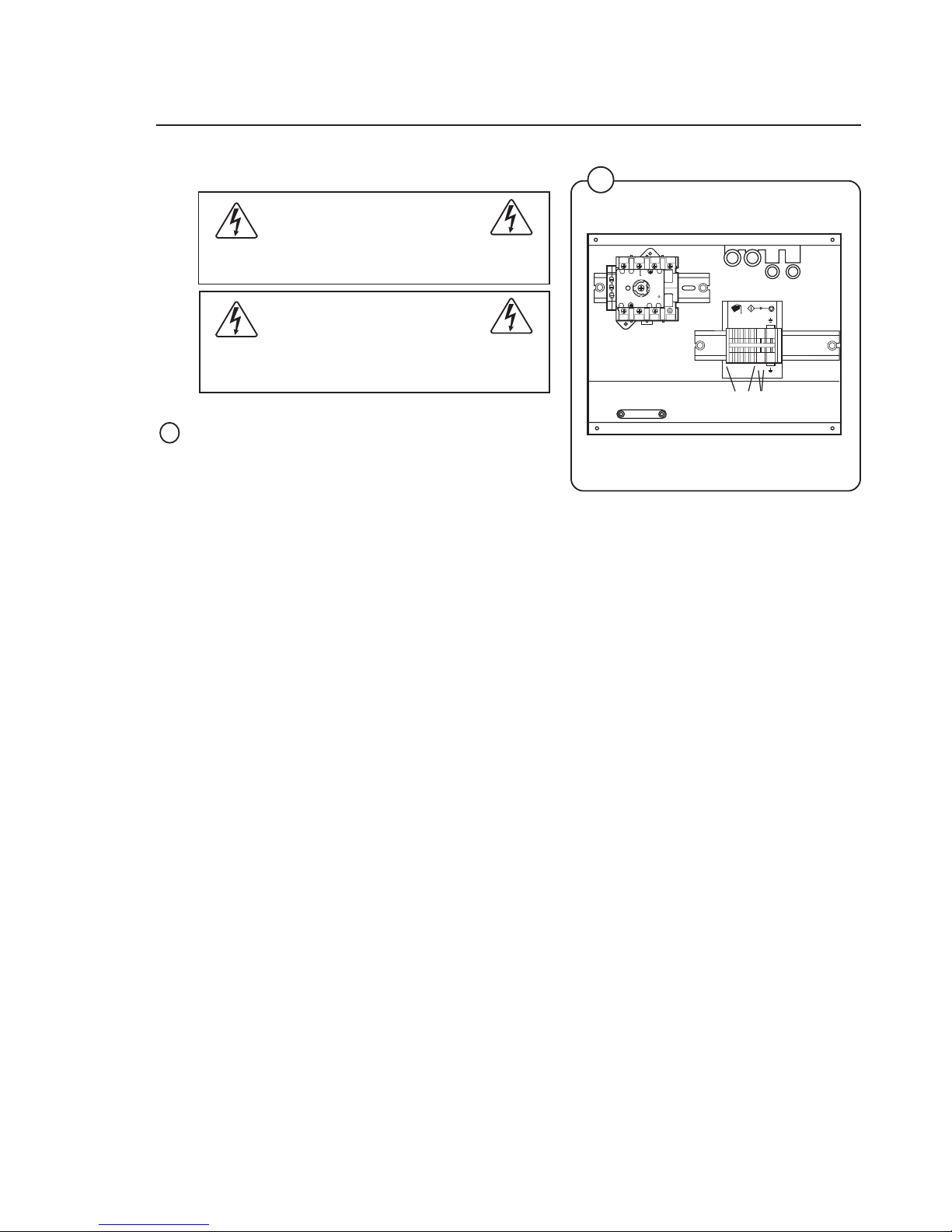

Connection for liquid supply (option)

Electrical installation must be carried out

by an authorized personnel!

Installed appliances must be EMC approved

according to EN 50081-1 and EN 50082-2.

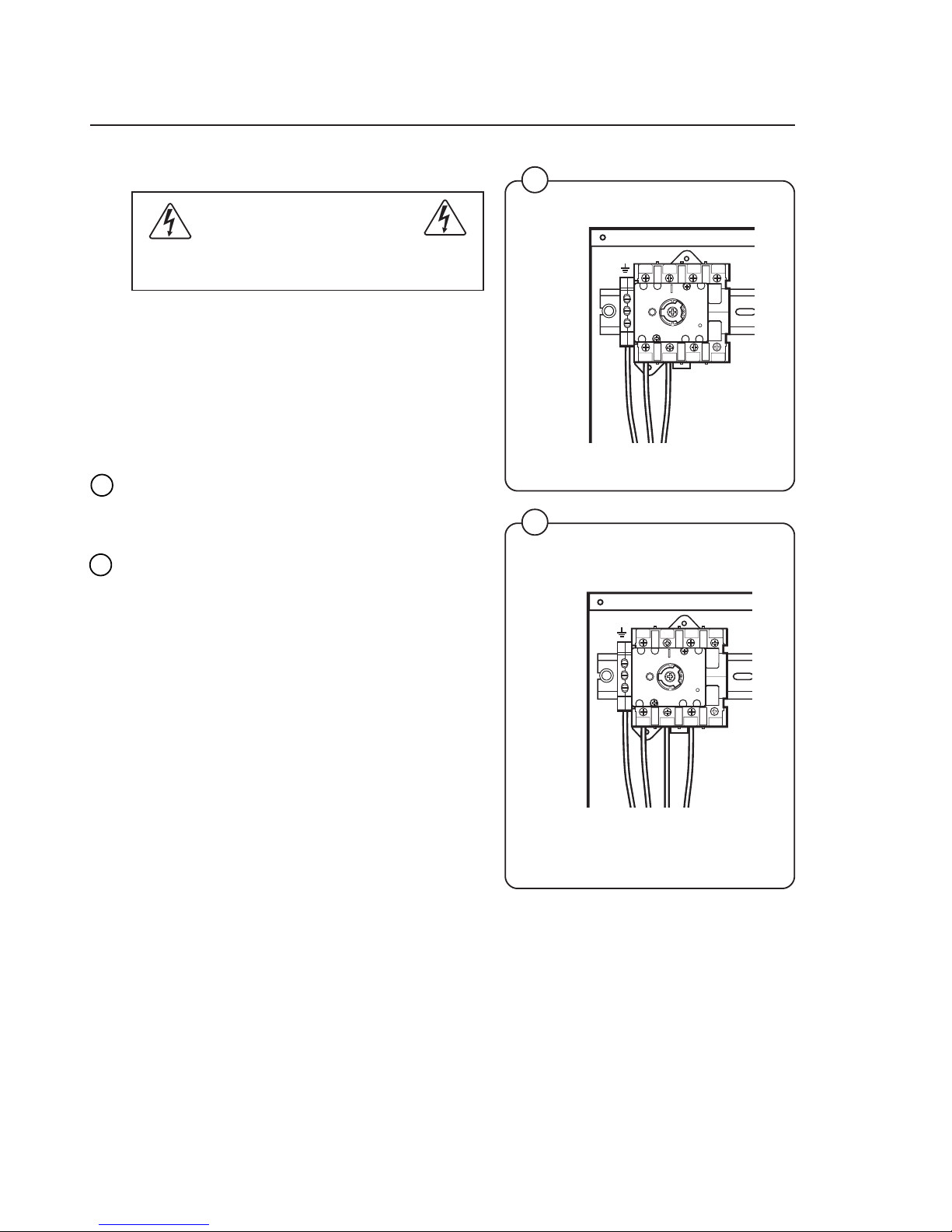

The connections A (1-5) are signals for the liquid

supply pumps.

The connections B are for Neutral (1) and Phase

(2).

8

4722

Fig.

8

T1

T2

T3L1N

N

L2

L3

X146-1

471 75 98 01

12

3

4

125

12

3

4

125

A B

14

Installation

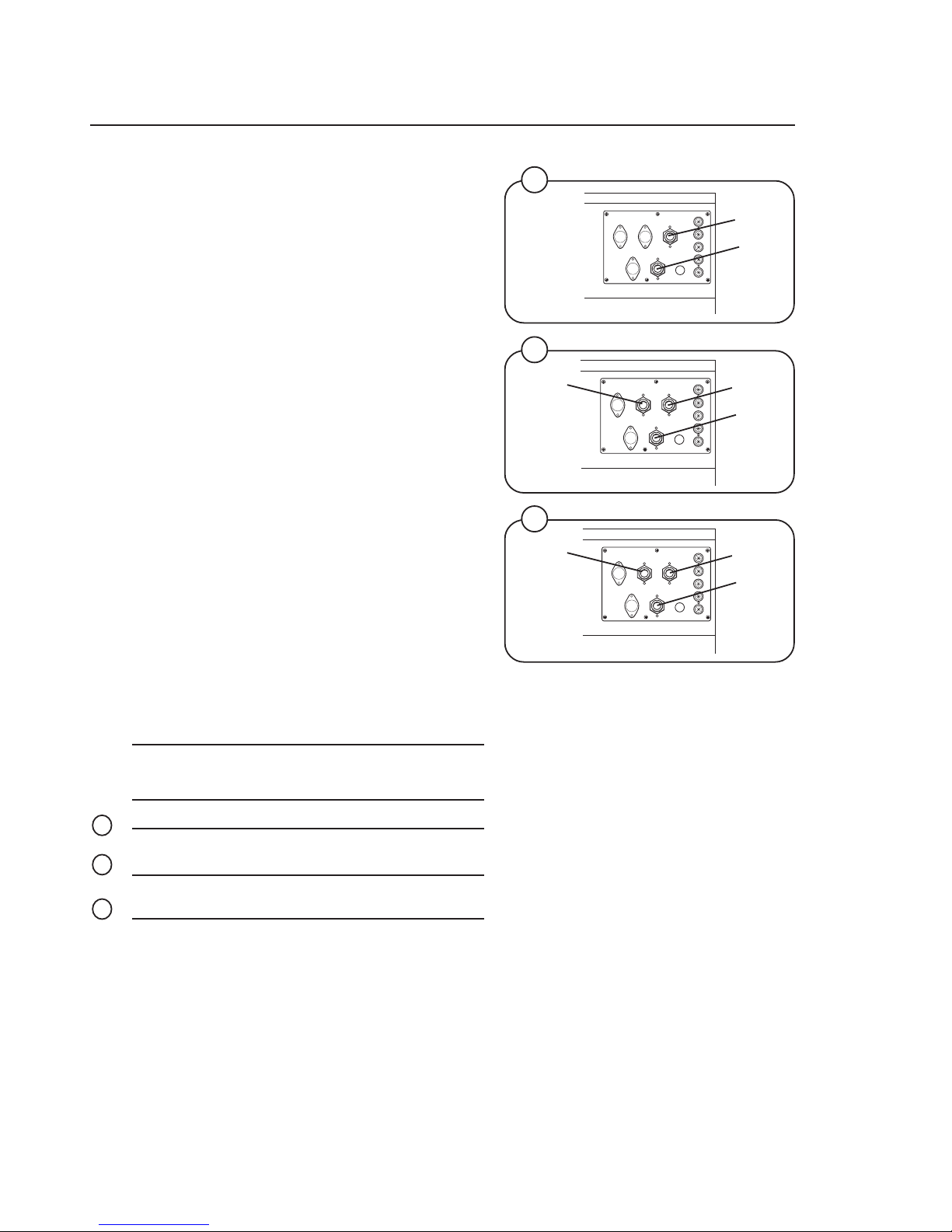

Water connections

All intake connections to the machine are to be

fitted with manual shut-off valves and filters, to

facilitate installation and servicing. In certain

cases non-return valves will need to be fitted

before the machine to comply with local plumbing

regulations.

Water pipes and hoses should be flushed clean

before installation. After installation hoses should

hang in gentle arcs.

The machine may have between two and four

DN 20 (R 3/4") water connectors. All connectors

present on the machine must be connected up.

The table shows the possible connection options,

which will depend on the water types to be

connected to the machine. Check the machine

plates too.

All water connectors must be connected up,

otherwise the wash program will not function

correctly.

Hoses are to be of an approved type and grade,

to comply with national regulations.

The water pressure data is as follows:

• min: 40 kPa (0,4 kp/cm

2

)

• max: 1 MPa (10 kp/cm

2

)

• recommended: 200-600 kPa (2-6 kp/cm

2

)

Water type Water connection

12 3 4

cold and hot cold hot

cold, hot and

cold/hard cold hot cold/hard

cold and hot cold hot cold or

hot

Fig.

9

Fig.

10

Fig.

11

9

10

11

4702

4703

4705

Hot

Cold

EX 30 S

Cold

EX 30 S

Hot

Cold

EX 50 S

Hot

Cold

Hot/

Cold

15

Installation

Drain connection

Connect a 3'’ (75 mm) flexible hose to the drain

outlet of the machine.

The drain must not have any sharp bends and

must slope downward from the machine to

assure proper drainage. The outlet must open

freely to the main drain.

Do not reduce the size of the drain connection

from the machine to the waste line.

12

1258

Fig.

12

16

Installation

13

1719

STEAM HOSE APPROVED FOR

min. 0,1 MPa

max. 0,8 MPa

CABLE FROM MACHINE

SEAL WITH TEFLON

OR SIMILAR

CONNECTION STEAM

INJECTOR IN MACHINE

For rebuilding look at the wiring diagram of the machine.

17

Installation

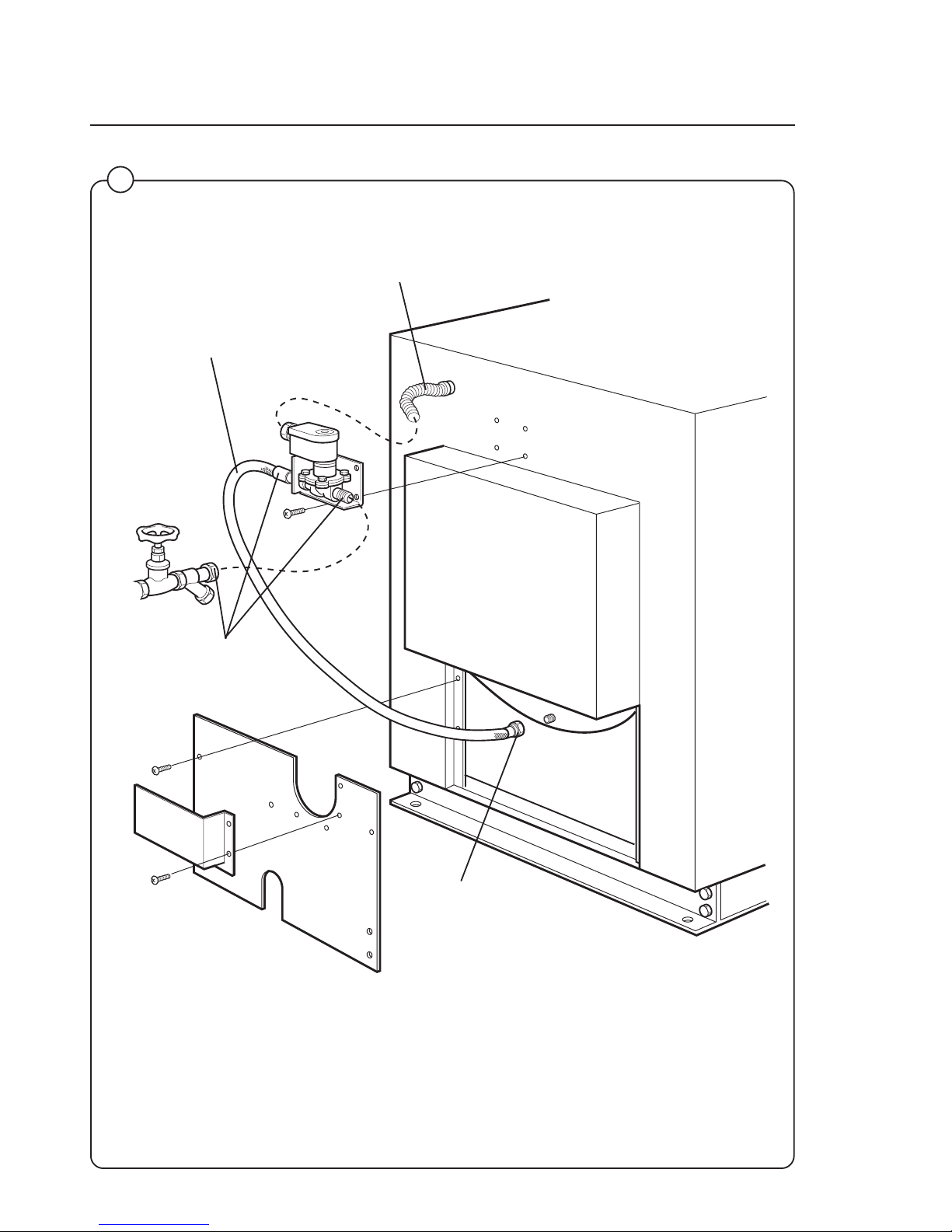

Steam connections (optional steam heating)

Steam pressure required:

• minimum 7 PSI

• maximum: 110 PSI

• recommended: 40-85 PSI

A steam valve for this machine type is fitted

separately in a bracket on the upper rear cover

plate. The steam valve, hose and filter are supplied with the machine.

Steam-flush all pipes and hoses before connection.

Installation instructions:

• Install rear cover plates.

• Install steam valve bracket and valve. The

steam valve must be mounted in upright

position.

• Connect the steam hose between the steam

valve and the steam intake on the machine.

• The steam inlet pipe must be fitted with a

manual cut-off valve. Fit the filter supplied with

the machine to the manual cut-off valve.

• Connect an approved 1/2'' steam hose between the steam valve and the filter. The

connection must be vertical or be fitted with a

pipe connector in order to avoid sharp angles

in the hose.

• Connection size at filter: DN15 (R 1/2''').

Check that there are no sharp angles or

bends in the connection hose.

14

1254

Fig.

14

18

Installation

15

Fig.

15

4724 B

Electrical installation

Electrical installation must be carried out

by an authorized personnel!

Mount a multi-pole switch prior to the machine to

facilitate installation and service operations.

The connecting cable should hang in a gentle

curve.

Fuse size can be found on next page.

Single-phase connection:

Connect the earth and other two wires as shown

in example "1AC" in the figure.

Three-phase connection:

Connect the earth, neutral and phase wires as

shown in example "3AC" in the figure.

When the installation is completed, check:

• that the drum is empty,

• that the machine operates by turning on the

mains switch, starting the machine and using

RAPID ADVANCE to reach the spin cycle

(see operations manual).

16

4726

Fig.

16

T1

T2

T3L1N

N

L2

L3

T1

T2

T3L1N

N

L2

L3

1AC

3AC

19

Installation

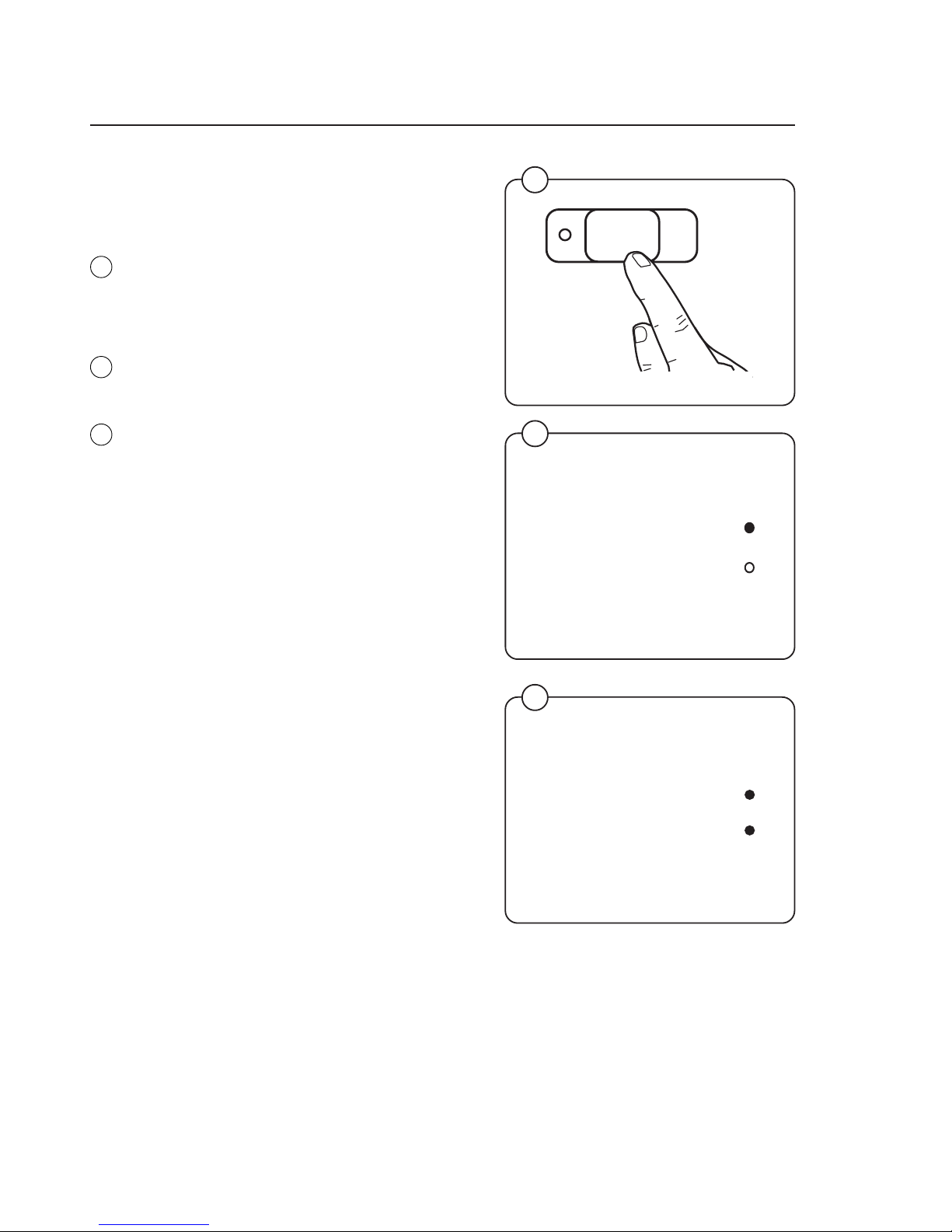

Setting the timing on the electrolube oil dispenser

This machine is equipped with an electronic oiler

which lubricate the seals on a timed bases. With

the rear panel removed locate the oiler, which is

attached to the base frame at the lower rear.

Pry off the switch panel cap with a screwdriver.

• Under the cap are the switches for time setting.

• The light will start flashing after a few minutes

and will continue to flash every 15th to 20th

seconds as long as the dispencer is in operation.

• The decal shown below should be affixed at

the front of the machine and updated as

required.

Fig.

19

2207

19

18

17

2208 A

Date Last Replaced Date Last Replaced

IMPORTANT

NOTICE

This machine is equipped with an automatic oiler,

located at the right rear of the machine, which keeps

it lubricated for long bearing and seal life.

The amount of oil in the container is sufficient for

approximately one year's lubrication. It is of utmost

importance that the oiler does not become empty.

Therefore we recommend that the rear panel be

removed and a visual inspection made on a

bimonthly basis. When the oil reaches a low level,

the cannister must be replaced with a new one

available from Wascomat as Part No. 827601.

Fig.

17

Fig.

18

20

4944

Start-up and safety checklist

Before initial start-up of an EX 30 S/EX 50 S

washer, the following safety checks must be

performed:

• Make sure that all electrical and plumbing

connections have been made in accordance

with applicable local codes.

• Use only flexible water fill and drain hoses of

the proper length to avoid sags and kinks.

• Make sure the machine is properly grounded

(electrically).

Before the machine is operated, the door safety

interlock must be checked for proper operation

as follows:

• When washer loading door is open, the

machine must not start. Verify this by attempting to start washer with door open.

• When washer is in operation, the loading door

is locked and cannot be opened. Verify this by

attempting to open the loading door when the

machine is operating. If necessary, consult

this manual for proper operation of the door

safety interlock or call a qualified serviceman.

If the machine starts with the door open or

the door can be opened after machine is

running, the machine must immediately be

placed OUT OF ORDER and the door

interlock system must be repaired or

replaced. Disconnect electrical power from

the machine until the necessay repairs are

made.

Door safety interlock must be checked

daily in accordance with above procedure.

Before servicing Wascomat equipment,

disconnect electrical power.

Fig.

20

Fig.

21

20

Installation

21

4945

123

45

6

7

89

0

123

45

6

7

89

0

21

• This machine is designed for water washing only.

• Machines must not be used by children.

• All installation operations are to be carried out by qualified personnel.

Licensed personnel are necessary for all electric power wiring.

• The interlock of the door must be checked daily for proper operation

and must not be bypassed.

• All seepage in the system, due to faulty gaskets etc., must be repaired

immediately.

• All service personnel must be fully familiar with the operating manual

before attempting any repair or maintenance of the machine.

• This machine must not be sprayed with water, otherwise short

circuiting may occur.

• Fabric softeners with volatile or inflammable fluids are not to be used in

this machine.

Safety rules

Safety rules

22

1

Supply

signals

A

B

2

3

4

5

START

STOP

6

1

Program

step

7

Final extract

Doorlock delay

Door unlocked

2

3

4

5

Prewash

Mainwash

Rinse

Operating instructions

Operating instructions

The Emerald Series program unit controls the various functions of the machine

in a certain time sequence with the aid of seven built-in standard programs.

The standard programs can also be modified by selecting various options. By

selecting options, the user has access to programs for all types of wash loads

and degrees of soiling.

The control panel consists of program selection buttons (A) and (B), a

combined start, pause and rapid advance button (C), symbols with LEDs (D)

which show the program selected and the program sequence, plus an alphanumeric display (E).

The alphanumeric display shows illuminated green characters.

In the event of faults, error codes will be displayed on this window. See Fault

codes.

22

Explanation of control panel

A Program selection buttons

B Option buttons

C Start/pause and rapid advance button

D Symbols with LEDs to indicate program sequence

E Information display

4996

Fig.

22

D

E

B

A

C

23

Operating instructions

Washing

• Press the button for the desired program.

• Now the LEDs alongside the program symbols will show what the selected program

consists of.

• Press the button(s) for any options required.

Gentle actions consists of 6 seconds

rotation, as opposed to 18 seconds pause

and 6 seconds pause and 14 seconds

rotation for Normal action.

• Press the START button.

3426

4995

3435

24

Fig.

23

Fig.

24

Fig.

26

27

Fig.

25

Perm Press

Quick-Wash

2

3

4

5

START

Hot

Warm

Cold

Delicate

Heavy Soil

6

1

7

START

Fig.

27

A

B

25

26

23

1

Supply

signals

Program

step

Final extract

Doorlock delay

Door unlocked

2

3

4

5

Prewash

Mainwash

Rinse

24

• Now the display will show the clock symbol

and two digits. The two digits are the time left

before the wash will be finished.

The two digits indicating time left will not

appear when the machine is first installed.

Each program needs to have been used at

least once before the time left will be displayed.

• For 5 minutes immediately after START is

pressed the colon character (

: ) will flash on

the display. As long as this character is still

flashing a new program can be selected

(without the drain opening). This means you

still have the chance to change the setting if

the wrong program has been selected. Do as

follows:

• Press START.

• Select a new program.

• Press START again after making any change

in the program selected.

If for any reason you wish to halt the wash cycle

for a time, press the START button for a moment

or two. The program will be suspended and the

drain will remain closed.

To restart the program, press the START button

again briefly.

Fig.

28

Operating Instructions

Fig.

29

Fig.

30

30

3435

START

4091

29

3141

28

1

25

START

Operating Instructions

For coin-operated machines

Select a wash program, then insert the number

of coins corresponding to the figure shown on

the display.

As each coin is added the machine counts

backwards towards 00 on the display. The

machine will not start until the display shows 00.

• Press the START button.

• Now the display will show the clock symbol

and two digits. The two digits are the time left

before the wash will be finished.

The two digits indicating time left will not

appear when the machine is first installed.

Each program needs to have been used at

least once before the time left will be displayed.

• For a time immediately after START is pressed the colon character (

: ) will flash on the

display. As long as this character is still

flashing a new program can be selected

(without losing anything). This means you still

have the chance to change the setting if the

wrong program has been selected.

• Press PAUSE/START.

• Select a new program.

• If the new program costs more to run than

the amount already paid, the difference will

be shown on the display. Insert enough coins

to make the display show 00 again.

• Press START again after making any change

in the program selected.

3435

2253

Fig.

31

3141

31

32

33

Fig.

32

Fig.

33

26

Doorlock delay

Door unlocked

Rapid advance

Whole steps in programs can be skipped using

rapid advance.

• Press and hold the START button until the

program indicator LEDs have moved past the

program steps you wish to skip.

Program end

After final extraction, the LED by the "doorlock

delay" comes on. This shows that the door lock

will shortly be unlocked.

The door will not actually be unlocked until the

green LED by the "door unlocked" comes on,

accompanied by an audible signal. This takes

about 1 minute.

Troubleshooting

If the machine won’t start, check that:

• the circuit breaker is on.

• the manual shut-off valves for water are open.

• a program has been selected.

• the door is properly locked.

3435

Fig.

34

3424

3425

Fig.

36

Operating Instructions

34

35

36

Fig.

35

START

Doorlock delay

Door unlocked

27

A

1

1

4

3

2

6

5

8

7

9

Programming

Coin-operated machines

In coin-operated machines the prices for the

various programs have to be programmed in.

Values from the coin mechanism (the

accumulated value) can be read out with the aid

of the service program.

If a machine is fitted with a coin mechanism after

its original installation the relevant electronic

circuitry will have to be activated before the prices

can be programmed in.

Only trained service personnel may use the

service program and program in prices for

coin operation.

Activation of electronic circuitry in machines fitted with coin operation after original

installation.

• Press the service button.

Now certain of the buttons switch to being

number keys (1 to 9), with the START button

being 0.

3429

Fig.

37

Fig.

38

38

3400

37

Loading...

Loading...