WARNING: ALL OPERATING AND MAINTENANCE PROCEDURES SHOWN ON THE NEXT

PAGE OF THIS MANUAL MUST BE FOLLOWED DAILY FOR PROPER OPERATION OF

YOUR WASCOMAT MACHINE.

PLEASE ENTER THE FOLLOWING INFORMATION AS IT APPEARS ON THE MACHINE(S)

DATA PLATE(S).

MAKE CERTAIN TO KEEP THIS MANUAL IN A SECURE PLACE FOR FUTURE

REFERENCE.

MACHINE TYPE OR MODEL

MACHINE SERIAL NUMBER(S)

ELECTRICAL CHARACTERISTICS:________ VOLTS, _______ PHASE, ______ HZ.

OPERATING & MAINTENANCE MANUAL

EX 7 ES – EX 10 ES

Emerald Series

471 1562-39/01

94.44

NOTICE TO: OWNERS, OPERATORS AND DEALERS OF WASCOMAT MACHINES

II

IMPROPER INSTALLATION AND INADEQUATE MAINTENANCE, POOR HOUSEKEEPING AND WILLFUL

NEGLECT OR BYPASSING OF SAFETY DEVICES MAY RESULT IN SERIOUS ACCIDENTS OR INJURY.

TO ASSURE THE SAFETY OF CUSTOMERS AND/OR OPERATORS OF YOUR MACHINE, THE FOLLOWING MAINTENANCE CHECKS MUST BE PERFORMED ON A DAILY BASIS.

1. Prior to operation of the machine, check to make certain that all operating instructions and

warning signs are affixed to the machine and legible. (See the following page of this manual

for description and location of the signs.) Missing or illegible ones must be replaced immediately. Be sure you have spare signs and labels available at all times. These can be obtained from your dealer or Wascomat.

2. Check the door safety interlock, as follows:

(a) OPEN THE DOOR of the machine and attempt to start in the normal manner:

For coin-operated models, insert the proper coins to start the machine.

For manually operated models, place the ON-OFF switch in the ON position and

press the Start switch.

For FL and EX models, insert a program card, turn the starter knob to the Start

position and place the ON-OFF switch in the ON position.

For HI-TEK microprocessor models, turn the key switch to the RUN position, choose

a program and press the START button.

For SELECTA 28 models, select a wash program and press the Start button.

THE MACHINE(S) SHOULD NOT START !

(b) CLOSE THE DOOR to start machine operation and, while it is operating, attempt to

open the door without exerting extreme force on the door handle. The door should

remain locked!

If the machine can start with the door open, or can continue to operate with the door

unlocked, the door interlock is no longer operating properly. The machine must be

placed out of order and the interlock immediately repaired or replaced.(See the door

interlock section of the manual.)

3. DO NOT UNDER ANY CIRCUMSTANCES ATTEMPT TO BYPASS OR REWIRE ANY OF

THE MACHINE SAFETY DEVICES AS THIS CAN RESULT IN SERIOUS ACCIDENTS.

4. Be sure to keep the machine(s) in proper working order: Follow all maintenance and

safety procedures. Further information regarding machine safety, service and parts can be

obtained from your dealer or from Wascomat through its Teletech Service Telephone - 516/

371-0700.

All requests for assistance must include the model, serial number and electrical characteristics as

they appear on the machine identification plate. Insert this information in the space provided on the

previous page of this manual.

5. WARNING: DO NOT OPERATE MACHINE(S) WITH SAFETY DEVICES BYPASSED, REWIRED OR

INOPERATIVE! DO NOT OPEN MACHINE DOOR UNTIL DRUM HAS STOPPED ROTATING!

CAUTION

1. Do not open washer door until cycle is completed, operating

light is off, and wash cylinder has stopped rotating.

2. Do not tamper with the door safety switch or door lock.

3. Do not attempt to open door or place hands into washer to

remove or add clothes during operation. This can cause

serious injury.

MACHINE SHOULD NOT BE USED BY CHILDREN

PRECAUCION

1. No abra la puerta de la máquina lavadora sino hasta que la

máquina haya terminado su ciclo, la luz operativa esté apaga

da y el cilindro de lavado haya completamento terminado de

girar.

2. No interferia o manipule el switch o la cerradura de la puerta.

3. No trate de abrir la puerta o meta las manos dentro de la

máquina para meter o sacar ropa mientras la máquina está

en operación, pues puede resultar seriamento herido.

LAS MÁQUINAS NO DEBEN SER USADAS POR NIÑOS

SAFETY AND WARNINGS SIGNS

Replace If Missing Or Illegible

One or more of these signs must be affixed on each machine as indicated, when not included as part of the front instruction panel.

LOCATED ON THE OPERATING INSTRUCTION SIGN OF THE MACHINE:

LOCATED ON THE DOOR:

WARNING!

THE DOOR IS LOCKED A SHORT

WHILE AFTER THE SYMBOL AT

TURN TO

DOOR OPENING

– DRUM STAND STILL

–PRESS – PULL

471 7676-02

If you need to order more safety or warning

signs, call Wascomat's parts department at

516-371-2000, or call your local dealer.

Contents

Introduction ...................................................................... 1

Technical data.................................................................. 2

Installation........................................................................ 5

Safety rules ....................................................................11

Operating instructions .................................................... 12

Programming..................................................................17

Wash cycles................................................................... 21

Mechanical and electrical design ................................... 30

Maintenance...................................................................47

Trouble-shooting ............................................................48

Service information ........................................................ 53

Safety instructions

• This machine is designed for water washing only.

• This machine must not be used by children.

• All installation operations are to be carried out by qualified

personnel. Licensed personnel are necessary for all electric

power wiring.

• The interlock of the door must be checked daily for proper

operation and must not be bypased.

• All seepage in the system, due to faulty gaskets etc., must be

repaired immediately.

• All service personnel must be fully familiar with the operating

manual before attempting any repair or maintenance of the

machine.

• This machine must not be sprayed with water, otherwise short

circuiting may occur.

• Fabric softeners with volatile or inflammable fluids are not to

be used in the machine.

The manufacturer reservs the right to make changes to design and

material specifications.

EX7, EX 10

1

Introduction

Introduction

The EX 7 and EX 10 Emerald models washer/extractor with high spin

speeds, have been developed to meet the needs of state-of-the-art professional laundromats, institutions, hospitals etc., where high quality automatic washing and quick formula variation are required.

Emerald models are unique because you can program different prices for

the seven wash cycles, giving the customer a real choice and allowing you

to maximize revenue by changing what each cycle is worth. In addition, you

can charge a higher price if the customer selects the Extra Extract option.

Using an external clock and wiring harness, these models may be programmed to lower the price by any percentage between any hours of any

days, for the ultimate in pricing flexibility!

The machines are free-standing, i.e. the drum is free to move relative to the

frame of the machine, being suspended from it by springs. This results in a

considerable reduction in vibration transferred to the frame of the machine,

which in turn simplifies installation: no special foundation is required.

The seven cycles offer different water temperatures, wash times, extraction

times, and normal or gentle drum rotation. EMERALD SERIES washers

achieve maximum environmental efficiency because only the minimum

amount of water is used for each cycle, which vary in duration.

When ordering spare parts or contacting Wascomat or your dealer for

service, always give the machine serial number, model, voltage and other

electrical characteristics appearing on the data plate at the top left of the

rear panel of the machine. The serial number is also printed on a sticker

inside the door...

KEEP THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE!

1821

1

Fig.

1

Technical data

2

Technical data EX 7

Dry load capacity up to 15 lbs

Overall dimensions Width 720 mm 28 11/32 in

Depth 660 mm 26 in

Height 1100 mm 43 5/16 in

Net weight 164 kg 361 lbs

Maximum floor load 1.64 ± 0.7 kN 390 ± 170 lbs force

Crated dimensions Volume 0.66 m

3

23.3 cu.ft

Weight 176 kg 387 lbs

Inner drum dimensions Diameter 520 mm 20 15/32 in

Depth 310 mm 12 3/16 in

Volume 60 litre 2.1 cu.ft

Drum speed Wash 52 rpm

Distribution 80 rpm

Extraction 1020 rpm

G-factor During wash 0.8

During extraction 300

Motor speed During wash 1140 rpm

During distribution 1740 rpm

During extraction 3430 rpm

Voltage requirements 120 V 1-Phase 60 Hz

Rated output power Motor, wash 140 W 0.19 HP

Motor, distribution 100 W 0.13 HP

Motor extraction 350 W 0.5 HP

Overcurrent protection 20 A

Water connections Rec. pressure 2-6 kp/cm

2

25-85 psi

Hose connection, water DN 20 3/4 in

Drain connection Hose 50 mm 2 in

Technical data

3

Technical data EX 10

Dry load capacity up to 25 lbs

Overall dimensions Width 720 mm 28 11/32 in

Depth 820 mm 32 9/32 in

Height 1100 mm 43 5/16 in

Net weight 225 kg 495 lbs

Maximum floor load 2.3 ± 0.9 kN 550 ± 220 lbs force

Crated dimensions Volume 0.77 m

3

27.2 cu.ft

Weight 240 kg 528 lbs

Inner drum dimensions Diameter 520 mm 20 15/32 in

Depth 470 mm 18 1/2 in

Volume 100 litre 3.5 cu.ft

Drum speed Wash 52 rpm

Distribution 80 rpm

Extraction 1020 rpm

G-factor During wash 0.8

During extraction 300

Motor speed During wash 1130 rpm

During distribution 1730 rpm

During extraction 3400 rpm

Voltage requirements 120 V or 208-240 V 1- Phase 60 Hz

Rated output power Motor, wash 200 W 0.27 HP

Motor, distribution 180 W 0.24 HP

Motor extraction 550 W 0.74 HP

Overcurrent protection 20 A at 120 V

15 A at 208-240 V

Water connections Rec. pressure 2-6 kp/cm

2

25-85 psi

Hose connection, water DN 20 3/4 in

Drain connection Hose 50 mm 2 in

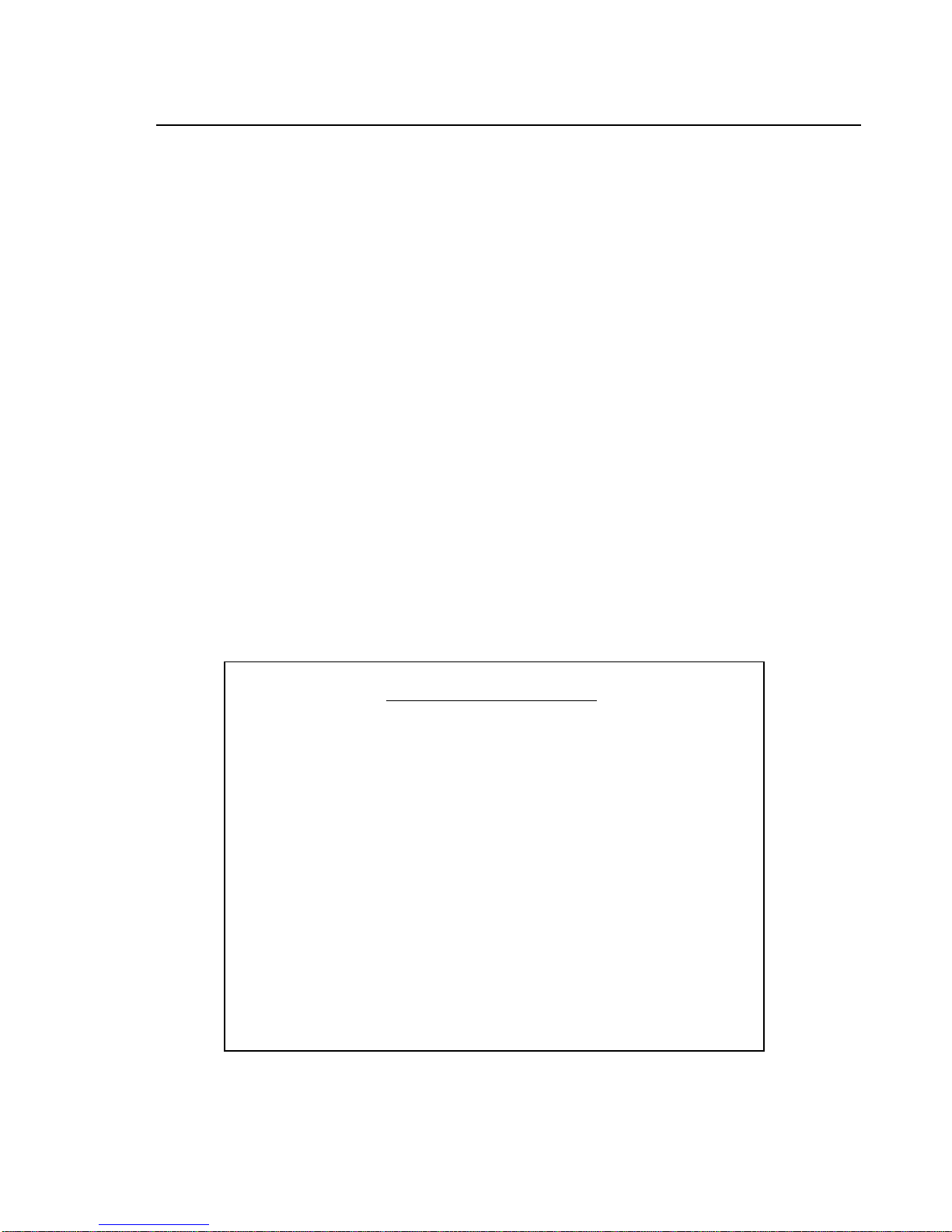

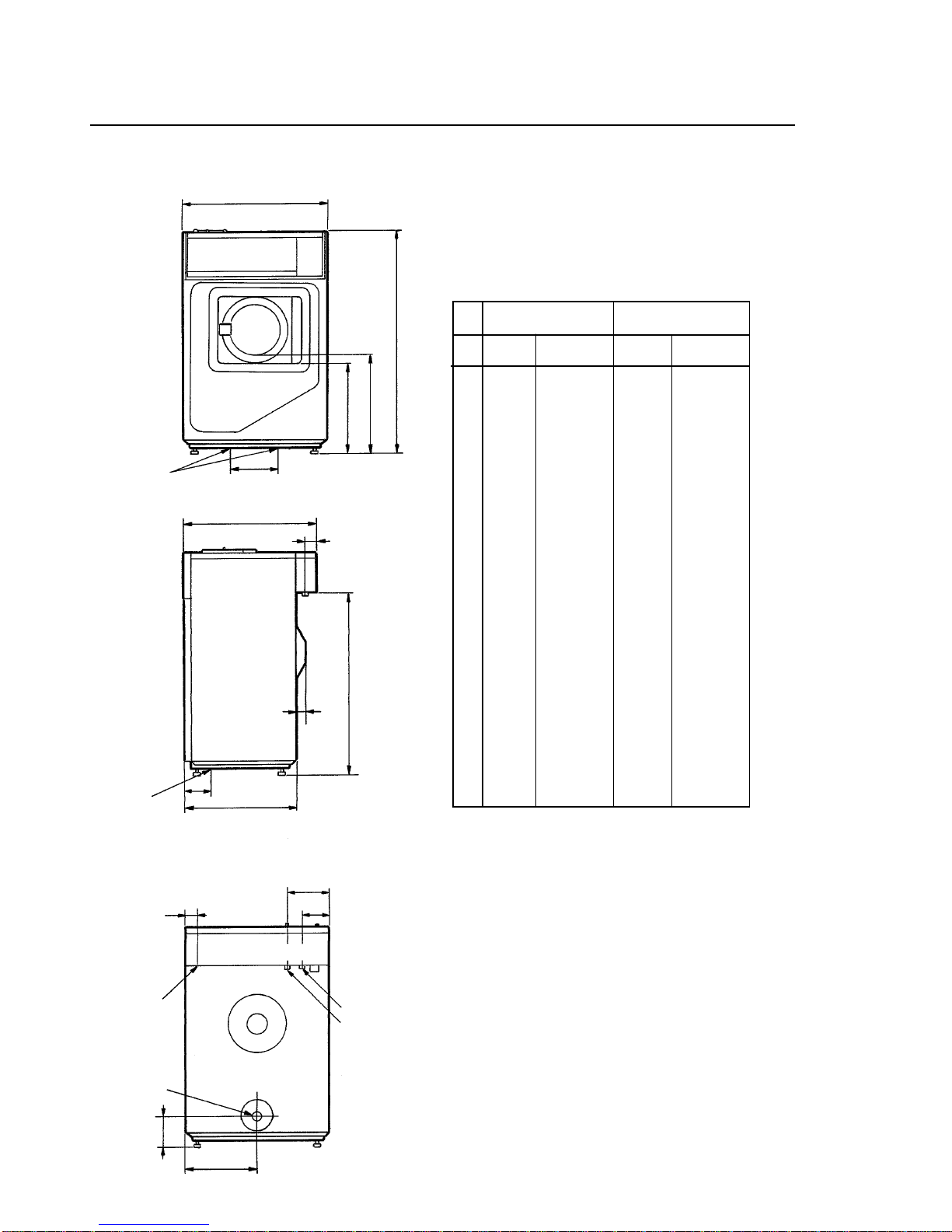

Outline and dimension

Technical data

EX 7 EX 10

mm inches mm inches

A 1100 43 5/16 1100 43 5/16

B 485 19 3/32 485 19 3/32

C 440 17 5/16 440 17 5/16

D 260 10 1/4 260 10 1/4

E 720 28 11/32 720 28 11/32

F 660 26 820 32 9/32

G 65 2 9/16 65 2 9/16

H 555 21 27/32 715 28 5/32

J 50 1 31/32 50 1 31/32

K 905 35 5/8 905 35 5/8

L 40 1 9/16 40 1 9/16

M 60 2 3/8 60 2 3/8

N 210 8 9/32 210 8 9/32

O 130 5 1/8 130 5 1/8

P 360 14 5/32 360 14 5/32

R 150 5 29/32 150 5 29/32

4

C

B

A

E

D

F

G

H

J

K

L

N

O

M

P

R

Drain

Electrical

connection

Mounting

holes

Mounting

holes

Hot water

Cold water

1596

Installation

2

0243

Installation

The machines are free-standing, i.e. the drum

can move relative to the frame of the machine.

This results in a considerable reduction in vibration transferred to the frame which in turn

simplifies installation: no special foundation is

required.

The machine is delivered complete with expansion bolts, template etc. packed inside the drum.

Move the machine on its pallet to where it is to be

installed before removing the pallet retaining

bolts.

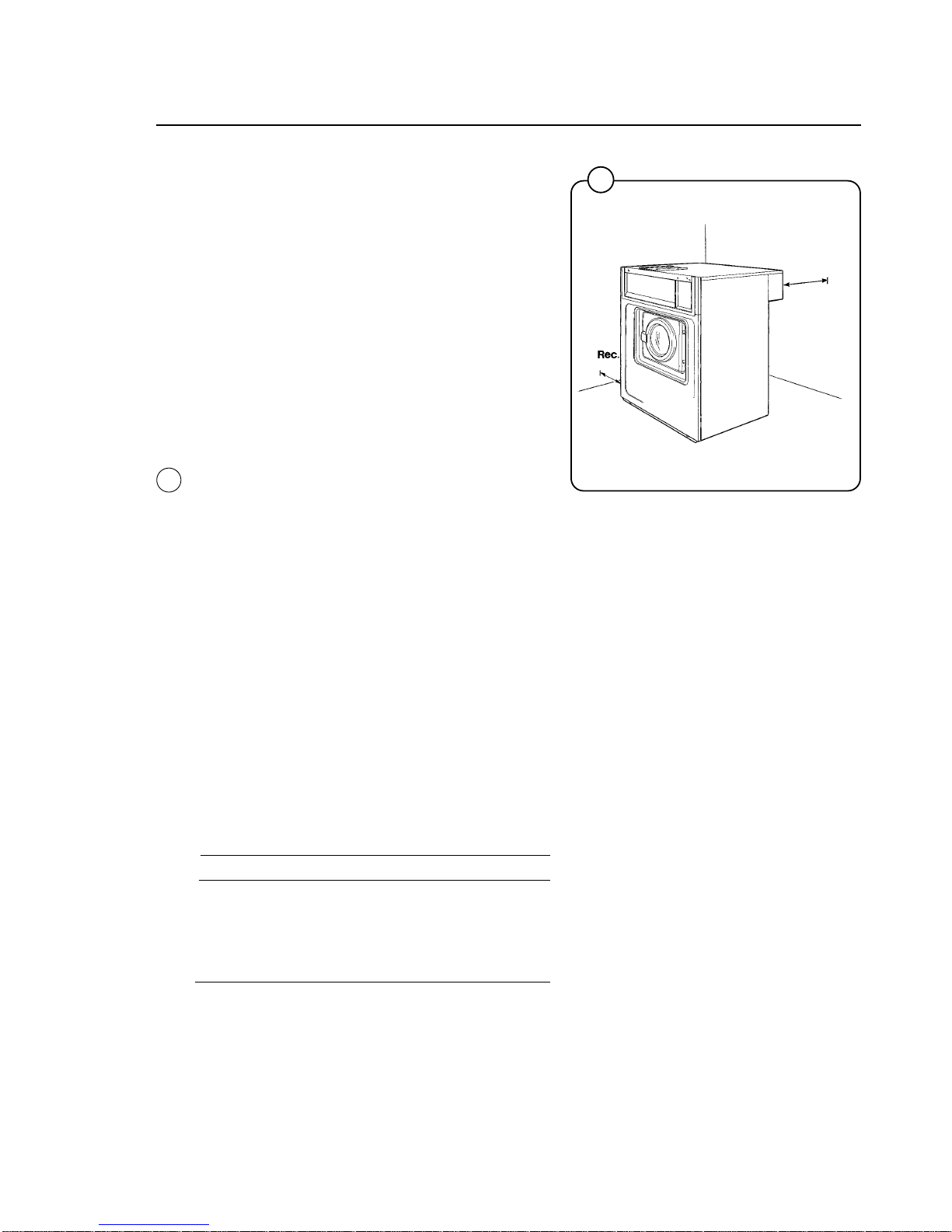

Location

Install the machine close to a floor drain or open

drain.

In order to make installation and servicing the

machine easier the following clearances are

recommended:

• At least 20" between the machine and the wall

behind

• and a minimum of 2" on both sides of the

machine whether installed next to the wall or

other machines.

Where space is limited it is possible to reduce

this distance to a minimum of 1" at the rear and

sides, since most service operations are carried

out from the front or top of the machine.

Floor

The floor must be able to withstand the following

loads:

EX7 EX10

static 390 lbs 550 lbs

dynamic 170 lbs 220 lbs

frequency of 17 kHz 17kHz

dynamic force

5

20"

2"

Fig.

2

Installation

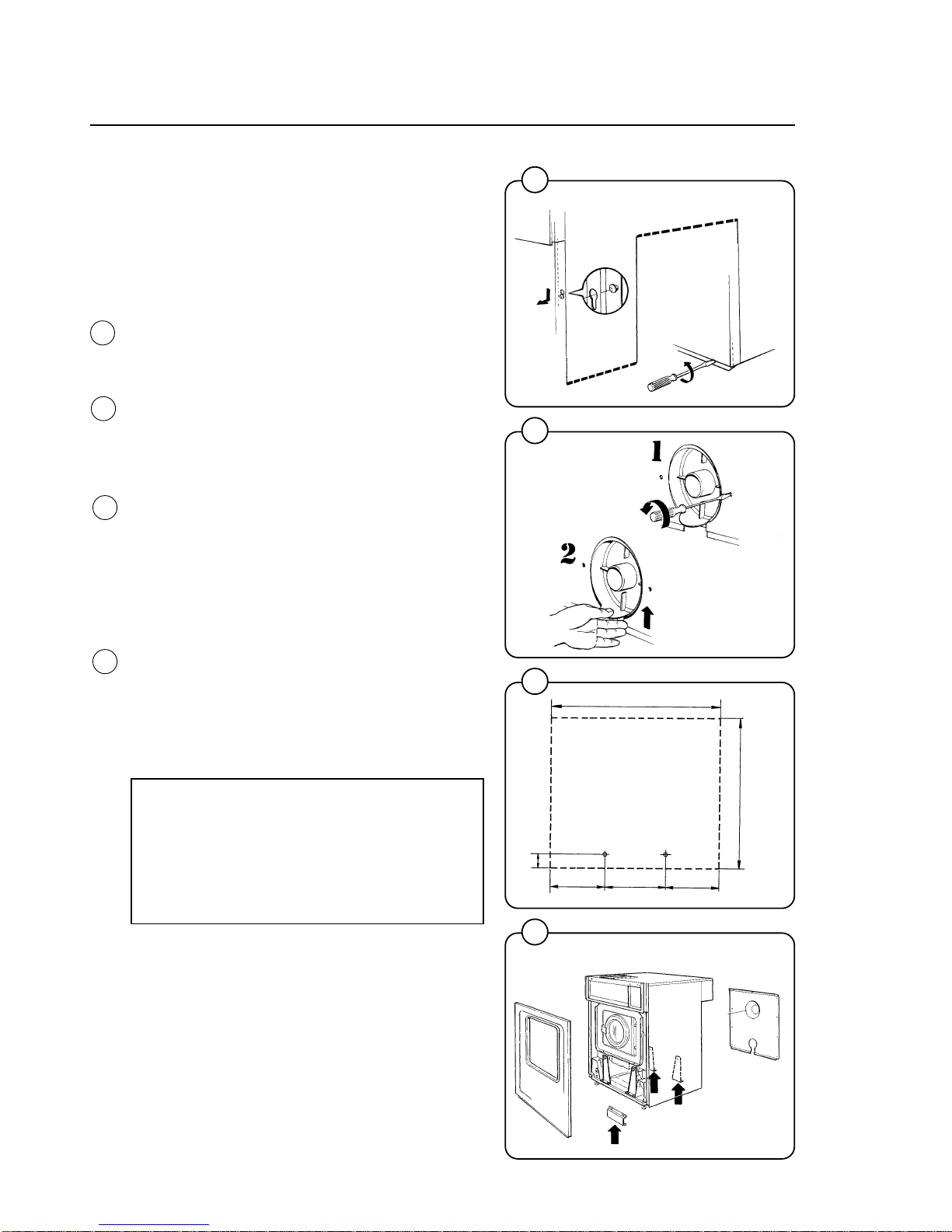

Mechanical installation

The machine is delivered with the drum locked in

place by four transport bolts fitted between the

frame and the drum. In orderto remove these

and install the machine, proceed as follows:

• Unpack the machine.

• Slacken off the screws in the lower edge of

the front cover plate and remove the plate by

pulling downward and outward to unhook it

from the chassis.

• Unscrew the retaining screws on the rear

plate and remove the plate. Remove the

drainage connection by unscrewing the two

screws. Lift the drainage connection upwards

until comes loose from the rear plate.

• Mark and drill two holes (diameter =5/16")

about 4" deep in the positions shown.

• Remove the machine from the transport pallet.

Fit the adjustable feet provided.

• Place the machine above the bolt holes you

just drilled. Always lift the machine by the

chassis, never by the door or door handle.

• Remove the four transport bolts securing the

drum to the chassis.

• Check that the machine is level and steady.

Adjust the level by using the four adjustable

feet (check first that they are screwed in as far

as possible). Lock the feet using the lock nuts

when the machine is satisfactorily positioned.

NOTE!

It is of utmost importance that the

machine be level, from side- to- side as

well as front- to- rear. If the machine is not

properly leveled, it may result in a false

out-of-balance cutout.

• Insert the expansion bolts supplied in the

holes drilled in the floor.

Fit the washers and nuts, and tighten well.

After the machine has been in use for a while

check and retighten the nuts if necessary.

3

4

5

6

0674

0244

0672

0671

6

EX 7

EX 10

720 mm

65mm

230mm

260mm

230mm

2 9/16 in

9 1/16 in

10 1/4 in

9 1/16 in

28 11/32 in

EX10:

820mm

32 9/32 in

EX7:

660mm

26 in

Fig.

3

Fig.

4

Fig.

5

Fig.

6

Installation

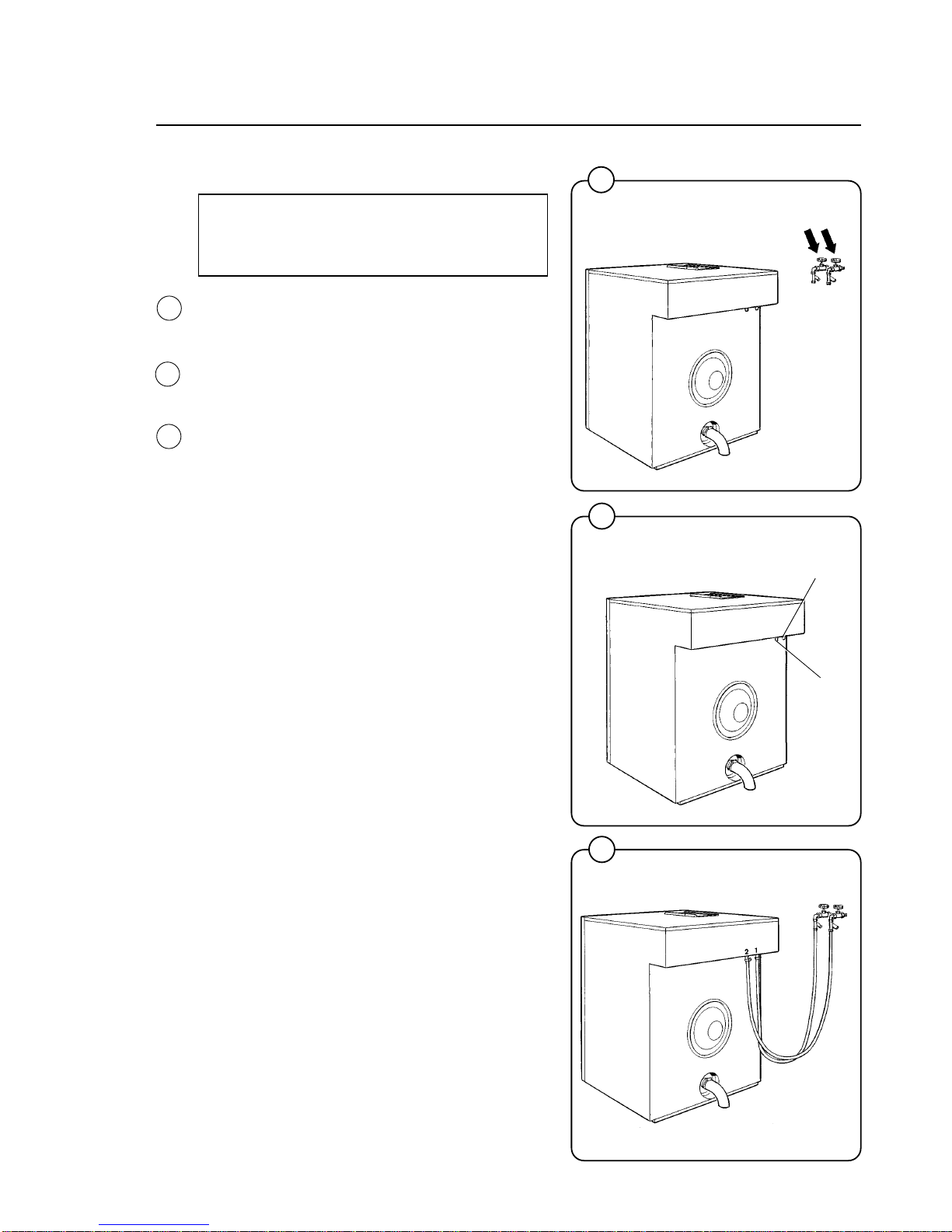

Water supply

NOTE

All plumbing must conform to national

and local plumbing codes.

The water supply to the machine should be fitted

with manual shut-off valves to facilitate installation and servicing.

Water inlets are labelled for hot and cold water

connections. Hoses should be flushed through

before being connected to the machine.

Connection hoses should be 3/4" reinforced

rubber hosing not to exeed 6 ft in length. Make

sure the hoses have no sharp bends or angles.

Water pressure should be:

maximum: 142 psi (10 kp/cm

2

)

recommended: 25-85 psi (2-6 kp/cm

2

)

7

7

8

9

0248

1597

1598

Cold water

Hot water

Fig.

7

Fig.

8

Fig.

9

Drain connection

Connect a 50 mm (2") flexible hose to the

machine’s drain outlet. Avoid sharp bends which

may prevent proper draining.

The drainage pipe should be located over a floor

drain, drainage channel or similar so that the

distance between the outlet and the drain is at

least 25 mm (1"). Refer to local regulations on

watersupply and drainage.

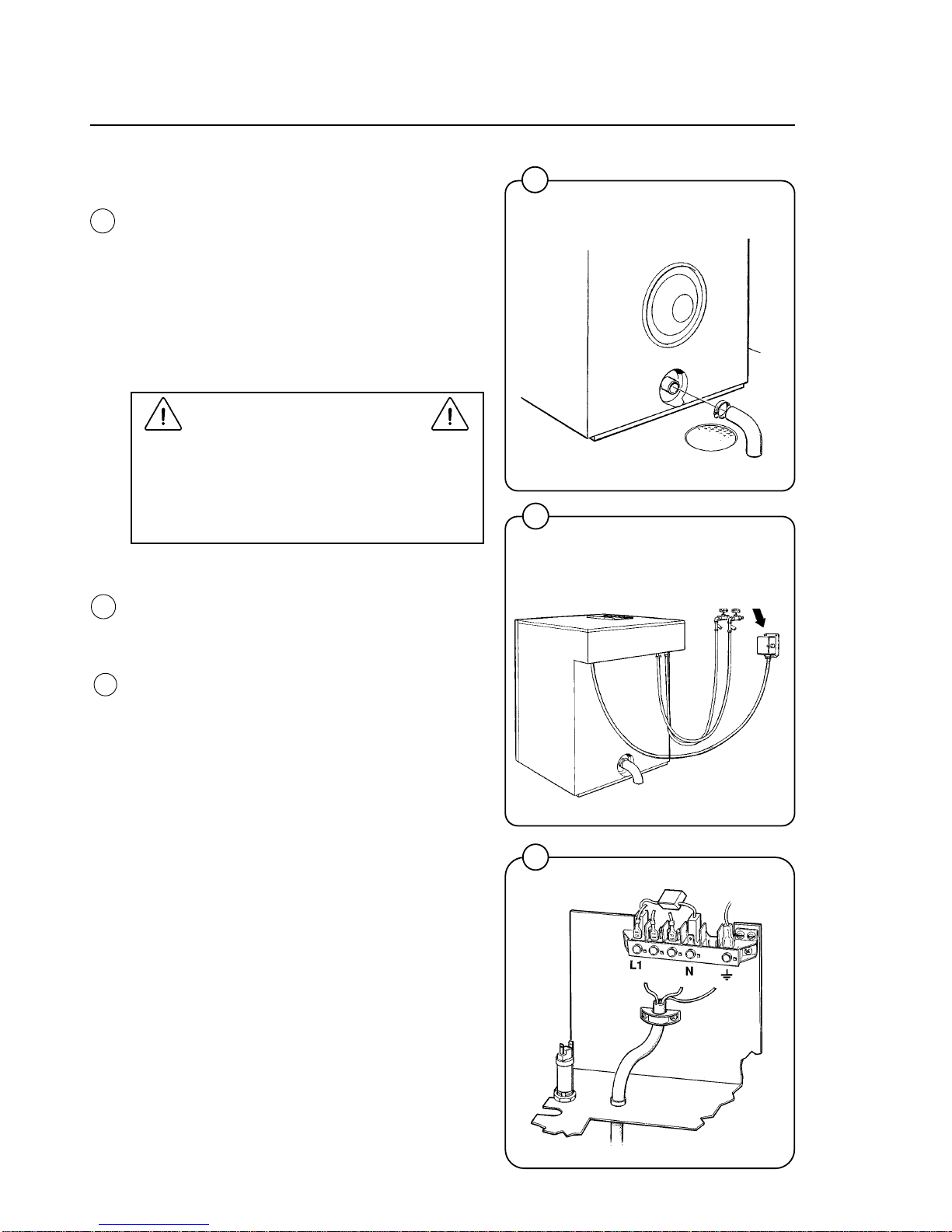

Electrical installation

Electrical installation must be carried out

by an authorized electrician, and must

follow national and local regulations.

Make sure that the ground wire is

correctly connected.

Each machine must be connected through its

own circuit breaker.

The cable must hang in a gentle arc.

Installation

0057

8

1599

10

11

Fig.

10

Fig.

11

Machines connected for 1 AC

2189

12

Fig.

12

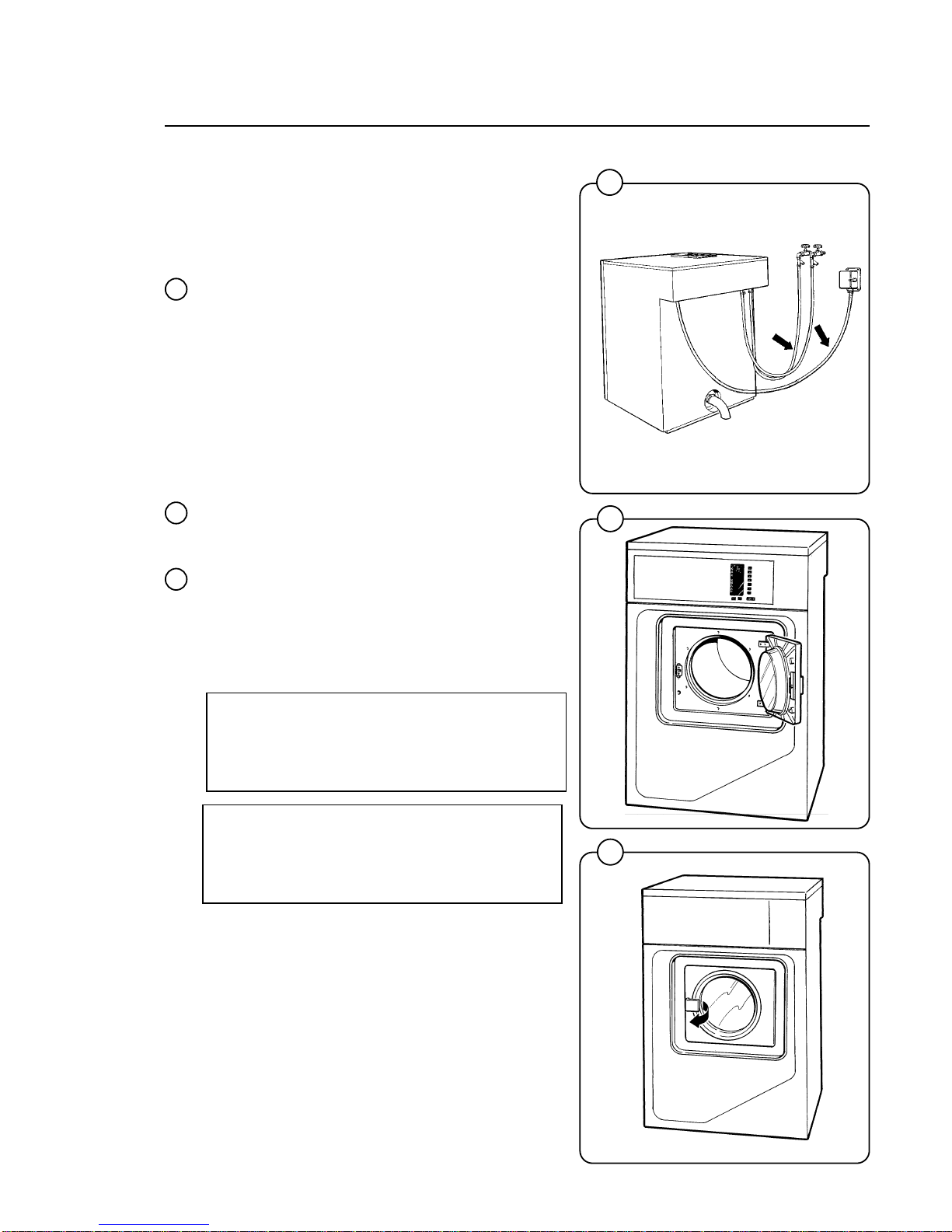

13

14

Installation

15

1600

1602

1820

Start-up and safety checklist

Before initial start-up of a Wascomat washerextractor, the following safety checks must be

performed:

• Make sure that all electrical and plumbing

connections have been made in accordance

with applicable local codes.

• Use only flexible water fill and drain hoses of

the proper length to avoid sags and kinks.

• Make sure the machine is properly grounded

electrically.

Before the machine is operated, the door safety

interlock must be checked for proper operation

as follows:

• When washer loading door is open, the

machine must not start. Verify this by

attempting to start washer with door open.

• When washer is in operation, the loading door

is locked and cannot be opened. Verify this by

attempting to open the loading door when the

machine is operating. If necessary, consult

this manual for proper operation of the door

lock and door safety interlock or call a

qualified serviceman.

IMPORTANT:

Door safety interlock must be checked daily

in accordance with above procedure.

WARNING:

Before servicing Wascomat equipment,

disconnect electrical power.

Fig.

13

Fig.

14

Fig.

15

9

1822

16

Function control check-out list

In the machine cylinder, you will find the warranty

registration card, a copy of the warranty policy

and other pertinent material.

The warranty card should be completed and sent

to Wascomat. All other items should be placed in

a safe place for future reference.

The machine should be cleaned when the

installation is completed, and checked out as

detailed below without loading the machine with

fabrics:

1. Check the incoming power for proper voltage,

phase and cycles.

2. Open manual shut-off valves to the machine.

3. Turn on electric power.

4. Check the door safety interlock as detailed on

page 10 of this manual.

5. Select the HOT program and start the

machine.

6. Run through a complete cycle, checking for

water temperature, drain operation and the

extract function.

7. In the wash cycle only hot water should enter.

If cold water comes in, the hoses are

improperly connected. Reverse hot and cold

water hoses.

NOTE

All machines are factory tested prior to

shipment. Occasionally, some residual

water may be found when the machine is

installed.

Installation

Fig.

16

10

17

Fig.

17

HOT

Time Temp.

(Min.)

Prewash 3 Warm

Detergent 1

Drain 0.8

Mainwash 6 Hot

Detergent 2

Drain 0.8

Extraction 0.5

Rinse 1 1 Warm

Drain 0.8

Extraction 0.5

Rinse 2 1 Cold

Drain 0.8

Extraction 0.5

Rinse 3 2 Cold

Detergent 3

Drain 1

Extraction 4

Shake-out 0.5

Total time 23

(water fill time

not included)

1203

Safety rules

• This machine is designed for water washing only.

• Machines must not be used by children.

• All installation operations are to be carried out by qualified personnel.

Licensed personnel are necessary for all electric power wiring.

• The interlock of the door must be checked daily for proper operation

and must not be bypassed.

• All seepage in the system, due to faulty gaskets etc., must be repaired

immediately.

• All service personnel must be fully familiar with the operating manual

before attempting any repair or maintenance of the machine.

• This machine must not be sprayed with water, otherwise short circuiting

may occur.

• Fabric softeners with volatile or inflammable fluids are not to be used in

this machine.

Safety Rules

11

12

2172

Operating instructions

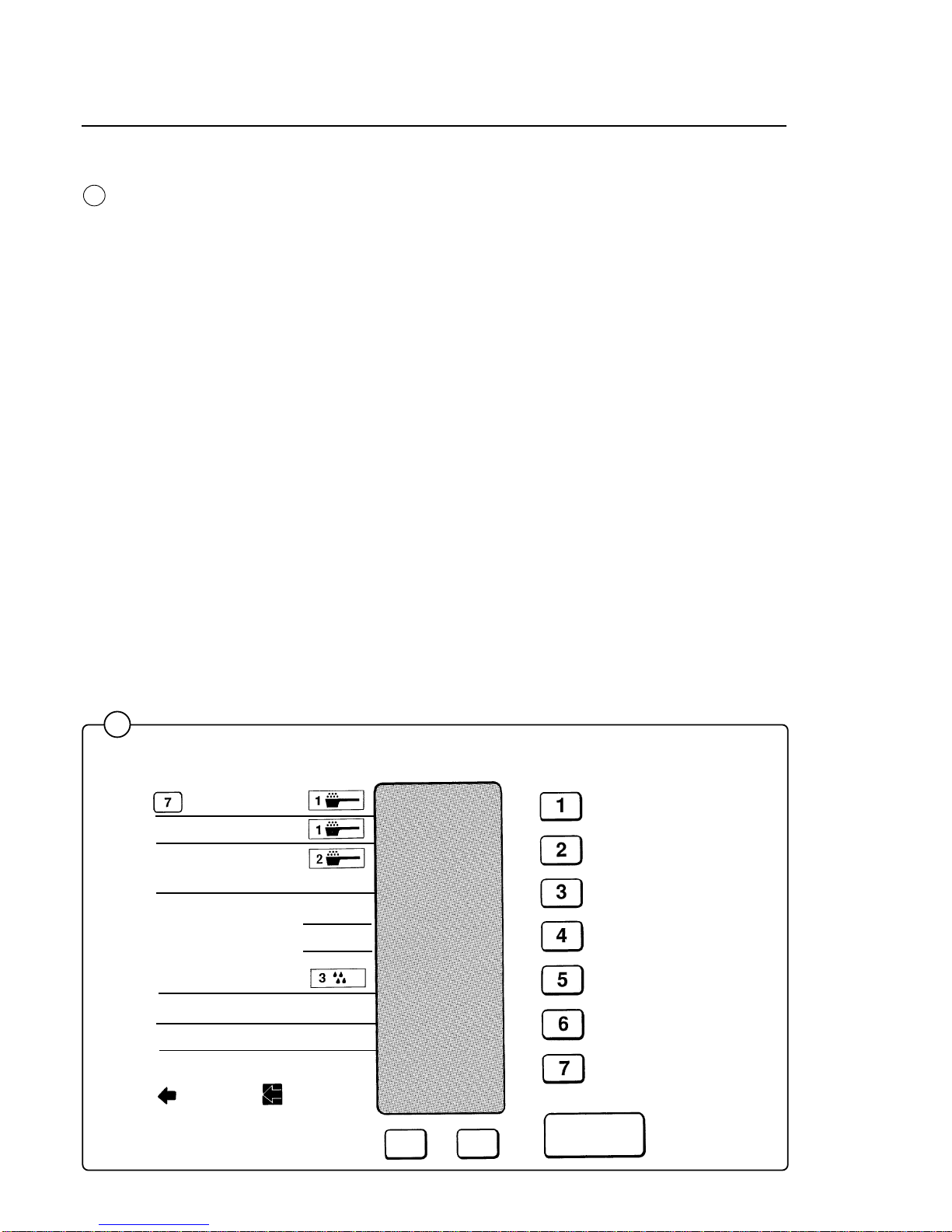

The keypad consists of seven wash program button, two option buttons and

a start button. An Information Display with illuminated symbols shows the

selected wash cycle, cycle options, steps in the wash cycle which have

been completed (indicated by squares around arrows), steps which remain

(indicated by arrows), remaining wash time, and the number of quarters

required to start the washer.

If a fault occurs then error numbers on the Information Display will refer you

tot he fault code list under Fault Finding in this manual.

START

Extra

extract

Gentle

action

Hot

Warm

Cold

Delicate

Permanent Press

Quick - Wash

Heavy Soil

Heavy Soil

Prewash

Wash

Rinses

Final Extract

Extra Extract

Open door after

becomes

Add bleach

if desired

Rinse

Rinse

Add

softener

INFORMATION

DISPLAY

18

Fig.

18

13

Operating Instructions

Operating Instructions

Preparations

Sort the wash according to the choices shown on

the control panel. Check washing tips on garment labels.

Make sure all pockets are empty and zips closed.

Load the washer and lock the door.

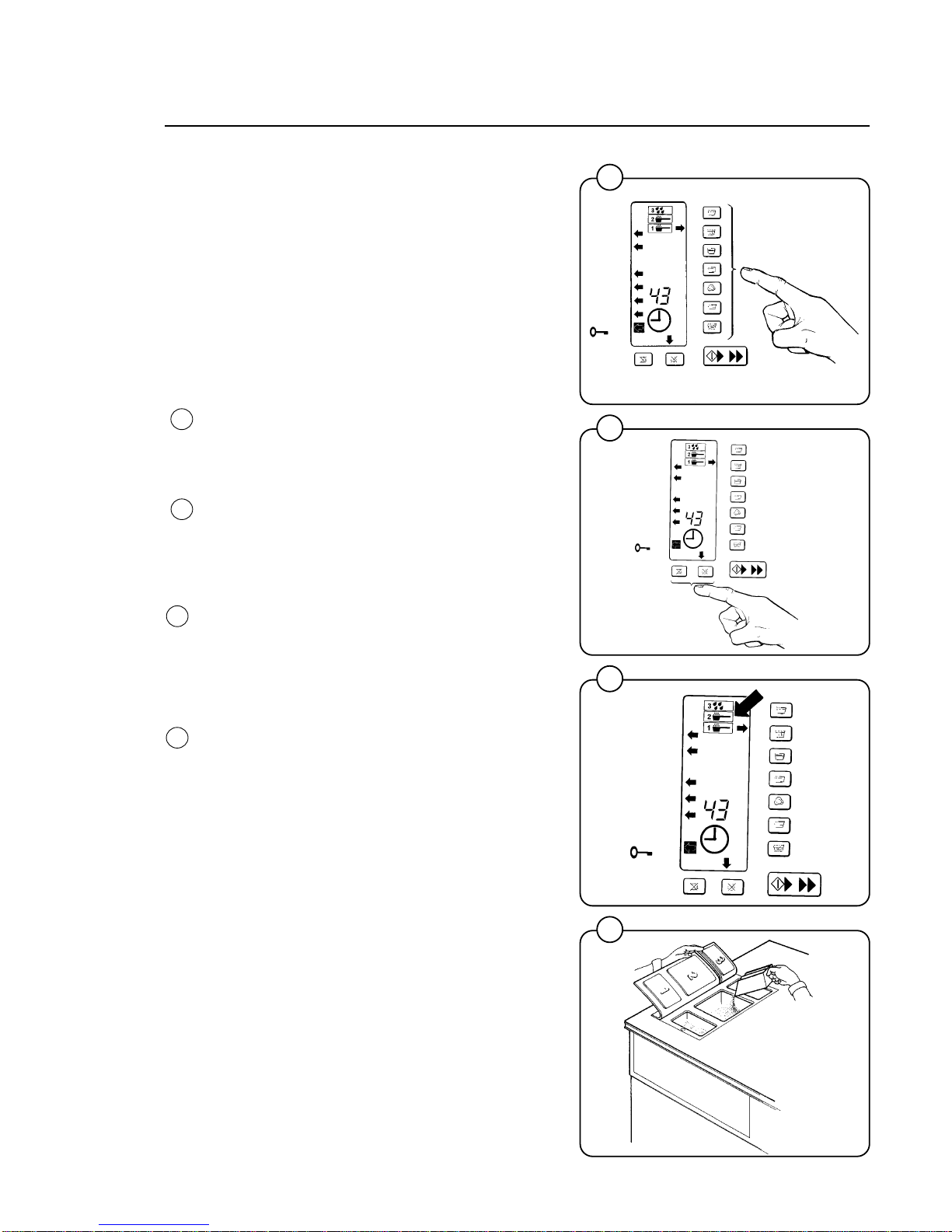

Washing

• Push one wash cycle button.

An arrow to the right of the control panel will

light up to show selection. Left arrows will light

to show the steps in the program.

• Select Extra Extract and/or Gentle Wash if

desired. Arrows will point to them.

• Three symbols in the Information Display

show in which compartments to put detergent

and softener.

- Prewash detergent in compartment 1.

- Mainwash detergent (and later bleach) in

compartment 2.

- Final rinse softener in compartment 3.

• You do not need more than 1/4 cup detergent

in a EX7 ES or EX10 ES..

0256

1302

1301

1300

Fig.

22

Fig.

21

Fig.

19

Fig.

20

19

20

21

22

14

Operating Instructions

1303

1022

1020

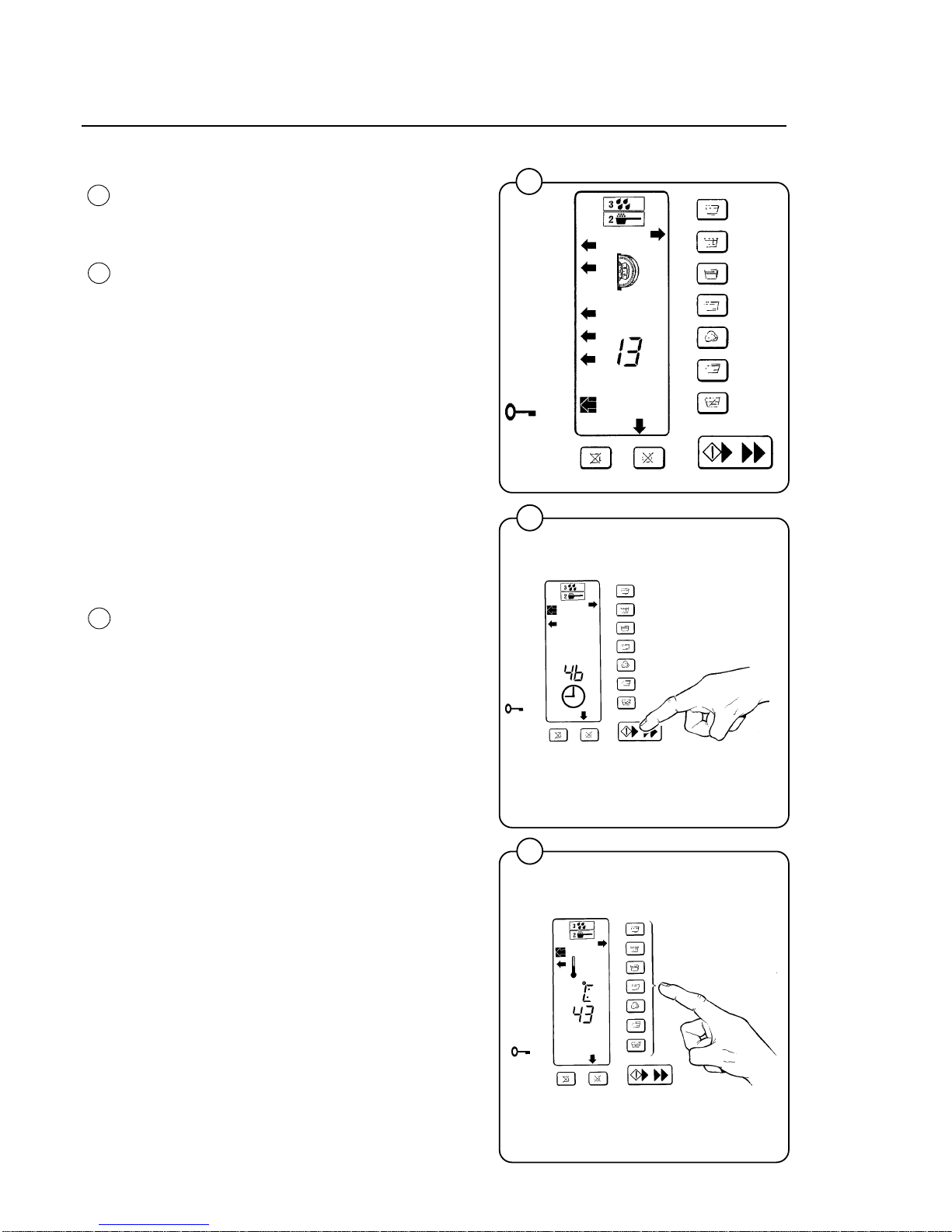

Insert required number of quarters as shown

on the display, which counts down quarters as

they are inserted. Press START button when

the display shows 00.

A clock symbol will now appear and remaining

wash time in minutes counts down. (The time for

each cycle will not be displayed until the cycle

has been run once completely from beginning to

end, so the microprocessor knows how long it

should take). The microprocessor retains in

memory how long it took to run each cycle the

last five times and displays the average time.

Since water pressure may fluctuate affecting fill

times, the displayed average cycle time is not

always exact and may vary from machine to

machine. If you find cycle times taking longer and

longer, use that information as a warning that

your water inlet screens may be clogged,

extending fill times, or some other problem may

exist.

Figure 25 illustrates a temperature display

function only available on washers with built-in

heating, which are not used in North America.

Fig.

23

Fig.

24

Fig.

25

24

23

25

Loading...

Loading...