HYDRAULIC WINCH

C10000NH

C15000NH

Assembly & Operating Instructions

CONTENTS

INTRODUCTION .................................................................................... 1

SAFETY WARNINGS AND PRECAUTIONS...........................................2

WINCH WARNINGS AND PRECAUTIONS ............................................3

UNPACKING ...........................................................................................4

INSTALLATION.......................................................................................4

OPERATION ...........................................................................................8

WINCH ACCESSORIES YOU WILL NEED .............................................9

RIGGING TECHNIQUES .........................................................................9

LUBRICATION ...................................................................................... 10

CABLE ASSEMBLY REPLACEMENT .................................................. 10

TROUBLE SHOOTING .......................................................................... 11

WINCH ASSEMBLY DRAWING ............................................................ 1 2

WINCH PARTS LIST ............................................................................. 1 3

SPECIFICATION(C10000NH) ............................................................... 1 4

SPECIFICATION(C15000NH) ............................................................... 1 5

1

INTRODUCTION

We have developed a several new series that make up the current

product line. Each series in our product line has unique design

characteristics; many new patented technologies are integrated into

our winches. This new technology has made winches the pinnacle in

user convenience and reliability. You will take pride in knowing that

your new winch has been designed to work as hard as you and that

it will be there when you need it.

Congratulations on your purchase of a highest class advanced powerful

two speed winch. We design and build winches to strict specifications

and with proper use and maintenance should bring you years of satisfying

service.

WARNING - Read, study and follow all instructions before

operating this device. Failure to heed these instructions may result

in personal injury and/or property damage.

Your winch can develop tremendous pulling forces and if used unsafely or

improperly could result in property damage, serious injury or death.

Throughout this manual you will find the following symbols for caution,

warning and danger. Pay particular attention to the notes preceded by

these symbols as they are written for your safety. Ultimately, safe

operation of this device rests with you, the operator.

This indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. This notation is also used to

alert you against unsafe practices.

This indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

WARNING

2

SAFETY WARNINGS AND PRECAUTIONS

WARNING: When using the tool, basic safety precautions should always be

followed to reduce the risk of personal injury and damage to the equipment. Read all

this instructions before using this tool!

WARNING –Do not use winch to lift (vertically).

WARNING – Keep children away. Children must never be allowed in the work

area Do not let them handle machines, tools, or extension cords.

WARNING – Store idle equipment. When not in use, tools must be stored in a

dry location to inhibit rust. Always lock up tools and keep out of reach of children.

WARNING – Dress properly. Do not wear loose clothing or jewelry as they can

be caught in moving parts. Protective, electrically non-conductive clothes and non-skid

footwear are recommended when working. Wear restrictive hair covering to contain

long hair.

WARNING – Use eye and ear protection. Always wear impact safety goggles.

Wear a full face shield if you are producing metal filings or wood chips. Wear a dust

mask or respirator when working around metal, wood, and chemical dusts and mists.

WARNING – Maintain tools with care. Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and changing accessories.

Inspect tool cords periodically and, if damaged, have them repaired by an authorized

technician. The handles must be kept clean, dry, and free from oil and grease at all

times.

WARNING – Disconnect switch. Unplug switch when not in use.

WARNING – Stay alert. Watch what you are doing, use common sense. Do not

operate any tool when you are tired.

WARNING – Check for damaged parts. Before using any tool, any part that

appears damaged should be carefully checked to determine that it will operate

properly and perform its intended function. Check for alignment and binding of moving

parts; any broken parts or mounting fixtures; and any other condition that may affect

proper operation. Any part that is damaged should be properly repaired or replaced by

3

a qualified technician. Do not use the tool if any switch does not turn “On” and “Off”

properly.

WARNING – Replacement parts and accessories. When servicing, use only

identical replacement parts. Use of any other parts will void the warranty. Only use

accessories intended for use this tool.

WARNING – Do not operate tool if under the influence of alcohol or drugs.

Read warning labels on prescription to determine if your judgment or reflexes are

impaired while taking drugs. If there is any doubt, do not operate the tool.

WINCH WARNINGS AND PRECAUTIONS

WARNING – Keep hands and body away from Fairlead (cable intake slot) when

operating.

WARNING – Secure vehicle in position before using winch.

WARNING – Be certain winch is properly bolted to a structure (or vehicle) that can

hold the winch load.

WARNING – Do not use inappropriate attachments to extend the length of the

winch cable.

WARNING – Never lift people or hoist loads over people.

WARNING – Never come in between the winch and the load when operating.

WARNING – Do not apply load to winch when cable is fully extended. Keep at

least 5 full turns of cable on the spool.

WARNING – After moving an item with the winch, secure the item. Do not rely on

the winch to hold it for an extended period.

WARNING – Examine winch before using. Components may be affected by

exposure to chemicals, salts, and rust.

WARNING – Never operate winch if cable shows any signs of weakening, such

as knotting or kinking.

WARNING – Do not cross over or under cable when the winch is under load.

4

WARNING – Do not move your vehicle with the cable extended and attached to

the load. You could easily exceed the winch rating and snap the cable.

WARNING – Use gloves while handling cable.

WARNING – When the vehicle is parked on an incline you should use wheel

chocks.

WARNING – Re-spool cable properly avoiding cable misalignment.

WARNING – The winch cable must be wound onto the drum under a load of at

least 10% of the rated line pull or the outer wraps will draw into inner wraps and

damage winch cable

WARNING – Before operating the winch under load you should check proper

function of the winch by engaging and disengaging the clutch, by operating the

directional controls, and operating the speed controls. This will ensure that the winch

is working properly and will help prevent unintended damage and injury. Cycling the

winch prior to loading will also ensure the gears are properly aligned.

UNPACKING

When unpacking, check to make sure all parts are included. Refer to Assembly

Drawings and Parts List (both with the like item numbers) at the end of this manual.

INSTALLATION

1. Your winch is designed with a bolt pattern that is standard in this class of winch.

Many winch mounting kits are available that utilize this bolt pattern for the most

popular vehicle and mounting channels. If you cannot find a kit locally, contact us

and we will provide you with the name of a dealer near you. If you will utilize the

mounting channel you must ensure that it is mounted on a flat surface so that the

three major sections (motor, drum and gear housing) are properly aligned. Proper

alignment of the winch will allow even distribution of the full rated load.

2. Start by connecting the roller fairlead to the mounting channel using 2 each of the

cap screw, flat washer, lock washer and securing with nut). (Make sure the screw is

placed through the mounting channel and roller fairlead from inside the channel.

5

This will allow enough clearance for the winch to be placed in the channel without

obstruction.)

3. Mount winch to the vehicle using high strength cap screw. It should be aligned and

secured to a solid part of the vehicle (front or rear) where the the full rated load will

be evenly distributed.

4. Please refer to installation illustration.

Mounting The Balance Valve:

The balance valve supplied is simply connected to motor. Be sure the balance valve’s

installing direction meets hydraulic principle chart. Otherwise, the winch will not reach

the rated line pull, and it is also dangerous for winch to power off the cable with heavy

load. If this symptom happens, simply disconnect the balance valve: exchange the oil

hole between hydraulic motor and balance valve, while your winch is working in

different direction ,change A→C1,B→C2 into A→C2,B→C1.And reconnect it. If your

order demand the balance valve should be supplied, it will have been connected with

the motor at the factory.

Plumbing Connections:

Keep all hoses away from any areas where heat may be considered too extreme such

as an exhaust manifold or turbo. Lines should not be allowed to rub on any abrasive

or vibrating surfaces. In some applications, 90°fittings on the directional valve and

motor or balance valve are necessary to make hose mounting more flexible. After

plumbing has been laid out on vehicle, install o-ring fittings supplied to valve. Torque

tight. Do not over tighten any fittings. Install o-ring fittings on Winch Motor. Torque

tight. Connect any hose port A on motor or port V1 on balance valve to port A on

directional valve, port B on motor or port V2 on balance valve to port B on directional

valve, port P on directional valve to pump’s high pressure port, port T on valve to

reservoir, if necessary Connect any hose port S on valve to steering box. Attach any

o-ring or seal from vehicles original tube fitting to tube fitting.

Working hydraulic principle chart and installation illustration:

6

7

Below is installation illustration with mounting channel:

Caution:

The hydraulic system needs a relief valve to ensure the system safety. The absence

of such a valve could cause serious injury and damage the winch.

Winch battery cables should be placed so that there is a small amount of slack in the

cable.

If you are using a heat exchanger with your application to cool the hydraulic fluid you

should refer to the illustration about mounting.

You should check the hydraulic fluid level and replace any that may have seeped out.

The hydraulic system should be purged at this time. Listed below are the directions on

how to purge the hydraulic system.

1) Start the engine.

2) Power the winch to draw out about 5 feet of cable.

3) Shut down the engine.

4) Check the fluid level and fill as needed.

5) Repeat steps 1 through 4 as necessary.

6) Start the engine.

7) Move the cable into the desired position.

8) Turn the wheels on the vehicle from the right lock to the left lock positions five

times to help bleed the hydraulic system.

9) If the hand control unit is working backwards, simple exchange the brown and

the white wire connections within the valve.

8

Test the winch for proper operation. Refer to the section below.

OPERATION

WARNING

1 Make sure clutch is totally engaged before starting any winch operation;

2 Stay clear and away from raised loads;

3 Stay clear of cable while pulling do not try to guide cable;

4 A min. of 5 wraps of cable around the drum barrel.

General information:

The Winch’s standard equipments contain gear reducer、drum、hydraulic motor、

solenoid valve、switch assembly、female connector and plumbing fittings. The winch

obtains its pressure from the vehicle’s existing power steering pump or other hydraulic

power. The winch is totally sealed, can be used underwater.

There are several other ways to supply power to the winch. The first way is to use

an individual pump for engineering use. The second way is to provide the winch’s

hydraulic pressure is with the vehicle’s exiting power steering pump (See Installation

Instructions).

① Use a suitable individual pump, which doesn’t have an oil pressure relief valve.

It will supply pressure for both the steering box and the winch.

② Use a combined pump with an integrated oil valve. The oil valve will supply two

kinds of flow based on the difference in demand. One type of flow will be constant and

should be used with the steering system. The other will provide higher pressure and

is for engineering use.

Caution:

Hydraulic system needs an relief valve to make sure the system is safe; If there is not

relief valve in the system; it would be serious danger and the system can’t operation. If

your winch drived by an existing hydraulic power system, the relief valve is also

existing.

9

Winch working demonstration:

1. Disengage the clutch by turning the clutch to the “CLUTCH OUT” position.

2. Grab the cable assembly and pull the cable to the desired length, then attach to

item being pulled.

Caution: Always leave at least five turns of cable on the drum; Review Winch Safety

Warnings and Precautions on page 2、3 before continuing.

3. Reengage the clutch by turning the clutch assembly to the “CLUTCH IN” position

as needed.

4. Insert the switch assembly connector onto the directional valve

5. Test-run winch in both directions. Turn the winch in each direction for about one or

two seconds meantime make the clutch totally engaged automatically.

6. While standing aside of the tow path, hold and operate the switch assembly

supplied by your choice. Wait until the motor stops before reversing directions.

7. When the towing is finished, remove the switch assembly from the female

connector of the directional valve and replace the female connector cover.

MaintenanceseWINCH ACCESSORIES YOU WILL NEED

NOT INCLUDED WITH YOUR WINCH

Gloves – For handling the wire rope and hook strap.

Anchor Strap/Chain – Tree saver anchor straps are made of high quality nylon with

high tensile strengths up to 15000lbs.

Heavy Blanket – place on the cable to absorb energy should the wire rope break.

RIGGING TECHNIQUES

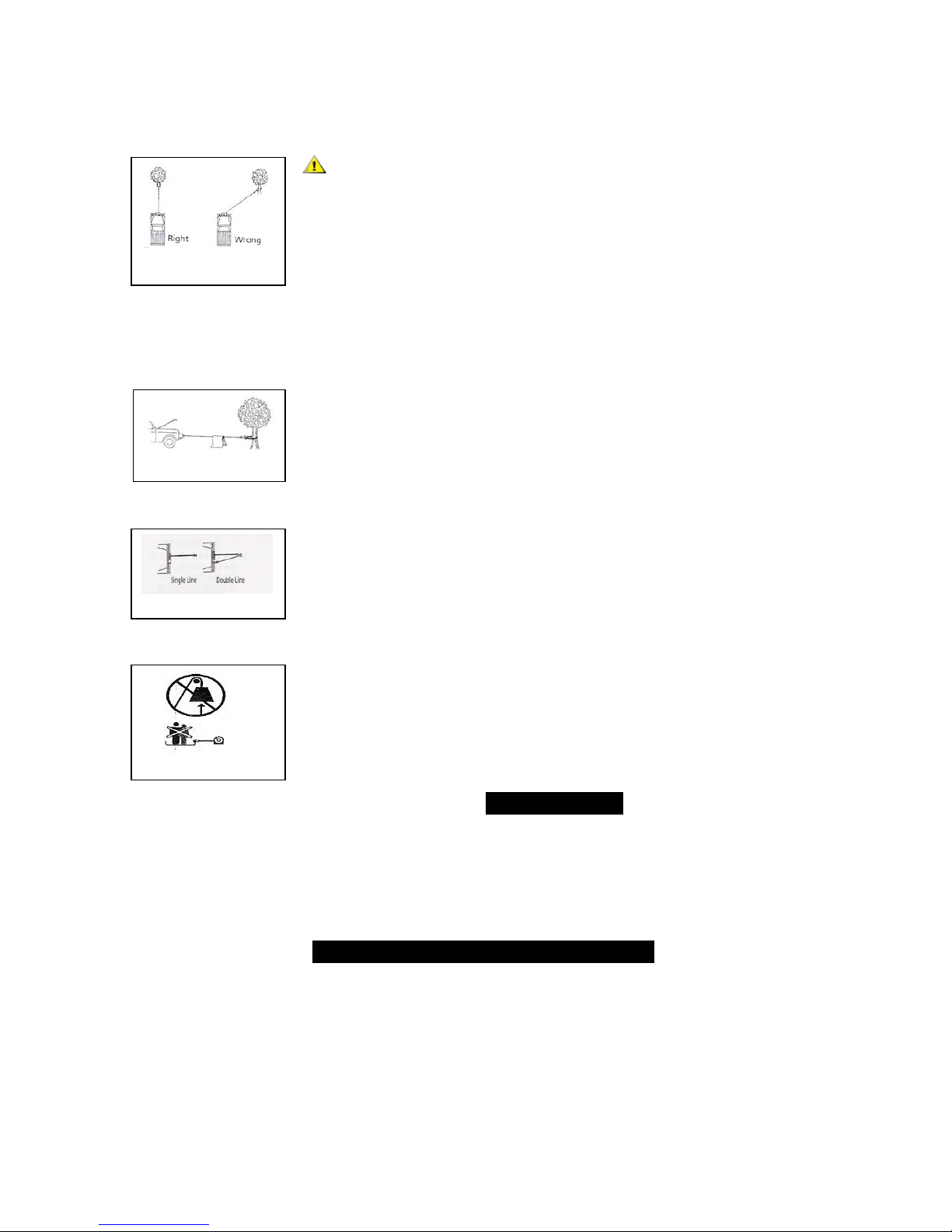

Self-Recovery

Locate a suitable anchor such as a strong tree trunk or boulder.

Always use a sling as an anchor point.

CAUTION Do not attach

the clevis hook back onto the cable as this could cause damage to

the cable.As shown in Fig 3.1

Fig 3.1

10

CAUTION Do not winch from an acute angle as the wire rope

will pile up on one side of the drum causing damage to wire rope

and the winch. Fig 3.2

Short pulls from an angle can be used to straighten the vehicle.

Long pulls should be done with the wire rope at a 90° angle to the

winch/vehicle.

When pulling a heavy load, place a blanket or jacket over the wire

rope five or six feet from the hook. In the event of a broken cable it

will dampen the snap back. For additional protection open the

hood of the vehicle as shown in Fig 3.3

For pulls over 70% rated line pull, we recommend the use of the

snatch block/pulley block to double line the wire rope. Fig 3.4

This reduces the load on the winch and the strain on the rope by up

to 50% depending on the included angle.

WARNING - Never use your winch for overhead hoisting or for

lifting people or moving people.

LUBRICATION

1. All moving parts within the Winch having been Lubricated using high temperature

lithium grease at the factory. No internal lubrication is required.

2. Lubricate Cable Assembly periodically using a light penetrating oil.

CABLE ASSEMBLY REPLACEMENT

If the wire rope has become worn or is beginning to show signs of strands breaking, it

must be replaced before being used again.

1. Turning clutch to the “CLUTCH OUT” position.

Fig 3.2

Fig 3.3

Fig 3.4

Fig 3.5

11

2. Extend cable assembly to its full length. Note how the existing cable is

connected to the drum.

3. Remove old cable assembly and attach new one as the ld cable connected to

the drum. Insert the end of the new rope and secure the screw being tightly

screwed

4. Turning clutch to the “CLUTCH IN” position.

5. Retract cable assembly onto drum, first five wraps being careful not to allow

kinking, then winch cable must be wound onto the drum under a load of at

least 10% rated line pull.

WARNING - Only replace the wire rope with the identical replacement part

recommended by the manufacturer.

TROUBLE SHOOTING

SYMPTOM

POSSIBLE CAUSE

SUGGESTED ACTION

Winch does not

turn .

-Insufficiently hydraulic

system pressure.

-Improper connections

of hydraulic system,

no oil into motor.

-Check relief valve regulate pressure.

-Check all the plumbing fixtures

according to the working principle chart.

-Defective directional control valve.

Motor runs but

Cable drum does

not turn

- The clutch is Not

engaged

-Turn the clutch to the high or lows peed

position. If problem still persists, a

qualified technician needed to check and

repair.

Winch drum runs

slowly or without

normal power.

-Insufficient pressure

or oil flow

-Insufficient fluid in the

system

- Wrong winch working

direction.

-Bump is not suitable or defective.

Change a new one or a suitable one

-Check fluid level. Add fluid until full.

-Change the connection of balance valve

and motor.

Winch brake not

working normally.

-Hydraulic pressure

remnants in brake

while winch stop.

-Wrong winch working

direction.

-Use bigger back oil pipe.

-Change the connection of balance valve

and motor.

Winch cannot

spool off wire

rope with load

smoothly.

-Wrong winch working

direction.

-Change the connection of balance valve

and motor.

12

WINCH ASSEMBLY DRAWING

13

WINCH PARTS LIST

No. Part # Qty Description Remark

1

C100NH0100 1 Hydraulic Motor Used in C10000NH

C150NH0100 1 Hydraulic Motor Used in C15000NH

2 C100NH0001 2 Screw M12×30

3 C100NH0002 2 Lock Washer Ø12

4 C100NH0003 4 Screw M8×25

5 C100NH0004 4 Lock Washer Ø8

6 C100NH0005 1 Coupling plate

7

C100NH0006 1 Front Bearing Used in C10000NH

C150NH0006 1 Front Bearing Used in C15000NH

8

C100NH0007 2 Bushing-Drum Used in C10000NH

C150NH0007 2 Bushing-Drum Used in C15000NH

9

C100NH0200 1 Break/Shift Assembly Used in C10000NH

C150NH0200 1 Break/Shift Assembly Used in C15000NH

10 C100NH0008 1 Transition Shaft

11

C100NH0300 1 Drum Assembly Used in C10000NH

C150NH0300 1 Drum Assembly Used in C15000NH

12 C100NH0009 1 Screw M8×10

13

C100NH0010 1 Inner supporting Used in C10000NH

C150NH0010 1 Inner supporting Used in C15000NH

14

C100NH0011 1 “O” Ring Seals Used in C10000NH

C150NH0011 1 “O” Ring Seals Used in C15000NH

15

C100NH0012 1 Gear-Ring Used in C10000NH

C150NH0012 1 Gear-Ring Used in C15000NH

16

C100NH0400 1 Gear Carrier Assembly(Output) Used in C10000NH

C150NH0400 1 Gear Carrier Assembly(Output) Used in C15000NH

17

C100NH0500 1 Gear Carrier Assembly(Intput) Used in C10000NH

C150NH0500 1 Gear Carrier Assembly(Intput) Used in C15000NH

18 C100NH0013 1 Transmission Shaft

19 C100NH0014 1 Antifriction Pad

20 C100NH0015 1

Screw M8×10

21 C100NH0600 1 Clutch handle Assembly

22 C100NH0016 1 Gear-Housing

23 C100NH0002 4 Lock Washer Ø12

24 C100NH0017 4

Screw M12×35

25 C100NH0018 4 Tamper

26 C100NH0019 4 Screw M10×35

27 C100NH0020 2 Tie Bar

28 C100NH0021 4 Lock Washer Ø10

29 C100NH0700 1 Tensioned Of Steel Wire Supplied Assembly

30 C100NH0021 4 Lock Washer Ø10

31 C100NH0022 4

Screw M10×25

32 C100NH0023 1 Back Mounting Plata

33 C100NH0002 4 Lock Washer Ø12

34 C100NH0024 4

Screw M12×30

35

C100NH0800 1 Cable Assembly Used in C10000NH

C150NH0800 1 Cable Assembly Used in C15000NH

14

SPECIFICATION(C10000NH)

Rated line pull 10000 lbs (4536 kgs)

Motor displacement

65ml/r

Oil flow 15~45L/min

Pressure 12.5Mpa

Gear reduction ratio

25.5:1

Cable (Dia.× L) Ø13/32"×83.7 ' (Ø10.2mm×25.5m)

Drum size(Dia.× L)

Ø2.8 "×8.6" (Ø72mm×219mm)

Mounting bolt

pattern

10 "×4.5 " (254mm×114.3mm) 4-M12

Overall dimensions

(L×W×H)

20.4"×8.1"×9.7"

519mm ×206mm ×246mm

Net weight

Ibs(kg)

117

53

Pull , Speed, Pressure, Flow (First layer)

Line pull lbs (kgs)

Pressure

Mpa(Psi)

Flow

G/min (L/min)

Line speed

ft/min(m/min)

0 2.0(290.1) 1.3(5.0) 2.3 (0.7)

3000(1361) 4.5(652.7) 2.6(10.0) 4.6(1.4)

6000(2722) 6.8(986.2) 5.3(20.0) 8.9(2.7)

9000(4082) 9.0(1305.3) 9.2(35.0) 15.1(4.6)

10000(4536) 12.5(1812.9) 10.6(40.0) 17.4(5.3)

Line Pull And Rope Capacity Inlayer

Layer of wire rope

Rated line pull

lbs(kgs)

Total rope on drum

ft (m)

1 10000(4536) 16.4 (5.0)

2 8012(3634) 37.2(11.3)

3 6683(3031) 60.9(18.6)

4 5732(2600) 83.7(25.5)

15

SPECIFICATION(C15000NH)

Rated line pull 15000 lbs (6804 kgs)

Motor displacement

80ml/r

Oil flow 5~60L/min

Pressure 13Mpa

Gear reduction ratio

33.4:1

Cable (Dia.× L) Ø15/32"×87 ' (Ø12mm×26.5m)

Drum size(Dia.× L)

Ø3.5 "×8.5" (Ø89mm×217mm)

Mounting bolt

pattern

10 "×4.5 " (254mm×114.3mm) 4-M12

Overall dimensions

(L×W×H)

21.4"×8.9"×10.3"

544mm ×226mm ×262mm

Net weight

Ibs(kg)

152

68.8

Pull , Speed, Pressure, Flow (First layer)

Line pull lbs (kgs)

Pressure

Mpa(Psi)

Flow

G/min (L/min)

Line speed

ft/min(m/min)

0 2.0(290.1) 1.3(5.0) 1.6 (0.5)

5000(2268) 4.3(623.7) 2.6(10.0) 3.3(1.0)

10000(4536) 8.7(1261.8) 5.3(20.0) 6.6(2.0)

12000(5443) 10.0(1450.3) 7.9(30.0) 9.8(3.0)

15000(6804) 13.0(1885.4) 15.9(60.0) 19.7(6.0)

Line Pull And Rope Capacity Inlayer

Layer of wire rope

Rated line pull

lbs(kgs)

Total rope on drum

ft (m)

1 15000(6804) 18.0(5.5)

2 12120(5498) 41.7 (12.4)

3 10168(4612) 65.9(20.1)

4 8757(3972) 86.9(26.5)

Loading...

Loading...