Page 1

Congratulations on your decision to own an advanced high quality and desirable Multi-Fuel

WARRIOR Stove. This Stove has been manufactured and designed in our factory from

premium grade materials to give you many years of excellent service when correctly

installed, operated and maintained. The main body is constructed from premium grade cast

iron, this is sand cast the traditional time honoured way by experts from freshly mined pig

iron. Cast Iron is the best material known for retaining and radiating heat, recycled scrap

iron is not used for any part of a WARRIOR Stove.

Please carefully and thoroughly read this manual prior to any installation or lighting of your

new stove.

If you have any questions regarding this stove which are not mentioned in this manual then

please contact the vendor of the stove or our head office, details below.

Manufactured by:

WARRIOR Stoves Ltd. (HEAD OFFICE)

Chapel Road

Tuckingmill

Camborne

Cornwall

UK. TR14 8QY

Tel: 01209 711115

Fax: 01209 612322

E-mail: info@warriorstoves.co.uk

Web: www.warriorstoves.co.uk

Please keep this manual for future reference. It has been produced for the WARRIOR

Stoves Aidan stove and may not be copied in whole, part or be used for any purpose apart

from which it is intended without express and written permission from a WARRIOR Stove

employee.

WARRIOR Stoves Ltd.

Manual for:Aidan Multi-Fuel Stove

Model no: WSDAID

Page 2

TECHNICAL DATA 1

SAFETY 2

STOVE LOCATION 3

STOVE ASSEMBLY 4

STOVE INSTALLATION. (Including Chimney Guidance) 5-12

STOVE OPERATION 13-16

STOVE AND CHIMNEY MAINTENANCE 17-18

TROUBLESHOOTING 19

PARTS DIAGRAM 20

LIST OF USEFUL ADDRESS’S 21

INSTALLATION RECORD 22

MAINTENANCE RECORD 23

GUARANTEE 24

OTHER PRODUCTS FROM WARRIOR STOVES LTD. 25

CONTENTS

Page 3

2

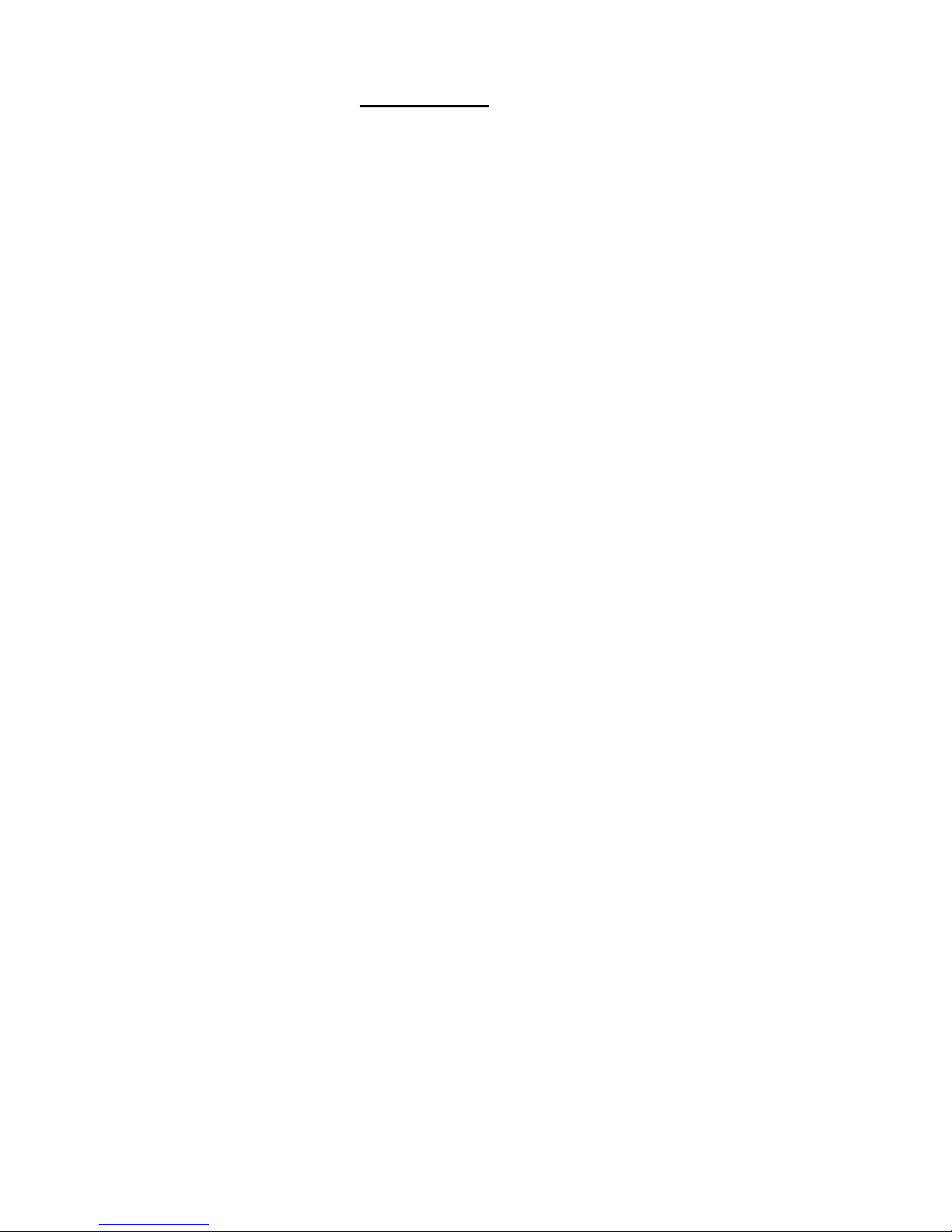

TECHNICAL DATA

WARRIOR Stoves:Aidan WARRIOR Stoves Ltd.

Model No:WSDAID Chapel Road, Tuckingmill

Continuously rated Multi-Fuel Stove Camborne, Cornwall.

Approved to EN13240 TR14 8QY.

This information is true.

Ricky MURRELL

WARRIOR Stoves Ltd

Authorised Signatory for this stove in the United Kingdom and Republic of Ireland

Useful Information:

1Kw ≈ 3412.14BTU’s (British Thermal Unit)

1cm ≈ 0.3937” / 25.4mm ≈ 1”

1Kg ≈ 2.2046 lbs.

Height (mm) 790

Width (mm) 620

Depth (mm) 600

Height to centre of

rear flue (mm)

445

Depth from back to

centre of flue (mm)

130

Flue Diameter Req.

(mm)

150

Net weight (Kg) 210

Gross weight (Kg)

[Packed]

220

Minimum distance to

Combustible surfaces.

Top 800mm

Side 450mm

Rear 1200mm

Type of boiler and

method of construction

N./A.

Boiler maximum

operating water

temperature

N./A.

Boiler maximum

operating pressure in

bar.

N./A.

Boiler test pressure in

bar

N./A.

Test Type NOMINAL OUTPUT NOMINAL OUTPUT

When fuelled with SOLID MINERAL WOOD

Refuelled every 5Hrs 0.75Hrs

Flue Gas Mass Flow 10.5g/s 9.2g/s

With a flue draught of 12Pa 12Pa

Output to room 8.8kW 11kW

Output to water N./A. N./A.

Mean Efficiency 67.8% 72.1%

Mean Flue Temperature 343 C 386 C

Mean CO concentration at 13% O 0.19% 0.37%

Test by: GASTEC@CRE IN THE UK GASTEC@CRE IN THE UK

1

Page 4

SAFETY

Safety is of paramount importance when deciding on locating, moving, installing, operating

and maintaining the stove.

Ensure that this manual is read and understood prior to installation or commissioning the

first fire.

This Stove must be installed in accordance with all local regulations including those

referring to national and European standards. WARRIOR Stoves recommend that a

competent person such as a HETAS approved installer is used for installation. HETAS

details are listed near the back of this manual for further reference. Most stove retailers will

be able to assist in advising a competent person for installation.

WARRIOR Stoves installation instructions cannot be taken as conforming to all standards in

all areas and also cannot account for changes in legislation.

This Stove must not be modified without the express and written permission of a WARRIOR

stoves employee. Alterations not authorised by WARRIOR Stoves Ltd. will terminate the

guarantee and may also be potentially dangerous.

Numerous further safety procedures are listed throughout this manual specific to separate

tasks of installation and usuage, etc. For your safety and others around you ensure these

procedures are adhered to.

2

Page 5

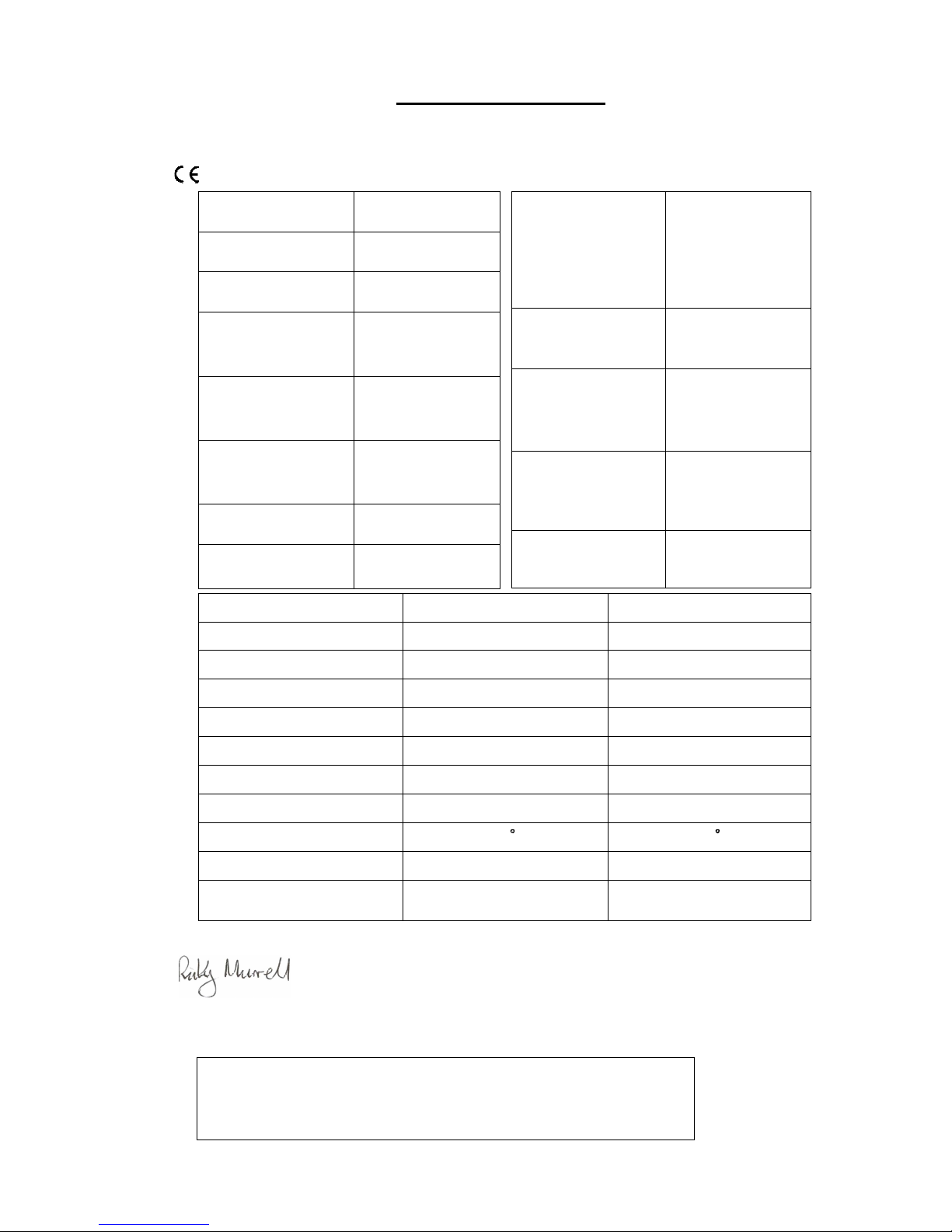

The floor which the stove is to be located on must have an adequate load-bearing capacity. If

the floor does not meet this requirement then suitable measures in accordance with building

control regulations need to be taken.

This stove has passed the requirements of building regulations so that it only requires a 12mm

Thickness hearth.

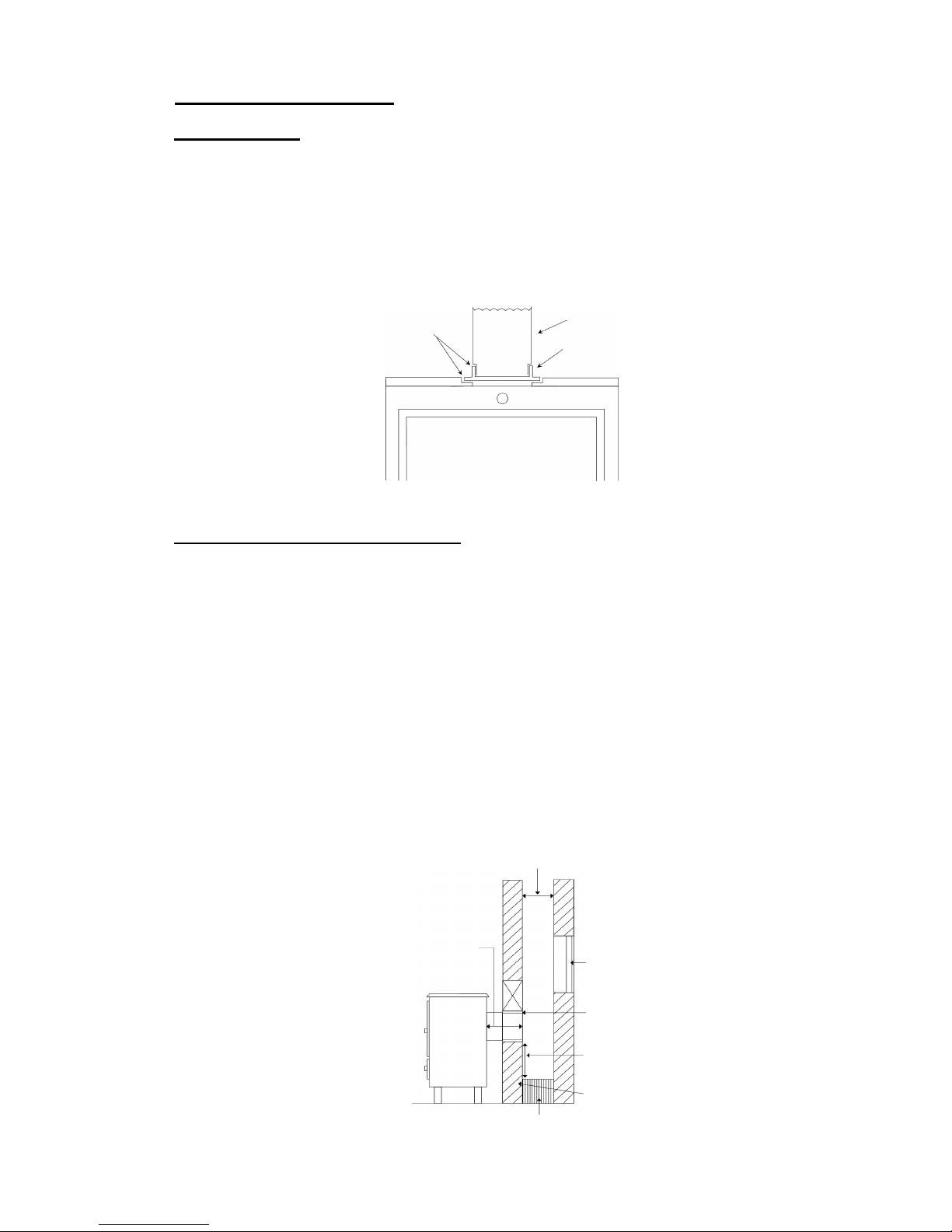

The stove must be located on a solid non combustible hearth/surface with the minimum

dimensions extending from the perimeter of the stove as shown below:

The stove surfaces must have a minimum distance away from any combustible materials as

listed in the technical data section of this manual.

Single wall fluepipes must be more than three times the diameter of the fluepipe away from

combustible materials i.e. 125mm (5”) Fluepipe should be a minimum of 375mm (15”) away.

For further assistance regarding flue pipe & liners please contact your stove dealer, approved

installer, building control officer or Midtherm Flue Systems Ltd. (Details listed at rear of this

manual). The complete range of Midtherm flues and ancillary components are available from

your stove retailer.

Further advice regarding chimney and flues for this stove is detailed in the Installation

section of this manual.

This stove must have its own dedicated chimney or flueway. It is not suitable for installing

into a shared flueway. The stove must always have a permanent free air supply into the room it

is being installed into. For Stoves rated above 5KW a permanent unobstructed air vent is

required. This vent should be in the same or adjoining room as the stove and must be

connected directly to the outside air, where possible locate the vent close to the stove to

confine draughts. The vent size should be a minimum of 550mm2 per KW over 5 KW, i.e.

A stove rated at 11kw would need a minimum vent size of 3,300mm2 for modern properties

(Generally only since 2008) with Design Air Permeability greater than or equal to 5.0Mtr3/

(h.m2) then 550mm2 is required per kW output. It is always advisable to install a vent if there

is not one present for a stove rated under 5Kw and like wise it is better to install a vent larger

than the minimum recommended size. This is to account for the possibility of operating the

stove at more than its rated output.

Extractor fans operating in the same room or air space as the stove may cause problems with

the air supply to the stove which in turn may cause problems with chimney draw.

Your approved installer or building control officer should be familiar with all these aspects of

where the stove may be installed.

STOVE LOCATION

A=150mm

B=225mm

C=150mm

D=150mm

3

A A

B

C

Front of stove

D

D

These distances may be

reduced if the Hearth

adjoins a non

combustible wall.

Page 6

STOVE ASSEMBLY

Care should be taken when unpacking and assembling your stove. Stoves are heavy and

therefore due consideration is required in lifting and moving into the final location. Where

possible use a sack truck or trolley and obtain assistance rather than struggling or risking

personal injury. You may find that it is easier to open the stove and remove loose items to

reduce the weight of the stove. The following are useful techniques for manual lifting:

•

Keep the stove close to your waist with your head facing forwards and your back

straight.

•

Do not twist at the waist, reposition your feet as necessary.

•

Bend both legs to maintain stability.

•

Avoid twisting your back, leaning forwards or sideways when handling the stove.

•

Smooth and controlled movement will help to keep the stove under control, avoid

snatching or jerking when moving the stove.

•

Always grip with the palms of your hands preferably wearing gloves to provide

additional grip, do not rely solely on fingertips for support.

•

Wear suitable clothing, avoid wearing ties and other loose items that could get caught

in the stove. The use of protective footwear with steel toecaps is advisable.

This stove requires little assembly prior to moving into it’s final location.

Firstly carefully unwrap the stove and the contents either on the original packing or onto a

sheet of plyboard or similar in order to minimize the risk of damage to the furnishings

below.

After unpacking remove the loose items from the stove which require fixing, these parts

should be: The Legs, the Stove Outlet and the Stove Outlet Blanking Plate and the Handles.

These parts should be easily identifiable from the exploded parts diagram listed near the end

of this manual. Attach the legs to the base of the stove with the bolts provided, these bolts

are already attached at the base of the stove in the correct location. Tighten with firm

pressure without over tightening.

The Stove Outlet and the Stove Outlet Blanking Plate again require bolting into the correct

position, (determined by flue exit, possible from the Top or the Rear of this stove) with the

bolts provided. Prior to fixing a smear of fire cement and or heat resistant rope is

recommended to ensure the join is airtight. See the note in the Stove Installation Section

regarding the caustic nature of fire cement, again do not over-tighten the bolts. The handles

simply bolt on.

Inside the Stove there should be the following:

•

Grate with Fuel Retainers.

•

Ashpan & Ashpan removal Tool.

•

Baffle/Throat Plate.

•

Side Cast/Refractory Brick Linings.

•

Rear Cast/Refractory Brick Linings, please note for Back-Boiler Model Stoves these

will not be in the stove, they are replaced by the Back-Boiler.

All of these internal parts should be easily identifiable from the exploded parts diagram

printed near the rear of this manual. If any parts have become dislodged during transit then

it should be straightforward to re-locate in their respective places. Should parts need bolting

back in place, do not over tighten.

If you have any questions regarding the parts within the stove which are not mentioned

above then please contact the vendor of the stove or our head office.

4

Page 7

STOVE INSTALLATION

Prior to any installation being undertaken ensure that all intended work conforms to Building

Regulations or Standards and any local laws including those referring to national and

European Standards. The following are applicable:

England & Wales > Building Regulations (2001) > Document J particularly relevant.

Scotland > Building Standards (2001) > Section F particularly relevant.

Northern Ireland > Building Regulations (1990)

Republic of Ireland > Building Regulations (1997) > Document J particularly relevant.

Isle of Man > Building Regulations (2003) > Part J particularly relevant.

The above listed Regulations and Standards are subject to change and should be confirmed

prior to installation.

Installation should be carried out avoiding any risk to yourself, the occupiers and any pets

etc. Fire cement used during installation should be used in accordance with the instructions

on the tub or cartridge. It is classed as an irritant so protective gloves are recommended.

If the stove requires touching up/repainting then ensure adequate ventilation is available as

most high temperature resistant paints release unpleasant odours. Always follow the stove

paint manufacturers instructions. The stove must not be alight whilst re-painting.

If the stove is being installed into an existing chimney ensure that protective eye ware is

worn during inspection and whilst attending to any remedial work that may be required.

In the case of installing into old Chimneys particular attention should be given to the

possibility of disturbing asbestos. There are many types of asbestos, the three most common

are white (chrysotile), brown (amosite) and blue (crocidolite). All three types are hazardous,

particularly blue and brown, however asbestos cannot just be identified by its colour. Asbestos should only be removed by a registered specialist.

Chimney & Flue Guidance

Effective Chimneys require numerous considerations. The purpose of a chimney is to

provide an up draught to ensure the safe removal of the products of combustion from the

stove to the outside air.

To maintain a safe and efficient up draught the chimney/flueway must conform to the

following:

•

The Chimney/Flue should be totally free from defects and not leak at any point

through to its terminal. A smoke test should be done to confirm this, a guide to smoke

testing is listed further on in this section of the manual.

•

The Chimney/Flue must have a height of no less than 4.5 Meters from the top of the

stove to a suitable Chimney terminal.

•

The Terminal of the Chimney/Flue must be in a position where the products of

combustion can freely discharge without preventing a hazard whatever the wind

conditions . See the diagram further on in this section regarding flue outlet positions.

5

Page 8

•

The Chimney/Flue diameter must never be decreased in size from the stove. It is good

practise to increase the chimney/flue diameter by 25 or 50mm, this will maintain a

suitable draw in the event of the flue way becoming partially blocked due to possible

tar build up in the chimney.

•

The Chimney diameter must be no less than 125mm diameter if only burning

smokeless fuels, for any other fuel type this must be increased to a minimum of

150mm.

•

The Chimney/Flue should be kept as straight as possible. Offsets in the flue way

should be kept to a minimum and should not exceed 45 degrees except when

connecting to the rear off the stove, a 45 or 90 Degree Tee should be used for these

installations completed by a soot box at the base.

•

No more than 4x45degree elbows should be installed, when using a 90 tee at the rear

of the stove this would be classed as 2x45degree elbows.

•

90 degree elbows are not suitable for this stove.

•

When connecting the flue to the rear of the stove the maximum horizontal run should

not exceed 150mm.

•

Provision must be made for cleaning the entire length of the chimney/flue other than

through the stove.

•

The Flue way must be kept warm to ensure a suitable up draught.

There are numerous ways of installing this stove including situations where a chimney is not

present in the building. The Chimney/Flue used should comply with the following:

Connecting Fluepipes (For connecting directly onto the stove outlet):

•

Vitreous Enamelled Steel Pipe> BS 6999: 1989 (1996)

•

Stainless Steel grades 1.4401, 14404, 14432 or 1.4436(Minimum flue wall thickness of

1mm)>BS EN10088-1:1995

•

Cast Iron Flue Pipes>BS41:1973 (1998)

•

Mild Steel Flue Pipes (Minimum flue wall thickness of 3mm)>BS 1449:Part1:1991

Fluepipe/Chimney Linings:

•

Concrete Chimney Blocks> BS EN 1858: 2003

•

Clay Chimney Blocks> BS EN 1806: 2000

•

Concrete Flue Linings> BS EN 1857: 2003

•

Clay Flue Linings> BS EN 1457: 1999

•

Factory Manufactured Metal Chimney> BS EN 1856-1: 2003

•

Tested Linings approved by a Notified Body.

Where applicable the Midtherm Flue Pipe available from WARRIOR Stoves dealers

conforms to the above standards.

6

Stove Installation Continued.

Page 9

All Installations:

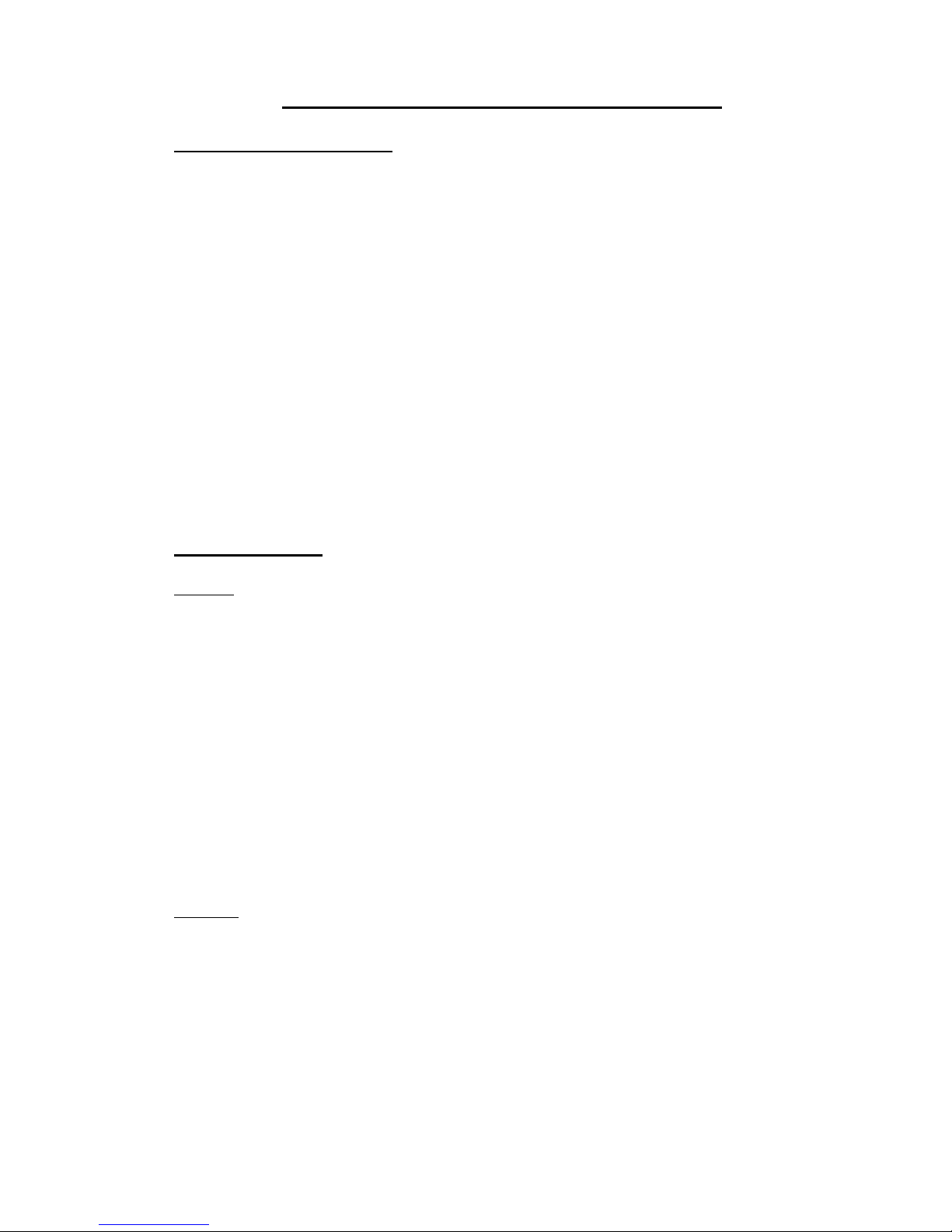

Place the stove carefully on its hearth and ensure it is stable and level. The spigot (male) end

of the Connecting Flue Pipe must fit inside the stove outlet and be sealed with fire cement.

The socket (female) end faces away from the stove. This is to ensure that any condensate,

etc. will run into the stove and dissipate rather than spoil the appearance of the final

installation. See diagram below:

For connecting into existing Chimney:

The Chimney should be swept prior to installation and smoke tested to ensure it is sound.

The Chimney must not have any hollow sections present, these should be filled to ensure

that any soot or tar, etc. does not build up which may present problems when sweeping the

chimney. Hollow sections within the chimney may also present problems with the chimney

draw. The connecting flue pipe must be sealed to the chimney with fire cement and high

temperature resistant rope as required. This is usually done into a register (Blanking) plate

with an access door/hatch to enable chimney sweeping. Particularly large chimneys may

require lining as the flue temperature may not get warm enough to provide a suitable

up-draught.

Use fire cement and stove

rope to ensure air tight seal.

Connecting Fluepipe

Stove Outlet

Fire retardant

Rope seal required

Build up opening

Soot/Access Door

Fill Void

Minimum diameter should be no less than the outlet size of the stove, 25to 50mm larger is

ideal. Where the stove outlet is less than 150mm this diameter should be no less than 125mm

when only burning smokeless fuels or a minimum of 150mm for any fuel types.

Maximum150mm

Horizontal flue.

7

Stove Installation Continued.

Allow area for collecting soot build up.

Minimum distance should be no less than

The outlet diameter of the stove.

Page 10

Some typical installations are shown as following:

If the chimney is not sound, i.e. found to be leaking after a smoke test then the chimney must

either be repaired or a flexible liner may be used, ensure the liner is the correct type for

Multi-Fuel applications. See diagram below:

Register plate.

TOP FLUE OUTLET

Access door

The register plate must be 1.5mm thick rust

resistant steel or heat resistant board. The

Flue Pipe must be 3 times it’s diameter

away from combustible materials. For

example 150mm Flue Pipe must be 450mm

away from combustible materials.

FLUE

Sealed door to

access chimney

for sweeping &

inspecting.

Support Bracket for Flexible Liner.

Support Bracket for the

connecting fluepipe

Flexible Liner

Register Plate

SW to TW Adapter

Maximum Recommended distance is

1.5mtrs of connecting fluepipe to existing

chimney or Twin Wall Class 1 system

8

Stove Installation Continued.

It is recommended that

this area is insulated or

backfilled.

Vitreous Fluepipe with

stainless access door.

Page 11

For Installations where no Chimney exists:

The Connecting flue pipe from the Stove should connect to the Twin Wall Insulated flue

pipe, ensure this flue pipe is the correct type for Multi-Fuel applications. The HT-Plus flue

pipe manufactured by Midtherm is suitable and available from WARRIOR Stoves dealers.

This flue pipe requires a minimum 50mm clearance from combustible materials and should

not be joined in a wall or floor. Where this flue pipes passes through a combustible floor a

ventilated fire stop kit must be used.

Some typical installations are shown as following:

Rain cap/Cowl

600mm minimum

One load bearing support every 6Mtrs

maximum. This should be increased if

elbows are used in the installation.

One wall band every 2Mtrs Max.

One every 1.5Mtrs if on an incline.

Access for soot removal

o

Maximum horizontal

150mm

Access for

soot removal

600mm

minimum

Support Collar

Fire Stop Spacer

Radiation Shield

Fire Stop Spacer

Twin Wall Flue Pipe must

start at least 425mm below

combustible surface.

45 degree elbow

9

Stove Installation Continued.

o

45

Page 12

All Installations:

The Chimney/Terminal Outlet must be no lower than the minimum positions shown in the

diagram below:

For terminations above easily ignited surfaces i.e. thatched roofs then minimum outlet

positions are shown below, this diagram needs observing in conjunction with the above

diagram:

Upon completion of the installation the Chimney/Flue must be smoke tested prior to the

stove being lit. Smoke pellets are available from your WARRIOR Stoves dealer.

Following is a complete Smoke Test Guide:

A

B

C

D

Point where flue passes through weather surface (Notes

1,2)

Clearance to flue outlet

A At or within 500mm of the ridge. At least 600mm above the ridge.

B Elsewhere on a roof

(Whether pitched or flat)

At least 2300mm horizontally from the nearest point on the

weather surface and:

A) at least 1000mm above the highest point of intersection of

the chimney and the weather surface; or

B) at least as high as the ridge

C Below (on a pitched roof) or within 2300mm hori-

zontally to an open able roof light, dormer window

or other opening .

(Note 3)

At least 1000mm above the top of the opening.

D Within 2300mm of an adjoining or adjacent building,

whether or not beyond the boundary.

(Note 3)

At least 600mm above the adjacent building.

Notes

1) The weather surface is the building external surface, such as its roof, tiles or external walls.

2) A flat roof has a pitch less than 10 degrees

3) The clearance given for A or B, as appropriate, will also apply

Outlets should be above the

shaded areas.

Area Location of flue outlet

At least 1800mm vertically above the weather surface and at least 600mm above the ridge

B At least 1800mm vertically above the weather surface and at least 2300mm horizontally from the

weather surface.

1800mm

1800mm

600mm

At least

2300mm

B B

10

Stove Installation Continued.

o

Page 13

Smoke Test Guide

These are two Primary purposes for smoke testing, the first test is to discover any major

defects which can cause leakage of fumes through a chimney or flue structure during normal

operation. The second is to test the draw in the appliance.

If in doubt about the condition of a chimney, especially when an old chimney is to be used

after a long period of being unused, it is recommended to have it smoke tested. This is

particularly relevant for chimneys constructed prior to the 1965 Building Regulations which

require all new chimneys to be built with a suitable flue liner to protect the chimney

structure . Smoke Testing should also be carried out during construction of traditional

masonry chimneys and on all completed chimney installations.

A smoke test should be done by a competent person using the following procedures which

are based on recommendations in British Standard BS5440-1:2008. A slightly different

procedure is required for testing flues for gas appliances.

It should be remembered that the pressure of smoke from a test is far greater than that of a

chimney during normal use. Consequently minor smoke leakage may occur in joints of a

traditional masonry chimney or connections between prefabricated metal chimneys and flue

pipes. Minor leakage detected should not be a major risk when the appliance is used,

providing that it does not indicate a fault that could get worse. Remedial work will be

required if heavy leakage is seen. The most likely problems are broken components,

incorrect fitting or incomplete joining of flue liners.

Smoke Test 1: Testing Air Tightness of Chimney

•

Ensure appliance is not alight and all doors and windows in the room are closed.

•

If there is a solid fuel appliance or open fire appliance fitted at the base or the bottom

of the chimney, heat the inside of the Appliance/Fireplace chamber with a blow Lamp,

gas stove or similar device for approx 10 minutes, a longer warming up time may be

needed with wet or cold flues. This will establish a flue draw to stimulate real

conditions. It should be realised that neither of these methods create the same

temperatures or volume of hot gases that would normally be created whilst the

appliance is in use. If the flue is to be used with a gas burning appliance, the smoke

test should be carried out before the fire is fitted and the flue warmed with a blow lamp

for only 5 minutes, or longer if the flue is cold.

•

For testing flues to be used with a solid fuel appliance place one smoke pellet with a

minimum burn time of 60 seconds producing 15 Mtr3 of smoke on a flat surface that

cannot be harmed by heat in the opening at the base of the flue or in the appliance if it

is fitted. Always follow the pellet manufacturer’s safety instructions.

•

Ignite the top edge of the pellet and when smoke appears seal the opening with a board

or plate sealed at the edges. If a solid fuel appliance is fitted, close all doors, ash

pit covers and vents. Do not seal off the base of the flue or opening if testing a flue for

a gas appliance.

•

Check that the smoke rises freely out of the correct flue. When smoke begins rising

out of the top of the chimney, seal the top of the flue, terminal or pot, if appropriate

use an inflated football, bladder or plastic bag sealed in position with tape. Do not seal

the top of the flue if it is to be used with a gas appliance.

•

Examine the full length of the chimney for any leakage of smoke such as the joints for

metal flues. If possible check for signs of leakage from wall cavities at the sides and

back of the chimney, if it is built into a wall, also check for leakage at openings around

11

Page 14

If smoke is seen establish the point of leakage and carry out remedial work to correct

any faults.

•

After completing the remedial work repeat the testing procedure until no major leakage

or fault is apparent. Remove the closures at the top and bottom of the chimney.

Smoke Test 2: Appliance Draw Test

•

Ensure appliance is not alight and all doors and windows in the room are closed.

•

If there is a solid fuel appliance or open fire appliance fitted at the base or the bottom

of the chimney, heat the inside of the Appliance/Fireplace chamber with a blow Lamp,

gas stove or similar device for approx 10 minutes, a longer warming up time may be

needed with wet or cold flues. This will establish a flue draw to stimulate real

conditions. It should be realised that neither of these methods create the same

temperatures or volume of hot gases that would normally be created whilst the

appliance is in use. If the flue is to be used with a gas burning appliance, the smoke

test should be carried out before the fire is fitted and the flue warmed with a blow lamp

for only 5 minutes, or longer if the flue is cold.

•

For testing flues to be used with a solid fuel appliance place one smoke pellet with a

minimum burn time of 60 seconds producing 15 Mtr3 of smoke on a flat surface that

cannot be harmed by heat in the opening at the base of the flue or in the appliance if it

is fitted. Always follow the pellet manufacturer’s safety instructions.

•

Ignite pellet and open all vents to stove or fireplace opening. Close the door to the

stove unless these can be correctly operated with the fire doors open.

•

For the first 30 seconds visually inspect that all smoke remains in the appliance or

fireplace opening and ensure that none of the smoke enters the room. Open a window

and check if smoke speeds up or is drawn quicker into the chimney. If either of these

two scenarios are noticed then there is insufficient ventilation, the appliance must be

closed down and further ventilation must be provided.

•

After checking internally go outside whilst pellet is still burning and observe the

smoke exiting the chimney. Ensure smoke is only exiting from correct chimney. If its

leaking from any brick work or any other chimney close the appliance or fireplace

down and attend to remedial repair prior to smoke testing again.

For complete peace of mind it is recommended that a Carbon Monoxide detector approved

to BS EN 50291:2001 is fitted in the same room as the stove. This detector should be fitted

in accordance with the manufacturers instructions. Carbon Monoxide is produced by the

incomplete combustion of fuels, it is extremely harmful and without a detector it is

impossible to detect as it has no colour, odour or taste.

12

Stove Installation Continued.

Page 15

STOVE OPERATION

Prior to lighting your new stove, ensure that this Manual has been read and completely

understood.

This Stove can get EXTREMELY hot, it is intended to!. If Children, Elderly, Infirm people

or pets will be in the presence of this stove whilst alight then a Fire Guard conforming to BS

8423: 2002 should be fitted in place, these will be available from your WARRIOR Stoves

retailer. This Stove should NOT be operated with the doors open.

AIR CONTROLS:

Your Aidan WARRIOR Stove is manufactured with Three air controls:

Primary; Secondary and Tertiary.

Primary:

This control as suggested by its name is the most important. It should be readily identified

by the parts diagram and is located on the lower section of the stove. Air enters the stove by

this control and it is the amount of air allowed to enter the stove that controls the burning

rate. The further open this control is then the more heat the stove will produce. See the

diagram below:

Secondary:

This control is also known as the ‘Air Wash’, it is located above the Fuel Door and should be

readily identified by the parts diagram. The Air is drawn in through this control and then

deflected down the stove behind the glass, this assists in keeping the glass clean and also

provides a secondary air for combustion. See the diagram below:

1

2

1

2

Shows direction of airflow

when using Top Flue Outlet

Shows direction of airflow

when using Rear Flue Outlet

1

2

13

Page 16

Tertiary:

This control is located at the side of the stove and should be readily identified by the parts

diagram. Air is drawn in through this control and deflected across the top of the fire from

the rear of the stove, this burns up some of the products of combustion and results in a

cleaner burning and more efficient stove. See the diagram below:

Flue Damper:

A flue damper may be put in-line in the flue pipe to assist the regulation of the flue draw,

these will be available from your WARRIOR Stoves dealer. Fit in accordance with

manufacturers fitting instructions. If any smoking does occur whilst the stove is burning

then open the damper more fully. Particular care using the damper must be exercised when

burning overnight or whilst the stove is burning unattended, if too far closed then smoking

may occur through the stove controls.

Experience will be the essence of perfection in controlling the Stove. The control settings

required will depend on the chimney type, location and the fuel being used along with the

heat output desired.

First Firing:

This stove is cast iron and should be seasoned. Seasoning is the process of gradually

warming through the castings of the stove to allow all components to heat up and cool down

together without causing any damage to the stove. Seasoning should be done with the first

five or six firings. The fire size for seasoning should be kept small and allowed to die down

straight after the stove has got to the point of being barely touchable. Particular care must be

taken to ensure the fire does not get to hot whilst seasoning the stove. Whilst seasoning the

stove surfaces may smoke slightly as the high temperature paint begins to cure. During this

period ensure that the vicinity of the stove is kept well ventilated, the odour produced is not

harmful however some individuals may find it nauseous.

Lighting the Fire:

Ensure matches, fire lighters and any other combustible articles are not in proximity of the

stove. Check the Ashpan is in the stove and open all the air vents. Place tightly wrapped

paper and kindling wood in the centre of the fire box. Fire lighters may also be used which

will assist in lighting the fire, follow the manufacturers instructions. Caution: Do NOT

use

liquid fuels for lighting the fire or at any time whilst burning, they can be extremely

1

2

2

14

Stove Operation Continued.

Page 17

dangerous. Immediately after lighting close the fire door or doors. Once the fire has been

established add more fuel to the fire bed and adjust the air controls according to your

requirements.

Fuel Types:

Wood:

All natural wood is suitable for burning on this stove, provided that it is well seasoned and

has a moisture content below Twenty Percent. The maximum suitable log length for this

stove is 40cm. Beware of using manmade woods i.e. Chipboard or Plywood which have a

high content of adhesive which can cause damage to the Stove and the Chimney. Manmade

woods are also now available manufactured primarily from plastic, these must not be burnt

in the stove. Recently felled generally green in colour or wet wood must not be burnt as this

can produce excessive tar and creosote which can damage the fire and chimney, in extreme

instances it could potentially cause a fire in the chimney. If you find that the wood is

burning very quickly reduce the primary air intake and increase the air through the

secondary (and tertiary) air inlets.

Solid Fuels:

Most Solid Fuels are suitable for burning on your stove, check with your fuel provider as to

the type that will suit best. Petroleum based solid fuels must NOT be used in your stove, the

use of such fuel will invalidate your guarantee as will the use of smaller sized fuels that can

clog the grate. Fuels which have a maximum dimension of less than 35mm are NOT

suitable. The larger the fuel size then the greater the draught will be in the fire box, this will

speed up the rate of combustion. i.e. The stove will burn more quickly. Household coal is

not particularly suited as it produces excessive ash and chimney deposits. Recommended

fuels are listed on the Hetas Ltd. website that is listed at the rear of this manual .

Peat:

Compressed peat is a suitable fuel where available, it must not be used in its original form

which is primarily water. Ensure from the supplier that the moisture content is low.

A combination of the above fuels may be used to best suit individual requirements.

Do NOT burn household waste or plastics in the stove. Burning plastic can produce toxic

fumes and some articles of waste may possibly explode as well as produce fumes. Burning

such products will also invalidate the guarantee.

Ash Removal:

Ash should frequently be removed, preferably before the ashpan is full and certainly before

the ash reaches the underside of the grate. If ash is allowed to build up close to the

underside of the grate then the life expectancy of the grate will be severely reduced as it will

be burning hot on both sides.

15

Stove Operation Continued.

Page 18

Some ash will automatically fall directly into the ash pan below the fire grate, more will fall

through when the grate is agitated by the riddler, this is the sliding arm connected directly to

the grate, ensure the door/s are closed prior to doing this. Do not exercise excessive force

when agitating the stove. If the grate will not move it could be due to small pieces of fuel

being stuck so removal will be required with a poker, tongs or similar tool. The ashpan is

easily removed using the operating tool. Use extreme caution when emptying as the ashes

are generally very hot and must only be emptied into a non combustible container. If

emptying outside beware of any draughty conditions that could cause the ashes to escape and

start a fire or cause an injury. Purpose made Ash Carriers are available from your

WARRIOR Stoves dealer that will assist in the safe removal and storage of ash until cold.

Overnight Burning:

This stove has been tested and approved as a continuously rated appliance when burning

solid mineral fuel. It will burn overnight so long as it has been correctly installed and

operated. For overnight burning follow the procedure below:

•

Empty the ashpan.

•

Load the fire with fuel and ensure the door/s are closed.

•

The Air inlet vents should be nominally open to allow only a small amount of air for

combustion to the stove.

Should the fire not stay in overnight and there is un burnt fuel in the stove then open the air

controls slightly more so extra air is available, conversely if the fire has burnt away too

quickly adjust the controls so that less air is available. If an optional flue damper has been

fitted then this should be regulated similarly to the air inlet controls, the further closed then

the slower the fire burn rate will be. Observe the note in the Air control section regarding

use of damper whilst the stove is unattended. The stove may also stay in overnight when

using wood or a mixture of fuels, experience and experimentation with the air inlet controls

will best teach you how to regulate the stove for burning at extended periods without

refuelling.

Slow overnight burning in your stove can produce excess tar deposits and soot build up in

the chimney, it is recommended that before and after overnight burning that the stove is

operated at high output for short periods. This will assist in reducing the build up of the

products of combustion in the chimney.

To restart the fire in the morning follow the procedure below:

•

Empty the ashpan.

•

Load the fire with fuel and ensure the door/s are closed.

•

Open air inlets and damper if fitted to re-establish fire.

•

Once the fire is established add more fuel to the fire bed as necessary and adjust the air

controls according to your heat requirements.

This stove must not be over fired, operating at extreme temperatures can damage the stove

and the chimney it is connected to and possibly cause a chimney or house fire. If any part of

the stove or chimney starts to glow red then the stove is being over fired. If this situation

does arise the air inlets should be swiftly closed, this will reduce the air for combustion in

the stove. If a chimney fire should ensue evacuate all members of the property and alert the

Fire Brigade immediately. The stove must not be reused after a chimney fire until the entire

flueway has been inspected by a competent person or installer such as a HETAS approved

engineer. Damaged sections will need to be repaired or replaced as necessary.

16

Stove Operation Continued.

Page 19

STOVE AND CHIMNEY MAINTENANCE

Chimney/Flueway Sweeping:

The entire chimney/flueway should be swept frequently from top to bottom to keep clean

and prevent the build up of the products of combustion. The frequency required is difficult

to gauge due to the nature of varying flue conditions and fuels burnt, we therefore suggest

that the chimney is swept within the first 4 to 6 weeks of use to reasonably establish the

frequency required. In any case the chimney/flueway should be swept at least twice a year,

generally best before and after the main winter burning season. The sweeping should be

done by a competent and qualified chimney engineer, a member of the National Association

of Chimney Sweeps (N.A.C.S.), Guild of Master Sweeps or The Association of

Professional & Independent Chimney Sweeps Ltd (APICS). They will provide a certificate

for sweeping and their details are listed at the rear of this manual under useful addresses.

The chimney/flueway should be inspected for blockage prior to lighting after a prolonged

period of not being used. Numerous chemical chimney cleaners are available to help reduce

the build up of the products of combustion. Ensure the cleaner is suitable for the intended

chimney type as many are not suitable for use with Stainless Steel flues and liners due to

their highly corrosive nature. The flue cleaner available from your WARRIOR Stoves

dealer supplied by WARRIOR Stoves is suitable for all chimney/flue types. Follow the

manufacturers instructions with regards to usage.

Stove Maintenance:

Internal:

The frequency required for cleaning your stove will vary considerably dependant upon usage

and fuel type. The inside of the stove should be cleaned at least Monthly during peak usage

to remove any build up of deposits from the products of combustion, experience will advise

whether this needs doing more or less often. It is advisable to wear goggles or safety glasses

as well as a dust mask and protective gloves when cleaning.

Use a stiff brush combined with a vacuum cleaner and start at the top underside of the stove

and work down to the bottom. Particular attention should be given to cleaning above the

baffle plate and the air inlet controls which are both important and often get overlooked.

Your stove should be inspected every year by a competent person who should thoroughly

strip down and clean the inside of the stove as well as visually checking components.

Damaged or broken parts should immediately be repaired or replaced with authorised spares,

your WARRIOR Stoves dealer will be able to obtain these for you. The use of spare parts

not supplied by WARRIOR Stoves may invalidate the stove guarantee.

External:

The outer surface of the stove body can periodically be cleaned as required with a soft dry

brush. When the stove surface needs retouching or rejuvenating use high temperature

resistant paint available from your WARRIOR Stoves dealer. The paint is available in liquid

or aerosol form, both are easy to use but ensure the manufacturers instructions are strictly

adhered to. The rope door seals need constant checking to ensure there is an air tight seal

between the door and the main body of the stove. If the rope comes loose then it is easy to

stick back with stove rope adhesive or it may need replacing if it has frayed or started to

disintegrate. The high temperature resistant adhesive and rope will be available from your

WARRIOR Stoves dealer.

17

Page 20

Stove Glass:

The stove glass should remain clean during normal daily use, however if the stove is being

operated at a slow burning rate for extended periods or with damp fuels then the glass can

become blackened. This blackening may be removed by burning the stove at a much higher

temperature for a short period or may require a special glass cleaner available from your

WARRIOR Stoves Dealer. If the glass ever breaks in your stove then it is quite easy to

replace. Ensure that the replacement glass is the heat resistant variety which will be

available from your WARRIOR Stoves dealer. Fitting should be done with the door

removed from the stove.

The glass is held in by clips that are screwed to the stove door, undo the machine screws that

hold the clips and safely dispose of all the old glass and any fragments. Penetrating oil may

assist in removing the machine screws if they are proving difficult to undo. If the rope seal

that the glass rests on is undamaged then the glass can be placed on top and the glass

retaining clips carefully screwed back down, ensure they are evenly and lightly tightened

otherwise this can cause the glass to break. Replace stove rope, retaining clips or machine

screws as necessary, all will be available from your WARRIOR Stoves dealer.

Where air intake vents which provide external air for combustion are fitted then these need

to be inspected Once a Month to ensure they have not been blocked or partially blocked.

During prolonged periods of not lighting a fire it is recommended that the stove door/s are

left slightly ajar and the air inlets are kept open to allow air to circulate in the stove and

flueway. This will help prevent excessive moisture and condensation forming in the stove

that may lead to rusting.

18

Stove and Chimney Maintenance Continued.

Page 21

TROUBLESHOOTING

If your WARRIOR Stove has been correctly installed, operated and maintained as outlined

in this Manual then it should perform extremely well for a great number of years. Like most

products the better it is looked after and the less it is abused then the longer it will last.

Unless the stove is damaged or requires new parts or servicing it will invariably be an

oversight during installation, poor fuel, extremities of location or adverse weather

conditions.

If your stove does not function satisfactorily from the initial installation, we suggest you

have the installation checked by an approved installer such as a Hetas engineer. Your Stove

dealer may be able to offer advice, however without viewing the installation or location of

the stove they will not find it quite so easy to remedy.

If your stove functions satisfactorily from the outset but later on subsides in performance it

will be the chimney or stove that require attention. Ensure the procedures in the Stove and

Chimney Maintenance section are adhered to.

During operation nominal fume and smoke emission may occur when refuelling or emptying

the ashes from the stove, following the procedures in this manual will assist in keeping these

emissions to a minimum. If the stove is correctly installed, operated and serviced then

smoke and fumes should not be released into the surrounding area where the stove is located.

If fumes or smoke are noticed coming from the stove then the following procedure should be

followed:

•

Put out the fire or allow it die out naturally if unsafe to extinguish.

•

Open all windows and doors in the immediate vicinity to allow the fumes or smoke to

disperse as quickly as possible. If necessary evacuate the area.

•

Do not relight the stove until cause of the emission has been rectified.

The leakage may be caused by many circumstances, it may be due to a blocked or partially

blocked chimney/flueway or may even be due to down draught. An approved installer such

as a Hetas engineer would be best deployed to identify the cause and rectify the situation.

19

Page 22

PARTS DIAGRAM

1 Top Plate

2 Top convection plate Inner

3 Stove Rope

4 Bottom Convection plate

5 Secondary Air Deflector

6 Secondary Air Slide

7 Front Plate

8 Fuel Retainer

9 Refractory Fire Brick

10 Right Plate

11 Air Slide Knob

12 Flue Outlet Top

13 Flue Blanking Plate Top

14 Top Outlet Connecting Plate

15 Tertiary Air burn Plate

16 Back Boiler

17 Flue Blanking Plate Rear

18 Refractory Fire Brick

19 Left Plate

20 Baffle Plate Lower Section

31 Door Handle & Catch

32 Door Handle Wooden

33 Machine Screw M6X70

34 Door Catch

35 Door Handle

36 Door Wooden Handle

37 Ash Door

38 Machine Screw M6X70

39 Hinge

30 Ashpan

21 Grate Inner

22 Grate Outer

23 Grate Support Plate

24 Base Plate

25 Leg

26 No Part

27 Grate Shaker Rod

28 Stove Rope

29 Glass

30 Door

20

Page 23

LIST OF USEFUL ADDRESS’S

21

Midtherm Ltd

New Road

Netherton

Dudley

West Midlands

DY2 8SY

T 01384 458800

F 01384 458811

W

www.midtherm.co.uk

E sales@midtherm.co.uk

Gastec CRE Ltd

Orchard Business Centre

Stoke Orchard

Cheltenham

Gloucestershire

GL52 7RZ

T 0845 6345626

W www.hetas.co.uk

E info@hetas.co.uk

NACS National Association of Chimney Sweeps

Unit 15 Emerald Way

Stone Business Park

Stone

Staffordshire

ST15 0SR

T 0800 833464

F 01785 811712

W www.nacs.org.uk

E nacs@chimneyworks.co.uk

Guild of Master Sweeps

The Bungalow

London Road

Attleborough

Norfolk

NR17 2DE

T 01953 451322

W www.guild-of-master-sweeps.co.uk

E

contactus@guild-of-master-sweeps.co.uk

Solid Fuel Association

7 Swanwick Court

Alfreton

Derbyshire

DE55 7AS

T 0845 6014406

F 01773 834351

W

www.solidfuel.co.uk

E sfa@solidfuel.co.uk

Solid Fuel Technology Institute

White House

All Saints

South Elmham

Suffolk

IP19 0PA

W www.soliftec.com

National Fireplace Association

PO Box 583

High Wycombe

Buckinghamshire

HP15 6XT

T 0121 288 2196

F 0870 130 6747

W www.nfa.org.uk

E enquiry@nfa.org.uk

Irish Nationwide Fireplace

Organisation

162 Capel Street

Dublin 2

T 01 801 5959

F 01 801 3645

W www.fireplace.ie

E

infoinfo@eircom.net

Page 24

LIST OF USEFUL ADDRESS’S

Teddington Appliance Controls Ltd

Holmbush

St Austell

Cornwall

PL23 3HG

T 01726 222505

F 01726 222502

W www.tedcon.com

E info@tedcon.com

The Association of Professional

Independent Chimney Sweeps Ltd. (APIC)

Bryallen,

Hengar Road,

St Tudy,

Bodmin,

Cornwall.

PL30 3PL

T 0845 604 4327

Water Regulations Advisory Scheme,

Fern Close

Pen-Y-Fan Industrial Estate

Oakdale

Gwent

NP11 3EH

T 01495 248454

F 01495 249234

W www.wras.co.uk

E info@wras.co.uk

HETAS Ltd.

Orchard Business Centre

Stoke Orchard

Cheltenham

Gloucestershire

GL52 7RZ

T 0845 634 5626

F 01242 673502

W

www.hetas.co.uk

E

info@hetas.co.uk

22

Page 25

INSTALLATION RECORD

This Installation Record helps you to ensure the hearth, Stove, and chimney/Flueway are satisfactory. If you have been

directly engaged, copies should also be offered to the client and to the Building Control Body to show what you have done

to comply with the requirements of part J. If you are a sub-contractor, a copy should be offered to the main contractor.

C)

If clay or concrete flue liners used confirm they are

correctly jointed with socket end uppermost and state

jointing materials used.

D)

If an existing chimney has been refurbished with a new

liner, type or make of liner fitted.

E)

Details of flue outlet terminal and diagram reference.

Outlet Detail:

Complies with:

F)

Number and angle of bends.

G)

Provision for cleaning and recommended frequency.

7

Hearth. Form of construction. New or existing?

8 Inspection and testing after completion

Tests carried out by:

Tests (Appx E in AD J 2002 ed) and results

Flue visual

Inspection sweeping

coring ball

smoke

Appliance (where included) spillage

1 Building address, where work has carried

out……………………………………………………………………………………………………………………..

…………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………

2 Identification of hearth, fireplace, Chimney or flue.

3 Firing capability:solid fuel/gas/oil/all.

4 Intended type of appliance.

State type or make. If open fire give

Finished opening dimensions.

5 Ventilation provisions for the appliance:

State type and area of permanently open air vents.

6 Chimney or flue construction

A) State the type or make and whether new or existing.

B) Internal flue size (and equivalent height, where

calculated-natural draught gas appliance only).

I/We the undersigned confirm that the above details are correct. In my opinion, these works comply with the relevant

requirements in part J of schedule 1 to the Building Regulations.

Print name and title………………………………………………... Profession….………………………………………

Capacity………………………………………………………………………..Tel no……………………...

Address……………………………………………………………………….……………………Postcode………………

Signed…………………………………………………..Date………………………

Registered membership of (e.g. CORGI, OFTEC, HETAS, NACE, NACS,NAPIT) …………………………………….

22

Page 26

MAINTENANCE RECORD

Date Company Name &

Address

Registered

Member of

Work

Conducted

Installation &

Chimney Safe

Y/N

Sign Name &

Print

Please kindly ensure this Maintenance Record is completed by the engineer every time work is completed on

either the stove or the chimney.

23

Page 27

GUARANTEE

WARRIOR Stoves thank you for purchasing One of our high quality multi fuel stoves.

Where correctly installed, operated and maintained as detailed in this manual you can expect

many years of trouble free service.

Your WARRIOR Stove is Guaranteed against defective manufacture or workmanship for a

non transferable period of Five years from date of purchase. Consumable parts are excluded

from this guarantee, which includes the following:

Stove Glass

Stove Rope

Grate (Inc. Fuel Guard)

Ashpan

Cast/Refractory Linings

Baffle Plate

In the highly unlikely event of a fault or problem developing with your WARRIOR Stove,

you should advise the stove dealer where you purchased your stove. They have the

competence and experience to assist you, furthermore your Contract of Sale is with the Stove

dealer and not the Manufacturer WARRIOR Stoves Ltd. The stove dealer will require the

model, receipt/invoice, the installation and service records, your full contact details,

description of the fault and the fuel type/brand used where applicable. Should your stove

require return to WARRIOR Stoves for analysis, repair or replacement the cost of insured

transit will be at the expense of the stove owner.

WARRIOR Stoves will not be accountable for any loss, damage or injury resulting from

your stove. Please also note that the Assembly, Installation and the Operation of this stove

are not covered by the guarantee as they cannot possibly be governed by WARRIOR Stoves

Ltd.

WARRIOR Stoves decision will be final in all eventualities.

The use of any spare parts other than those originally supplied by WARRIOR Stoves will

invalidate the guarantee. The Guarantee will also be deemed void if your WARRIOR Stove

is not correctly installed, operated and maintained as detailed in this manual.

This WARRIOR Stoves guarantee is additional to your standard statutory rights.

.

24

Page 28

25

OTHER PRODUCTS

Fluepipe

Fireside Accessories

Garden Collection

To view our full range of products please visit our website at:

WWW.WARRIORSTOVES.CO.UK

WWW.WARRIORSTOVES.CO.UKWWW.WARRIORSTOVES.CO.UK

WWW.WARRIORSTOVES.CO.UK

OR

E-mail us to find your nearest stockist at:

info@warriorstoves.co.uk

info@warriorstoves.co.ukinfo@warriorstoves.co.uk

info@warriorstoves.co.uk

Loading...

Loading...