WARRIOR GENERATORS LDG4600E Owner's Manual

LDG4600E

DIESEL GENERATOR

OWNERS MANUAL

BEFORE OPERATING THIS EQUIPMENT

PLEASE READ THESE INSTRUCTIONS CAREFULLY

This manual contains information how to maintain and how to do troubleshooting.

Keep this owner’s manual handy, so you can refer to it at any time.

This service manual describes correct method of the maintaining this equipment. As a result of

this disregard of our rules caused by person casualty and equipment damaged, our company

does not assume any responsibility.

NOTICE:

Copyright reserved, and no part of this publication may be reproduced without our

Company’s written permission.

SAFETY MESSAGES

Your safety and the safety of others are very important. We have provided important safety

mes3ges in this manual and on the generator. Please read these messages carefully.

A safety message reminds you to potential hazards that could hurt you or others. Each safety

message is preceded by a safety alert symbol and one of three words: DANGER,

WARNING, or CAUTION. These mean:

You WILL be KILLED or SERIOUSLY HURT

DANGER

if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT

WARNING

if you don’t follow instructions.

CAUTION

You CAN be HURT if you don’t follow instructions.

Your generator or other property could be damaged

NOTICE

if you don’t follow instructions.

CONTENTS

1 PREFACE 1

1-1 Generator Component Identification 1

1-2 Control Panel 3

1-3 Specifications of generator 4

1-4 Specifications of engine 6

1-5 Maintenance Standard 7

2 Periodic Maintenance 9

2.1 Service Intervals 9

2.2 Routine Maintenance Procedures 10

3. Engine Disassembly and Reassembly 13

3.1 Disassembly 13

3.2 Reassembly 19

3.3 Recoil Starter Assembly 25

4. Inspection and Service 28

4.1 Cylinder Head 28

4.2 Piston and Piston Pin 30

4.3 Connecting rod 32

4.4 Crankshaft, main bearing and flywheel 33

4.5 Camshaft 34

4.6 Timing Gear 34

4.7 Crankshaft Cover 35

4.8 Cylinder Sleeve and Block 36

4.9 Lubricating System 36

4.10 Fuel System 38

4.11 Governor 39

4.12 Adjustments 40

5. Troubleshooting 42

5.1 No fuel delivery to injection pump 42

5.2 No fuel flow from drain valve 42

5.3 Low compression 42

5.4 Hard starting (fuel delivery and compression normal) 42

5.5 No start or hard start (engine cranks) 42

5.6 Engine over speed 43

5.7 Unsteady engine speed 44

5.8 Unexpected shutdown 44

6 Generator 45

6.1 Removal/Installation 45

7 Circuit diagram 51

8 Appendix 53

1. PREFACE

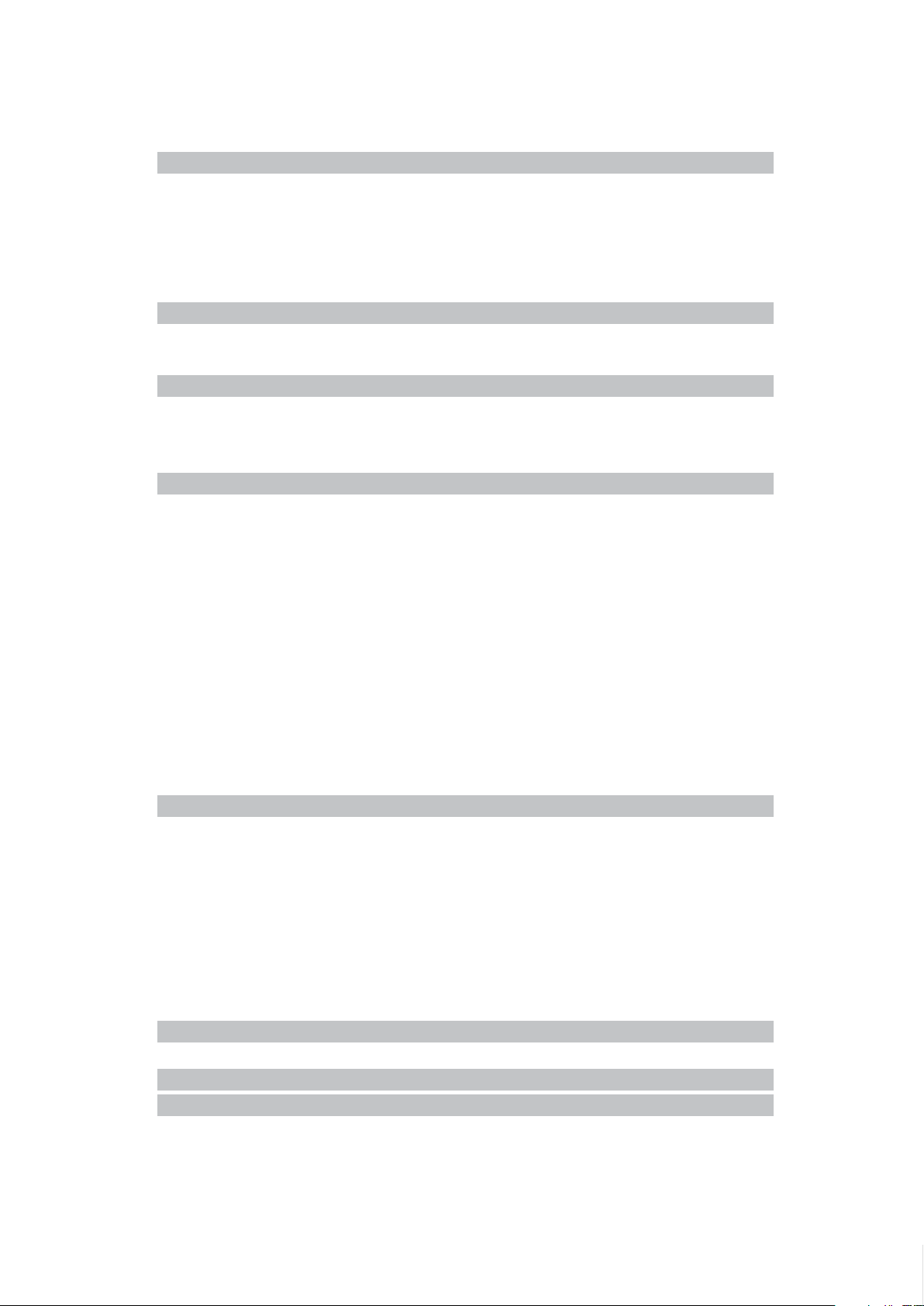

1-1 Generator Component Identification

Open Type: D*

FUEL TANK

CONTROL PANEL

ALTERNATOR

RUBBER ABSORBER

FUEL TANK CAP

BOTTOM FRAME

UP COVER

FRAME

DIESEL ENGINE

INJECTION PUMP

RECOIL STARTER

SPEED GOVERNOR

COCK OF OIL DRANING

OIL PUMP

AIR CLEANER

MUFFLER

START MOTOR

BATTERY CHARGER

OIL DIPSTICK

BATTERY

PUSH WHEEL KIT

1

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

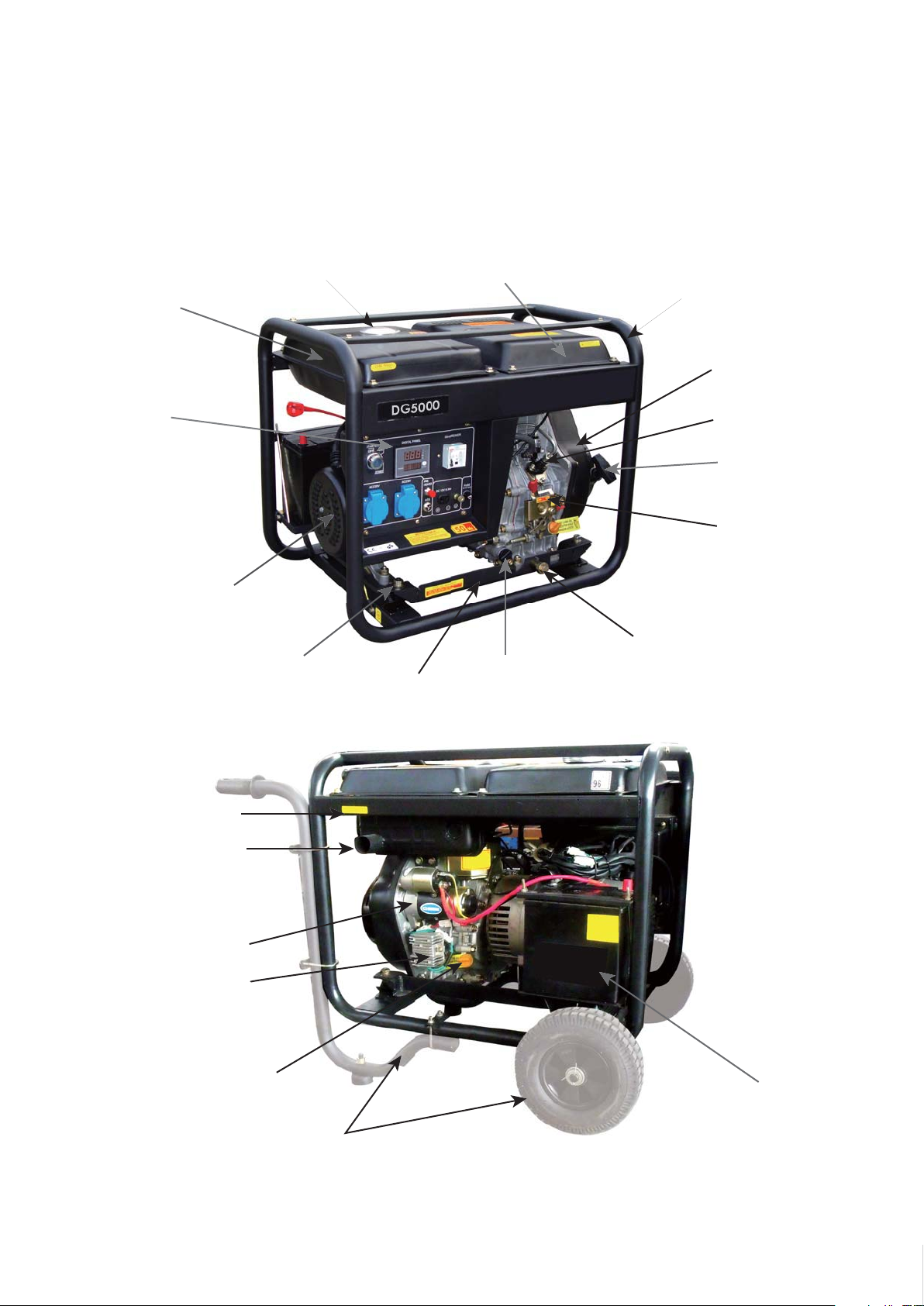

1-2 CONTROL PANEL

ELECTRIC START KEY

SOCKET

PCB

ATS SIGNAL SOCKET

LED4 DISPLAY

12V DC SOCKET

LEAKAGE BREAKER

PRE-HEATER BUTTON

12V DC FUSE

GROUND TERMINAL

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

LDG4600E Specifi cations

Frequency (HZ) 50 Cooling system Forced Air cooled

Starting Watts 4600 Lubricaton system Forced lubrication

Running Watts 4200 Operation capacity (hr) >12 hrs (25% load)

Voltage (V)

DC output (VA) 12 / 8.3 Net Weight (kgs) 95

Pole Numbers 2 Noise Level dBa@7m 84-89

Insulation B Certifi cation

Engine Model 182FE Start System Electric Key

Engine Type

Displacement (cc) 296 Lube oil capacity (L) 1.1 (SAE10x30)

Engine Speed (RPM) 3000

Low oil pressure alarm

system

1 x 110v 32 Amp / 1 x 240v

32 Amp

Single cyinder, vertical, 4

stroke air cooled direct

injection diesel engine.

Included

Dimension L*W*H (mm) 720 x 492 x 650

ISO9001-2000, GS,

TUV & CE

Fuel tank capacity (L) 15

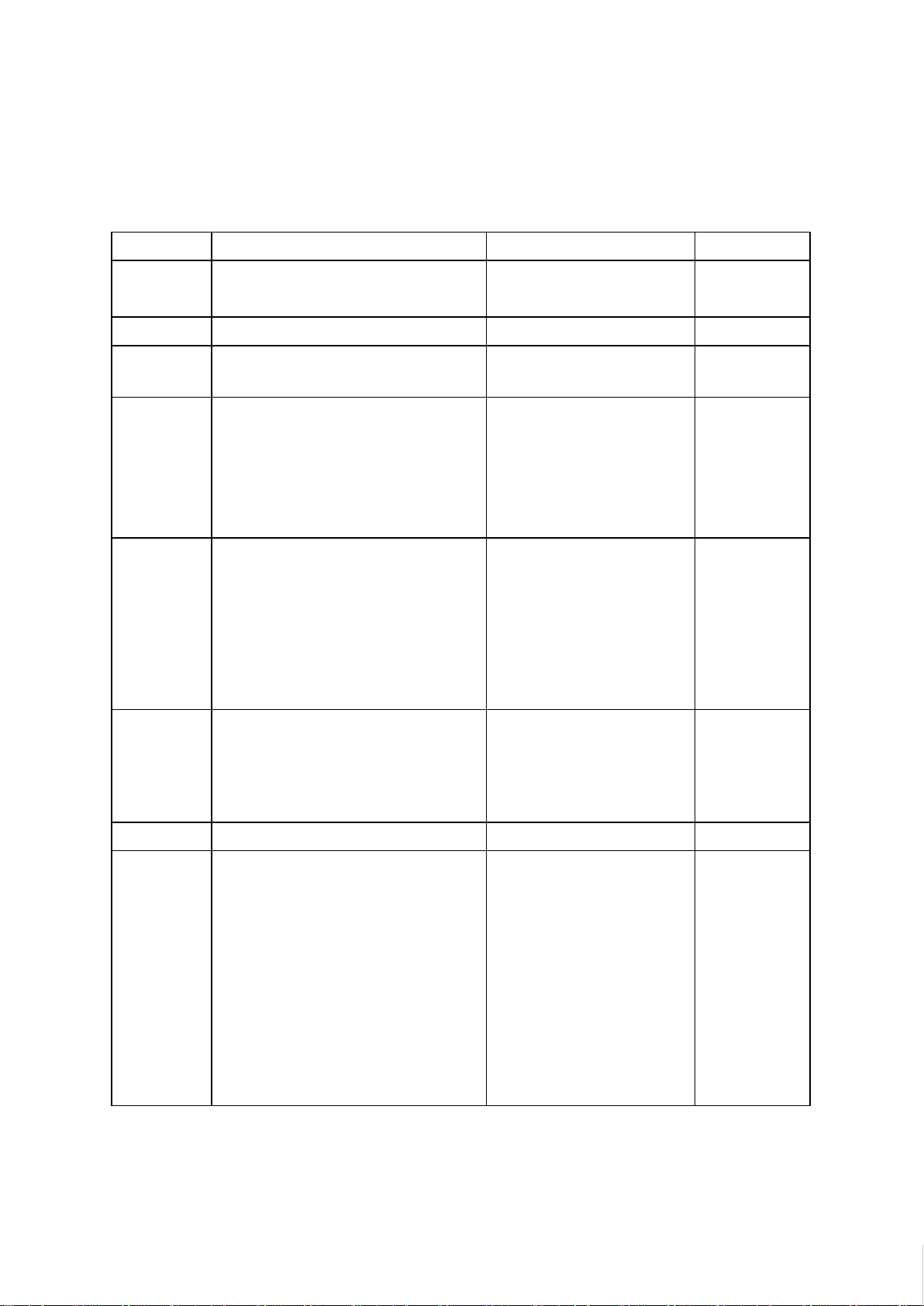

1-5 Maintenance Standard

Diesel Engine

Parts Item Standard Service limit

POWER PRODUCTS

Diesel

Engine

Maximum Speed (No Load)

Cylinder Compression

Cylinder Sleeve I.D

Cylinder Head

Cover

Warpage -- 0.10mm

Skirt O.D.

Piston-to-Cylinder Clearance

Piston

Piston Pin Bore I.D.

Piston Pin O.D

Piston Pin-to-Piston Pin Bore Clearance

Ring Side Clearance:

Piston Rings

Ring Enc Gap:

Ring Width

Small End I.D

Second

Second

Second

3150~3180rpm

≥1.17Mpa(1400rpm)

86.0mm

+0.035

0

85.94mm

0.015-0.05mm

Ø23mm Ø23.05mm

-.0002

-0.008

18.0mm

0.002-0.014mm

0.015-0.045mm

--

0.2-0.4mm

0.15-0.35mm

1.5mm

2.5mm

18.002mm

--

--

86.185mm

85.80mm

0.12mm

17.954mm

0.06mm

0.15mm

--

1.0mm

1.0mm

1.37mm

2.37mm

18.07mm

Connecting

Rod

Big End I.D

Big Oil Clearance

Big End Side Clearance

30.02mm

0.040-0.063mm

0.1-0.7mm

30.066mm

0.12mm

1.1mm

Crankshaft Crankshaft pin O.D 29.98mm 29.92mm

Valve

Valve Clearance IN

EX

Stem O.D IN

EX

Guide I.D

Stem Clearance IN

EX

Seat Width

Spring Free Length

0.15±0.02mm

0.20±0.02mm

5.48mm

5.44mm

5.50mm

0.02-0.044mm

0.06-0.087mm

0.8mm

34mm

--

--

5.318mm

5.275mm

5.572mm

0.1mm

0.12mm

2.0mm

32.5mm

7

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

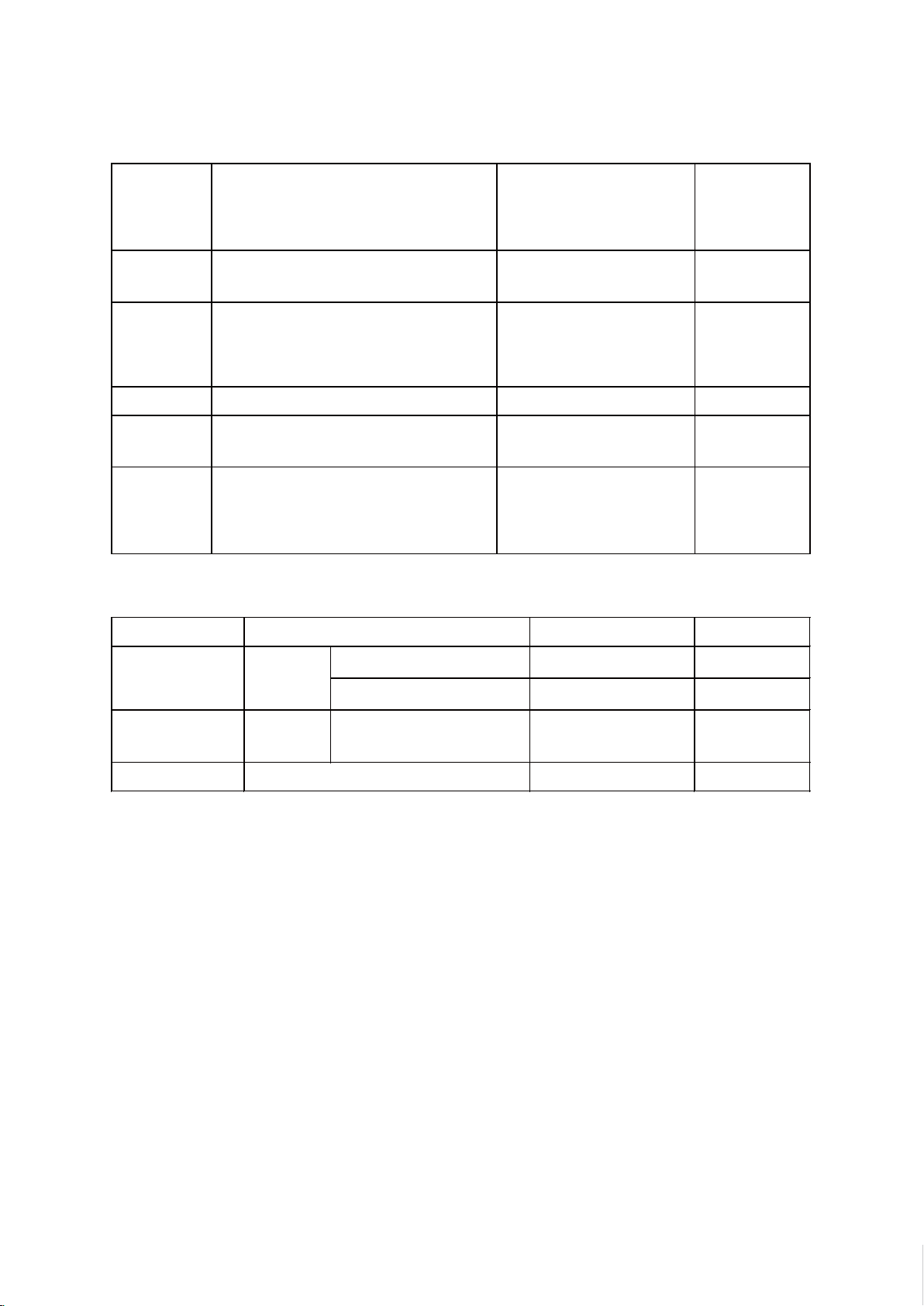

POWER PRODUCTS

Cam Height IN

Camshaft

Crankcase

Cover

Carburetor

Spark Plug Gap 0.7-0.8mm -Spark Plug

Cap

Ignition Coil

Cam Height EX

Journal O.D

Camshaft Bracket I.D 14.0mm 14.048mm

Main Jet

Float Height

Pilot Screw Opening

Resistance 5kΩ --

Resistance Primary Coil

Secondary Coil

Air gap

27.7mm

27.75mm

13.984mm

#68

13.7±1.5mm

2-1/8 turns

0.8-1.0Ω

5.9-7.1kΩ

0.4-0.6mm

y Generator

27.45mm

27.50mm

13.916mm

--

--

--

--

--

--

Parts Item Standard Service limit

Stator Winding 1.8±10%Ω at 20℃ --

Stator Winding Resistance

Stator Auxiliary Winding 3.5±10%Ω at 20℃ --

Rotor Excitation

Winding

Carbon Brush Carbon Brush Length 10mm 6mm

Resistance Excitation Winding 51.3±10%Ω at 20℃ --

8

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS

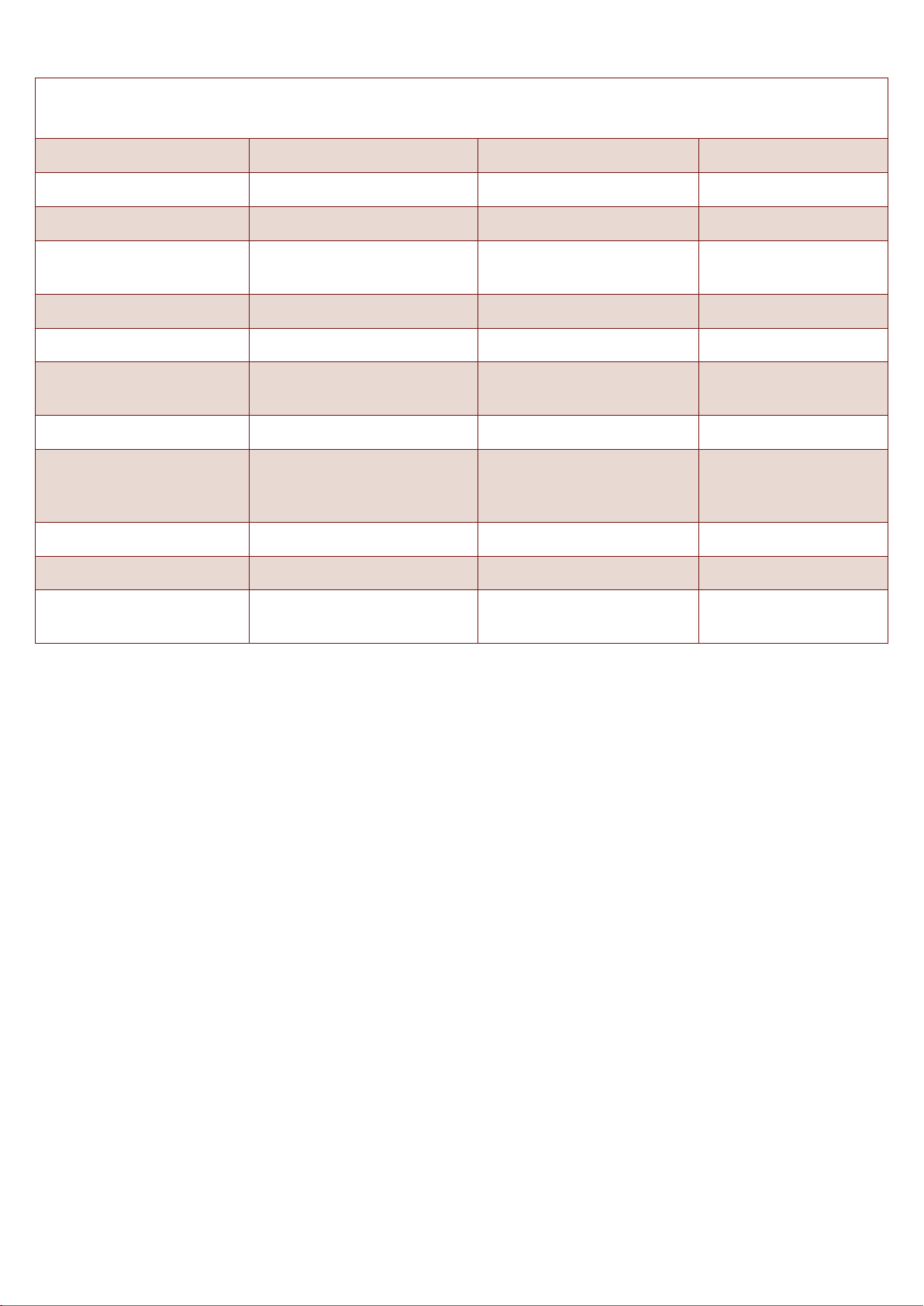

2. Periodic Maintenance

2.1 Service Intervals

Good maintenance is essential for safe, economical, and trouble-free operation. It will also help reduce air

pollution.

Exhaust gas contains poisonous carbon monoxide. Shut off the engine before

perform any maintenance. If the engine must be run, make sure the area is well

WARNING

ventilated.

Periodic maintenance and adjustment is necessary to keep the generator in good operating condition.

Perform the service and inspection at the intervals shown in the Maintenance schedule below:

(1) Service more frequently when used in dusty areas.

(2) These items should be serviced by an authorized generator dealer.

(3) When more often use, only servicing according to above correct intervals can insure the generator set

long-term use.

9

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

POWER PRODUCTS

2-2 Routine Maintenance Procedures

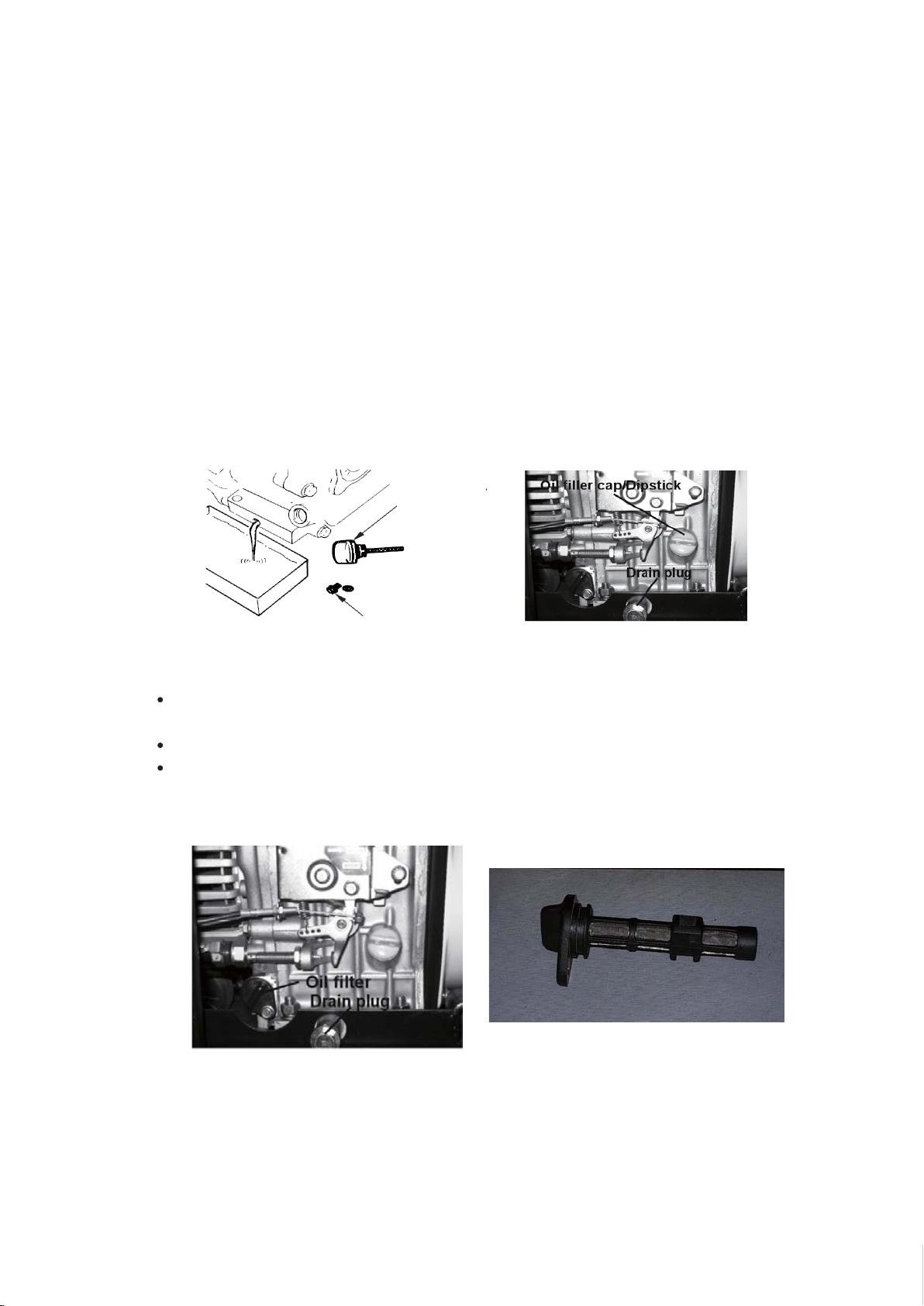

2.2.1 Oil Change

Drain the used oil while the engine is warm. Warm oil drains quickly and completely.

1. Place a suitable container below the engine to catch the used oil, and then remove

the filler cap/dipstick and the drain plug.

2. Allow the used oil to drain completely, and then reinstall the drain plug, and tighten

it securely.

3. With the engine in a level position, fill to the outer edge of the oil filler hole with the

recommended oil.

DIPSTICK

DRAIN BOLT

2.2.2 Oil Filter Service

Remove the bolt that secures the filter and carefully pull the assembly toward

you.

The filter may be immersed in solvent then blown dry with compressed air.

Replace the filter at the scheduled service interval or anytime the screen is

damaged or all deposits cannot be removed.

10

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

2.2.3 Air Filter Service

Remove the air cleaner cover and inspect the filter. Clean or replace dirty filter elements.

Always replace damaged filter elemen ts.

POWER PRODUCTS

2.2.4 Fuel Filter Service

1. Drain out the fuel from the fuel tank. Turn the screw in the drain plug counter

clockwise until fuel flows. Use a suitable container to catch the fuel.

2. Remove the three screws securing the fuel cock assembly and remove the filter

from the housing.

FUEL TANK

DRAIN PLUG

FUEL COCK

FUEL FILTER

ASSEMBLY

11

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

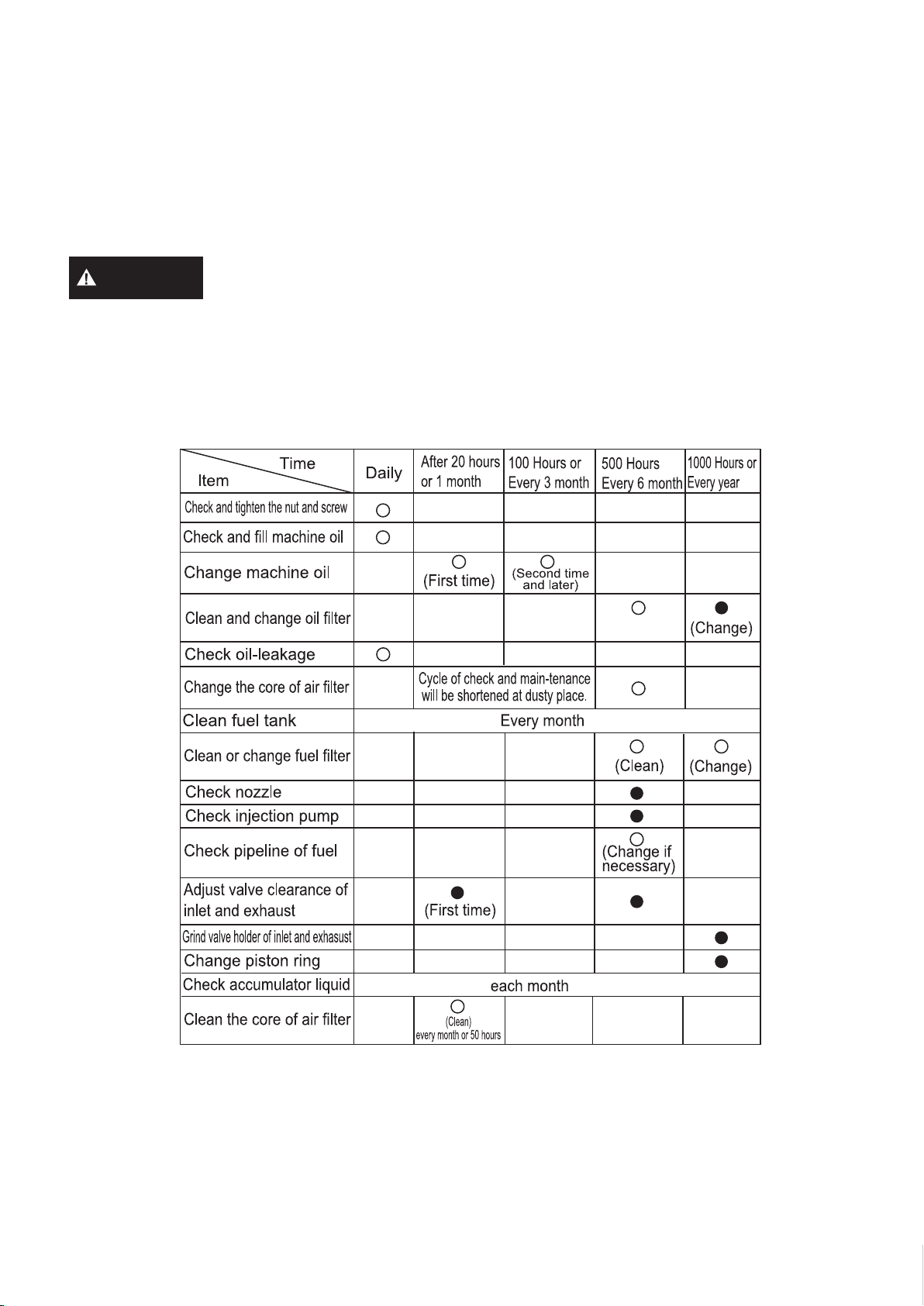

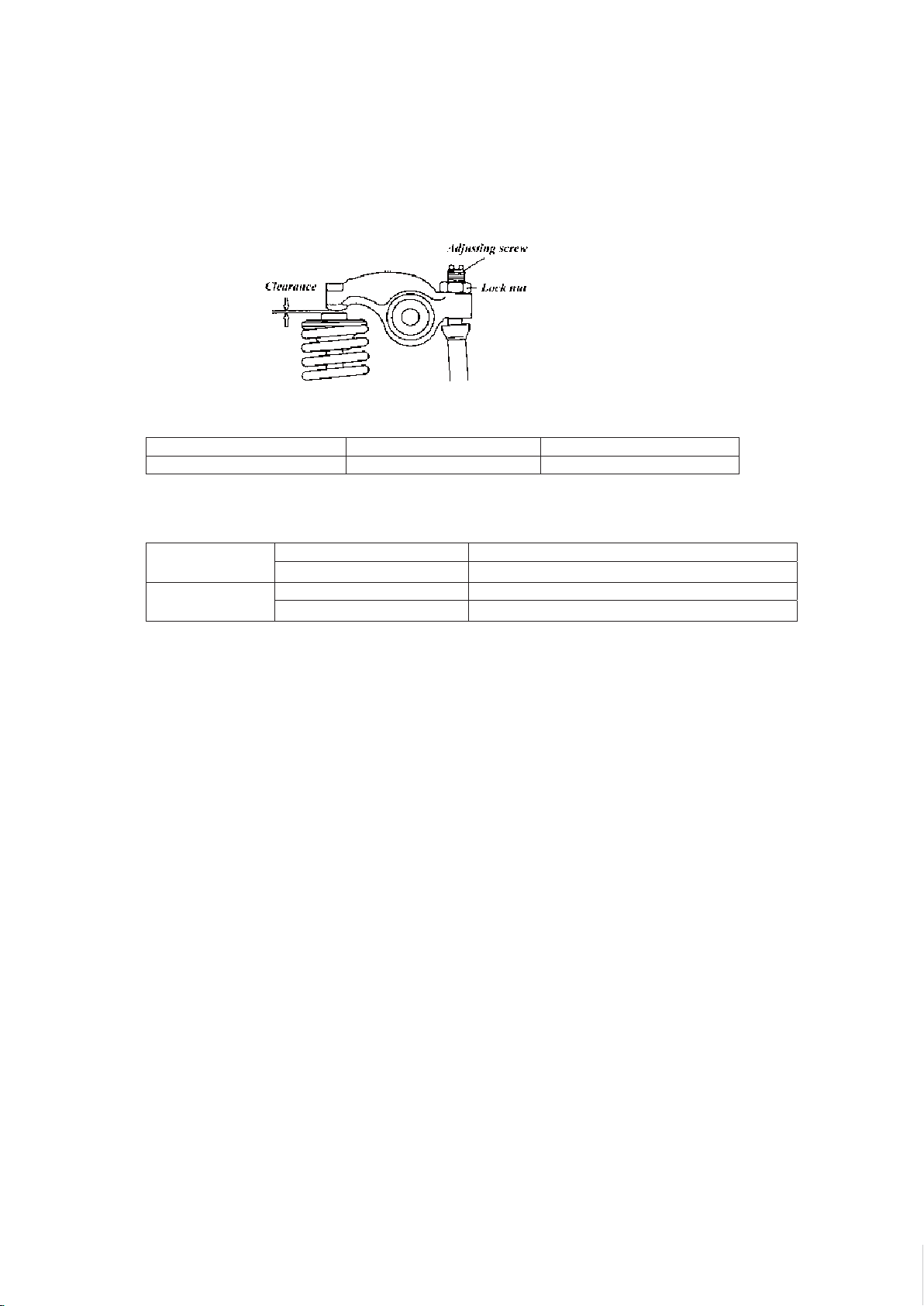

2.2.5 Adjust the va lve clearance

(1) The clearance must be adjusted when the engine is cold.

(2) Valve timing

Intake

Exhaust

Close

Close

POWER PRODUCTS

timiL ecnanetniaM dradnatS

-- mm 51. ecnaraelc tsuahxE/ekatnI

CDT erofeb °41 nepO

50°after BDC

CDB erofeb °45 nepO

10°after TDC

12

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

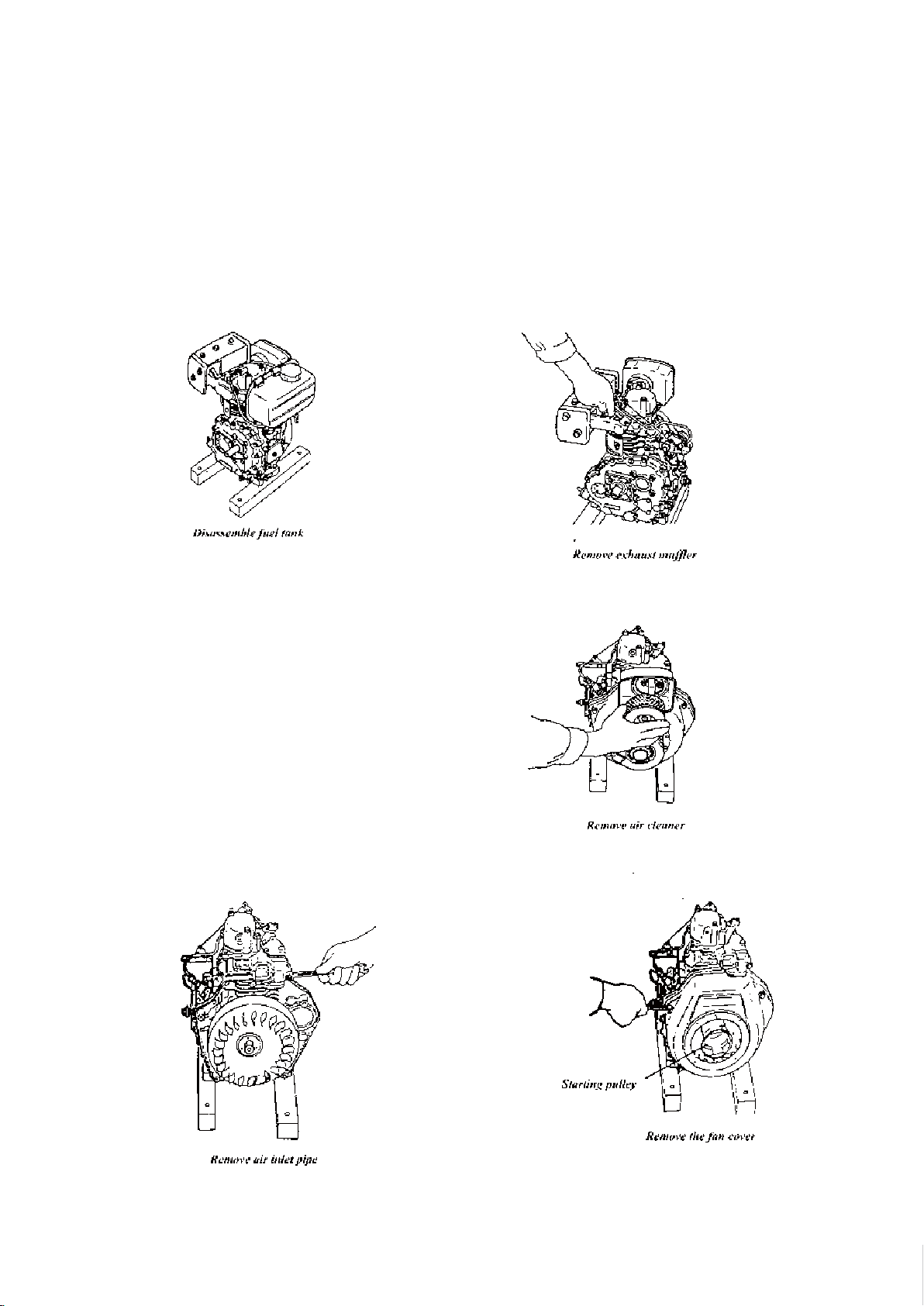

3. Engine disassembly and reassembly

3.1 Disassembly

3.1.1 Fuel tank

1. Release the joint between the fuel line and fuel tank.

2. Release the hose clamp of the fuel line on the pump side.

3. Remove the tank.

POWER PRODUCTS

3.1.2 Exhaust Muffler

1. Remove the flange bolt

2. Remove the set bolt

3. Discard the muffler gasket. Do not reuse.

3.1.3 Air cleaner

(1). Disassemble the air cleaner cover.

(2). Pull out the element.

(3). Disassemble the air cleaner bottom case.

3.1.4 Recoil starter unit

(do not disassemble)

3.1.5 Disassemble the fan cover

Unbolt and remove the fan cover.

4.1.6 Starter pulley

Unbolt and remove

13

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

3.1.7 Air inlet pipe

3.1.8 Remove electric starter motor

3.1.9 Remove cylinder head cover

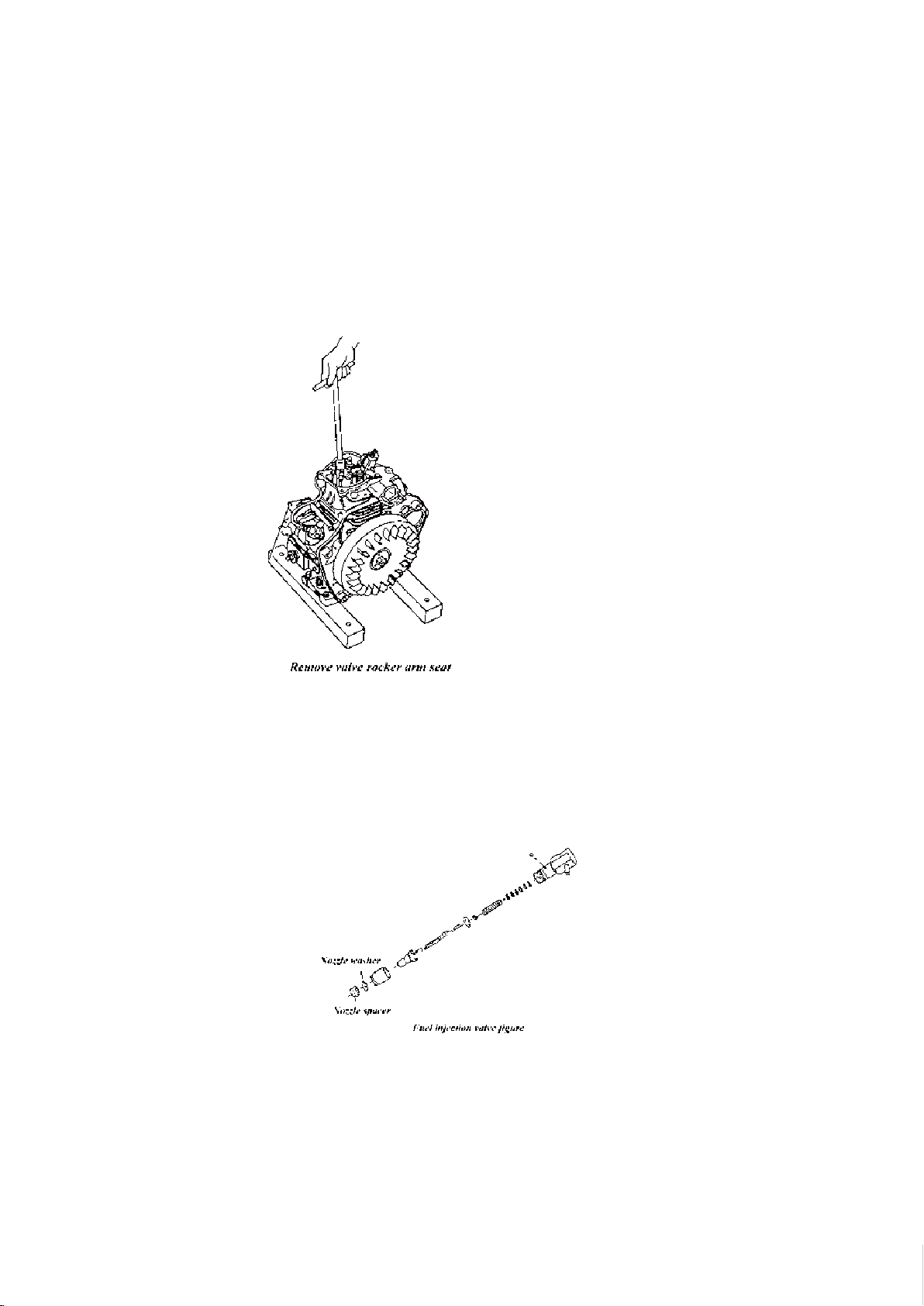

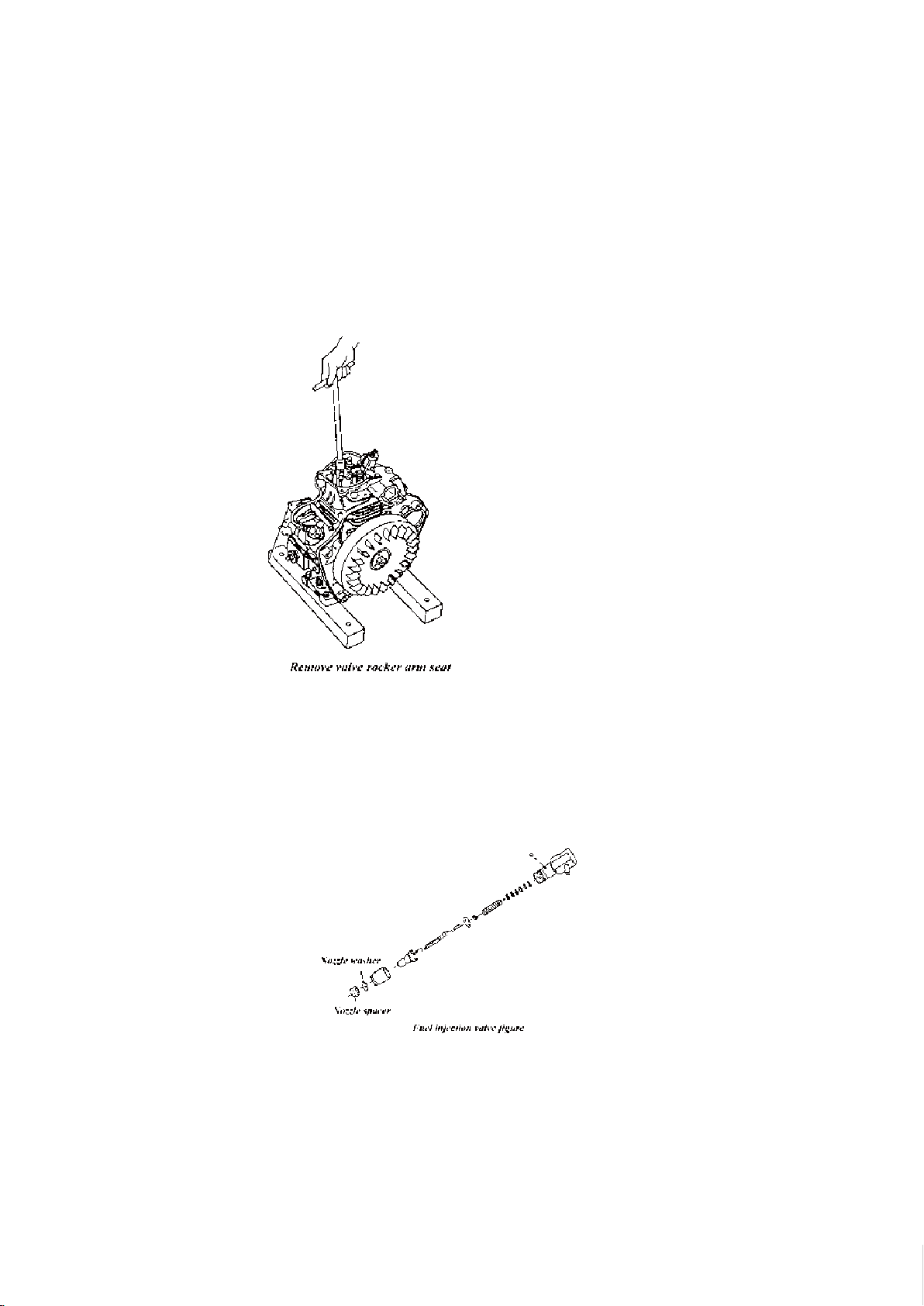

3.1.10 Valve rocker arm seat

POWER PRODUCTS

3.1.11 Push rods

3.1.12 Fuel injector

(1) Remove the high-pressure fuel line.

(2) Remove fuel injector.

(3) Be careful not to damage the nozzle washer and spacer.

14

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

3.1.7 Air inlet pipe

3.1.8 Remove electric starter motor

3.1.9 Remove cylinder head cover

3.1.10 Valve rocker arm seat

POWER PRODUCTS

3.1.11 Push rods

3.1.12 Fuel injector

(1) Remove the high-pressure fuel line.

(2) Remove fuel injector.

(3) Be careful not to damage the nozzle washer and spacer.

15

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

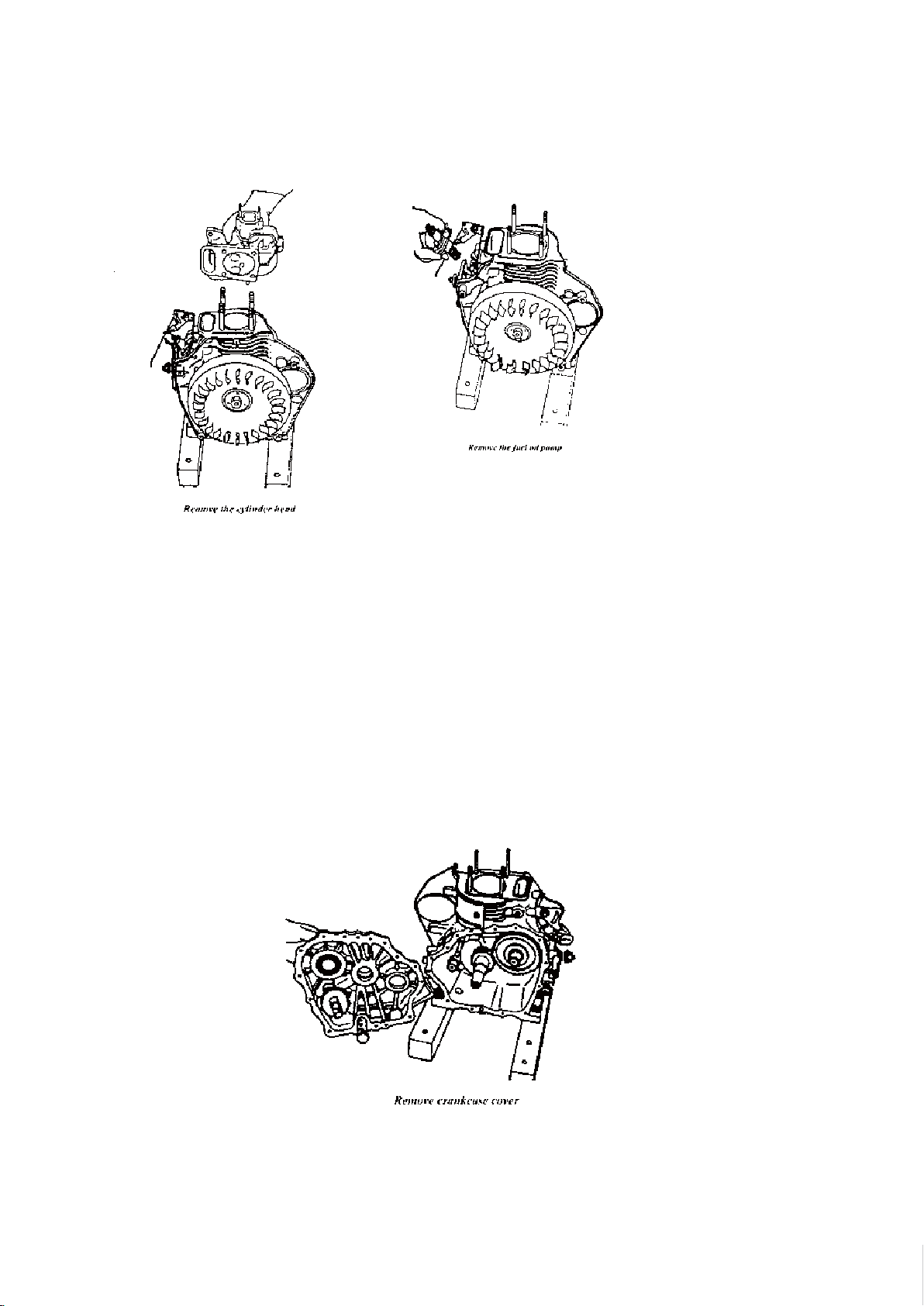

3.1.13 Remove the cylinder head

POWER PRODUCTS

3.1.14 Remove the injection pump

(1) Remove the pump together with the base.

(2) Ensure the hooking part of control lever is at the meshing position before

disassembling.

(3) Pull out the flat tappet remaining inside the housing

3.1.15 Crankcase cover

(1) Remove the engine oil injection pump cover.

(2) Remove the engine oil filter cover.

(3). Remove crankcase cover.

16

Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.Changzhou ITC Power Equipment Manufacturing Co.,Ltd.

Loading...

Loading...