Page 1

User Manual

Read and understand this manual before using machine.

15” PLANER

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY & GUIDELINES

GENERAL SAFETY RULES

ADDITIONAL SPECIFIC SAFETY RULES

FUNCTIONAL DESCRIPTION

CARTON CONTENTS

PRODUCT SPECIFICATIONS..................................6

ATTACHING

HANDWHEEL

......................................3

..................................5

...............................................5

......................................7

.....................2

................4

ATTACHING TOP COVER AND DUST HOOD

HOW TO ATTACH THE WINGS

OPERA

HOW T

HOW TO

HOW TO SET A KNIFE

HOW TO ADJUST THE TABLE ROLLERS

ADJUST THE HEIGHT OF THE CHIPBREAKER

MAINTENANCE

TROUBLESHOOTING

TING CONTROLS AND ADJUSTMENTS

O CONTROL THE FEED SPEED

CHECK, ADJUST & REPLACE KNIVES

..................................................12

..............................................................17

....................................................18

......................................8

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

using tools or equipment, basic safety precautions should always be followed to reduce the risk of

personal injury. Improper operation, maintenance or modification of tools or equipment could result in

serious injury and property damage. There are certain

designed. We strongly recommends that this product

application other than for which it was designed.

Read all warnings and operating instructions before using any tool or equipment. When

applications for which tools and equipment are

NOT

be modified and/or used for any

................8

............9

.......................10

.........11

.....................14

..........15

SAVE THESE INSTRUCTIONS!

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR

SAFETY and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

DANGER:

WARNING:

CAUTION:

NOTICE:

WARNING:

contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

Lead from lead-based paints

Crystalline silica from bricks and cement and other masonry products

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well-ventilated area, and work with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

indicates an imminently hazardous situation which, if not avoided,

indicates a potentially hazardous situation which, if not avoided,

indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

indicates a practice not related to personal injury which, if not avoided, may result in property dam

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

will result in death or serious injury.

could result in death or serious injury.

age.

2

Page 3

GENERAL SAFETY RULES

Failure to follow these rules may result in serious personal injury.WARNING:

For your own safety, read the instruction manual 1.

before operating the machine. Learning the machine’s

application, limitations, and specific hazards will greatly

minimize the possibility of accidents and injury.

Wear eye and hearing protection and always use 2.

safety glasses. Everyday eyeglasses are not safety

glasses. Use certified safety equipment. Eye protection

equipment should comply with ANSI Z87.1 standards.

Hearing equipment should comply with ANSI S3.19

standards.

Wear proper apparel. 3. Do not wear loose clothing, gloves,

neckties, rings, bracelets, or other jewelry which may get

caught in moving parts. Nonslip protective footwear is

recommended. Wear protective hair covering to contain

long hair.

Do not use the machine in a dangerous environment. 4.

The use of power tools in damp or wet locations or in rain

can cause shock or electrocution. Keep your work area

well-lit to prevent tripping or placing arms, hands, and

fingers in danger.

Do not operate electric tools near flammable liquids 5.

or in gaseous or explosive atmospheres. Motors and

switches in these tools may spark and ignite fumes.

Maintain all tools and machines in peak condition. 6.

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories. Poorly maintained tools and

machines can further damage the tool or machine and/or

cause injury.

Check for damaged parts. 7. Before using the machine,

check for any damaged parts. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

and any other conditions that may affect its operation.

A guard or any other part that is damaged should be

properly repaired or replaced with SCTW or factory

authorized replacement parts. Damaged parts can cause

further damage to the machine and/or injury.

Keep the work area clean. 8. Cluttered areas and benches

invite accidents.

Keep children and visitors away. 9. Your shop is a

potentially dangerous environment. Children and visitors

can be injured.

Reduce the risk of unintentional starting. 10. Make sure

that the switch is in the “OFF” position before plugging in

the power cord. In the event of a power failure, move the

switch to the “OFF” position. An accidental start-up can

cause injury. Do not touch the plug’s metal prongs when

unplugging or plugging in the cord.

Use the guards. 11. Check to see that all safety devices are

in place, secured, and working correctly to prevent injury.

Remove adjusting keys and wrenches before starting 12.

the machine. Tools, scrap pieces, and other debris can

be thrown at high speed, causing injury.

Use the right machine. 13. Don’t force a machine or an

attachment to do a job for which it was not designed.

Damage to the machine and/or injury may result.

Use recommended accessories. 14. The use of accessories

and attachments not recommended by SCTW may cause

damage to the machine or injury to the user.

Use the proper extension cord. 15. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord

will cause a drop in line voltage, resulting in loss of power

and overheating. See the Extension Cord Chart for the

correct size depending on the cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord.

Secure the workpiece. 16. Use clamps or a vise to hold the

workpiece when practical. Loss of control of a workpiece

can cause injury.

Feed the workpiece against the direction of the 17.

rotation of the blade, cutter, or abrasive surface.

Feeding it from the other direction will cause the

workpiece to be thrown out at high speed.

Don’t forc

the machine and/or injury may result.

Don’t overreach. 19. Loss of balance can make you fall into

a working machine, causing injury.

Never stand on the machine. 20. Injury could occur if the

tool tips, or if you accidentally contact the cutting tool.

Never leave the machine running unattended. 21. Turn

the power off. Don’t leave the machine until it comes to a

complete stop. A child or visitor could be injured.

Turn the machine “22. OFF”, and disconnect the machine

from the power source before installing or removing

accessories, changing cutters, adjusting or changing

set-ups. When making repairs, be sure to lock the start

switch in the “OFF” position. An accidental start-up can

cause injury.

Make your workshop childproof with padlocks, master 23.

switches, or by removing starter keys. The accidental

start-up of a machine by a child or visitor could cause

injury.

Stay alert, watch what you are doing, and use 24.

common sense. Do not use the machine when you

are tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating

power tools may result in injury.

25.

disperse dust or other airborne particles, including

wood dust, crystalline silica dust and asbestos dust.

Direct particles away from face and body. Always operate

tool in well ventilated area and provide for proper dust

removal. Use dust collection system wherever possible.

Exposure to the dust may cause serious and permanent

respiratory or other injury, including silicosis (a serious

lung disease), cancer, and death. Avoid breathing the

dust, and avoid prolonged contact with dust. Allowing

dust to get into your mouth or eyes, or lay on your skin

may promote absorption of harmful material. Always

use properly fitting NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure, and wash

exposed areas with soap and water.

e the workpiece on the machine. 18. Damage to

WARNING:

Use of this tool can generate and

3

Page 4

ADDITIONAL SPECIFIC SAFETY RULES

WARNING:

1.

DO NOT OPERATE THIS MACHINE until it is

completely assembled and installed according to the

instructions. A machine incorrectly assembled can

cause serious injury.

2. OBTAIN ADVICE from your supervisor, instructor,

or another qualified person if you are not thoroughly

familiar with the operation of this machine. Knowledge

is safety.

3.

FOLLOW ALL WIRING CODES and recommended

electrical connections to prevent shock or

electrocution.

4. KEEP KNIVES SHARP and free from rust and pitch.

Dull or rusted knives work harder and can cause

kickback.

5. NEVER TURN THE MACHINE “ON” before clearing the

table of all objects (tools,scraps of wood,etc.). Flying

debris can cause serious injury.

6. NEVER TURN THE MACHINE “ON” with the work- piece

contacting the cutterhead. Kickback can occur.

7. SECURE THE MACHINE TO A SUPPORTING SURFACE to prevent the machine from sliding, walking or

tipping over.

8. PROPERLY SECURE THE KNIVES IN THE CUTTERHEAD before turning the power “ON”. Loose blades

may be thrown out at high speeds causing serious

injury.

9. LOCK THE SPEED SETTING SECURELY before feeding

the workpiece through the machine. Changing speeds

while planing can cause kick-back.

10. AVOID AWKWARD OPERATIONS AND HAND POSI-

TIONS. A sudden slip could cause a hand to move

into the knives.

11. KEEP ARMS, HANDS, AND FINGERS away from the

cutterhead, the chip exhaust opening, and the feed

rollers to prevent severe cuts.

12. NEVER REACH INTO THE CUTTERHEAD AREA while

the machine is running. Your hands can be drawn into

the knives.

13. DO NOT STAND IN LINE OF THE WORKPIECE

Kickback can cause injury.

Failure to follow these rules may result in serious personal injury.

14. ALLOW THE CUTTERHEAD TO REACH FULL SPEED

before feeding a workpiece. Changing speeds while

planing can cause kickback.

15. WHEN PLANING BOWED STOCK place the concave

(cupdown) side of the stock on the table and cut with

the grain to prevent kickback.

16. DO NOT FEED A WORKPIECE that is warped , contains

knots, or is embedded with foreign objects (nails,

staples, etc.). Kickback can occur.

17. DO NOT FEED A SHORT, THIN, OR NARROW

WORKPIECE INTO THE MACHINE. Your hands can be

drawn into the knives and/or the workpiece can be

thrown at high speeds. See the Operation section of

this instruction manual for details.

DO NOT FEED A WORKPIECE

18.

the machine. The workpiece will be thrown out of the

opposite side at high speeds.

19. REMOVE SHAVINGS ONLY with the power “OFF” to

prevent serious injury.

20. PROPERLY SUPPORT LONG OR WID

Loss of control of the workpiece can cause serious

injury.

21. NEVER PERFORM LAYOUT, ASSEMBLY or set-up work

on the table/work area when the machine is running.

Serious injury will result.

22. TURN THE MACHINE “OFF”, DISCONNECT IT FROM

THE POWER SOURCE, and

before leaving the machine. LOCK THE SWITCH IN

THE “OFF” POSITION to prevent un-authorized use.

Someone else might accidentally start the machine

and cause injury to themselves or others.

23. ADDITIONAL INFORMATION regarding the safe and

proper operation of power tools (i.e. a safety video)

is available from the Power Tool Institute, 1300

Sumner Avenue, Cleveland, OH 44115-2851 (www.

powertoolinstitute.com). Information is also available

from the National Safety Council, 1121 Spring Lake

Drive, Itasca, IL 60143-3201. Please refer to the

American National Standards Institute ASNI 01 .1

Safety Requirements for Woodworking Machines and

the U.S. Department of Labor Regulations.

into the outfeed

E W ORK-PIECES.

clean the table/work

end of

area

SAVE THESE INSTRUCTIONS

Refer to them often and use them to instruct others.

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should be

protected with a time delay fuse. NOTE: Time delay fuses should be marked “D” in Canada and “T” in the US. If an extension

cord is used, use only 3-wire extension cords which have 3-prong grounding type plugs and matching receptacle which will

accept the machine’s plug. Beforeconnecting the machine to the powerline, make sure the switch is(are) in the“OFF”position

and be sure that the electric current is of the same characteristics as indicated on the machine. All line connections should

make good contact. Running on low voltage will damage the machine.

DANGER:

Do not expose the machine to rain or operate the machine in damp locations.

4

Page 5

FOREWORD

FUNCTIONAL DESCRIPTION

This Model

has cutting capacities of 15" (381mm) width, 6-1/2" (165mm) thick, and 1/8" (5mm) depth of cut. Feed rate is 16/20 FPM.

NOTICE: The photo on the manual cover illustarates the current production model. All other illustrations contained in the

manual are representative only and may not depict the actual labeling or accessories included. These are intended to

illustrate technique only.

is a 15" (381mm) Planer with an adjustable feed rate for optimum planing underload. This machine

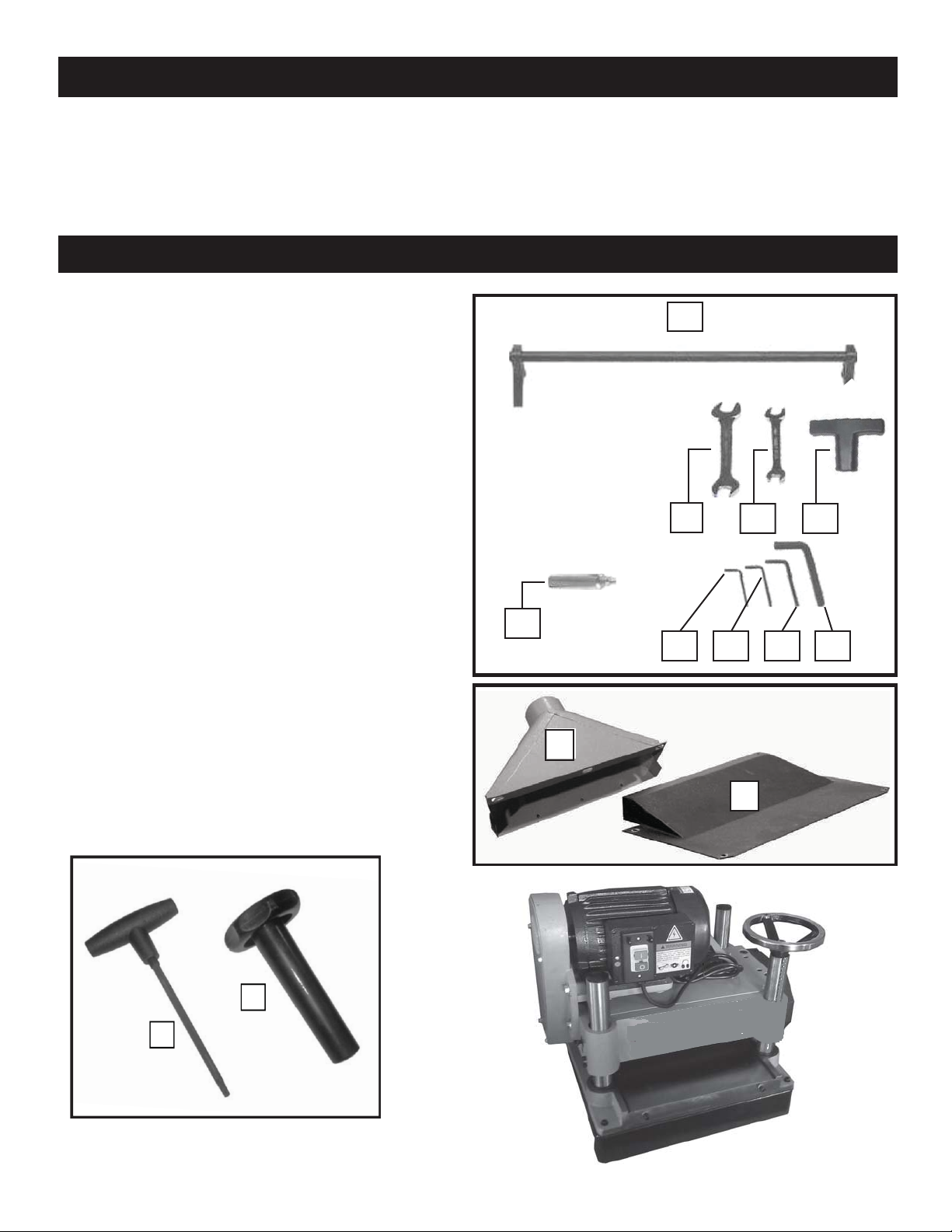

CARTON CONTENTS

Your new 15" (381 mm) planer head is shipped

complete in one box. The machine is very heavy.

Take care when you remove the machine. (See the

section How To Lift The Machine).

nepO .xob emas eht ni semoc dnats renalP ehT

and locate all parts prior to assembly.

1. Knife setting gauge (straight knife only)

2. Open endwrench (14 and 17mm)

3. Open endwrench (10 and 12mm)

4. Handwheel handle

5. Shifter knob

6. 2.5 mm hex wrench

7. 3 mm hex wrench

8. 4 mm hex wrench

9. 6 mm hex wrench

10. Dust hood

11. Top cover (installed)

12.

Planer head

13.

Torx tool

14.

Lock knob (long)

4

1

2

6

3

7

5

8 9

13

10

11

14

14

13

13

5

Page 6

PRODUCT SPECIFICATIONS

Capacities

Maximum stock width 15-in.

Maximum stock thickness 6-in.

Maximum depth-of-cut 1/8-in.

Minimum length of stock 7-in.

Feed Rate 16-20 FPM

Cutterhead

Number of Knives 3

Cuts Per Minute 15,000

Motor Specifications

Product Dimensions

Footprint 27.5” x 28”

Length 44”

Width 28”

Height 42-1/2”

Weight 9 lbs. / 204 kg

Wings

MPR0005deepS

”8/7-2retemaiD

noitcudnIepyT

Shipping Dimensions

Carton Type Wooden Crate

Length 27”

Width 31”

Height 25-1/2”

Gross Weight lbs. / 2 kg

12” x 14-1/2”

Horsepower 3HP

21spmA

V 042-02V 2egatlo

elgniSesahP

DEFINITION OF TERMS

Workpiece – The wood or lumber that you are working

on.

Planing – Refers to the sizing of the lumber to a

desired thickness, while creating a level surface.

Snipe – Gouging that can occur at the end of a board.

Chatter Marks – An uneven “washboard” type of cut

caused by incorrect chipbreaker settings.

Chip Marks – Occur when knives catch the chips and

drag them across the lumber being planed, caused by

exhaust blockage or improper chip deflector settings

Tear Out – Deep gouging caused by improper chipbreaker settings.

6

Page 7

ATTACHING HANDWHEEL

Attach handwheel handle (N) Fig.7 to handwheel (O).

1.

Use 12 mm open end wrench on flats to tighten.

2. Attach handwheel (O) to elevation shaft (may be installed prior)

(P) Fig.8 Install and tighten washer and nut Fig.9A (A+B).

NOTE: Be sure two head-locking knobs

(S) Fig.10 are loose before raising head assembly.

3. Raise head assembly and remove shipping brace.

Fig.9

Fig.7

N

O

Fig.9A

A

Fig.10

Fig.8

P

R

B

S

7

Page 8

ATTACHING TOP COVER AND DUST HOOD

Using a 10mm wrench, fasten top cover (T) Fig.11 to

1.

planer head using three M6 hex head flange screws at

three spots (U).

NOTE: May be installed prior.

2. Loosen bolts (V&W) Fig.12 with provided 17 mm wrench

and fit the dust collector’s slots (W) down behind the

washers. Be sure the top lip of the dust collector rests

on top of the top cover.

3. Attach top & bottom of dust collector at 6 points (X) Fig.13.

4. Tighten bolts (V&W) Fig.12.

W

T

U

Fig.11

X

Fig.12

V

Fig.13

HOW TO ATTACH THE WINGS TO THE HEAD ASSEMBLY AND TO THE BASE

1.

Attach the wings (A) Fig.16 to base using the Hex head

Allen screws (B) Fig.18 two per side with washers

as shown.

2. Then use the adjustments screws in the wings (C)

Fig 18 to level. Level using a straight edge on the bed

and each wing.

3. Rear aligned wing shown Fig.19.

B

Fig.16

C

A

X

Fig.17 Fig.18 Fig.19

8

Page 9

OPERATING CONTROLS AND ADJUSTMENTS

HOW TO START AND STOP THE MACHINE

1. The on/off switch is located on the front of the planer. To turn the machine “ON”, push the START button (A) Fig.30.

2. To turn the machine “OFF”, push the STOP button (B) Fig.30.

WARNING:

the plug’s metal prongs when unplugging or plugging in the cord.

Make sure that the switch is in the “OFF” position before plugging cord into outlet. Do not touch

HOW TO LOCK THE SWITCH IN THE "OFF" POSITION

IMPORTANT: When the machine is not in use, the switch should be locked in the “OFF” position to prevent unauthorized

use, using a padlock (B) Fig.31 with a 1/8 (8.17mm) diameter shackle. Note: Different style switch is shown for clarity.

A

C

N

B

Fig.30

Fig.32

WARNING:

machine. Never use this machine without the dust chute

attached. You can install a standard 4"diameter flexible dust

collection hose directly to chute for optimal chip and dust

collection.

HOW TO ADJUST FOR DEPTH OF CUT

The depth of cut on your planer is controlled by raising or lowering the head assembly (A) Fig.33 that contains the cutter head

and feed rollers. The head assembly (A) moves on four

the two head assembly lock-knobs, one of which is shown at (C) Fig.32, and turn the head elevating handwheel (D). (T urning the

handwheel (D) clockwise raises the head assembly. Counterclockwiselowers it).Tighten the two head assembly lock knobs (C).

The maximum depth of cut when planing stock narrower than 6" (152mm) wide is 3/16" (4.76mm). A limiter (E) Fig.34 limits

the depth of cut to 1/8"(3.18mm) on stock wider than 6"(152mm). (Helical unit only).

A dust chute (N) Fig.32 is attached to the

B

Fig.31

steel columns,three of which are shown at (B).To adjust, loosen

Fig. 33

B

D

B

A

B

C

9

E

Fig.34

Page 10

HOW TO CONTROL THE FEED SPEED

NOTICE:

Your planer has two feed roll speeds: 16/20fpm and 8/10cm per second. The slower feed rate provides more cuts per inch and

a finer, smoother finish. For efficiency, operate the machine at the faster feed rate for general planing and switch to the slower

feed rate for the final finish. When planing wide stock-wider than 8" (203mm) - particularly in hard wood, the slower feed speed

is better because of less strain on the motor and a better finish.

With the shifter knob (S) Fig.35 pushed all the way in, the feed speed is 20fpm (10cm/s). With it pulled all the way out, the feed

speed is 16fpm (8cm/s). When the knob is in the center (neutral) position, the machine will not feed.

Change speeds only while the motor is running. DO NOT change speeds while planing.

USE OF THE ANTI-KICKBACK FINGERS

WARNING:

A series of anti-kickback fingers (A) Fig.36 are provided on the infeed end of the planer. These anti-kickback fingers.

operate by gravity and no adjustment is required. However, you should inspect them occasionally to confirm that they

are free of gum and pitch and that they move and operate correctly.

When inspecting and cleaning the anti-kickback fingers, disconnect the machine from the power source.

S

Fig.35 Fig.36

HOW TO ADJUST BELT TENSION

WARNING:

1. Take out the four bolts (A) Fig.37 to remove the belt and pulley guard cover (B).

Place a 2x4 (D) Fig.38 between the motor plate and the top of the head casting.

2.

3. Loosen the four screws (C) Fig.38. Leverage the motor plate upward until the belts deflects approximately

1/4"

4. Tighten the three screws (C) Fig.38 and replace the belt and pulley guard cover (B) Fig.37.

Disconnect the machine from the power source.

(6.4mm) in the center span with light finger pressure.

B

C

D

A

A

Fig.37 Fig.38

10

Page 11

HOW TO CHECK, ADJUST, AND REPLACE KNIVES

WARNING:

are very sharp.

WARNING:

1. Remove the four screws, three of which are shown at (A) Fig.39 and the screw (B) Fig.40.

Remove the top cover.

2. Loosen the two screws (C) Fig. 41 and pivot the motor assembly to the front.

NOTE: Belt tension is not disturbed when pivoting the motor forward.

3.

Take out the three bolts (E) Fig.42 and remove the chip deflector (F).

Wear gloves when you remove the knives for sharpening or replacement. The knives in this planer

Disconnect the machine from the power source.

A

A

Fig.39 Fig.40

B

E

F

C

4. To check and adjust the knives:

A. Carefully place the knife-setting gauge (G) Fig. 43 on the cutter head.

B. Correctly adjusted knives (H) Fig.44 will contact the bottom of the gauge (J) at each end. Check all three knives.

Fig.41

J

G

H

Fig.43

Fig.44

Fig.42

11

Page 12

HOW TO SET A KNIFE

Loosen (clockwise) all five locking screws, two of which

are shown at (K) Fig.45. Use the supplied wrench to turn

Fig. 45

H

N

the hex screw (L) Fig.45 counterclockwise to lower or clockwise

to raise the knife on each end of the cutterhead until the cutting

edge of knife (H) Fig.44 touches the bottom of the gauge

L

(J) Fig.44. Tighten the knife locking bar (N) Fig.45 by lightly

backing out the five locking screws (K) Fig.45 against

the knife slot.

IMPORTANT: Tighten the knife in the slot only enough

to hold it in position.

K

After all three knives are set, tighten the five locking screws (K) Fig.45 against the slot. Start with the end screws first, then the

center screws until the knife is secure. Tighten the other knives in the same manner.

HOW TO CLEAN AND CHECK THE KNIVES

WARNING:

WARNING:

A. Remove the knife (H) Fig.46, lockingbar (N), and

locking screws (K) from the cutterhead. Repeat

this process for the other knives, locking bars,

and locking screws.

B. Thoroughly clean the knives, knife slots, locking

bars, and locking screws. If the threads of the

screws appear worn or stripped, or if the heads

are becoming rounded, replace them.

C. Insert the locking bars, knives, and screws in all

three slots in the cutterhead. Loosen the locking

screws, two of which are shown at (K) Fig.45

enough to hold all three knives in the cutterhead.

D. Adjust all three knives as explained under STEP 4.

Wear gloves when you remove the knives for sharpening or replacement. The knives are very sharp.

Disconnect the machine from the power source.

Fig. 46

H

N

K

IMPORTANT: After the knives have been adjusted, replace the chips deflector that was removed in STEP 3 and the top cover

that was removed in STEP 1 (under HOW TO CHECK, ADJUST AND REPLACE KNIVES). Pivot the motor assembly back to

its original place.

(SEE NEXT PAGE FOR LARGER DIAGRAM)

HOW TO CONSTRUCT THE GAUGE BLOCK

Use a gauge block to check and adjust the height of the

chipbreaker and the infeed and outfeed roll. Adjust the

cutterhead parallel to the table. Construct a gauge block

from hard wood using the dimensions in Fig.47.

4"

(101.6mm)

3"

4"

(101.6

mm)

(76.2mm)

12

Fig. 47

2"(50mm)

1/2"

(12.7mm)

1/4" (6.35mm)

Page 13

GRAIN

13

Page 14

HOW TO ADJUST THE TABLE ROLLERS

Your planer is supplied with two table rollers (A) Fig.56 that help feed the stock by reducing friction.

Since each type of wood behaves differently, exact dimensions of the proper height setting are not

available. Generally, however, when planing a rough workpiece, set the table rollers HIGH (0.003”

to 0.005”) (.08mm to .13mm) above the work surface. When planing a finish workpiece, set the table

rollers LOW (0.001”) (.03mm) above the table surface or level with the table surface. The table rollers

on your planer are set for average planing and are parallel to the table surface.

(FURTHER INSTRUCTIONS INCLUDED WITH THE “MAKING CUTTING HEAD PARALLEL”)

Fig. 56

A

14

Page 15

ADJUST THE HEIGHT OF THE CHIP BREAKER

The chip breaker extends down around the front of the cutter head and raises as the stock is fed through the planer. The chip

breaker “breaks or curls” the chips as they leave the cutter head. The bottom edge of the chip breaker helps hold the stock flat

on the table. Confirm that the bottom of the chip breaker is parallel to the knives and set 0.020” (0.5mm) below the cutting circle.

WARNING:

1. Make certain the knives are adjusted properly as explained under HOW TO CHECK, ADJUST AND REPLACE KNIVES.

2. Place the gauge block (A) Fig.48 on the table directly under the cutter head. Use a 0.020” (0.5mm) feeler gauge (B) placed

on top of the gauge block. Raise or lower the head assembly until one of the knives touches the feeler gauge. Lock the

head assembly.

3. Place the gaugeblock (A) Fig.48 without the feeler gauge

underone end of the chip breaker (C) Fig.49. The bottom of

the chip breaker (C) should touch the top of the gauge block.

4. To adjust the height of the chip breaker, remove the top

cover of the machine. Loosen the nut (D) Fig.50. Turn the

screw (E) until that end of the chip breaker is properly

adjusted. Tighten the nut (D).

5. Place the gauge block on the other end of the chip breaker

Loosen the nut(F)Fig.50and turn the adjusting screw (G).

Disconnect the machine from the power source.

Fig.48

B

A

G

C

E

F

D

A

Fig.49

Fig.50

HOW TO ADJUST THE HEIGHT OF THE INFEED ROLLER

The infeed roller was adjusted at the factory at 0.040" (1.01mm) below the cutting circle. To check and adjust the height of the

infeed roller:

WARNING:

1. Confirm that the knives are adjusted properly as explained

under HOW TO CHECK, ADJUST AND REPLACE KNIVES.

2. Place the gauge block (A) Fig.51 on the table directly

underneath the cutterhead. Use an 0.040” (1.01mm) feeler

gauge (B) placed on top of the gaugeblock. Raise or lower

the head assembly until one of the knives touches the feeler

gauge. Tighten the head-locking knobs.

Disconnect the machine from the power source.

Fig.51

B

A

15

Page 16

3. Move the gauge block (A) Fig.52 without the feeler gauge

under one end of the infeed roller (C). The bottom of the infeed

roller (C) should touch the top of the gauge block (A).

4. To adjust, loosen the nut (D) Fig.52 and turn the adjusting set

screw (E) until that end of the infeed roller touches the top of

the gauge block. Tighten the nut (D).

D

E

5. Repeat this adjustment with the gauge block on the opposite

end of the infeed roller.

A

HOW TO ADJUST THE HEIGHT OF THE OUTFEED ROLLER

The outfeed roller was adjusted at the factory to be 0.040" (1.01 mm) below the cutting circle. To check and adjust

the height of the outfeed roller:

C

Fig.52

WARNING:

1. Make sure the knives are adjusted properly as ex plained under HOW TO CHECK, ADJUST AND REPLACE KNIVES.

2. Place the gauge block (A) Fig.53 on the table directly underneath the cutterhead. Place a 0.040” (1.01mm) feeler gauge (B)

on top of the gauge block. Raise or lower the head assembly until one of the knives touches the feeler gauge. Tighten the

head locking knobs.

3. Move the gauge block (A) Fig.54 without the feeler gauge under the end of the outfeed roller (C). The bottom of the outfeed

roller (C) should touch the top of the gauge block (A).

4. To adjust, loosen the nut (D) Fig.54 and turn the screw (E) until the outfeed roller is properly adjusted.

5. Repeat this adjustment procedure on the opposite end of the outfeed roller.

Disconnect the machine from the power source.

C

D

B

A

E

Fig.53

Fig.54

A

HOW TO ADJUST THE TENSION OF THE INFEED AND OUTFEED ROLLERS

The infeed and outfeed are under spring tension. The tension

should be sufficient to feed the stock uniformly without slipping,

but should not be so tight that it causes damage to the board.

The tension should be equal at both ends of each roller. To adjust

the spring tension of the infeed roller, turn two screws, one of which

is shown at (A) Fig.55. The other screw is located on the opposite

side of the machine. Adjust the two screws (A) until FOUR (4)

thread show above the table casting. Further tension adjustment

may be necessary. To adjust the spring tension of the outfeed

roller, turn two screws, one of which is shown at (B) Fig.55. The

other screw is located on the opposite side of the machine. Adjust

the two screws (B) until ONE thread shows above the table casting.

Further tension adjustment may be necessary.

16

A

B

Fig.55

Page 17

MAINTENANCE

GENERAL

ake a habit of inspecting your planer each time you

M

use it. Check the following conditions and repair or

replace as necessary.

1. Worn Switch

2. Damaged cords and/or plugs

3. Damaged belts

4. Loose bolts

5. Any other condition that could hamper the safe and

proper operation of the machine.

TABLE

The table and other non-painted surfaces on the planer

should be protected against rust. Be sure to wipe the

table clean after every use. This will help prevent

moisture from the wood condensing on the bare metal

table. It is also a good idea to use an automotive paste

wax on the bare metal surfaces. This will keep moisture

from the table and hence help keep it from rusting. Over

time , some rust may still develop on the table. To get rid

of the rust, use some WD-40 and a fine steel wool.

GEAR BOX

Gear box oil should be drained after the first 20 hours

of operation. Replace with 80W -90 gear oil for use in

room temperature shops and 50W gear oil for unheated

winter shops. Inspect levels periodically and change

yearly for occasional use, more frequently with heavy use.

To inspect oil level,

1. Remove fill plugusing the short end of a hex

wrench, dip the wrench inside the fill hole and

rotate so the long end of the wrench is parallel to

the table.

2. Remove the wrench. If the end of the hex wrench

is coated with oil, then the gearbox level is okay.

3. If the end of the hex wrench is not coated with oil,

then you need to add more oil.

4. Replace fill plug when finished.

DRIVE CHAIN

The drive chain should be inspected and lubricated

monthly using a general purpose grease.

KNIVES

Make sure that your knives are sharp and properly

adjusted before eachuse. The sharpness and proper

setting of the knives is essential to good planing. Refer

back to the section on knives in this manual for detailed

instructions.

LUBRICATION:

BEARINGS

Your planer is equipped with factory sealed bearings

requiring no lubrication during its lifetime. If the bearing

should fail, the planer will produce a pronounced rumble

that will get even louder under load. If it is allowed to get

worse, overheating can occur and eventually the bearing

can seize up, possibly cuasing damage to other parts of

the machine.

FEED ROLLER

The infeed / outfeed pressure setscrews double as the

lubrication ports for the rollers. Add 1-2 drops of light

machine oil to all ports before every use. Daily

lubrication of feed rollers is CRUCIAL to the operation

of the planer. Lubricate before start up.

CHAIN

The table height adjustment chain should be inspected

regularly and lubricated as needed. Lubricate with a

general purpose grease.

17

Page 18

TROUBLESHOOTING GUIDE

This section covers the most common processing problems encountered in planing and what to do about them. Do not make any

adjustments until planer is unplugged and moving parts have come to a complete stop. See the section on Wood Characteristics

for additional troubleshooting information.

PROBLEM LIKELY CAUSE(S) SOLUTION

Motor will not start.

Motor will not start;

fushes or circuit

breakers blow.

Motor overheats.

Motor stalls

(resulting in blown

fuses or tripped

circuit).

Machine slows

when operating.

Loud, repetitious

noise coming from

machine.

1. Low voltage.

2. Open circuit in motor or loose connections.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose connections.

3. Incorrect fuses or circuit breakers in power

line.

1. Motor overloaded.

2. Air circulation through the motor restricted.

1. Short circuit in motor or loose connections.

2. Low voltage.

3. Incorrect fuses or circuit breakers in power

line.

4. Motor overloaded.

1. Feed rate too fast.

2. Depth of cut too great.

1. Pulley setscrews or keys are missing or

loose.

2. Motor fan is hitting the cover.

3. V-belt is defective.

1. Check power line for proper voltage.

2. Inspect all lead connections on motor for loose or open

connections.

1. Inspect cord or plug for damaged insulation and

shorted wires.

2. Inspect all connections on motor for loose or shorted

terminals or worn insulation.

3. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted

terminals or worn insulation.

2. Clean out motor to provide normal air circulation.

3. Install correct fuses or circuit breakers.

4.Reduce load on motor.

1. Change speed.

2. Reduce depth of cut.

1. Inspect keys and setscrews. Replace or tight if

necessary.

2. Tighten fan or shim cover.

3. Replace V-belt.

Machine is loud

when cutting.

Overheats or bogs

down in the cut.

Infeed roller marks

are left on the

workpiece.

Outfeed roller marks

are left on right side

of workpiece.

Cannot control

snipe.

Machine howls on

startup.

Table moves down

while cutting.

1. Excessive depth of cut.

2. Knives are dull.

Depth of cut too shallow Increase depth of cut.

Too much spring tension on feed roller. Refer to Feed Roller Pressure section for adjustment.

Long or heavy board sags as it enters

and exits.

Chip deflector too close to the cutterhead. Move chip deflector back 1/8” to 1/4” from the

1. Knives dull.

2. Table locking knobs are loose.

1. Decrease depth of cut.

2. Sharpen knives.

Lift up on unsupported end of board as it enters and

exits cutterhead.

cutterhead.

1. Replace knives.

2. Tighten table locking knobs.

18

Page 19

DATE MAINTENANCE PERFORMED REPLACEMENT COMPONENTS REQUIRED

19

Loading...

Loading...