Warrior 9000-SR, 9000 User Manual

ELECTRICAL WINCH

9000 / 9000-SR

Assembly & Operating Instructions

INTRODUCTION

Congratulations on your purchase of a winch. We design and build winches to strict

specifications and with proper use and maintenance should bring you years of satisfying

service.

WARNING - Read, study and follow all instructions before operating this

device. Failure to heed these instructions may result in personal injury

and/or property damage.

Your winch can develop tremendous pulling forces and if used unsafely or

improperly could result in property damage, serious injury or death. Throughout

this manual you will find the following symbols for caution, warning and danger.

Pay particular attention to the notes preceded by these symbols as they are written

for your safety. Ultimately, safe operation of this device rests with you, the operator.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. This notation is also used to alert against unsafe

practices.

Indicates a potentially hazardous situation which, if not avoided

could result in death or serious injury.

1/19

CAUTION

WARNING

3/19

GETTING TO KNOW YOUR WINCH

Your 9500lb winch is a powerful piece of machinery. It is important that you

understand the basics of its operation and specifications so that when you

need to use it, you can use it with confidence and safety. Below is a list of

the components of your winch and their use. Practices using your winch

before you are in a situation to need to use it.

1. Motor: Your 3.6/4.6hp motor is powered by a 12/24 volt battery and provides power to

the gear mechanism which turns the drum and winds the wire rope;

2. Winch Drum: The winch drum is the cylinder on which the wire rope is stored. It can

feed or wind the rope depending on the remote winch switch.

3. Wire Rope: Your winch has a 3/8"X65.6' galvanized aircraft cable designed specifically

for load capacity of 9500lbs. The wire rope feeds onto the drum in the “under wind”

position through the roller fairlead and is looped at the end to accept the clevis hook pin.

4. Roller Fairlead: When using the winch at an angle the roller fairlead acts to guide the

wire rope onto the drum and minimizes damage to the wire rope from abrasion on the

winch mount or bumper.

5. Mechanic Gear System: The reduction gears convert the winch motor power into

extreme pulling forces.

6. Braking System: Braking action is automatically applied to the winch drum when the

winch motor is stopped and there is a load on the wire rope. The braking action is applied

by a separate mechanical brake.

7. Free Spooling Clutch: The clutch allows the operator to manually disengage (“Out”) the

spooling drum from the gear train, free spool. Engaging the clutch (“In”) locks the winch

into the gear system.

8. you can control your winch through a solenoid control box by press button of the power

switch which you selected as you like, and you can also operate your winch with wireless

remote control.

9. Solenoid: Power from the vehicle battery flows through the weather sealed switch before

being directed to the winch motor.

4/19

10. Remote Switch: The Power switch lead has a dual switch for powering in

or powering out your winch drum. The Power switch leads allow you to

stand clear of the wire rope when the winch is under load.

11. Wireless Remote Control: allow you control winch far from 50 Ft away.

12. Universal Flat Bed Speed MountTM Hitch Adapter: Your winch has been

optional supplied with a flat bed speed mount

TM

hitch adapter that can be

mounted to most flat surfaces such as trailers, step bumpers, truck beds,

etc. The speed mount

TM

hitch adapter also has holes to accept your roller

fairlead.

13. Snatch Block: If Your winch were supplied with a snatch block that, used

properly, can double the pulling power of winch, or change your pulling

direction without damaging the wire rope. We recommend you to use

double line and snatch block for pulling over 85% related line pull.

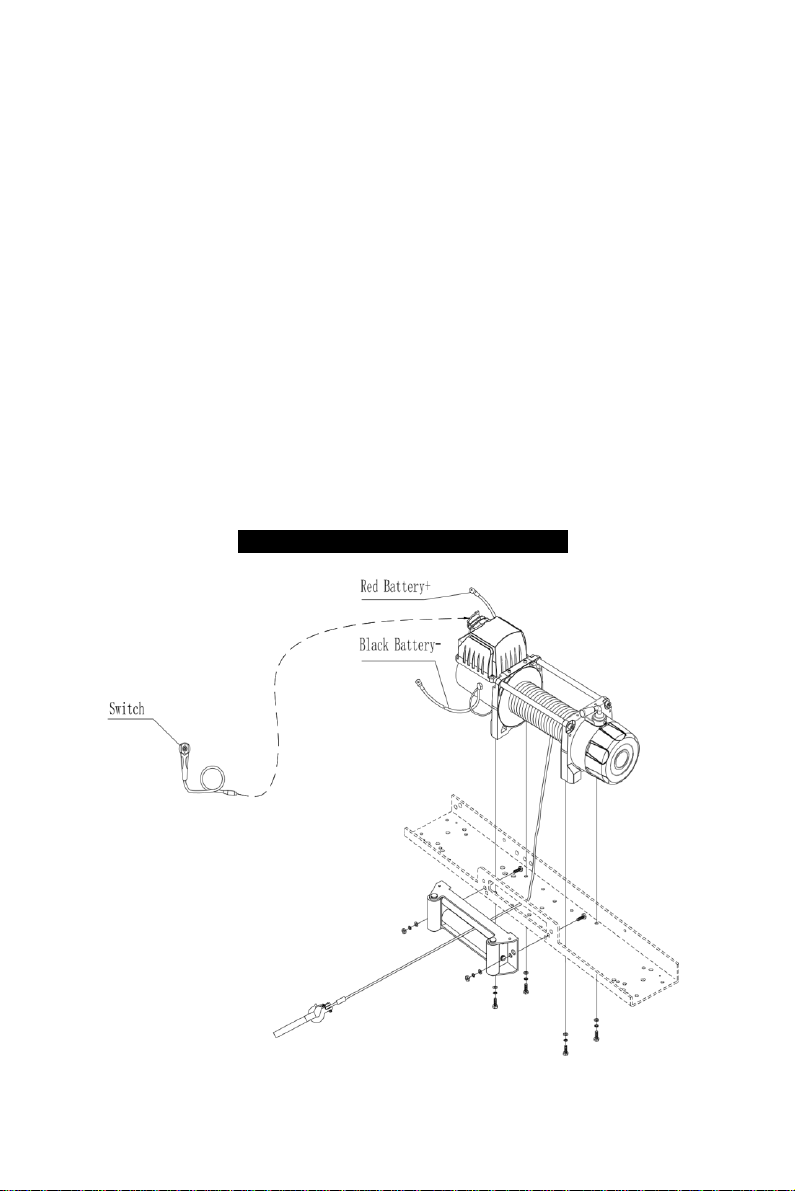

WINCH ASSEMBLY AND MOUNTING

9500:

5/19

1. Your 9500lb winch is designed with a bolt pattern that is standard in this class of

winch. Many winch mounting kits are available that utilize this bolt pattern for the

most popular vehicle and mounting channels. If you cannot find a kit locally,

contact us and we will provide you with the name of a dealer near you. If you will

utilize the mounting channel you must ensure that it is mounted on a flat surface

so that the three major sections (motor, drum and gear housing) are properly

aligned. Proper alignment of the winch will allow even distribution of the full rated

load.

2. Start by connecting the Roller Fairlead (Part# 950700) to the Mounting Channel

(Part# 950025) using 2 each of the Cap Bolt M10 X 35 (Part# 950002), Flat Washer

(Part# 950004), Lock Washer (Part# 950003) and securing with M10 Nut(Part#

950024) (Make sure the bolt is placed through the mounting channel and roller

fairlead from inside the channel. This will allow enough clearance for the winch to

be placed in the channel without obstruction.)

3. Assemble the winch to the Mounting Channel (Part# 950025) by first pulling and

releasing the clutch knob to “Off” position (Free Spooling). Pull out a few inches

of cable from the drum and feed the wire loop through the opening in the front of

the mounting channel and roller fairlead. Now, using the remaining M10 x 35 Cap

Bolts (Part# 950002), Flat Washer (Part# 950004), Lock Washer (Part# 950003)

and M10 Nut (Part# 950005) secure the winch to the mounting channel.

4. Connect the battery and motor leads as the drawing above every type of winch is

different each other.

CAUTION – Batteries contain gases which are flammable and explosive.

Wear eye protection during installation and remove all jewelry. Do not lean over

battery while making connections.

1. Assemble the Clevis Hook to the cable. Take off the pin from the Clevis Hook,

connect the Clevis Hook to the cable and mount the pin back to the Clevis Hook.

2. Always use the Hand Saver when free-spooling and re-spooling the wire rope.

Using the Hand Saver keeps your hands and fingers away from the rotating drum.

3. Check for proper drum rotation. Pull and turn the clutch knob to the “off” position

(Free-spooling). Pull out some cable from the drum, and then turn the clutch knob

to the “In” position to engage the gears. Press the cable out button on the power

6/19

switch. If the drum is turning and releasing more cable then your connections are

accurate. If the drum is turning and collecting more cable then reverse the leads

on the motor “F1”, “F2”. Repeat and check rotation.

SAFETY PRECAUTIONS

WARNING

WARNING – DO NOT EXCEED RATED CAPACITY.

WARNING – Intermittent use only.

WARNING - Do not use winch in lifting or moving or persons.

WARNING - A minimum of five wraps of cable around the drum

barrel is necessary for pulling and holding the rated load. The

cable clamp is not designed to hold the load without 5 wraps of

cable around the barrel.

WARNING - Keep yourself and others a safe distance to the side

of the cable when under tension.

WARNING – The wire rope may break before the motor stalls.

For heavy loads at or near rated capacity, use a pulley

block/snatch block to reduce the load on the wire rope.

WARNING -Never step over a cable, or near a cable under

load.

WARNING - Don’t move the vehicle to pull a load (towing) on the

winch cable. This could result in cable breakage.

WARNING-Disconnect the remote control and battery leads

when not in use.

WARNING- Do not exceed maximum pull rating. Avoid “shock

loads” by using the control switch intermittently to take up the

slack in the wire rope. “Shock loads” can far exceed the rate

capacity for the wire rope and drum.

WARNING- Do not exceeds maximum line pull ratings shown on

the tables.

Loading...

Loading...