Page 1

Protecting Your Adventure Lifestyle

========================================================================================

QUALITY • INTEGRITY • INNOVATION • SERVICE

Warrior, Inc.

16850 SW Upper Boones Ferry Rd

Ste. A

Durham, OR 97224

Phone: (888) 220-6861

Fax: (503) 692-0364

sales@warriorproducts.com

www.warriorproducts.com

FJ Cruiser 3” Lift Kit Stg1

INSTALLATION INSTRUCTIONS

WAR 3300/3310

FJ Cruiser Front Coil Spring Spacer Kit

INSTALLATION INSTRUCTIONS

IMPORTANT: Warrior recommends that this kit be installed by a certified technician. While these instructions are

complete, a thorough professional knowledge of disassembly and reassembly procedures, as well as postinstallation checks is important. Installing this system without this knowledge and expertise may compromise the

operating safety of the vehicle.

Before beginning this installation, take a look at the end of the install instructions. You will find a torque

specification chart. Reference this chart when tightening any bolts. This chart is located toward the end of the

step-by-step instructions.

Disassembly

1. Set the parking brake. You may also want to chock the rear tires.

2. Raise the front of the vehicle and secure it on a level surface with jack stands on the frame.

3. Remove the front tires.

4. Mark each strut driver and passenger so that you do not switch them during re-installation.

5. Unbolt and remove the front skid plate.

6. Unbolt and separate the sway bar end links from the knuckle. Twist the sway bar up and out of the way

as far as you are able to.

7. Remove the cotter pin from the castle nut that holds the upper control arm to the

knuckle. Loosen the nut most of the way, but do not remove. You now need to break

the ball joint taper free from the knuckle. Illustration 1 shows the location at which you

can safely strike the knuckle to break the taper free. Once the taper comes loose,

remove the castle nut. Repeat on both sides of the vehicle.

8. Remove the 3 nuts from the top of each strut that secure the strut to the frame.

9. Remove the lower bolt on each side that secures the strut to the lower control arm.

10. Carefully remove the struts from each side of the vehicle.

11. Test fit the Warrior coil spring spacers to the vehicle by sliding the bracket in place

bolts pointed up. The bolts we use are larger than stock, you may need to drill out the factory holes to

make clearance for the 7/16” bolts in the new spacer.

Assembly

1. Place one of your new front coil spring spacers over the studs on top of each of the struts and use the

factory nuts removed in step 8 above to secure them to the strut. Tighten to torque spec using the

reference chart below.

2. Slide the struts back into place and attach to the lower control arm re-using the factory hardware.

3. Attach top of strut with new spacer installed to the frame bracket using the included flat washers and

nylock nuts.

4. Re-assemble knuckle to upper control arm. Torque down and re-install cotter pin.

5. Install sway bar links back into knuckle.

6. Use chart below to be sure you’ve torqued all bolts and nuts to the proper specification.

7. Re-install lower front skid plate.

8. You may now finish your installation by re-installing your wheels and tires and lowering the vehicle back

onto the ground. Be sure to double check all bolts and nuts, including lug nuts to ensure they are tight.

Page 2

Protecting Your Adventure Lifestyle

========================================================================================

QUALITY • INTEGRITY • INNOVATION • SERVICE

Warrior, Inc.

16850 SW Upper Boones Ferry Rd

Ste. A

Durham, OR 97224

Phone: (888) 220-6861

Fax: (503) 692-0364

sales@warriorproducts.com

www.warriorproducts.com

Test drive and check again. It is also recommended that after a few hundred miles, all bolts be passed

over and re-torqued.

SUBJECT: FJ Cruiser Rear Coil Spring Spacer Kit Installation Instructions

Disassembly

12. Put the vehicle in 4WD High and chock the front tires.

13. Raise the rear of the vehicle and secure it on a level surface with jack stands on the frame.

14. Support the axle with a floor jack and remove the rear tires.

15. Unbolt the sway bar end links from the sway bar.

16. Unbolt and slide the bottom of the shocks free of the axle. If you are replacing shocks, unbolt them from

the frame as well and remove them completely.

17. Unbolt the track bar (panhard bar) from the frame.

18. Lower the axle until there is plenty of room to slide the coil springs out. Be sure to keep track of driver

and passenger sides as well as top and bottom of the springs.

Assembly

9. Set your new coil spring spacers on top of the factory spring. The spacers have a taper on them which

should point up, and a shoulder on them which will sit over the spring and factory rubber isolator.

10. Slide the coil spring and new spacer back into place on the axle. The spring must be rotated so that the

end of the coil is locked into the pocket on the coil perch on the axle. If it is not put into place properly,

your lift may end up uneven.

11. With both coils and spacers now in place, begin raising the axle to put pressure on the top and bottom of

the coils. As the coils make contact with their frame end perches, make sure they are properly aligned.

12. Re-assemble track bar (panhard bar) to frame. Torque to specification using the chart below.

13. If you are using new shocks, now is the time to install them. Otherwise, secure the lower end of the

shock back onto the axle. Tighten to spec.

14. Install sway bar end links onto sway bar and tighten.

You may now finish your installation by re-installing your wheels and tires and lowering the vehicle back onto the

ground. Be sure to double check all bolts and nuts, including lug nuts to ensure they are tight. Test drive and

check again. It is also recommended that after a few hundred miles, all bolts be passed over and re-torqued.

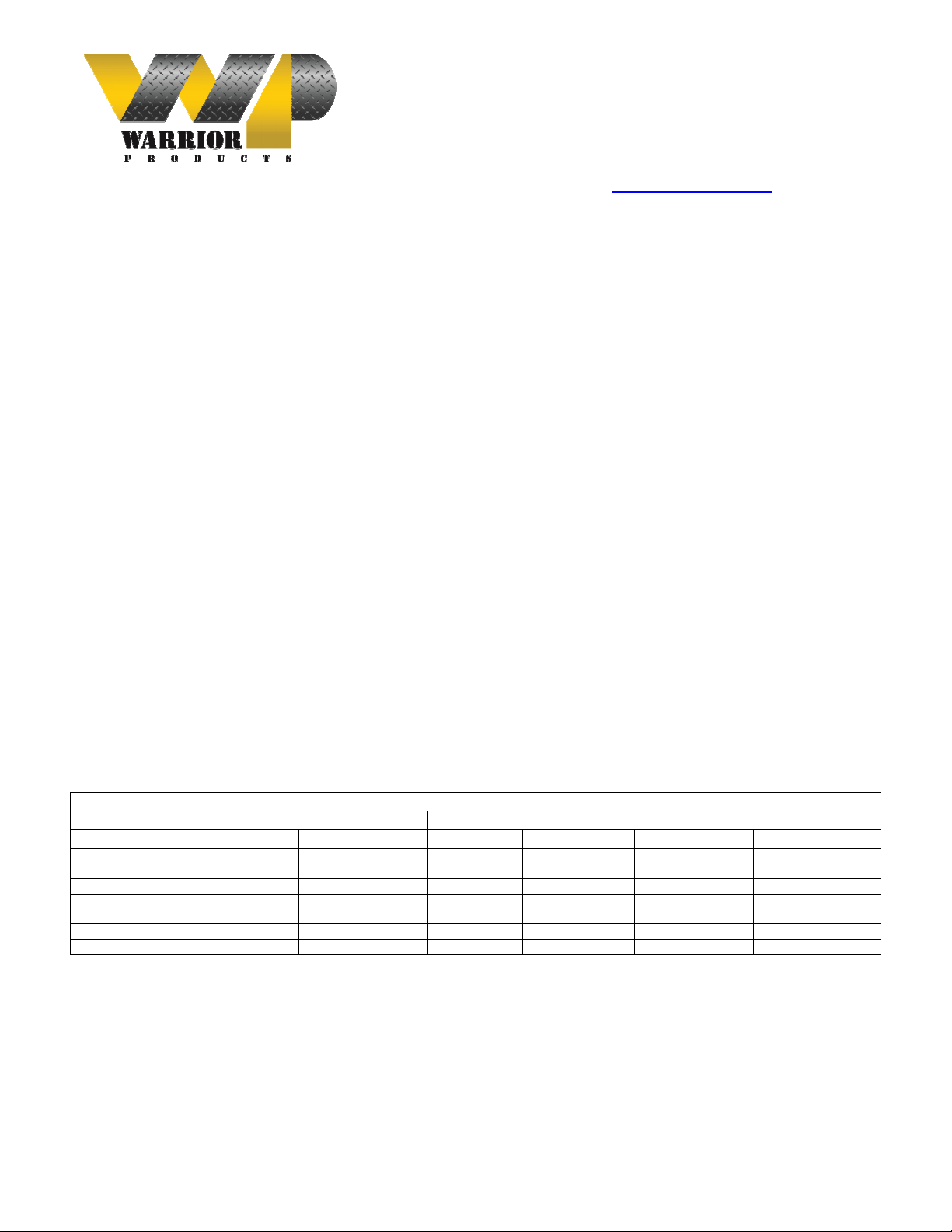

STANDARD BOLT TORQUE SPECIFICATIONS

INCH SYSTEM

METRIC SYSTEM

Bolt Size

Grade 5

Grade 8

Bolt Size

Class 8.8

Class 10.9

Class 12.9

5/16

15 Ft – Lbs

20 Ft – Lbs

M 6

5 Ft – Lbs

9 Ft – Lbs

12 Ft – Lbs

3/8

30 Ft – Lbs

35 Ft – Lbs

M 8

18 Ft – Lbs

23 Ft – Lbs

27 Ft – Lbs

7/16

45 Ft – Lbs

60 Ft – Lbs

M10

32 Ft – Lbs

45 Ft – Lbs

50 Ft – Lbs

_

65 Ft – Lbs

90 Ft – Lbs

M12

55 Ft – Lbs

75 Ft – Lbs

90 Ft – Lbs

9/16

95 Ft – Lbs

130 Ft – Lbs

M14

85 Ft – Lbs

120 Ft – Lbs

145 Ft – Lbs

5/8

135 Ft – Lbs

175 Ft – Lbs

M16

130 Ft – Lbs

165 Ft – Lbs

210 Ft – Lbs

_

185 Ft – Lbs

280 Ft – Lbs

M18

170 Ft – Lbs

240 Ft – Lbs

290 Ft – Lbs

Loading...

Loading...