Series DF

Dual Function Controls

Solid State Reliability Spade Terminals for Easy Wiring

Compact Size Manual Reset (optional)

Meets CSD1 Requirements Power Outage Feature (optional)

U.L. “Motor Control” U.L. “Limit Control”

AC Current Minimizes Electrolysis

Optional Test Feature Time Out Option

Optional Dirty Electrode Detection

RELAY OUTPUT

Dual function Series DF models are designed to control two independent level

functions, one single-level control operation and one differential-level operation.

Optional Power Outage feature resets after nuisance outages. Optional Reset Button is

used when device has been deactivated due to low water condition. Reset is activated

only after water has returned to normal level. This control is ideal in applications on

boilers, food service equipment, and chemical delivery systems.

Specifications

Contact Design 1 N.O. & 1 N.C. (1 form C) extra function

WARRICK CONDUCTIVITY SENSORS

Contact Rating (120, 240 VAC) 10 amp Resistive 1/3 hp

Mode of Operation H/L Direct/Inverse, LLCO – factory set

Sensitivity 0-26K ohm, factory set

Primary Voltage 120 VAC, 240 VAC1, 24 VAC (+10%/-15%)

208/240: 187 V min. to 255 V max. VAC 50/60 Hz

Secondary Voltage 12 VAC

Temperature -40°F to +150°F (-40°C to +65°C)

Approvals U.L. 508 File # E44426, U.L. 353 File # MP1430

Terminal Style Spade connection

Options Time Delays, Manual Reset, Power Outage, Retrofit Plate,

Test Feature, Dirty Electrode Detection;

See page E-11 for descriptions

Notes:

1. 240 VAC and 208/240 VAC units do not carry U.L. Limit Control recognition.

How to Order

Use the Bold characters from the chart below to construct a product code.

DF X X X X X XX XX XX

1. Series

DF

2. Mode of Operation

Direct Inverse

A – 4.7K K – 4.7K

B – 10K L – 10K

C – 26K M – 26K

D – 50K N – 50K

E – 100K P – 100K

3. Supply Voltage

1 – 120 VAC; 2 – 240 VAC;

3 – 24 VAC; 8 – 208/240 VAC

4. Standoff Style*

A – 1/16˝ Panel C – Screw Mount

B – 1/8˝ Panel D – Retrofit

5. Enclosure

0 – None; 1 – NEMA 1; 4 – NEMA 4

6. Option Package

See page E-11, Chart B for code letter.

7. Time Delay (increasing level) H/L function

00-90 seconds; Blank 0 seconds

8. Time Delay (decreasing level) H/L function

00-90 seconds; Blank 0 seconds

9.Time Delay (decreasing level) LLCO function only

03-90 seconds; Blank 3 seconds

Series DF

Applications

• Dual Function

• Single-Level Service

• Differential Service

• Feedwater Control / Low-Water Cutoff

• High Level / Low Level

• Pump Down / High Level

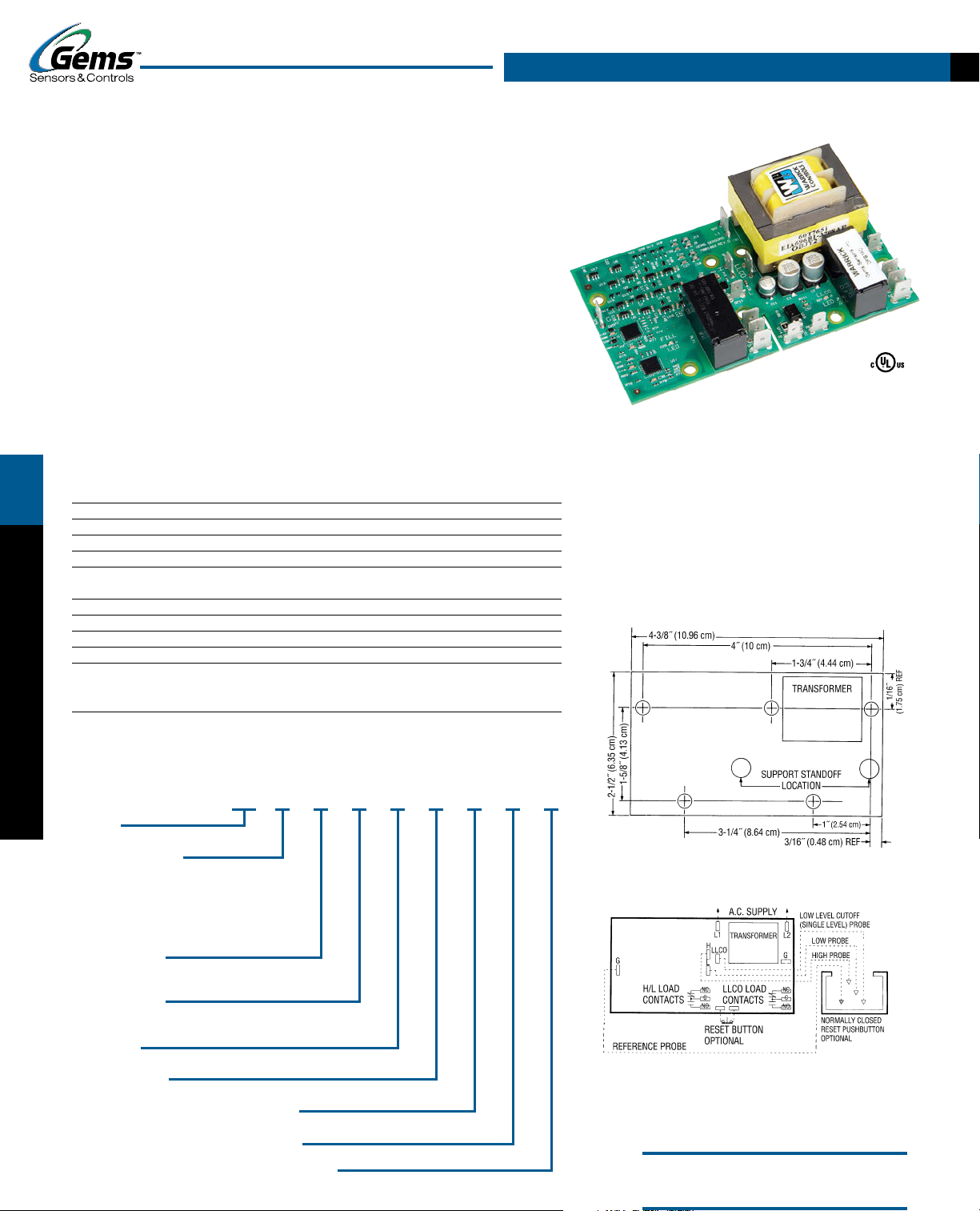

Dimensions

Wiring

Note: For single level service, use “H” and “G” connections.

Socket Details and Option Availability

are located on web site.

1.66˝

8-PIN DIN SOCKET

BOTTOM

STANDOFFS, SOCKETS AND OPTIONS

Sockets and Standoffs – 16, 26 and DF Series Only

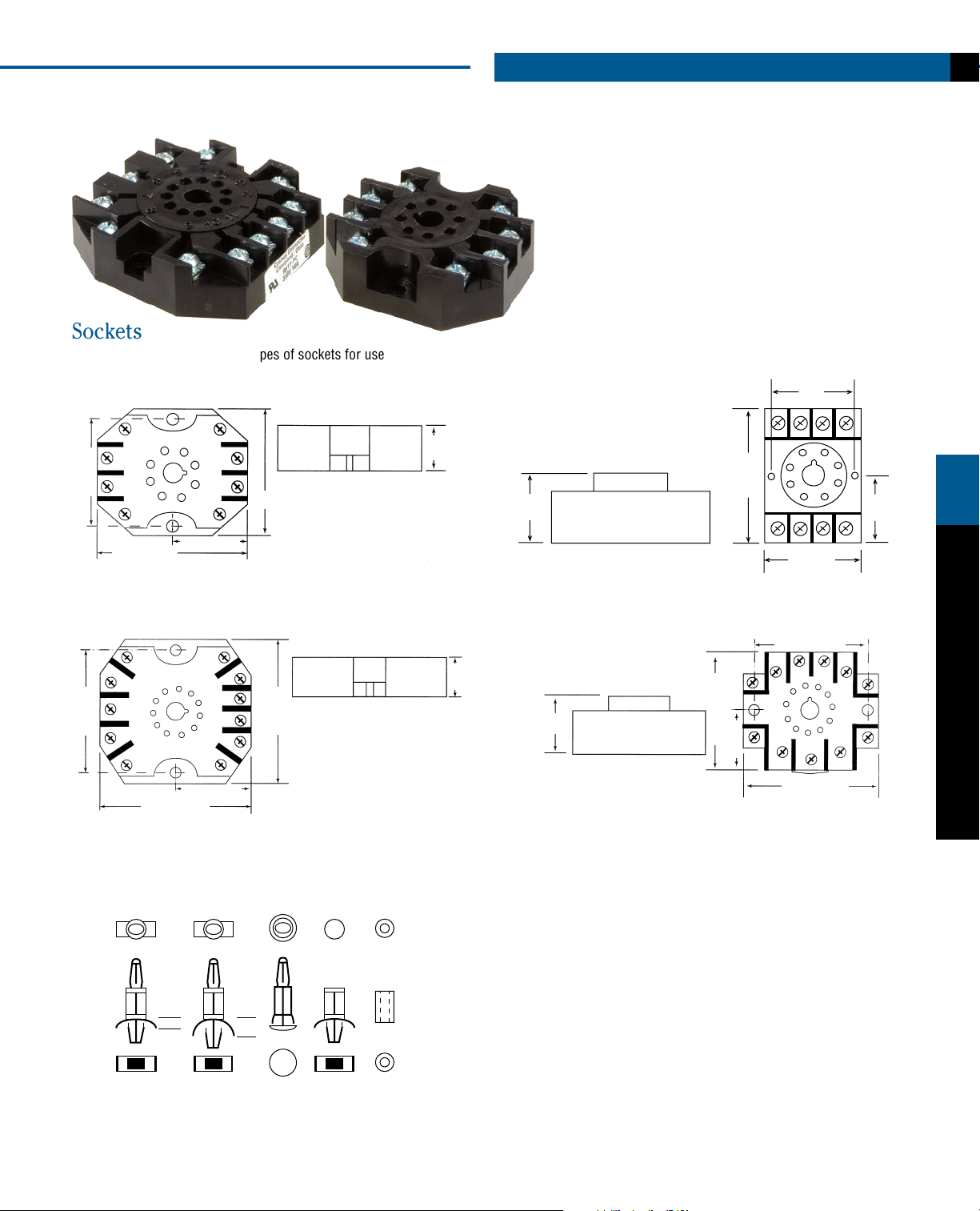

Sockets

Warrick provides four different types of sockets for use

with plug-in control modules.

8-PIN OCTAL SOCKET

0.625˝

(15.9 mm)

(42.16 mm)

2.31˝ (58.7 mm)

1.14˝ (28.96 mm)

2˝

(50.8 mm)

.980˝

(24.89 mm)

2.04˝

(51.82 mm)

1.30˝

(33.02 mm)

1.60˝

(40.64 mm)

1.01˝

(25.65 mm)

11-PIN OCTAL SOCKET

2.21˝

(56.13 mm)

1.3˝ (33.02 mm)

2.60˝ (66.04 mm)

2.53˝

(64.26 mm)

Standoffs

Warrick provides four different types of standoffs

designed to connect circuit boards to panels.

TOP

VIEW

SIDE

VIEW

VIEW

1/16˝

STANDOFF

1/16˝

1/8˝

STANDOFF

1/8˝

RETROFIT

STANDOFF

CIRCUIT

BOARD

STANDOFF

SCREW

MOUNT

STANDOFF

0.625˝

(15.88 mm)

1.0˝

(2.54 mm)

11-PIN DIN SOCKET

2.04˝ (51.82 mm)

1.02˝

(25.91 mm)

2.04˝ (51.82 mm)

2.33˝ (59.18 mm)

WARRICK CONDUCTIVITY SENSORS

Loading...

Loading...