WARREN-SHERER S3(J), S3(j)C Installation And Operaion Manual

. . .

. . ‘. Y’,.‘ . .

,..

. . . . . :r *,,.

,’ I

*’ : , * ., I c, * :‘y:.’

. .;

-

1

WARREN//SHERER ..(.; /-;::_:~;. :;:. ;.;.::,s;f.. -; ‘,-r :- .T .,

DIVISION OF KYSOR INDUSTRIAL CORPORATION ” .‘.: ,‘. ,‘. ’ .-“’ * ‘: : ’

- ‘-

.

‘,, ’

. : r .

.

-

1600-ROCKDALE INDUSTR'iAL BLVD., 60NYERS, GEORGIA ;0207,404483&600 .

INSTALLATION AND OPERATING INSTRUCTIONS

FOR

S3J, S3JC, S3, S3C MODELS

.m

SERVICE DELI/MEAT CASES

. . . . . . . . .._.... . . . . . . . . . .

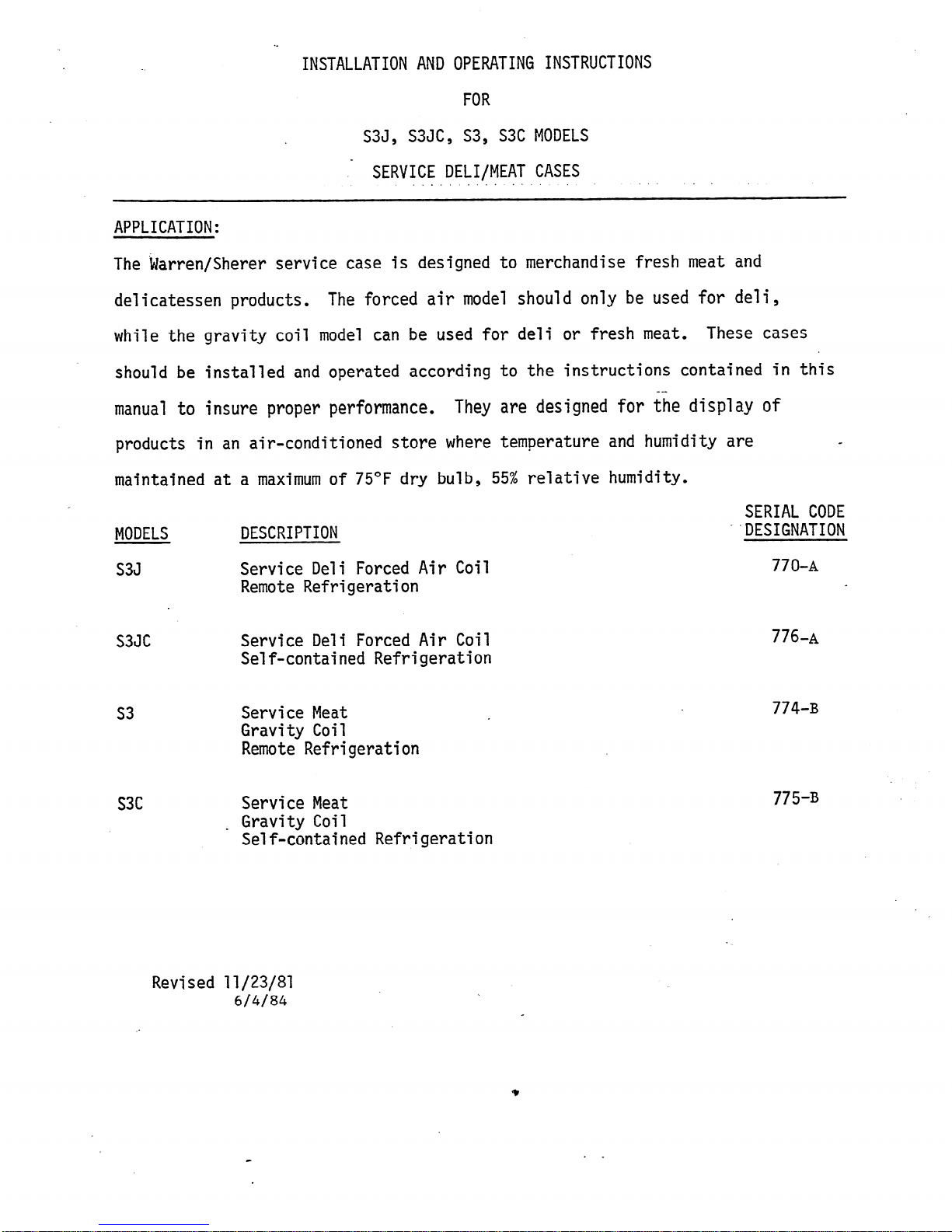

APPLICATION:

The kJarren/Sherer service case is designed to merchandise fresh meat and

delicatessen products.

The forced air model should only be used for deli,

while the gravity coil model can be used for deli or fresh meat. These cases

should be installed and operated according to the instructions contained in this

manual to insure proper performance.

They are designed for the display of

products in an air-conditioned store where temperature and humidity are

4

maintained at a maximum of 75*F dry bulb, 55% relative humidity.

I

SERIAL CODE

MODELS

DESCRIPTION

"DESIGNATION

S3J

Service Deli Forced Air Coil

770-A

Remote Refrigeration

e

S3JC

Service Deli Forced Air Coil

Self-contained Refrigeration

s3

Service Meat

Gravity Coil

Remote Refrigeration

s3c Service Meat

L

Gravity Coil

Self-contained Refrigeration

776.~

774-B

775-B

Revised 11/23/87

6/4/84

9

GENERAL

These display refrigerators may be installed individually or in a continuous

line-up consisting of several 8-foot and V-foot sections by using a joint trim

.

kit A plexiglass divider'kit must be used between cases operating on different

refrigeration systems.

Divar will be factory installed if specified on order.

SHIPPING DAMAGE

All equipment should be examined for shipping damage before and during unloading.

If there is any damage,

the carrier should 'be notified immediately and an inspection

requested. The delivery receipt "must"

be noted that the equipment was received

damaged. If damage is of a conceamnature you must contact the carrier immediately

or

no later than three (3) days following delivery.

A-claim must be filed with the

carrier by the consignee for all damages.

- --

- _ -

LOCATION

This refrigerator must be located on a firmly based floor and leve

or minus l/16".

Use shims provided to level your refrigerator.

JOINING

Two or more fixtures of like models can be joined together to form

line-up. Instructions for joining fixtures are included in the jo

ed within plus

a continuous

nt kit.

Before-lining up refrigerator, inspect refrigeration lines, electrical connections,

and controls to insure refrigerators are in proper line-up and are in the proper

sequence.

Note: THESE REFRIGERATORS ARE LINED UP AT THE FACTORY AND ARE NUMBERED.

. .

. .i

: INSURE THEY ARE LINED UP IN THE FIELD IN THE SAME SEQUENCE NUMBER.

WASTE OUTLET .

These cases are equipped with a l-l/Z'* FPI waste outlet connection which terminates

in the center of the refrigerator below the insulated bottom. A l-l/Z" galv,

. water seal trap is provided for field installation.

INSTALLING DRIP-PIPE

Improperly installed drip pipes can seriously effect the operation of this

equipment and result in increased maintenance cost.

general rules for drip pipe installation.

Listed below are some \..

1. Never use a double water seal.

2. Never use a pipe smaller than the size pipe or water seal supplied with the

equipment.

3:Always provide as much as fall as possible in drip pipe. (l** fall for each

4' of drip pipe).

4. Avoid long runs in drip pipe which make it impossible to provide maximum fall

7iijZpe.

5. Provide a drip space between drip pipe and-floor drain or sewer connection.

6. Do not allow drip pipe to come in contact with uninsulated suction lines,

nhichwill cause the condensation from your refrigerator to freeze.

Rev. 6/4/84

1)

2

--

SXJ)

,

CLEANING

To 'insure minimum maintenance cost, cabinet should be emptied and throughly

washed out once a week.

A mild soap and water solution is recommended for painted

surfaces of the cabinet.

Do not use cleaners containing abrasive materials which

will scratch or dull finish.

The waste outlet should be flushed with a bucket

of water following each cleaning.

Caution: Never introduce water into the fixture faster than the waste outlet

can carry it away.

When cleaning lighted shelves, wipe down with a wet sponge or cloth so that water

does not enter the light rails.'

DO'NOTUSE'A'HOSE'ORSUBMERGE SHELVES IN'lrJATER.

BE SURE REFRIGERATION IS SHUT-OFF AND ALL ELECTRICAL IS OFF BEFORE WASHING YOUR

REFRIGERATOR.

LOADING

Merchandise should not be placed in the fixture until all controls have been

adjusted and the refrigerator is at proper temperature.

At no time should the fixture be stocked beyond the load line or over the front

. -.

edge of adjustable shelves.

In doing so, you will seriously affect the performance

which will result in higher product temperatures and increase operating costs.

ELECTRICAL

All field installed wiring must comply with the NATIONAL ELECTRICAL CODE AND

LOCALCODES.

ELECTRICAL JUNCTION

On these cases, an electrical junction box is provided for field connections.

The junction box is located at the left rear of the case and contains the case

;

thermostat an6 all lighting ballasts. \On self-contained models, a separate -

circuit should be provided for the condensing unit. '

ELECTRICAL CONNECTIONS

ml field connections

are

made in the electrical junction box.

Make sure that proper voltage is supplied to your refrigerator. Check refrigerator

nameplate for correct circuits, volts, and amps.

*ALL'REFRIGERATORS'MUST BE'GROUNDED.

When refrigerators are-mu1 tiplexed, add the total of these amperage values to

determine wire size and circuit protection.

Make sure that proper wire size and branch circuit protection are employed for

safe operation.

.

.

Chart #l shows the electrical ratings for your refrigerator. This is the same

information that appears on your refrigeration nameplate.

REFRIGERATION FAN MOTORS (S3J Only)

The fan motors employed are permanently oiled for the life of the-motor and

require no periodic maintenance.

They are wired according to the enclosed

wiring diagram and'MUST'RUN%ONTINUOUSLY.

+

3

- -

WJ)

EXPANSION VALVE -*

The expansion valve furnished with your refrigerator has been sized for maximum

coil efficiency.

To adjust superheat, place a thermocouple under the expansion

valve bulb. Read the suction line pressure as near coil as possible. (If, at

the condensing unit, estimate suction line loss at 2 PSIG). Convert coil suction

pressure to temperature. The difference between coil temperature and the

thermocouple temperature is superheat. (Use average superheat when expansion

valve is hunting). Do not set superheat until cases have pulled down to operating

temperature and never open or close valve over l/Z turn between adjustments and

allow 10 minutes or more between adjustments. Superheat should be set to 6-8OF.

REFRIGERATION LINES

Refrigerant connections (suction & liquid) are stubbed underneath the case.

Cases multiplexed together must be field connected by running refrigerant

lines in the space under the case. The field installed suction lines must be

insulated to prevent condensation accumulation on the floor. See the section

on "Recommended Piping Practices" for additonal details on piping practices.

IMPORTANT A SEAL AROUND LINES AFTERCONNECTIONS ARE'MADE. KEEP DIRECT FLAME

FROM BOTTOM OF REFRIGERATOR, AS HEAT WILL DISINTEGRATE THE BOTTOM AND INSULATION.

USE A HEAT SHIELD WHEN WELDING NEAR THE BOTTOM OF THE CASES.

REFRIGERANT

R-12 expansion valves are standard. If other refrigerant is used, the order

must specify the expansion valve to be supplied.

*,HEAT EXCHANGER (S3J

only)

Heat exchangers are standard in these refrigerators. They aid to increase

operating efficiency and reduce frosting and flood-'back to compressor.

OPERATION

On single condensing unit systems,

a thermostat should be used to control

temperatures.

The thermostat bulb is mo[lnted on the rear baffle on S3.modeld and

'.in the discharge air on the S3J,

On parallel units, temperature control can be .

provided by EPR valve and thermostat.

Chart #2 shows approximate settings for .

merchandisers. Since many variables are present in each-installation, such as 'i

. store temperature, length of tubing runs, temperature desired in refrigerator, etc.,

'Chart #2 is only a guide for-the installer.

DEHYCRATION OF REFRIGERATION SYSTEMS

Please read'ca~~fully.befd~~'~l~~i~g'~~~t~m intd operation. After laying

. refrigerant lines, they should be blown out before making final connection at

fixture or condensing unit.

Use dry nitrogen to prevent any foreign matter

being left in the lines.

Keep pressure below 250 pounds. To prevent scaling

due to brazing, dry nitrogen should be allowed to flow through lines while

brazing operations are taking place.

. After the refrigeration system has been pressure-tested and proven leak-free,

it is recommended that the system be dehydrated with a vacuum pump to 100 microns

for the first two evacuations and 500 microns on the third. The triple evacuation

method requires evacuating the system three successive times and breaking each

vacuum with dry refrigerant.

Allow the pressure to rise above atmospheric pressure.

Revised 11/23/81

9

4

LI -

WJ)

DEF.ROST CYCLE

Off-time defrost is standard on these models.

The fans run continuously on the

S3J.

Defrost termination is by time (fail safe).. es f '-

( See Chart #2 for defrost

settings.

Self-Contained Models

The self-contained S3(J)C uses a Copeland 'F" line air cooled condensing unit.

The condensing unit is located under the display area. R-12 is the standard

refrigerant in this system.

The unit may be serviced by sliding out of case.

This is done by removing

the retaining clamps on back of the case and pulling

the unit out carefully.

Care must be taken so as not to block the condenser air

inlet and outlet.

.-m

Revised 11/23/87

m

v?

5

- -

WJ)

Loading...

Loading...