WARREN-SHERER MIA, MIAG Installation & Operation Manual

FORM NUMBER: M-1

DATE: .9/25/79

REVISED:

WARRENKHERER

INSTALLATION &

OPERATION

MANUAL

MODEL:

MIA (G)

MEAT MERCHANDISERS

(AIR DEFROST)

THIS REFRIGERATOR CONFORMS TO THE COMMERCIAL

REFRIGERATOR MANUFACTURERS ASSOCIATION HEALTH AND

SANITATION STAN+DARD. ’

CRS-SI-78

WARREN

HERER

DIVISION OF KYSOR INDUSTRIAL CORPORATION

1600 ROCKDALE INDUSTRIAL BLVD.,CONYERS, GEORGlA30207/404~483+j600

INSTALLATION

MODEL M

Page 1

AND OPERATING INSTRUCTIONS

FOR

A MEAT MERCHANDISER

(FRESH MEAT)

APPLICATION: This meat merchandiser was designed to display fresh

packaged meats under proper storage temperature. They

are designed for use in an air conditioned store where

temperatures'and humidity are maintained @ 75' dry bulb

and not higher than 64O wet bulb (55% relative humidity).

Your meat merchandiser should be installed and operated

according to the instructions contained in this manual to

insure proper performance.

GENERAL: These meat merchandisers are a self service merchandiser.

They can be installed in a continuous line-up consisting of

several 8-foot and.l2-foot sections by using a joint trim kit.

When the line-up is operated on two (2) or more units it is

necessary to use a plexiglass divider between the separate

refrigeration systems.

The merchandiser can also be installed individually. En&

are removable so additional sections may be added.

MODEL:

-MlA

DESCRIPTION

Meat merchandiser sing

"AIR DEFROST"

MlAG G

Meat merchandiser sing

with glass front. "AIR

SERIAL NUMBER DESIGNATION

e duty.

737 A

e duty

DEFROST"

738 A

SHIPPING DAMAGE:

All equipment should be examined for shipping damage before

and during unloading. If there is any damage, the carrier

should be notified immediately and an inspection requested.

The delivery receipt "must" be noted that the equipment was

'~

received 'damaged. If damage is of a concealed nature you

must contact the carrier immediately or no later than three

(3) days following delivery.

A claim must be filed with the

carrier by the consignee for all damage.

NOTE: Your equipment, when delivered, will have a

sticker attached advising what must be done to

report any damage.

LEVELING: Your new refrigerator must be perfectly level to insure proper

operation of the refrigeration system and also to insure proper drainage after defrost.

Proper leveling when multiplexing can be accomplished by finding

the highest point on the floor at the location of the line-up

(continued) .

LEVELING:

by using a level and a

chalk

line. Place a refrigerator at this

. point and use shims as needed to line the other refrigerators to

this high point.

Se sure sufficient shims are employed so as to

prevenet settling of the refrigerators.

STORE DRAFTS:

JOINING:

WASTE OUTLET

CONNECTIONS:

INSTALLING

DRIP PIPE:

CLEANING:

Page 2

Room air currents or drafts will seriously affect the operation

of any open-type fixture.

Be sure fans, space heaters, or air

conditioning grilles do not produce currents sufficent to more

air across the fixtures. Air movements across an open fixture

will cause the case temperature to be high and create defrosting

di'fficulties.

This will result in an increase of operating costs.

Two or more fixtures of like models can be joined together to form

a continuous line-up. Instruction for joining fixtures are included in the joint

kit&d& n~-~zbds

These cases are equipped with a l-1/2" (nominal 2") FPT waste

outlet connection which terminates in the center of the refrigerator below insulated bottom. An open drip space

between case and sewer connection is recomended.

(nominal 2") in line water seal and street ell is furnished with

each fixture for field installation.

This assembly must be installed directly to the fixture waste outlet. CAUTION: Do not

install a second water seal or drain trap as this will cause a

double trap and drainage problems.

Improperly installed drip pipes can seriously effect the operation

of this equipment and result in maintenance cost and proper installation.

1 . Never use a pipe smaller than the size pipe or water seal

supplied with the equipment.

2 . Always provide as much fall as possible in drip pipe (l-1/8"

per foot in the minimum.)

-~

3 .

Avoid long runs in drip pipe which make it impossible to

provide minimum fall in pipe.

4 . Provide a drip space between drip pipe and floor drain or

sewer connection.

5 . Do not allow drip pipe to come in contact with uninsulated

suction lines, which will cause the condensation from your

refrigerator to freeze.

The bottom display we1 1 is sectional so pans can be removed for

easy cleaning. The fan plenum is hinged for access to waste

outlet.

_.

Page 3

CLEANING:(cont'd.)

To insure minimum maintenance cost, cabinet should be

thoroughly emptied and washed inside at least every

three months (3). The exterior should be washed down

weekly. A mild soap and water solution is recommended

for painted surfaces of the cabinet. Do not use cleaners

containing abrasive materials which will scratch or dull

finish. The waste outlet should be flushed with a bucket

of water following each cleaning.

Caution: Never introduce water into the fixture faster

than waste outlet can carry it away.

Be sure refrigeration is shut-off and all electrical is off

before washing your refrigerator.

L.OADI NG : Merchandise should not be placed in the fixture until all

controls have been adjusted and the refrigerator is at

proper temperature.

At

no time should the fixture be stacked beyond the load

line located on the top of the back baffle and each end

of the refrigerator.

For proper operation, you must not stack merchandise above

the load lines. In doing so, you will seriously affect the

performance, which will result in higher temperatures.

LOAD LINES:

. For proper operation, you must not stack merchandise above

the air return grilles. In doing so, you will seriously

affect the performance of the refrigerator, which will result in higher temperature of the merchandise stored within.

Therefore,-IT IS ESSENTIAL THAT MERCHANDISE IS NOT STORED

ABOVE THIS POINT.

IMPORTANT :

Before loading the refrigerator, be sure to check all access

plates and be sure they are thoroughly sealed, and the

rubber on the bottom of the plenum chamber is sealed firmly

to the bottom.

ELECTRICAL:

All field installed wiring must comply with the National

'~

Electrical Code and Local Codes.

ELECTRICAL

CONNECTIONS : Be sure proper voltage is supplied to your refrigerator.

Check refrigerator serial plate for fan and anti-condensate

volts. ALL REFRIGERATORS MUST BE GROUNDED.

When multiplexing refrigerators to one 115V electrical source,

the total case fan and anti-condensate amperes must be added

.i

together, and proper wire size and branch circuit fuse or

circuit breaker as required by the National Electric Code must

be employed. THIS CIRCUIT MUST BE RUN CONTINUOUSLY AND MUST BE

MARKED suffi

ciently to prevent the fan motors and anti-conden-

sate from be

ing turned off accidentally.

(continued) Page 4

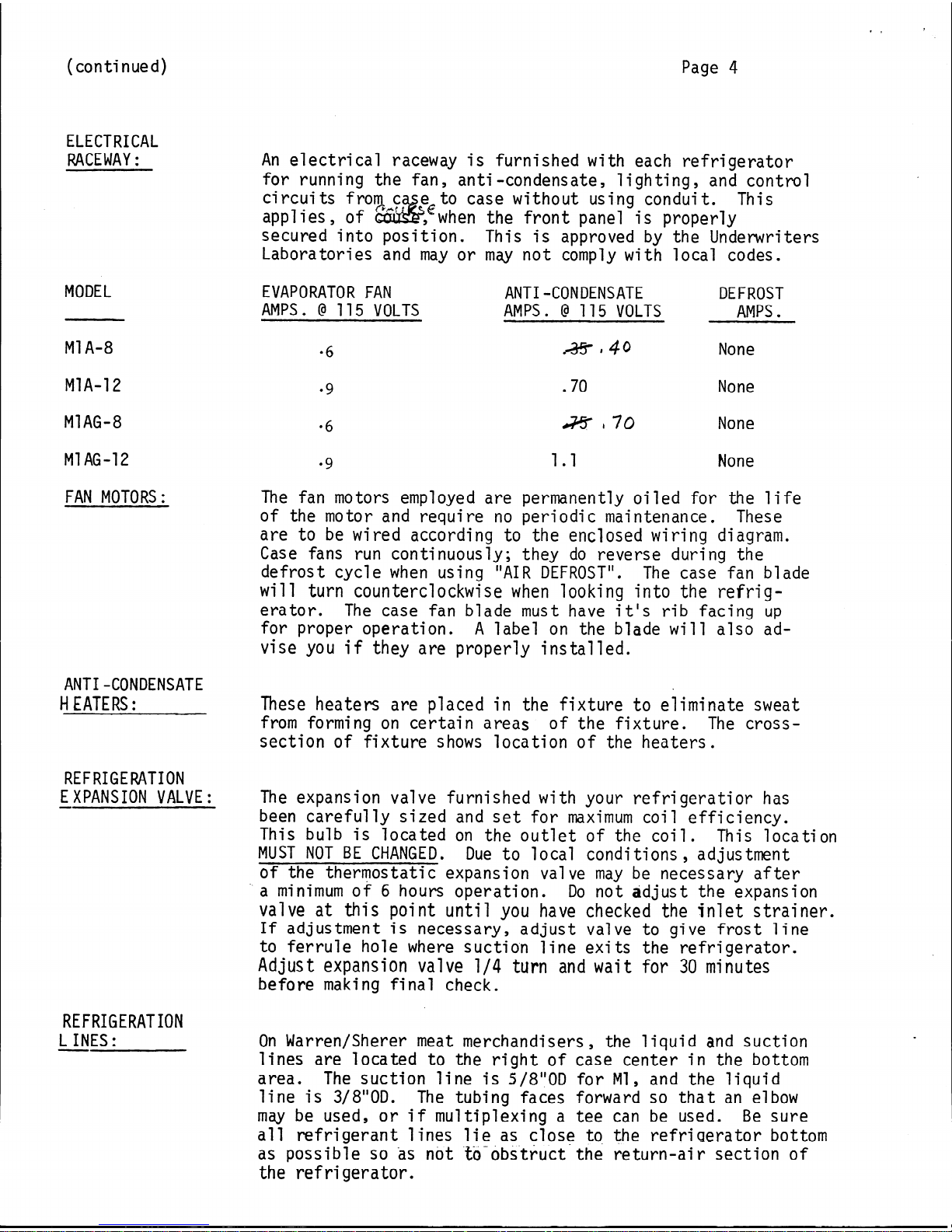

ELECTRICAL

RACEWAY: An electrical raceway is furnished with each refrigerator

for running the fan, anti-condensate, lighting, and control

circuits fro? c

applies, of Iv*

cizad&

ecto case without using conduit. This

when the front panel is properly

secured into position.

This is approved by the Underwriters

Laboratories and may or may not comply with local codes.

MODEL

EVAPORATOR FAN

AMPS. @ 115 VOLTS

ANTI-CONDENSATE

AMPS. @ 115 VOLTS

DEFROST

AMPS.

MlA-8 .

6

None

MlA-12 .

9

.

70 None

MlAG-8 .

6

JF t 70 None

MlAG-12 .

9

11

.

None

FAN MOTORS: The fan motors employed are permanently oiled for the life

of the motor and require no periodic maintenance. These

are to be wired according to the enclosed wiring diagram.

Case fans run continuously; they do reverse during the

defrost cycle when using "AIR DEFROST". The case fan blade

will turn counterclockwise when looking into the refrigerator.

The case fan blade must have it's rib facing up

for proper operation. A label on the blade will also advise you if they are properly installed.

ANTI-CONDENSATE

HEATERS: These heaters are placed in the fixture to eliminate sweat

from forming on certain areas of the fixture. The crosssection of fixture shows location of the heaters.

REFRIGERATION

EXPANSION VALVE: The expansion valve furnished with your refrigeratior has

been carefully sized and set for maximum coil efficiency.

This bulb is located on the outlet of the coil. This location

MUST NOT BE CHANGED. Due to local conditions, adjustment

of the thermostatic expansion valve may be necessary after

+‘a minimum of 6 hours operation.

Do not adjust the expansion

valve at this point until you have checked the inlet strainer.

If adjustment is necessary,

adjust valve to give frost line

to ferrule hole where suctio'n line exits the refrigerator.

Adjust expansion valve l/4 turn and wait for 30 minutes

before making final check.

REFRIGERATION

LINES: On Warren/Sherer meat merchandisers, the liquid and suction

lines are located to the right of case center in the bottom

area. The suction line is 5/8"OD for Ml, and the liquid

line is 3/8"OD. The tubing faces forward so that an elbow

may be used, or if multiplexing a tee can be used.

Be sure

all refrigerant lines lie as close to the refriserator bottom

as possible so as not Q-obstruct-the return-air section of

the refrigerator.

Loading...

Loading...