Page 1

OPERATION MANUAL FOR

ARC WELDING RECTIFIER

Model WTR-400

WARPP ENGINEERS PVT. LTD.

B-1005, Western Edge II, Near Metro Mall, Off. Western

Express Highway, Borivali (E), Mumbai-400 066.

Tel: 91-22-28542272/73/74. Fax: 28542275.

E-mail:sales@warpp.co.in Web Site:www.warpp.co.in

Page 2

INDEX

Sr. No. Description Page No.

1 Introduction 1

2 Installation 2

3 Operation 2

4 Maintenance 3

5 Safety 3

6 Trouble shooting 4

7 Spare part List 10

ILLUSTRATIONS

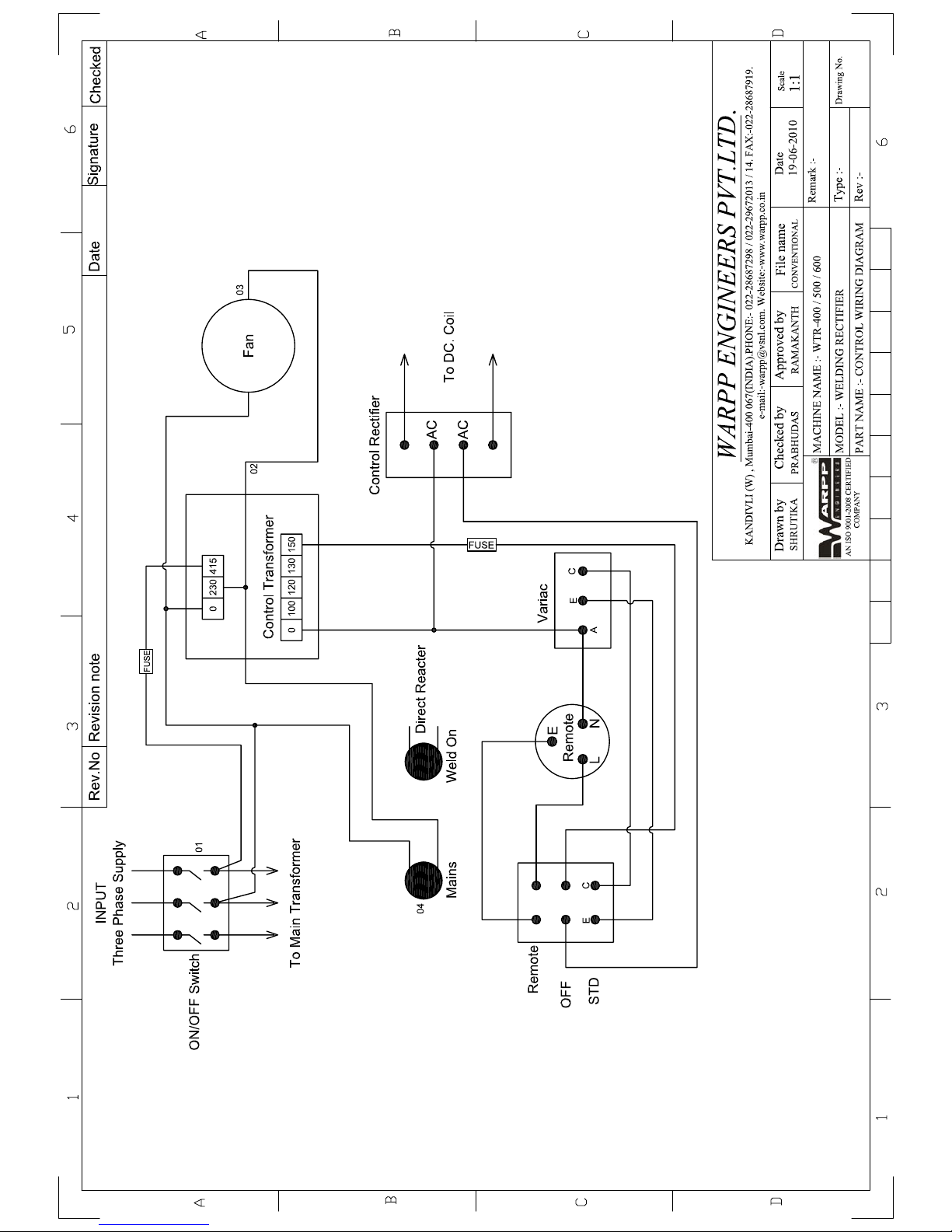

1) Control Circuit Wiring Diagram 6

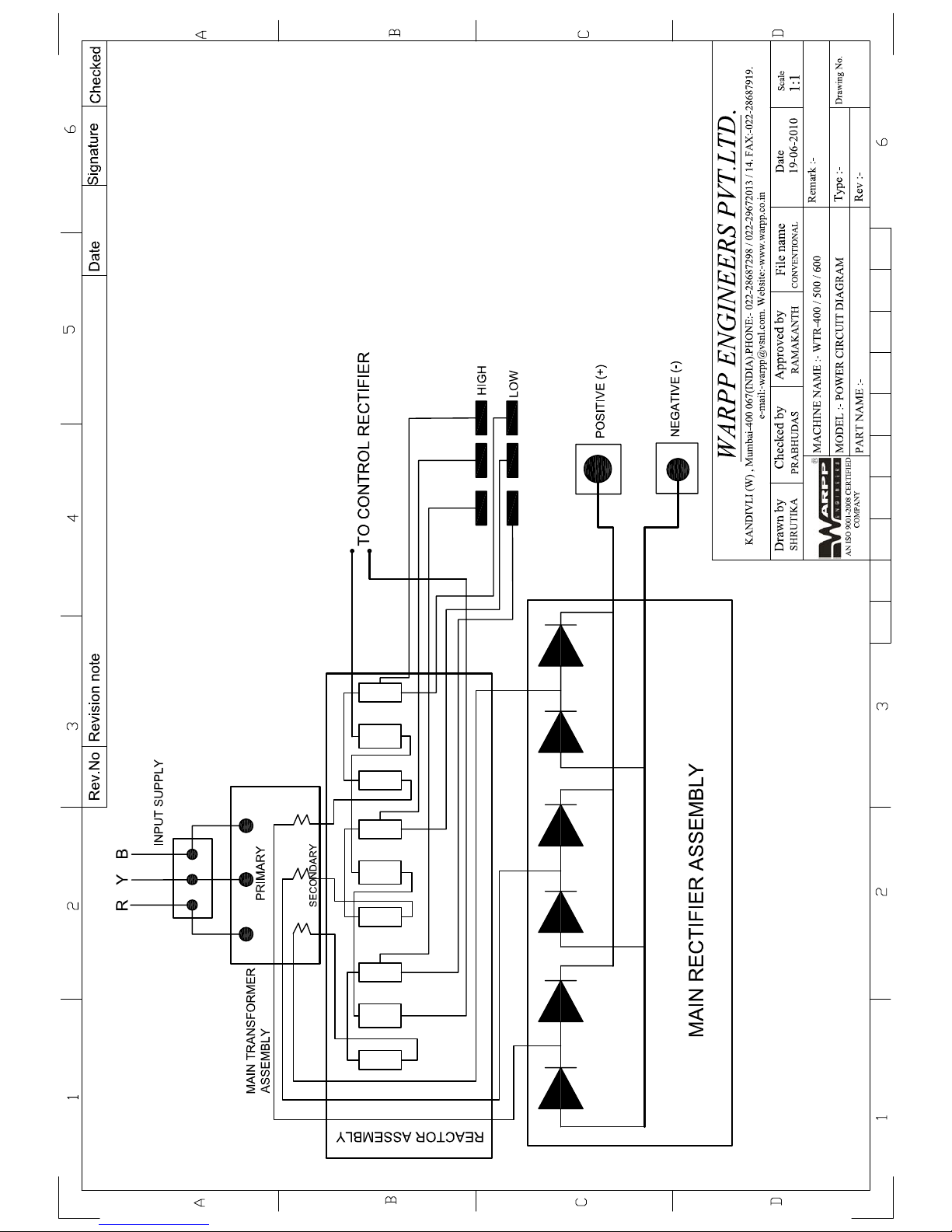

2) Power Circuit Wiring Diagram 7

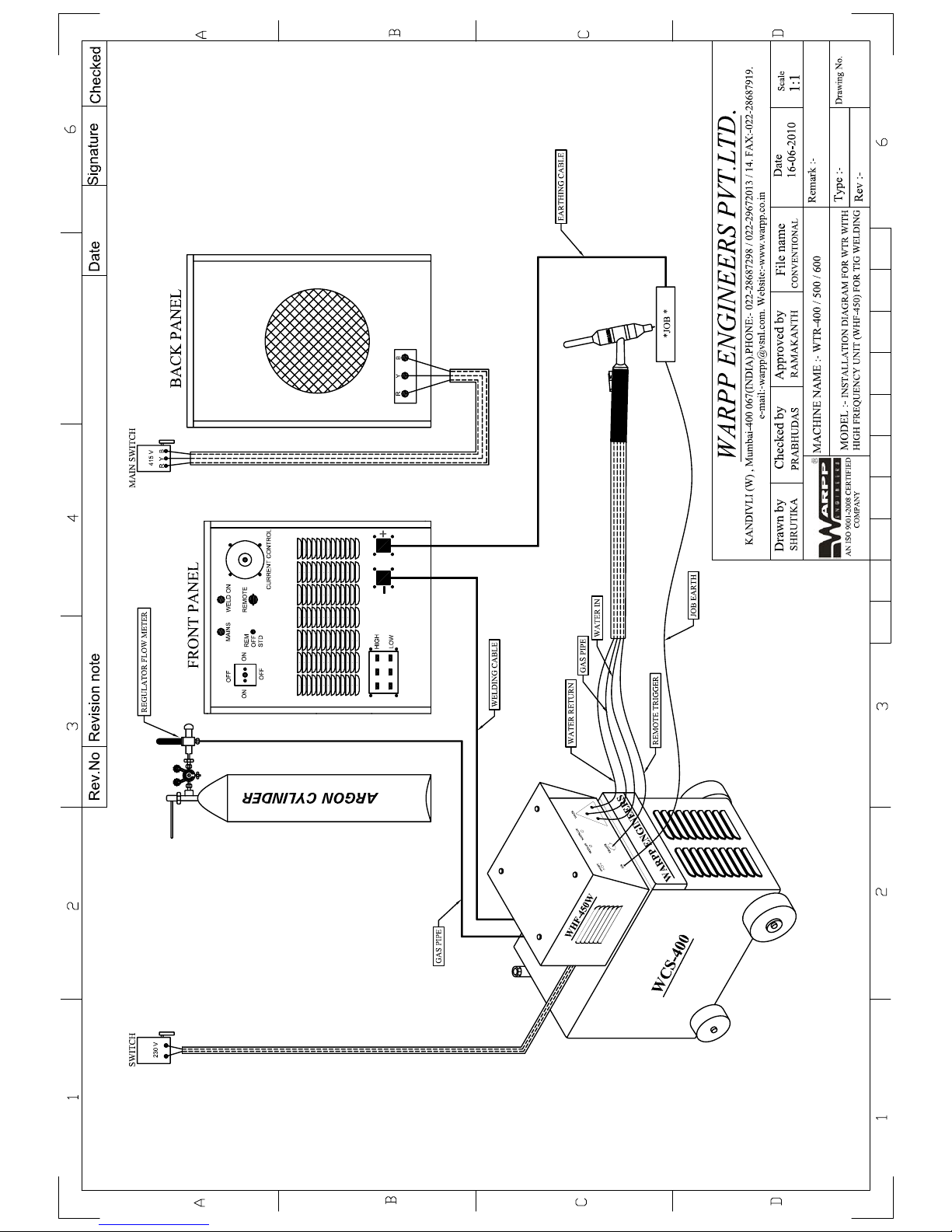

3) Installation Diagram 8

Page 3

INTRODUCTION.

This manual describes the equipment, installation, operation, safety, and

maintenance of WARPP make DC arc welding rectifiers. Tease welding

equipments are designed for manual metal arc and manual TIG welding

application in heavy duty fabrication. Simple design and rugged construction

makes it most ideal for maintenance free operation. This equipment is mounted

on four wheel chassis with two fixed wheels in the front and two revolving wheels

at the back side.

This equipment consists of a three phase step down transformer along with

three phase magnetic amplifier (Transductor) and three phase silicon diode

rectifier. The welding current is varied by varying the current in the DC coils of

the transductor. This current is obtained by a control transformer and an auto

transformer along with a single phase silicon diode rectifier. The transformer

steps down 415 Volts input supply to a voltage around 100 volts which is fed to

the rectifier via the autotransformer. The output of the rectifier is given to the DC

coils of the transductor.By varying the autotransformer setting the current fed to

the DC coils of the transducor varies and hence the actual welding current varies

accordingly. The autotransformer is calibrated for exact output welding current.

Main transformer is provided with primary tapping to work on 380/415/440 volts

input supply. All the components of the equipment is cooled by an single phase

fan. A simple change over of output cables allows the operator to use either

straight OR reverse polarity.

1

Page 4

INSTALLATION.

1) The machine should be kept in a relatively clean and dry place and a minimum

of 0.3 meters of space should be left around the equipment for easy circulation of

air.

NOTE THAT THE MACHINE DRAWS FRESH AIR FR OM THE FRONT AND

FORCES IT THROUGH THE BACK

2) A separate mains switch should be provided for this equipment. The mains

switch should be of good quality with proper contacts. The switch should be

easily accessible to the operator.

3) Three core 7/20 gauge cables can be used for the input supply connection.

The equipment should be properly earthed and all the electrical connections

should be firm and tight. Power connection point is provided on the back cover of

the equipment.

4) The equipment must be connected to a proper earth point.

.

OPERATION.

1) After installation of the equipment connect the holder to the negative and job

earth cable to the positive output of the equipment. (This connection is termed as

Straight polarity. Reverse polarity can be made by interchanging the job earth

and holder cables).

2) Switch on the mains Supply.

2

Page 5

3) Put the ON-OFF Switch on front panel of the equipment in ON position this will

a) Start the cooling FAN

b) Energies the main transformer

c) Puts on the MAINS indicator.

4) Set the current regulator to the required output current.

5) Connect the JOB EARTH cable firmly to the job.

6) Hold the required electrode in the holder.

7) Strike an arc by scratching the electrode to the job.

MAINTENANCE

1) Switch OFF the mains supply.

2) Open the top cover

3) Clean the equipment by removing dust by a blower.

4) Lubricate the fan bearings in regular intervals.

CAUTION: SWITCH OFF THE SUPPLY BEFORE OPENING THE EQUIPMENT.

.

SAFETY PRECAUTION:

1) Welding light is dangerous to the eyes as it has ultraviolet rays. Always use

welding screen with proper glass while welding.

2) Wear leather gloves, Apron and leather shoes while welding.

3) Keep the welding area relatively clean and free from inflammable materials

4) Use fully insulated holder.

5) Do not touch the electrode with the bare skin.

3

Page 6

TROUBLE SHOOTING.

TROUBLE CAUSE REMEDY

Mains supply is

switched ON and ONOFF switch is put to

ON position but welder

does not come ON.

Equipment comes on

but the welding current

varies.

The equipment comes

ON but the control

fuse blows.

i) Three phase supply is not

proper

ii) Mains Switch is not proper.

iii) Control fuse is blown off

i)The mains connection is not

proper.(Loose connection)

ii) Current regulator is not

working properly. (Either the

carbon brush is weared out

OR it is not making the proper

contact.

i) Control Transformer

Damaged

ii) Fan Damaged

iii) Current Regulator

Damaged

iv) Control Rectifier

Damage

i)Wait till the three phase

power is available

ii) Check for the proper

electrical contacts in the

mains switch.

iii) Replace the control fuse.

(This fuse is mounted on

the control transformer.

i) Check the mains for

proper and firm

connection.

ii) Replace the carbon

brush.

i) Check & Replace

ii) Check & Replace

iii) Check & Replace

iv) Check & Replace

Welding arc is

sluggish.

i) Welding current is low.

ii) Loose connection

iii) Input supply is less.

I) Increase the current.

ii) Make firm connection.

iii) Check the input

Supply.

and use proper tapping

(380/415/440) by changing

the jumper on the main

transformer

Page 7

the equipment give

i) Current regulator burnt OR

i) Check & Replace

minimum current but

the current doesn’t

increases

not working.

ii) Control transformer is

dead.

iii) Control rectifier is failed.

iv) Control fuse is blown.

Welding arc is not

smooth and spatter is

more

i) Current setting is too high.

ii) DC polarity used for that

particular electrode is not

right.

iii) Diodes have failed.

Mains fuse blows i) Short circuit in the primary

of the main transformer.

ii) Short circuit in main diodes

ii) Check & Replace

iii) Check & Replace

iv) Check & Replace

i) Reduce the current.

ii) Use proper polarity

(Interchange the polarity

and check).

iii) Replace the diode OR

Diodes.

i) Remove the short circuit.

ii) Replace the diodes.

Page 8

Page 9

Page 10

Page 11

M

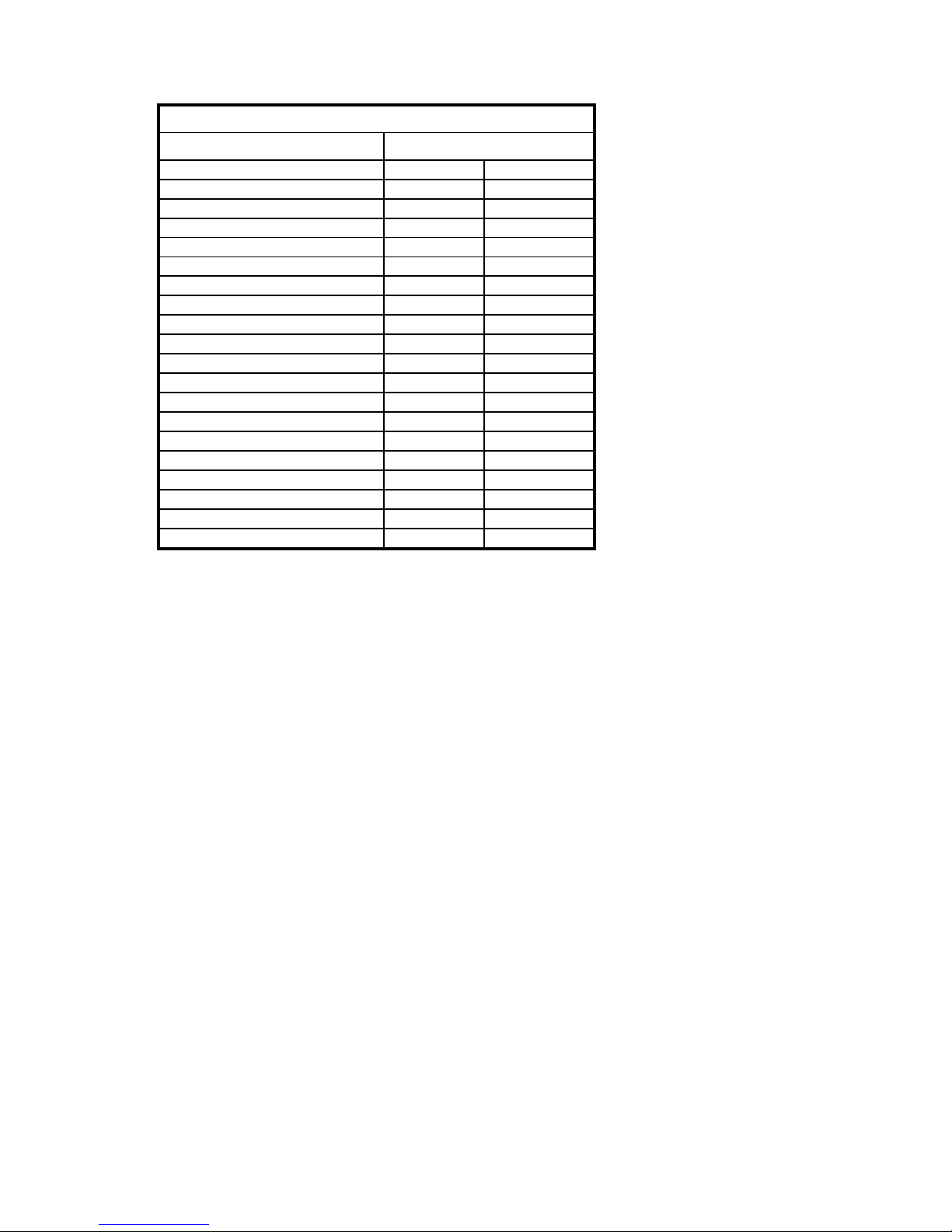

SPARE PART LIST FOR WTR-400

WTR-400

Description PART NO PRICE

Control Transformer C140401

Control Rectifier C244801

Auto transformer C140101

Fan C160201

Primary coil Top C1102

Primary Coil Bottom C1101

Secondary Coil C1112

DC Coil C1122

Load Coil Without Tappings C1121

Load Coil With Tappings C1119

Diode C150401

Out Put Terminal C180101

High-Low out put terminal C180401

Indicator Red 220V 20MA 20M

Toggle Switch C221801

Power plug backalite Male C240901

Power plug backalite Female C241001

Rotary Switch C220401

C240701

2900

450

1150

1850

1600

1500

2600

1500

800

850

600

400

750

100

100

75

75

500

Loading...

Loading...