Page 1

DC INVERTER AIR PLASMA

CUTTING MACHINE

LGK-40

Instruction Manual

M/s WARPP ENGINEERS PVT. LTD.

B-1005, WESTERN EDGE II, NEAR METRO MALL,

OFF.WESTERN EXPRESS HIGHWAY, BORIVALI (E),

MUMBAI-400 066.

Tel:91-22-28542272/73/74. Fax: 91-22-28542275.

Email:sales@warpp.co.in W ebsite:www.warpp.co.in

Page 2

Introduction

The cutting machine applies the advanced technology of inversion. Its

principle is making the 50/60Hz line frequency inverted to high frequency

(more than 100 kHz) with the V-MOSFET high power binistor, and then

stepping down and rectifying to attain high power DC source through the

pulse width modulation (PWM) technology. Thus the weight and size of the

transformer is greatly decreased and the efficiency is improved up 30%. The

principle of high frequency oscillation (HFO) is applied in the arc striking

system and makes it easy to arcing. Furthermore, the gas pre-flow and

post-flow function is available. It is stable, reliable, portable, energy saving,

noiseless, fast cutting speed, smooth scarfing and free of burnishing.

The cutting machine can be widely used. It can cut stainless steel, low carbon

steel, copper and other non-ferrous metals. The conversion efficiency of the

whole machine is over 85%.

Page 3

CONTENTS

1. MAJOR TECHNICAL PARAMETERS ................................................................... ................ 1

2. INSTALLATION ......................................................................................................................... 2

3. OPERATION ............................................................................................................................... 3

4. PRECAUTIONS .......................................................................................................................... 4

5. MAINTENANCE ........................................................................................................................ 6

6. TROUBLESHOOTING ............................................................................................................. 7

Page 4

r

r

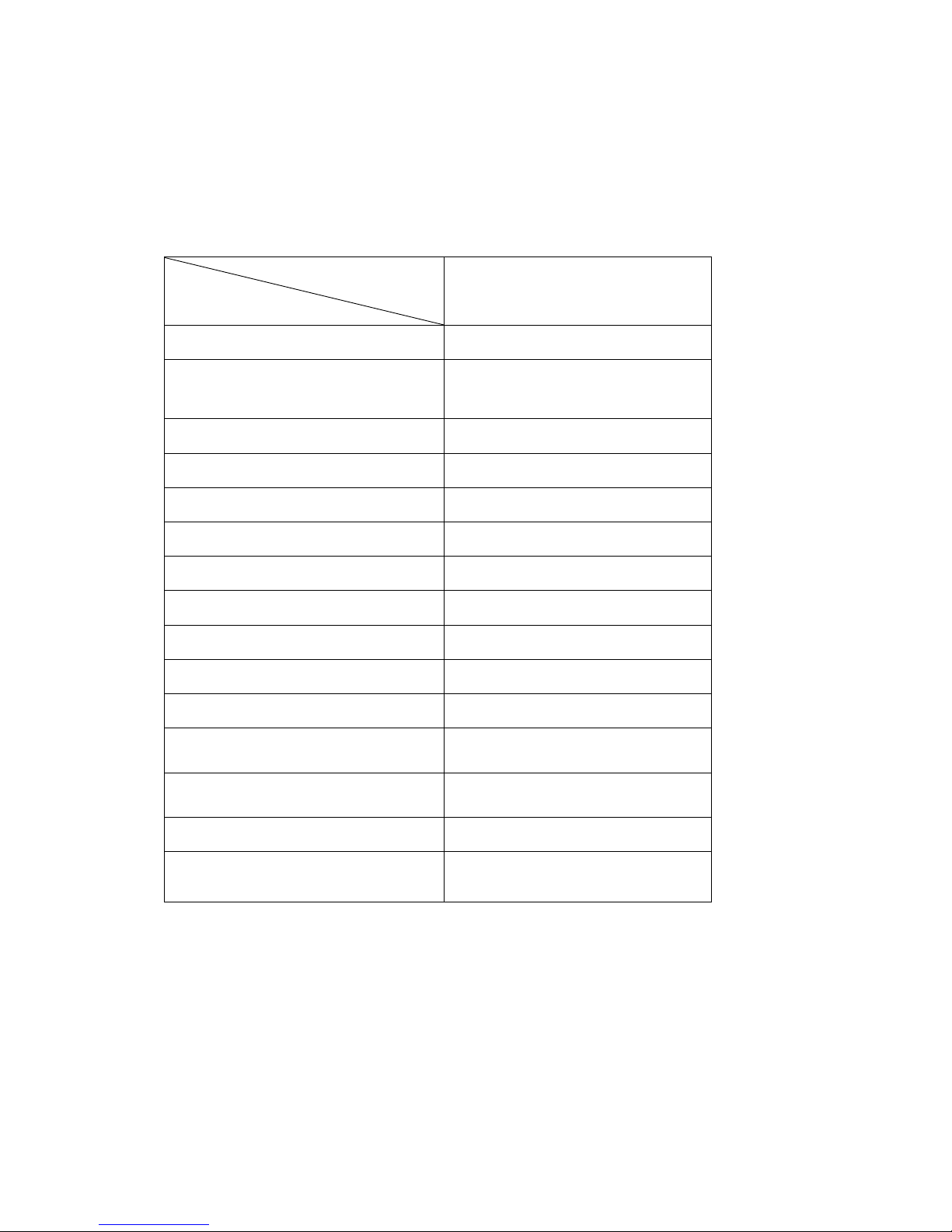

1. Major Technical Parameters

Model

LGK-40

Parameters

Input voltage(V) AC220V±10%

Input power supply capacity

(KVA)

6

No-load voltage(V) 230

Current adjustable range(A) 10-40

Rated output voltage(V) 100

Rated duty cycle(%) 60

Efficiency ≥ 85

Power factor cosø 0.93

Insulation level B

Casing protection level IP21

Arcing mode contacted

Recommended air compresso

pressure(KG)

Recommended air compresso

air displacement(KG)

4.5

0.17

Net weight(kg) 8

Dimensions(mm)

( L×W×H )

375×155×240

Page 5

2. Installation

2.1.Connection of the input lines

1. Every cutting machine is equipped with a power line, which should be

connected to appropriate voltage level. Some users directly connect the

220V power source to the 380V AC power supply due to carelessness and

make the components inside the machine burnt.

2. The power line should be well connected to the power switch or the

connector and prevented from oxidization. If possible, check if the power

voltage lies in the range percent with instruments.

2.2.Connection of the output lines

power source abnormity indicator cutting current knob

integrated electro-gas output cutting torch output terminal

A

terminal to cutting torch switch connector to workpiece

Figure 1. Control panel of LGK-40

Page 6

1. Connect the output terminal of the compressor and the input terminal (IN) of

the pressure reducing valve with a gas pipe; there should be closed butt

joint between the output terminal (OUT) and the copper tube on the back of

the machine.

2. Connect the copper nut on the cutting torch with the integrated electro-gas

output terminal and clockwise rotate it (to avoid air leakage). The fast plug

on the ground cable should be connected to the positive output terminal on

the front panel of the cutting machine and tightened up.

3. Connect the switch plug on the cutting torch with the cutting torch switch

connector on the panel.

4. Rotate the electrodes into the cutting torch in proper order. Tighten them

when they reach the end. Then correctly install the spray nozzle and the

shielding case onto the designated positions successively. (Attention: the

machine should be turned down each time the spray nozzle or the electrode

is replaced or examined.)

2.3.Examination

1. Whether the cutting machine is grounded according to the standard.

2. Whether all the connection points is well contacted.

3. Whether the voltage that the power line is connected to is correct.

4. Whether there is no abrasion, breakage or bending on the connection cable

and the gas pipe.

3. Operation

1. Turn on the power switch on the front panel and keep it to “ON”. This time

the power LED shines and the screen of the gauge outfit displays the preset

current value.

2. Rotate the air pressure knob to the value you want. Open the valve of the

compressed air.

3. Press down the control button on the cutting torch and the electromagnetic

valve acts. The discharging sound of high frequency arc striking from inside

the machine can be heard, and at the same time, gas flows out from the

spray nozzle of the cutting torch.

4. Preset the corresponding cutting current according to the thickness of the

workpiece to be cut.

Page 7

5. Contact the copper nozzle of the cutting torch with the workpiece (if the

copper nozzle carries with pilot arc, the distance between the nozzle and the

workpiece is approximately 2mm), and press down the button on the cutting

torch to ignite arc. Properly raise the cutting torch, making it about 1mm

from the workpiece, and then cutting can be started.

4. Precautions

4.1.Operating environment

• Use the machine in relatively dry air (humidity≤80%).

• The ambient temperature should lie between -10°C and +40°C.

• Avoid using the machine in direct sunlight or in the rain.

• Avoid using the machine in environments that is dusty or filled with

corrosive gas.

4.2.Summary for safety items

1. Keep good ventilation

The size of the machine is relatively small with compact structures, and the

output current is heavy. The natural ventilation condition cannot meet the heat

radiation requirements of the components, so an axial flow fan is installed inside

the machine for forced cooling.

NOTE: Do not cover or block the louver for ventilation on both sides and on the

front of the machine. The place that the welding machine is installed should at

least 0.3m from the surrounding objects. The ventilation condition should be

ensured to be ceaselessly improved. This is extremely important for the failure

free operation and service life of the welding machine.

2. By all means avoid overload

Overload operation is strictly forbidden. Otherwise sudden ceasing operation will

emerge during the cutting process. This is because the thermosensitive element

inside the cutting machine functions when it works at an overload. The primary

power source does not need to be cut off. Let the fan continue working to

quicken the cooling down process. The operation can be resumed when the

temperature drops to the tolerance range.

3. By all means avoid overvoltage

Consult the table of “major technical parameters” for the range of the power

supply voltage range of the cutting machine. In this case, the automatic

compensation circuit in the machine can ensure that the welding current does

not exceed the permitted level. If the supply voltage exceeds the specified value,

the components will be damaged, so please be twice as careful.

Page 8

4. There is a ground terminal on the back of each welding machine, whose

symbol is the earthing mark. Before working starts, connect the casing of the

machine with the ground with a wire whose sectional area is 10mm

2

to avoid

static electricity or electric leakage that can cause failure.

5. During working, do not touch the output terminal with bare hands to avoid

electric shock.

4.3.Matters needing attention during cutting

1. Hold the cutting torch with your hands and press the switch when you are

preparing to cut. If this moment there is plasma arc blowing out from the

nozzle bore, the electrode and the nozzle are correctly installed. If no

plasma or only weak plasma arc blows out from the nozzle bore, the

electrode and the nozzle are incorrectly installed and need reinstalling after

the machine is turned off.

2. The external rim of the nozzle bore should aim at the edge of the workpiece

when cutting begins. Press the switch of the cutting torch to strike arc. If the

arc is not stricken, release the switch and press it again. After the arc is

successfully stricken, move the cutting torch at a uniform speed to conduct

normal cutting (The speed varies according to the thickness of the plate. If

the sparks upwell, it indicates that the moving speed is too high and the

workpiece is not cut to full depth so that the moving speed should be

adjusted).

3. The cutting speed should be slowed down when cutting comes to the end

and the workpiece is about to be broken. Release the switch of the cutting

torch and cutting is finished.

4. If splashing matters adhere to the surface of the nozzle and affect the

cooling result, they should be cleaned without delay. In addition, the dust

and splashing matters on the head of the cutting torch should be often

cleaned so that the effect of heat elimination can be kept.

5. The wheel carrier of the cutting torch is for the purpose of keeping the

distance between the end face of the nozzle and the plate. It is strictly

forbidden to dismount the wheel carrier of the cutting torch. Otherwise the

distance between the end face of the nozzle and the plate cannot be

ensured and may cause the nozzle to contact the plate to burn the cutting

torch.

6. Replacement of the electrode and the nozzle

Page 9

The electrode and nozzle should be replaced when:

(1) The consumption depth of the hafnium wire of the electrode is over 1.5mm;

(2) The diameter of aperture of the nozzle is irregularly out of shape;

(3) The cutting speed obviously slows down and green flare emerges in the arc;

(4) It is hard to strike arc;

(5) The cut is skew or widen.

The electrode and the nozzle should be simultaneously replaced without delay;

otherwise strong arc will emerge inside the nozzle and break down the electrode

and the nozzle or even burn the cutting torch out. The nozzles are different if the

models are different so that the model uniformity should be kept when the

nozzle is replaced.

7. During cutting, the cable line should be kept as fully as possible. Even if the

space is too limited, dog leg should be avoided. Do not step on or extrude

the cable line in order to avoid gas suffocate and gas inadequacy that may

burn the cutting torch out. The cable line should be prevented from

contacting with sharp things so as to avoid breakage.

8. Dismount the nozzle casing, the nozzle, the electrode and the pilot arc line

(if the pilot arc line is not removed the cutting torch will be burned out).

Press down the switch after the machine is started up and this moment there

is gas blowing out from the hole of the air injector to clean the soil inside the

air injector. It should be cleaned once every day after used, which lasts

about 15s each time.

9. The head of the cutting torch should not be used as a knocking tool.

5. Maintenance

1. Periodically get rid of the dust with dry and clean compress air. If the welding

machine is used in environments with heavy smoke and serious polluted air,

dust elimination should be conducted at least once a month.

2. The pressure of the compressed air should be adjusted down to the value

required to prevent from damaging the small components in the machine.

3. Examine whether the electrical continuity places are well contacted

(especially the socket connectors). Reinforce the loosen connection points.

If there are oxidation phenomena, erase the oxide film with sandpaper and

reconnect them.

Page 10

4. Prevent the machine from water entering or being affected with damp,

otherwise dry it by blowing and examine the insulation condition with a

megohmmeter (both between the connected nodes and the between the

connection points and the casing). Welding cannot be continued unless no

abnormal circumstance is found.

5. If the welding machine will be disused for a long time, it should be put into

the original packaging and stored in a dry environment.

6. Troubleshooting

Note: The following operation requires that the operator have enough

professional knowledge on electricity and overall elementary knowledge of

safety. The operation should have the qualification certificate that can

prove his ability and knowledge.

Troubleshooting for LGK-40:

Faults Correction actions

The power LED shines

The fan does not rotate and the

control button is out of control.

The power LED shines.

The fan rotates. If the control

button of the cutting torch is

pressed, the electromagnetic

valve acts without the sound of

high frequency arc striking

discharging, and the red LED

inside the machine shines.

The power LED shines.

The fan rotates. If the control

button of the cutting torch is

pressed, the electromagnetically

operated valve acts without the

sound of high frequency arc

striking discharging, and the red

LED inside the machine does not

shine.

Overvoltage protection. Turn off the machine and wait for a

moment. Then restart the machine.

1. The MOS field effect tube K1170 of the upper board is

damaged (the driving module is damaged).

2. The step up electric transducer is damaged.

3. The control module is damaged.

There is something wrong with the arc striking part:

1. The distance of the discharging nozzle may be too long or

there may be edge adherence phenomenon.

2. There may be the phenomenon of open circuit or loose

contact in the primary coil of the arc striking transformer.

3. The quadruple voltage rectifier diode may be sparked

over.

4. The high frequency capacitor 102/10KV may leak

electricity.

5. The relay may be damaged.

Arc cannot be stricken during

welding, and the else is normal.

1. The input voltage is too low.

2. The pressure of the air compressor is too high or too low.

Page 11

Loading...

Loading...