WARPP INTIG-PULSE series Operating Manual

-1-

INTIG- PULSE

Digital Inverter

MMA/TIG / Pulse TIG

Welding Machines

Operating manual

WARPP ENGINEERS PVT. LTD.

B-1005, 10TH FLOOR, WESTERN EDGE II, NEAR METRO MALL,

OFF.WESTERN EXPRESS HIGHWA Y, BORIVALI (E,)

MUMBAI-400 063.

TEL: 91-22-28542272 /73/74 / 32404434 Fax91-22-28542275.

E-mail:sales@warpp.co.in Web Site: www.warpp.co.in

-2-

Thank you for selecting WARPP brand inverter welding machine. In order to keep

THE operator safe, away from unexpected accidents, and enjoy full benefits offered by

our quality products during welding, please read the instruction in details prior to

operation. Complying with procedures defined in this manual is always appreciated.

INDEX

1. Usage& Features……………………………………..…(3)

2. Safety Precautions………………………………………(3)

3. Installation…………….………………………………...(5)

4. Principle in Brief…………….………………………....(7)

5. Operating Instruction…………………………………..(8)

6. Repair& Maintenance.………………………….…….(14)

7. Technical Data………………………………………..(16)

8. Appendix A: Ordinary failures, probable cause &

countermeasures……………………(17)

9. Structural Diagram……………………………………….(18)

10. Spare Part List………………………………………….(24)

-3-

Usage & Features

IN TIG series pulse TIG welders include 315 A, and 400A types, can

Perform DC TIG, Pulse TIG, and DC MMA, used for mild steel, alloy

steel, stainless steel, Copper, Silver, and Titanium welding. This series

welder enjoy reasonable static characteristic and sound dynamic

characteristic as well as comprehensive functions:

& Soft switch Inverter, high efficiency and reliability, small size,

light weight and portable

& Non-source power factor correcting technical, high PF(power

factor)

& Multifunction, convenience, good adjustability

& Less spatter, less weld distortion, pretty weld formation.

& High success rate of arc-starting due to stronger pulse strike

& Pulse frequency, pulse ratio, pulse amplitude can be adjusted

freely in wider range.

Safety precautions

General safety precautions:

z Please strictly comply with rules defined in this manual to avoid

unexpected accidents

z How to connect to power supply, select working area and use

pressure gas, please comply with proper rules

z Not allow non-operator for entering working area

z Welding machine installation, inspection, maintenance, operation

should be completed by authorized person.

z Don’t use welding machine for unrelated purpose (Such as

recharging, heating or pipe thawing )

z Must take safe precaution in case welder falling when it is put on

the uneven ground

-4-

Avoid being electric shocked and burnt

z Never touch on the hot electrical units.

z Please instruct the authorized electrician to ground the welder

case by using proper sized copper wire.

z Please instruct the authorized electrician to connect the welder to

power supply by using proper- sized, well-insulated copper wire.

z When operating in the damp, space-limited area, must ensure

well-insulated between body and work piece

z When operating at the high-rising location, must ensure safety by

using safe net.

z Please power off the welder while no longer using.

Avoid breathing in hazardous welding fume or gas

z Please use specified ventilation to prevent being gas poisoned

and asphyxiated

z Especially in the container where oxygen is depleted easily

Avoid being harmed by arc flash, hot spatter and slag

z Arc rays can injure your eyes and make your eyes feel

uncomfortable.

z Hot spatter and slag can burn your skin.

z Please wear proper welding helmet, leather gloves, long- sleeved

suit, cap, apron and boot before welding.

Preventing accidents from fire, explosion, container

break

z Don’t put flammable material in the working area. Hot spatter

and hot weld can easily start a fire.

z Cable must be connected the work piece firmly to ensure good

conductivity in case causing fire by resistance heat.

z Don’t weld in the flammable gas or weld container which

contains flammable material, otherwise it can cause explosion.

z Don’t weld encapsulated container, otherwise it can break.

z Ensuring fire extinguisher at hand in case a fire break out.

-5-

Avoid being hurt by moving parts

z Never let the finger, hair, and cloth near the rotary cooling fan

and wire feeder rollers.

z When feeding wire, don’t let the bottom of gun near your eyes,

face and body, to prevent being harmed by wire.

Avoid gas bottle falling or gas regulator breaking

z Gas bottle must be firmly fixed on the ground, else if injure will

exerts on.

z Never place bottle under high temperature or sun light.

z Never let your face near gas outlet while turning on the gas valve

to prevent from being hurt by pressure gas.

z Customer should use gas regulator provided by our company, and

comply with the proper instruction.

Avoiding being hurt by welders while in transport

z When moving the welding machine by fork-lift truck or crane,

nobody can be allowed for standing downright the route of the

moving welder, in case being hurt by the falling welder.

z The ropes or wires which used for hanging up the welding

machine must be strong enough to withstand corresponding

tension strength. The rope or wire inclination hanging on the

tackle must be no more than 30°.

Installation

1. Installing situation:

(1) Must place welding machine in the room where is no straight

sunlight, no rain, less dust, low humidity, and temperature range

of -10~+40

(2) The gradient of ground must be no more than 15°

(3) Ensure no wind at the welding position, or use screen to block

the wind.

-6-

(4) The distance between welder and wall must be more than 20cm,

between welders more than 10cm to ensure enough heat

radiation.

(5) When using water cooled gun, must be care of not being frozen.

2. Requirement of input supply:

(1) Input volt must be standard sine wave, effective value 350 ~

465V,frequency 50Hz/60Hz

(2) Unbalance degree of three phase volt must be no more than 5%

3. Power supply:

Table1: The size of fuse and breaker in the table are for reference only.

4. Installation:

The input power of this series welding machines is three phase

AC 350 ~ 465 V. Operator must use the properly disconnected

switchboard or switch box(not outfitted by our company) which is

equipped air switch or breaker, and make sure to ground the

machine safely and firmly.

Product type IN TIG-315 P IN TIG-400 P

Power supply

3 phase AC380V

Min. capacity Power network 13.8KVA 18.4KVA

Input volt

protection

Fuse 32 A 32 A

Circuit breaker 32 A 32A

Cable size

(cross-section)

Input side 4mm

2

4mm2

Output side 35mm2 50mm2

Earth lead 4mm2 4mm2

-7-

4.1 For MMA welding:

(1) Connect welding cable to welding machine tightly.

(2) Reset the circuit beaker on the rear panel of the machine

(3) Connect the input power cable to the disconnected switchboard,

then power on.

4.2 For TIG welding:

(1) Well-connect welding cable with welder (+), and well-connect TIG

torch with welder (-).

(2) Well-connect gas hose and gas source; well-connect water pipe and

water source when using water cooled torch.

(3) Close air switch of the welder.

(4) Connect 3 phase cable with the switchboard and power it on.

Principle in Brief

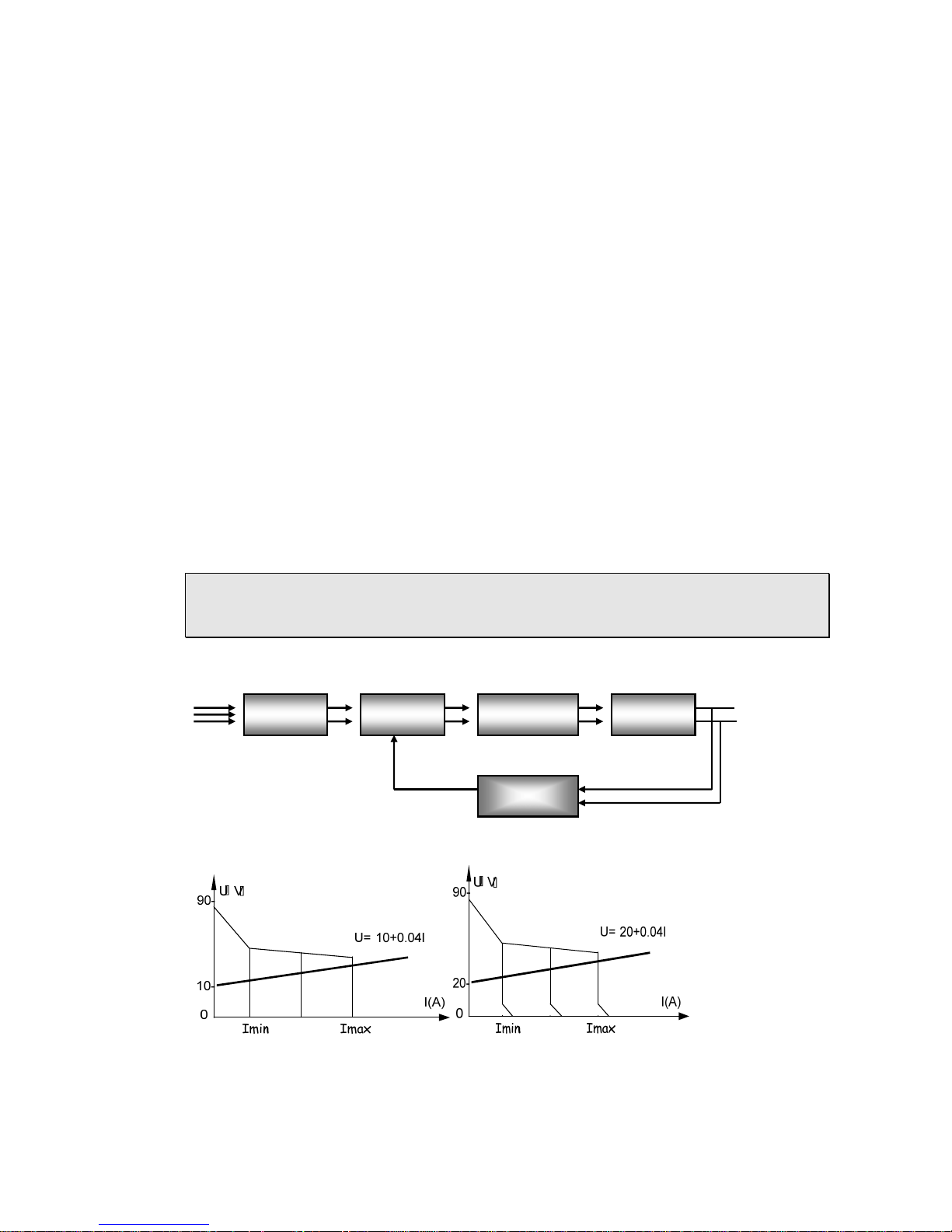

Fig 2 Block diagram of principle

Fig 3a TIG Output Characteristic Fig 3b SMAW output characteristic

3~380V/50Hz

Rectifier HF inverter Main transformer

Rectifier Filter

Control circuit

+

-8-

This series welding machines apply IGBT soft switch inverter technology.

3- phase input volt are rectified by rectifier, inverted into HF AC, reduced

by HF transformer, rectified and filtered by HF rectifier, then output DC

power suitable for welding. After this process, the welder’s dynamically

responsive speed has been greatly increased, so the welder size and

weight are reduced noticeably result in energy saving. Power source enjoy

sound anti-fluctuating ability and high-quality performance during

external context changes (As to fluctuation in input power supply and

extended welding cables). Easy to arc start, stable arc length, pretty weld

formation and capability of continuous regulation the current of welding,

arc-starting and arc force as well as time of down-slope add significant

values to customers. They have down-slope, pre-gas flow and post-gas

flow function due to reasonable logic circuit design.

Operating Instruction

1. Function introduction

1.1 Front panel illustration and parts number reference

Fig.4: Front panel

Loading...

Loading...