Page 1

IN ARC-I / IN TIG-I Series

Inverter Ar c W elding Machines

Operating Manual

WARPP ENGINEERS PVT. LTD.

B-1005, Western Edge II, Western Express Highway,

Near Metro Mall, Borivali (E), Mumbai-400 066.

Tel: 91-22-28542272/ 73/74. Fax: 91-22-28542275.

E-mail:sales@warpp.co.in

Web Site: www.warpp.co.in

1

Page 2

Thank you for selecting WARPP brand inverter welding machine. In order to keep you safe away from

unexpected accidents, and enjoy full benefits offered by our qua lity products during welding, please read the

instruction in details prior to operation. Complying with procedures defined in this manual is always

appreciated.

INDEX

1. Usage& Features……………………………………...…………………..(3)

2. Safety Precautions………………………………………………………...(3)

3. Installation…………….……………………………….………………….(5)

4. Definition of Product Model Number………………….…………………(6)

5. Principle in Brief…………….……………………………………………(6)

6. Operating Instruction………………………………….…………………..(7)

7. Repair and Maintenance.………………………….………….………….(12)

8. Main technical parameters……………………………………………….(15)

9. Appendix A: Common failures, probable cause & countermeasures…... (19)

10. Spare Part List…………………………………………………………(20)

2

Page 3

Usage & Features

This Series Inverter Arc welding machines include 2 welding combinations: IN ARC

(SMAW) & IN TIG (SMAW/TIG) with different specifications of rated current: 400A,

500A, 630A, etc., which are novelty high-efficient and energy-saving DC Arc welders,

not only are used in carbon steel and low alloy steel welding, but also used in stainless

steel, high alloy steel, copper, silver, molybdenum and titanium welding. As to its sound

static and dynamic characteristic and HF arc starting function, the series welders have

the following features:

¾ Invert technology can assured welding current high stability and arc length

consistency in fluctuating input primary power. Welding arc enjoys high

self-adjustability and mild strength.

¾ Low spatter

¾ Easy to start arc

¾ High deposit efficiency

¾ the machine can adjust its down- slope time while stopping arc. Weld formation are

pretty good.

¾ With remote control function, welding parameters can be adjusted in extended

distance.

¾ Light, small and portable.

¾ High power factor, high efficient and energy saving

Safety Precautions

General safety precaution:

z Please strictly comply with rules defined in this manual to avoid unexpected

accidents

z How to con nect to power supply, select working area and use pressure gas, please

comply with proper rules

z Not allow non-operator to ent er working area

z Welders’ installation, inspection, maintenance, and manipulation must be completed

by authorized person.

z Don’t use welding machine for unrelated purposes (Such as recharging, heating or

pipeline thaw, etc.)

z Must take safe precaution in case welder falling when it is put on the uneven ground

Avoid being electric shocked and burnt

z Never touch on the hot electrical units.

z Please instruct the authorized electrician to ground the welder frame by using

3

Page 4

proper-sized copper wire.

z Please instruct th e authorized electrician to connect the welder to power supply by

using proper- sized, well-insulated copper wire.

z When operating in the damp, space limited area, must ensure w ell-insulated betw een

body and work piece

z When operating in the high-rising location, must ensure safety by using safe net.

z Please power off the input voltage while no longer using.

Avoid breathing in hazardous welding fume or gas

z Please use specified ventilation to prevent being gas poisoned and asphyxiated

z Especially in the container where oxygen is depleted easily

Avoid being harmed by arc flash, hot spatter and slag

z Arc rays can injure your eyes and make your eyes feel uncomfortable.

z Hot spatter and slag can burn your skin. Please wear proper welding helmet, leather

gloves, long- sleeved suit, cap, apron and boot before welding.

Preventing from fire, explosion, container break accidents

z Don’t put flammable material in the working area. Hot spatter and hot weld can

easily start a fire.

z Cable must be connected the work piece firmly to ensure good conductivity in case

causing fire by resistance heat.

z Don’t weld in the flammable gas or weld container which contains flammable

material, otherwise it can cause explod e.

z Don’t weld encapsulated container, otherwise it can cause break.

z Ensuring a fire extinguisher at hand in case fire break out.

Avoid being hurt by moving parts.

z Never let the finger, hair, and cloth near the rotary cooling fan and wire feeder

rollers.

z When feeding wire, don’t let the bottom of gun near your eyes, face and body, to

prevent being harmed by wire.

Avoid gas bottle falling or gas regulator breaking

z Gas bottle must be firmly fixed on the ground, else if injure will exerts on.

z Never place bottle under high temperature or straight sun light.

z Never let y our face near gas outlet while turning on the gas valve to prevent from

being hurt by pressure gas.

z Customer should use the gas regulator provided by our company, and comply with

the proper instruction.

4

Page 5

O

Avoid being hurt by welding machine while in transport

z When moving the welding machine by fork-lift truck or crane, nobody can be

allowed for standing downright the route of the moving welder, in case being hurt

by the falling welding machine.

z The ropes or wires which used for hanging up the welding machine must be strong

enough to withstand corresponding tension strength. The rope or wire inclination

hanging on the tackle must be no more than 30°

Installation

1. Installing situation

1. Must place welding machine in the room where is no straight sunlight, no rain, less

dust, low humidity ,and temperature range of -10Ԩ~+40Ԩ

2. The gradient of ground must be no more than 15°

3. Ensure no wind at the welding position, or use screen to block the wind.

4. The distance between welder and wall must be more than 20cm, between welders

more than 10cm to ensure enough heat radiation.

5. When using water cooled gun, must be care of not being frozen.

2. Requirement of input volt:

(1) Input volt must be standard sine wave, effective value 380V±10%, frequency

50Hz/60Hz

(2) Unbalance degree of 3- phase volt must be no more than 5%

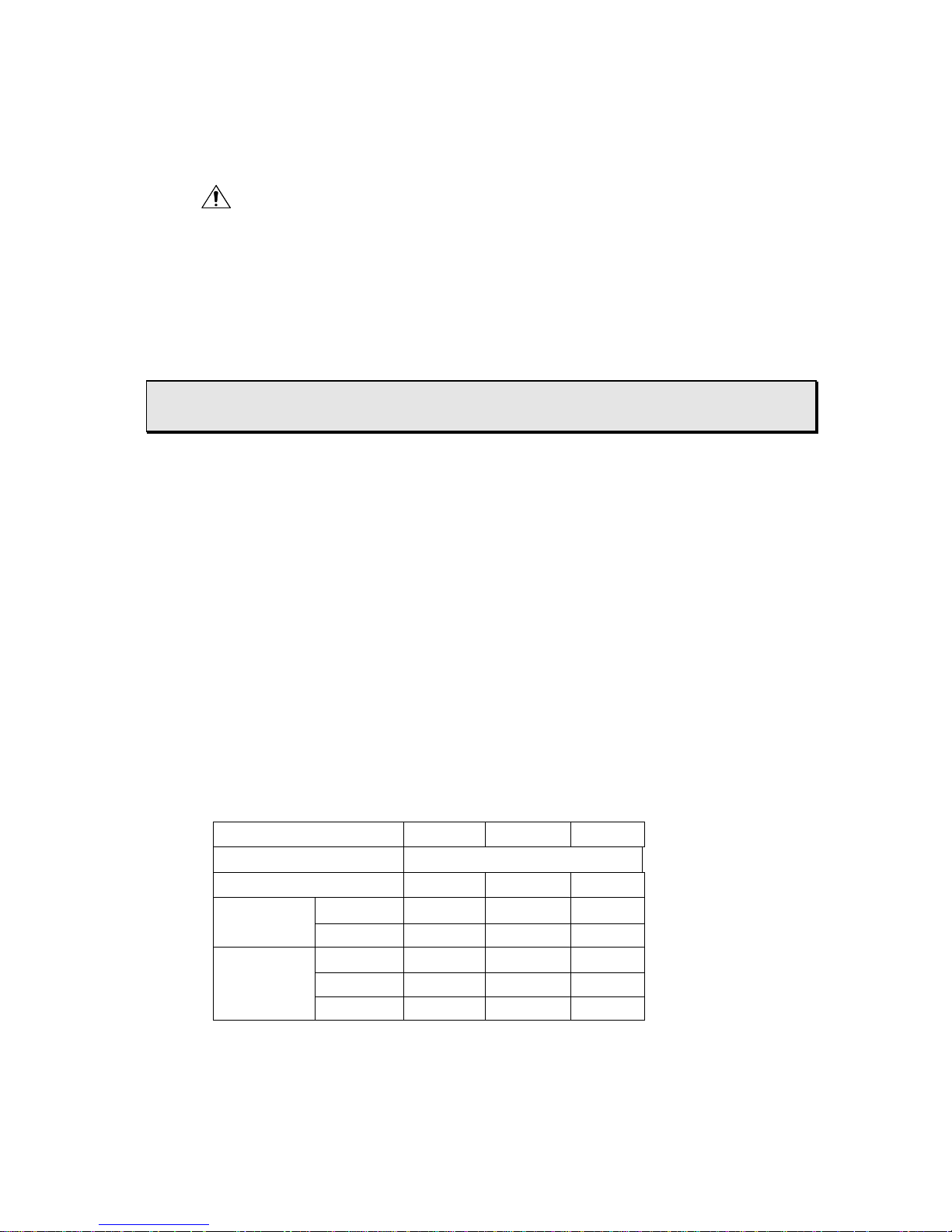

(3) Power supply:

z The size of fuse and breaker in the table are for reference only.

Product type 400 500 630

Power supply 3 phase AC380V

Min. power capacity 28KVA 38KVA 51KVA

Input

protection

Min.

Cable

size

Fuse 50A 63A 63A

breaker 63A 100A 100A

2

Input side 4mm

6mm2 6mm2

utput side 50mm2 50mm2 70mm2

Earth lead 4mm2 6mm2 6mm2

5

Page 6

3. Installation

The machines are portably designed, can be effortlessly moved by operators without

fix-up. But it should be settled in even and dry places with well ventilation.

3.1 SMAW mode

(1) Ensure firmly connection to welding cable.

(2) Connect to remote controller( If needed)

(3) Adjust every knobs, and switches on the front panel to proper position in line

with selected mode.

(4) Turn on the air switch on the power source.

(5) Connect input 3 phase primary power cable to switch box.

3.2 TIG mode

(1) Ensure firmly connection to welding cable and TIG torch.

(2) Ensure firmly connection to gas hose and gas bottle and or water hose and

water supply as to using water-cooled welding torch.

(3) Connect to remote controller(If needed)

(4) Adjust every knobs, and switches on the front panel to proper position in line

with selected mode.

(5) Turn on air switch on the power source.

(6) Connect input 3 phase power cable to switch box and close it.

Attention: Before you plug the welding cable, please turn off the power and rightly

calibrate the plug key to the socket slot a t first, then insert and turn the plug clockwise until

it firmly seated. Make sure the plug and the socket are well-connected to be sound

conductivity in case that they are burnt out by over resistance heat.

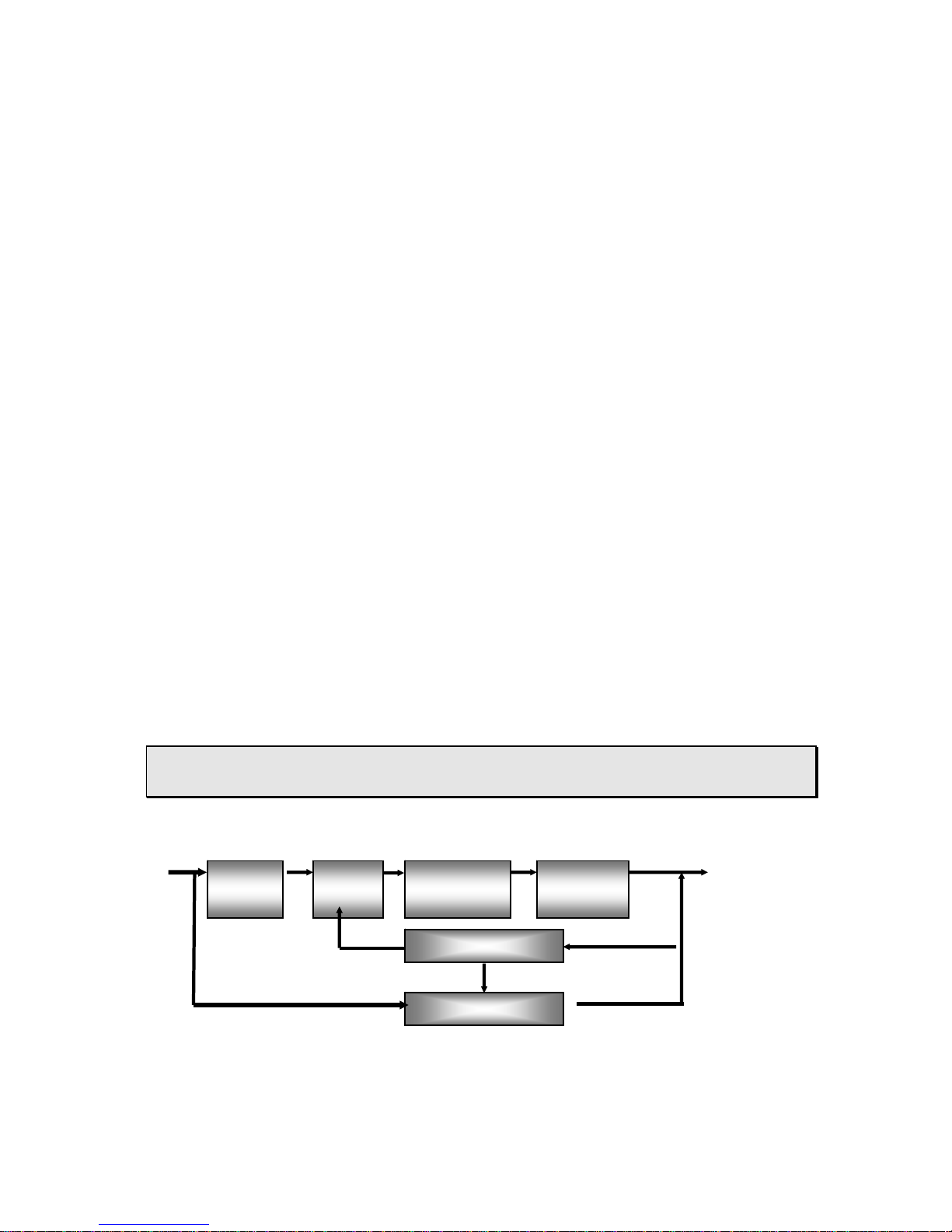

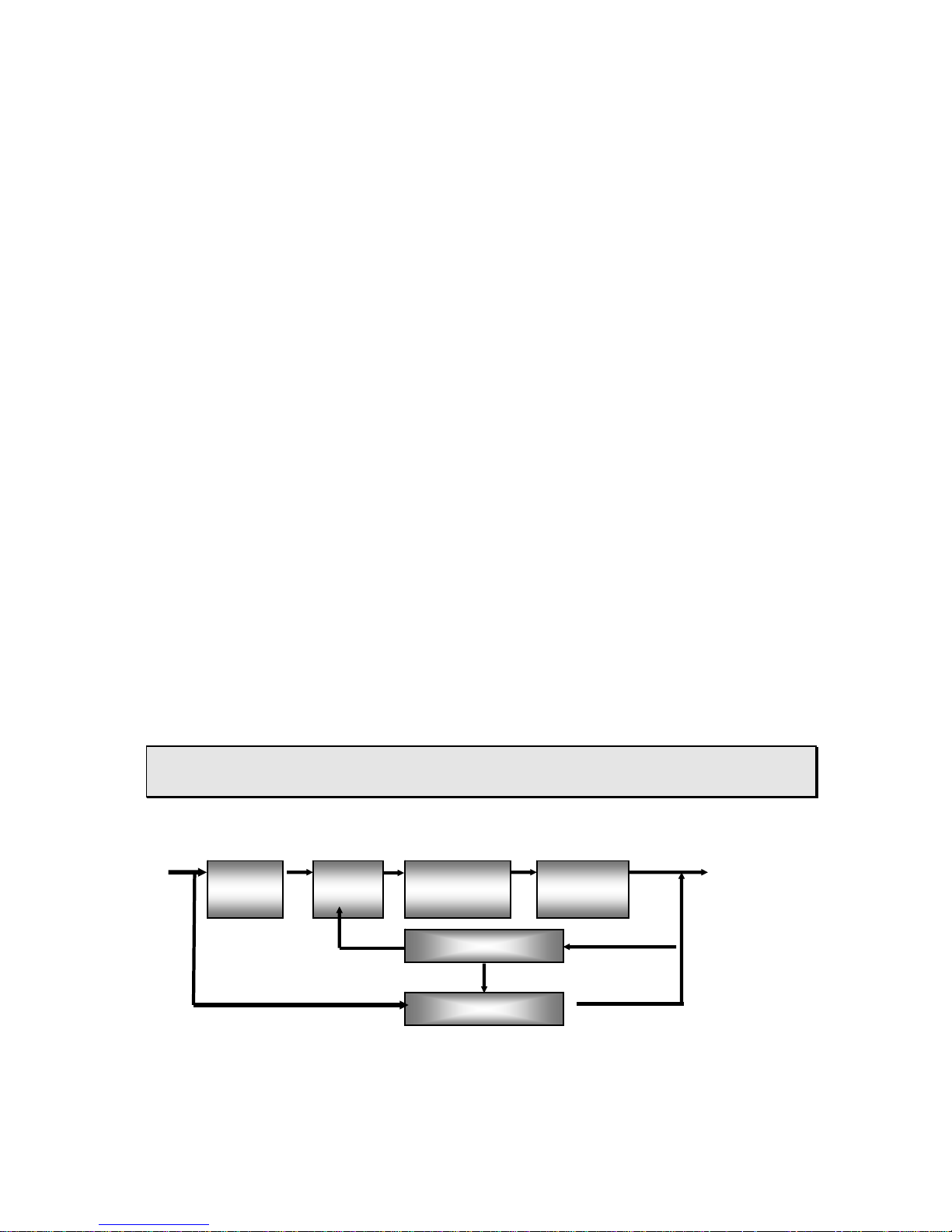

Block diagram of principle

3~380V/50Hz Output

3 phase

Rectifier

HF

Inverter

Transformer

High frequency arc start

HF

Control circuit

6

Principle in Brief

Rectifier &

Filter

Page 7

3. Installation

The machines are portably designed, can be effortlessly moved by operators without

fix-up. But it should be settled in even and dry places with well ventilation.

3.1 SMAW mode

(1) Ensure firmly connection to welding cable.

(2) Connect to remote controller( If needed)

(3) Adjust every knobs, and switches on the front panel to proper position in line

with selected mode.

(4) Turn on the air switch on the power source.

(5) Connect input 3 phase primary power cable to switch box.

3.2 TIG mode

(1) Ensure firmly connection to welding cable and TIG torch.

(2) Ensure firmly connection to gas hose and gas bottle and or water hose and

water supply as to using water-cooled welding torch.

(3) Connect to remote controller(If needed)

(4) Adjust every knobs, and switches on the front panel to proper position in line

with selected mode.

(5) Turn on air switch on the power source.

(6) Connect input 3 phase power cable to switch box and close it.

Attention: Before you plug the welding cable, please turn off the power and rightly

calibrate the plug key to the socket slot a t first, then insert and turn the plug clockwise until

it firmly seated. Make sure the plug and the socket are well-connected to be sound

conductivity in case that they are burnt out by over resistance heat.

Block diagram of principle

3~380V/50Hz Output

3 phase

Rectifier

HF

Inverter

Transformer

High frequency arc start

HF

Control circuit

6

Principle in Brief

Rectifier &

Filter

Page 8

(A)

This series welding machines apply IGBT soft switch inverter technology. 3- phase input

volt are rectified by rectifier, inverted into HF AC, reduced by HF transformer, rectified and

filtered by HF rectifier, then output DC power suitable for welding. After this process, the

welder’s dynamical responsive speed has been greatly increased, so the welder size and

weight are reduced noticeably result in energy saving. Power source enjoy sound

anti-fluctuating ability and high-quality performance during external context changes (As to

fluctuation in input power supply and extended welding cables).Easy to arc start, stable arc

length, pretty weld formation and capability of continuous regulation the current of welding,

arc-starting, arc force and time of down-slope as well as remote control availability add

significant values to customers. They can also perform down-slope, pre-gas flow and

post-gas flow function due to reasonable logic circuit design.

IN ARC Series arc welding machines output characteristic curve is as follows:

90–

20 –

0

U=20+0.04I

I

1. Functional introduction

Operating Instruction

7

Page 9

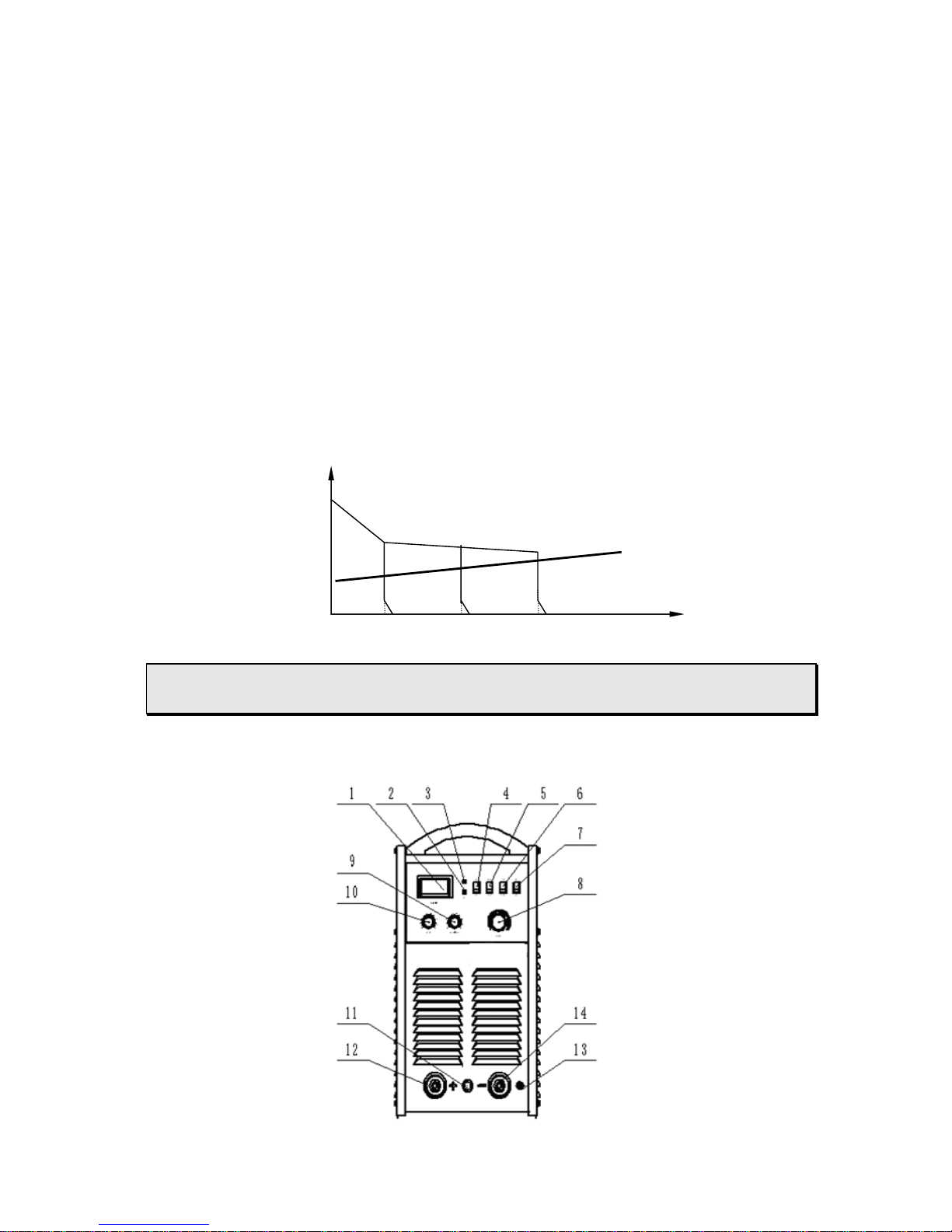

Front panel illustration and parts number reference

1.1

(1) “ Amp/volt ” meter

When meter mode switch indicates to “Amp”, the meter display s preset value while

in open load, and display practical value of welding current while in actual working.

To “Volt”, display practical value while in welding.

(2) “Protection” indicator lamp

Welding machine will automatically stop working when it is overheat, and the lamp

will be light on.

(3) “Power” indicator lamp

Lamp indicating whether power source is effectively connected to power supply

(4) “Amp/Volt” meter mode switch

(5)”SMAW/TIG” Switch (Only in IN TIG Series).

When it is indicated to “SMAW”, the machine is to work on SMAW;

When it is on “TIG”, the machine is to work on TIG

4-step/ 2-step switch (Only in IN TIG Series).

(6) “Remote/ Panel control” switch ((200 series only equipped with Panel control)

When it is on “Panel control”, you can adjust current of welding, arc force or

down-slope time through the knobs and switches on the panel; when it is on “Remote

control’, you can adjust the above parameters through remote control box in a

extended distance from the welding areas

(8) “Welding current” regulation knob

Used to adjust welding current on panel control mode

(9) “Arc force current/ down-slope time” regulation knob

Used to adjust arc force current under SMAW or stop-arc time under TIG

(10) “Arc-starting current “regulation knob used to adjust arc starting current

(11) “Remote control/ TIG” cable socket

It is used to connect with remote control cable to adjust welding current, arc force

current or down-slope time through remote control box when it is on the “Remote

control” mode, used to weld in extended distance.

To weld in normal distance on TIG, it is used to connect TIG torch's control cable

directly.

(12)Welding cable (+) quick plug socket

It is used to connect with stick holder on SMAW mode. Connect to work leads on

TIG mode.

(13)Gas outlet (S series not equipped with it)

Connect to TIG torch gas hose.

(14)Welding cable (-) quick plug socket

It is connected to work lead on SMAW mode and connected to TIG torch welding

cable on TIG mode.

.

8

Page 10

(11) “Remote control/ TIG” cable socket

It is used to connect with remote control cable to adjust welding current, arc force

current or down-slope time through remote control box when it is on the “Remote

control” mode, used to weld in extended distance.

To weld in normal distance on TIG, it is used to connect TIG torch's control cable

directly.

(12)Welding cable (+) quick plug socket

It is used to connect with stick holder on SMAW mode. Connect to work leads on

TIG mode.

(13)Gas outlet (S series not equipped with it)

Connect to TIG torch gas hose.

(14)Welding cable (-) quick plug socket

It is connected to work lead on SMAW mode and connected to TIG torch welding

cable on TIG mode.

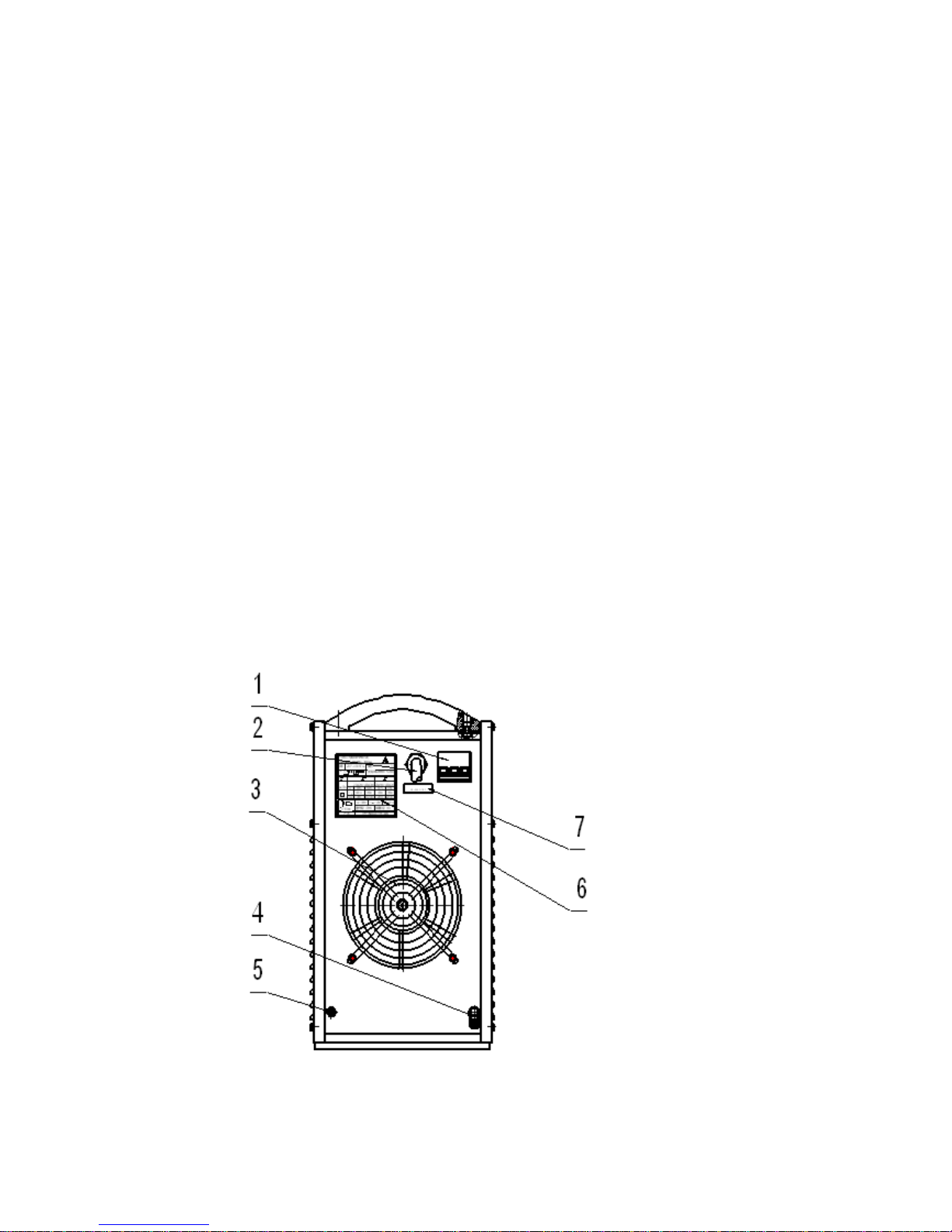

1.2 The rear panel and parts number reference

(1) Air switch

The function of air switch is to protect welding machine by automatic trip to turn-off

power supply while in machine overload or failure. Normally, the switch flipped to

upward means power-on. Use switch on the switch box to start or stop welding

machine, avoiding using the breaker.

(2) Input power cable

It is 4-pin cable. The mixed-colored wire must be firmly grounded, the rest wires

connect to corresponding 3-phase power supply (380v/50Hz).

8

Page 11

2.1.1 Shift between two working styles:

(1) Shift from down-slope to non-down-slope

Switch to “TIG” mode, pull TIG torch trigger, then loose it, open load voltage of

power source will disappear to indicate working style being shifted to

non-down-slope.

(2) Shift from non-down-slope to down-slope

Switch to “SMAW” mode from “TIG”, then back to “TIG” to complete shift.

2.1.2 Scratch arc-start with down-slope working style

Reference to 2.2.2 operation procedure

2.1.3 Scratch arc-start with non-down-slope working style

Reference to 2.2.3 operation procedure

2.2 Working styles on TIG mode of type STG series

Can be divided into 2 working styles: scratch arc-start and high frequency arc-start.

2.2.1 Shift between two working styles:

Shift scratch arc-start to high frequency arc-start

(1)Switch to “TIG” mode, then pull TIG torch trigger, then loose it, open load

voltage of power source will disappear to indicate working style is shifted to HF

arc-start.

(2)Shift HF arc-start to scratch arc-start

Switch to “SMAW” mode from “TIG”, then back to “TIG” to complete shift.

2.2.2 High frequency arc-start

Procedure flow sheet shows below :( Next page)

In principle, welders’ maintenance and repair should be co mpleted by us or our authorized

distributors. Customers can also solve the problems instructed by us or our authorized

distributors.

1. Attention:

(1) Rivet equipment name tag on the specified area of the case, otherwise the inside

parts will be damaged.

(2) Connect welding cable to terminal lug firmly, otherwise the terminal lug will be

burn out which will lead to welding process instability.

(3) Prevent jointer of welding cable and terminal lug from contacting with other

metals on the ground to avoid short circuit.

(4) Operating carefully not to make welding and control cable to be worn out or

Repair and Maintenance

11

Page 12

(1) “Amp” meter

It displays preset value while in open load, and displays practical value of

welding current while in actual working.

(2) “Welding current” regulation knob

(3) “Arc force current/ down-slope” regulation knob

(4) Socket 1

Connect to remote control cable.

(5) Socket 2

Connect to welding torch control cable which has a plug. There are 2 control wires

welded to lug 1 and lug 2 respectively on the plug

2. Operating instruction

Turn on the air switch on the switch box, the “Normal” indication lamp will light

on and cooling fan rotate. Before welding normally, set up parameters by adjusting

knobs and switches on the control box and front panel according to the selected

mode. Customer should refer to parameters defined in table 1 and table 2 showing

below:

Table 1 SMAW welding parameters

Work piece thickness

(mm)

<1

2 3

4~5 6~12

≥13

Electrode diameter

(mm)

Welding current(A) 20~40 40~50 90~110 90~130 160~250 250~400

1.5 2 3.2

10

3.2~4 4~5 5~6

Page 13

Table 2 TIG welding parameters

Welding current

(A)

40~50

50~80

80~120

120~160

160~200

200~300

Tungsten electrode

diameter(mm)

1~2

2~4

Max Argon gas

flow rate(L/min)

Work piece

thickness(mm)

1~3

3~6

6~9 300~400 4~6

Attention: On SMAW, when welding current is low and cable length of stick holder is

short(no more than 40m), arc force current should be adjusted in the range of 1-7 .

As to large welding current and long cable of stick holder, where volt potential

difference is very high between the two ends of cable, arc force current should be

adjusted in the range of 7- 10.

2.1 Working styles on TIG mode of ST series

Can be divided into 2 working styles: scratch arc-start with down-slope and

scratch arc-start without down-slope.

2.1.1 Shift between two working styles:

(1) Shift from down-slope to non-down-slope

Switch to “TIG” mode, pull TIG torch trigger, then loose it, open load voltage of

power source will disappear to indicate working style being shifted to

non-down-slope.

(2) Shift from non-down-slope to down-slope

Switch to “SMAW” mode from “TIG”, then back to “TIG” to complete shift.

2.1.2 Scratch arc-start with down-slope working style

Reference to 2.2.2 operation procedure

2.1.3 Scratch arc-start with non-down-slope working style

Reference to 2.2.3 operation procedure

4

6

7

8

9

10

12

11

Page 14

2.2 Working styles on TIG mode of type STG series

Can be divided into 2 working styles: scratch arc-start and high frequency arc-start.

2.2.1 Shift between two working styles:

Shift scratch arc-start to high frequency arc-start

(1)Switch to “TIG” mode, then pull TIG torch trigger, then loose it, open load

voltage of power source will disappear to indicate working style is shifted to HF

arc-start.

(2)Shift HF arc-start to scratch arc-start

Switch to “SMAW” mode from “TIG”, then back to “TIG” to complete shift.

2.2.2 High frequency arc-start

Procedure flow sheet shows below :( Next page)

Repair and Maintenance

In principle, welders’ maintenance and repair should be co mpleted by us or our authorized

distributors. Customers can also solve the problems instructed by us or our authorized

distributors.

1. Attention:

(1) Rivet equipment name tag on the specified area of the case, otherwise the inside

parts will be damaged.

(2) Connect welding cable to terminal lug firmly, otherwise the terminal lug will be

burn out which will lead to welding process instability.

(3) Prevent jointer of welding cable and terminal lug from contacting with other

metals on the ground to avoid short circuit.

(4) Operating carefully not to make welding and control cable to be worn out or

Broken

12

Page 15

Auto-lock Non-Auto lock

Release trigger

Hold on trigger

Pull TIG torch trigger

Pre-gas flow , HF/ scratch arc-start

Hold on trigger

Welding Welding

Release trigger

Down -slope

Down-slope

Release

Until crater fill

Until crater fill

Push trigger

Post-gas flow

Post-gas flow

Up -slope

Release trigger

Up-slope

Reset power source

Fig. HF arc-start procedure flow sheet

(5) Never let welding machine be bumped into or stacked up by heavy objects.

(6) Ensure good ventilation

(7) Temperature of cooling water is no more than 3 0 and no less than 0. The water

must be clean without impurity for fear of blocking water circulation which will

result in torch damage.

The machines can halt automatically, when work with large current for a long time.

Overheat protection lamp will light on. The machines will recovery after running up several

minutes in open load.

13

Page 16

(8) If the air switch on rear panel trips when the machine has worked with large

current for a long time, operator should power off the switch, then start the

machine in 5 minutes. Remember before starting the machine, turn on the air

switch on the rear panel, power on the switch box. The machine will be ready after

running under open load for several minutes.

(9) Be sure to turn off argon and water as well as power source when finish welding.

2. Periodic inspection and maintenance

(1) Removes dust from power resource with pressure air by authorized maintainer

every 3-6 months. Check if the bolt is loose.

(2) Check frequently if control cables are worn out, adjusting knobs are loose, and

components of panel are damaged.

(3) Check output cable periodically, if jointers are loose or plugs are distortion, please

repair in time, otherwise the sockets will burn out.

(4) Clear up or change contact tips and tungsten electrodes timely.

3. Trouble shooting

3.1. Checking procedure prior to maintenance

(1) Check if the panel switches and potentiometers are on the proper position

(2) Check if the input volt has phase missing, and range are between 340-420V.

(3) Check if the input cable connects correctly and firmly with the power source.

(4) Check if the welding cables connect correctly and firmly.

(5) Check if water circulation and CO2 flows out smoothly.

Warning:

Don’t open up case uninstructed, the max volt inside mach ine is 600V. Take safe

precautions to prevent from being electric shocked while in maintenance.

Never discharge high voltage to welder case with welding torch! Shut down power

source before changing or repairing welding cable or torch

14

Page 17

Technical data

Main technical parameters

Description

400 500 630

Primary power voltage/frequency 3 phase 380V±10%/50Hz

Rated output capacity 14.4KW 20KW 27.7KW

Rated input current 28A 38A 52A

Rated duty cycle 60%

Parameters

Range of output current

20~400A 20~500A 50~630A

Output voltage of open load 80±8V

Full-load efficiency 89%

Power factor(full-load)

Welding electrode diameter

Tungsten electrode diameter

2~6mm 2~6mm 2~6mm

1~6mm 1~6mm 1~6mm

0.95

Weight 43Kg 47Kg 55Kg

Dimension 636×322×582 mm 576×297×557 mm

Max argon flow rate 25L/min

Main transformer H

Insulation grade

Power source transformer、

B

output reactance

15

Page 18

z IN ARC / IN TIG-400 I

No. Tab Item Qua. Memo

1 K1 Air switch 1

2 D1 3-phase rectifier module 1 Small

3 L1 Polypropylene capacitor 1

4 C30 Polypropylene capacitor 1

5 C4 IGBT module 1

6

M1、M2

Voltage sensitive resistance 2

7 R1 Ceramic dielectric capacitor 1

8

C8~C17

Ceramic dielectric capacitor 10

9 T1 Main transformer 1

10 T4 Power source transformer 1

11 T5 Insulation transformer (IN TIG) 1

12

D1~D4

13 L2

Fast recovery diode module 2

Current exchange inductor (IN

TIG)

1

14 F1 Fuse size 1

15 YHB

Arc-start board components (IN

TIG)

1

16 T3 Stray transformer (IN TIG) 1

17 M axial airflow fan 1

18 Switch 4

19 Digital displayer 1

20 SW Thermal relay 1

21 Potentiometer 1

Current

adjustment

22 Potentiometer 2

23 Electromagnet valve (IN TIG) 1

24 Main control board 1

25 Driving board 1

Force

arc-starting

adjustment

16

Page 19

z IN ARC / IN TIG-500 I

No. Tab Item Qua. Memo

1 K1 Air switch 1

2 D1 3-phase rectifier module 1 big

3 L1 Polypropylene capacitor 1

4 C30 Polypropylene capacitor 1

5

6

C4~5

M1、M2

IGBT module 2

Voltage sensitive resistance 2

7 R1 Ceramic dielectric capacitor 1

8

C8~C19

Ceramic dielectric capacitor 12

9 T1 Main transformer 1

10 T4 Power source transformer 1

11 T5 Insulation transformer (IN TIG) 1

12

D1~D6

13 L2

Fast recovery diode module 3

Current exchange inductor (IN

TIG)

1

14 F1 Fuse size 1

15 YHB

Arc-start board components (IN

TIG)

1

16 T3 Stray transformer (IN TIG) 1

17 M axial airflow fan 1

18 Switch 4

19 Digital displayer 1

20 SW Thermal relay 1

21 Potentiometer 1

Current

adjustment

Force

22 Potentiometer 2

arc-starting

adjustment

23 Electromagnet valve (IN TIG) 1

24 Main control board 1

25 Driving board 1

17

Page 20

z IN ARC / IN TIG-630 I

No. Tab Item Qua. Memo

1 K1 Air switch 1

2 D1 3-phase rectifier module 1

3 L1 Polypropylene capacitor 1

4 C30 Polypropylene capacitor 1

5

C4~5

IGBT module 2

6

M1、M2

Voltage sensitive resistance 2

7 R1 Ceramic dielectric capacitor 1

8

C8]~C21

Ceramic dielectric capacitor 14

9 T1 Main transformer 1

10 T3 Power source transformer 1

11 T5 Insulation transformer (IN TIG) 1

12

D3~D8

13 L2

Fast recovery diode module 4

Current exchange inductor (IN

TIG)

1

14 F1 Fuse size 1

15 YHB

Arc-start board components (IN

TIG)

1

16 T3 Stray transformer (IN TIG) 1

17 M1 axial airflow fan 1

18 Switch 4

19 Digital displayer 1

20 SW Thermal relay 1

21 Potentiometer 1 Current adjustment

22 Potentiometer 2

23 Electromagnet valve (IN TIG) 1

24 Main control board 1

24 Driving board 1

Force arc-starting

adjustment

18

Page 21

Appendix A: common failures, probable cause & countermeasures

№ Phenomena Reason Solving methods

1 After power on, it

doesn’t work.

2 Air switch on

back panel trips

while the

machine is

working

normally.

3 Welding current

is unstable.

Phase missing power source, in

Fuse(2A)in welder is broken.

Cable is broken

The following components may be

damaged: IGBT module, 3-phase

rectify module, outputting diode

module, or other components, Driving

board is damaged.

Short circuit between lines.

Phase missing

The following components may be

Check power source

Check if cooling fan,

power source transformer

and main control board are

good or not.

Check connection

Check and replace.

When IGBT module is

damaged, please check

12Ω, 5.1Ω resistance or

SR160 on driving board is

damaged or not.

Check power source.

Check and replace.

4 Welding current

is not adjustable.

5 TIG welding is

abnormal.

damaged: Potentiometers, switches

on front panel and remote control

cable, potentiometer on remote

controller.

Main control board is damaged

Potentiometer of welding current

adjustment is damaged.

Remote control cable is broken.

Main control board is damaged

The switch on the front panel is

damaged

TIG torch switch is damaged.

Remote control cable is broken.

The tungsten electrode in welder is in

the wrong position.

Main control board is damaged

Check and replace.

Check and replace.

19

Page 22

Page 23

Page 24

Page 25

Front Panel of ARC series

Remote /

Protection on LED (LED2)

Power on LED (LED1)

Panel Control

Switch (KD1)

Digital Display

(DSP001)

Arc-starting Current

Potentiometer (W3)

A

mp / Volt

Switch (KD2)

Arc-force Current /

Down-slo

p

e Time

Welding Current

Potentiometer (W1)

p

Potentiometer (W2)

Control Socket

Output Terminal (-)

(

OUTN

)

(P20)

Output T erminal

()

(+) (OUTP)

Page 26

Front Panel

VOLTAGE/AMPERE

SMAW/TIG SELECTION

SWITCH (PSW01)

SWITCH (PSW01)

LED YELLOW

(LED Y01)

2 / 4 TRACK

SELECTION SWITCH

(PSW01)

Digital Display

Meter (DSP001)

LED RED (LED R01

)

REMOTE/PANEL

SELECTION SWITCH

(PSW01)

()

POTENTIOMETER

FOR CURRENT

(POT001)

POTENTIOMETER FOR

STRIKING CURRENT

(POT001)

POTENTIONMETER

FOR ARC FORCE

(POT001)

Output T erminal (+)

(OUTP)

7 PIN CONNECTOR

MALE (CON7PNM)

OUTPUT

TERMINAL (-)

(OUTN)

Page 27

Left

View

Fan (FAN

Main

(

002)

Transformer

Thrust Coil

Output

Choke (CHK

001)

Snubber PCB

Isolation

PCB

(

PSB-

For O/P FRM

(PCB-SNB-

OUT-01)

(

ISO-01)

Output Rectifier

Module (FRM001)

Page 28

Right View

-

g

Thermal Cut

Out

SNUBBER CARD

Over Current

Protection

PCB

HF PCB (PCB-

HF-01)

HF T

ransformer

(CTRAX007)

Resonant Coil

IGBT

Input Bridge

AC Capacitor

Module

Fan Capacitor

p

(CAP05)

Solonaid Valve

Shunt

MOV (MOV001)

DC Capacitor

(CAP001)

(SV001)

Insulation

Transformer

(INSTRX001)

Page 29

Top View

p

Drive CARD

(PCB-DRV-01)

CONTROL

TRANSFORMER

(CTRAX001)

Input Surge

Suppressor (ISS

01)

Main PCB

Fuse (F1)

Page 30

Rear

Panel

FAN

MCB

Page 31

List for the spares of INTIG I Series machines

DESCRIPTION INTIG-315 INTIG-400 I INTIG-500 I INTIG-630 I

MAIN PCB

DRIVE CARD

IGBT

INPUT BRIDGE MODULE

OUTPUT RECTIFIER MODULE

FAN

DC CAPACITOR

AC CAPACITOR

SNUBBER CARD

MCB

DIGITAL DISPLAY METER

INPUT SURGE SUPPRESSOR

SNUBBER CAPACITOR

CONTROL TRANSFORMER

OUTPUT CHOKE

HF PCB

HF PCB CAPACITOR

SOLONAID VALVE

INSULATION TRANSFORMER

MOV

ISOLATION PCB

SNUBBER PCB FOR OUTPUT

FRM

POTENTIOMETER FOR

KNOB FOR THE POT

OVERCURRENT PROTECTION

PCB

MAIN TRANSFORMER

FAN CAPACITOR

TWO POLE SWITCH FOR

OUT PUT CONNECTOR

MACHINE SIDE

OUT PUT CONNECTOR

CABLE SIDE

7 PIN CONNECTOR MALE

SHUNT

LED RED

LED YELLOW

Part Code Part Code Part Code Part Code

PCB-TIG-315I PCB-TIG-400I PCB-500I PCB-TIG-630I

PCB-DRV-01 PCB-DRV-01 PCB-DRV-01L PCB-DRV-01L

IGBT7512 IGBT7512 IGBT10012 IGBT15012

IBDG003 IBDG003 IBDG004 IBDG004

FRM001 FRM001 FRM001 FRM001

FAN002 FAN002 FAN003 FAN003

CAP001 CAP001 CAP001 CAP001

CAP002 CAP003 CAP003 CAP04

PCB-SNB-01 PCB-SNB-01 PCB-SNB-02 PCB-SNB-02

MCB001 MCB001 MCB002 MCB003

DSP001 DSP001 DSP001 DSP001

ISS001 ISS001 ISS001 ISS001

SCAP001 SCAP001 SCAP001 SCAP001

CTRAX001 CTRAX001 CTRAX001 CTRAX001

CHK001 CHK001 CHK001 CHK001

PCB-HF-01 PCB-HF-01 PCB-HF-01 PCB-HF-01

PCB22.01 PCB22.01 PCB22.01 PCB22.01

SV001 SV001 SV001 SV001

INSTRX001 INSTRX001 INSTRX001 INSTRX001

MOV001 MOV001 MOV001 MOV001

PCB-ISO-01 PCB-ISO-01 PCB-ISO-01 PCB-ISO-01

PCB-SNB-OUT-01 PCB-SNB-OUT-01 PCB-SNB-OUT-01 PCB-SNB-OUT-01

POT001 POT001 POT001 POT001

KNOB001 KNOB001 KNOB001 KNOB001

PCB-OC-315 PCB-OC-400 PCB-OC-500 PCB-OC-630

MTRX001 MTRX002 MTRX003 MTRX004

CAP05 CAP05 CAP05 CAP05

PSW001 PSW001 PSW001 PSW001

FST-PLG-F-01 FST-PLG-F-01 OUT-CON-01 OUT-CON-01

FST-PLG-M-01 FST-PLG-M-01 NA NA

CON7PNM CON7PNM CON7PNM CON7PNM

SHUNT001 SHUNT001 SHUNT002 SHUNT002

LEDR01 LEDR01 LEDR01 LEDR01

LEDY01 LEDY01 LEDY01 LEDY01

Page 32

DESCRIPTION INARC-315 INARC-400 I INARC-500 I INARC-630 I

/

/A

Part Code Part Code Part Code Part Code

MAIN PCB PCB-ARC-315I PCB-ARC-400I PCB-ARC-500I PCB-ARC-630I

DRIVE CARD PCB-DRV-01 PCB-DRV-01 PCB-DRV-01L PCB-DRV-01L

IGBT IGBT7512 IGBT7512 IGBT10012 IGBT15012

INPUT BRIDGE MODULE IBDG003 IBDG003 IBDG004 IBDG004

OUTPUT RECTIFIER

MODULE

FRM001 FRM001 FRM001 FRM001

FAN FAN002 FAN002 FAN003 FAN003

DC CAPACITOR CAP001 CAP001 CAP001 CAP001

AC CAPACITOR CAP002 CAP003 CAP003 CAP004

SNUBBER CARD PCB-SNB-01 PCB-SNB-01 PCB-SNB-02 PCB-SNB-02

MCB MCB001 MCB001 MCB002 MCB003

DIGITAL DISPLAY METER DSP001 DSP001 DSP001 DSP001

INPUT SURGE

SUPPRESSOR

ISS001 ISS001 ISS001 ISS001

SNUBBER CAPACITOR SCAP001 SCAP001 SCAP001 SCAP001

CONTROL TRANSFORMER CTRAX001 CTRAX001 CTRAX001 CTRAX001

MOV MOV001 MOV001 MOV001 MOV001

ISOLATION PCB PCB-ISO-01 PCB-ISO-01 PCB-ISO-01 PCB-ISO-01

SNUBBER PCB FOR

OUTPUT FRM

PCB-SNB-OUT-01 PCB-SNB-OUT01 PCB-SNB-OUT-02 PCB-SNB-OUT-02

POTENTIOMETER FOR

CURRENT/STRIKING

POT001 POT001 POT001 POT001

CURRENT/ARC FORCE

KNOB FOR THE POT KNOB001 KNOB001 KNOB001 KNOB001

OVERCURRENT

PROTECTION PCB

PCB-OC-315 PCB-OC-400 PCB-OC-500 PCB-OC-630

MAIN TRANSFORMER MTRX001 MTRX002 MTRX003 MTRX004

FAN CAPACITOR CAP05 CAP05 CAP05 CAP05

TWO POLE SWITCH FOR

REMOTE & V

PANEL

OUT PUT CONNECTOR

MACHINE SIDE

OUT PUT CONNECTOR

CABLE SIDE

PSW001 PSW001 PSW001 PSW001

FST-PLG-F-01 FST-PLG-F-01 OUT-CON-01 OUT-CON-01

FST-PLG-M-01 FST-PLG-M-01 NA NA

7 PIN CONNECTOR MALE CON7PNM CON7PNM CON7PNM CON7PNM

Loading...

Loading...