Page 1

INVERTER GAS SHIELDED

MIG WELDING MACHINE

OPERATION MANUAL

WARPP ENGINEERS PVT. LTD.

B-1005, Western Edge II, Near Metro Mall, Off. Western

Express Highway, Borivali (E), Mumbai-400 066.

Tel:022-28542272 / 73/74 Fax:022-28542275.

Website:www.warpp.co.in Email:sales@warpp.co.in

Page 2

CONTENTS

Safe item........................................................................................................ (3)

Brief of product............................................................................................... (4)

Properties..................................................................................................... (5)

Assemble.......................................................................................................(6)

Operation ...................................................................................................... (8)

Welding parameter checking list...................................................................(10)

Attention ...................................................................................................... (11)

Maintain ...................................................................................................... (13)

Regular check...............................................................................................(14)

Spare Part list............................................................................................... (15)

Page 3

Safe Item

Please do the best safeguard when operator does the welding work, welding work will

be bringing the harm to you and others. Regarding the detailed information regarding

the accident when welding, please check the manual carefully.

There is necessary to have a train for the welding work operator, in order to use this

machine safely.

·using the necessary and good quality safeguard dressing.

·operator should be the person who has enough welding skill and ability to operate the

machine.

·please cut off the power connection when they maintain and repairing being in.

Electric sh o ck -------- it would be issuing the deeply harmful, even die.

·please connect and assemble depending on the application standard.

·please do not touch the electriferous elements when you keep your skin bareness,

dressing the wet gloves or wet clothes.

·please make sure that you, ground and working material would be isolated.

·please make sure your working position is in safe situation

Fume -------- may be harmful for your health

·please keep your head out of the smoke avoid to take in the welding fume.

·while welding working, please keep the ventilation running well, in order to keep the

working condition well for surrounding air

.

Arc light radiation --------- may be harmful for your eyes and burn your skin

·please use the qualified welding mask, dressing the safeguard clothes, to keep your

eyes and body in safe situation.

·please use the suitable mask and curtain to keep the onlookers in healthy situation.

Fire hazard

welding spark would issue the fire, please make sure there is no combustibles thing

·

nearby welding place, and also there is necessary to do the fire protection.

·to be making sure the fire unit near the place of welding and confirm there is at least

one person could use the fire unit

.

Noise ------------- more noise would be harmful for hearing.

·protection your ears, please wear the necessary unit to protect your ears from

harmful noise.

·please warn the onlookers, noise would hurt their hearing

.

.

Page 4

Product Brief

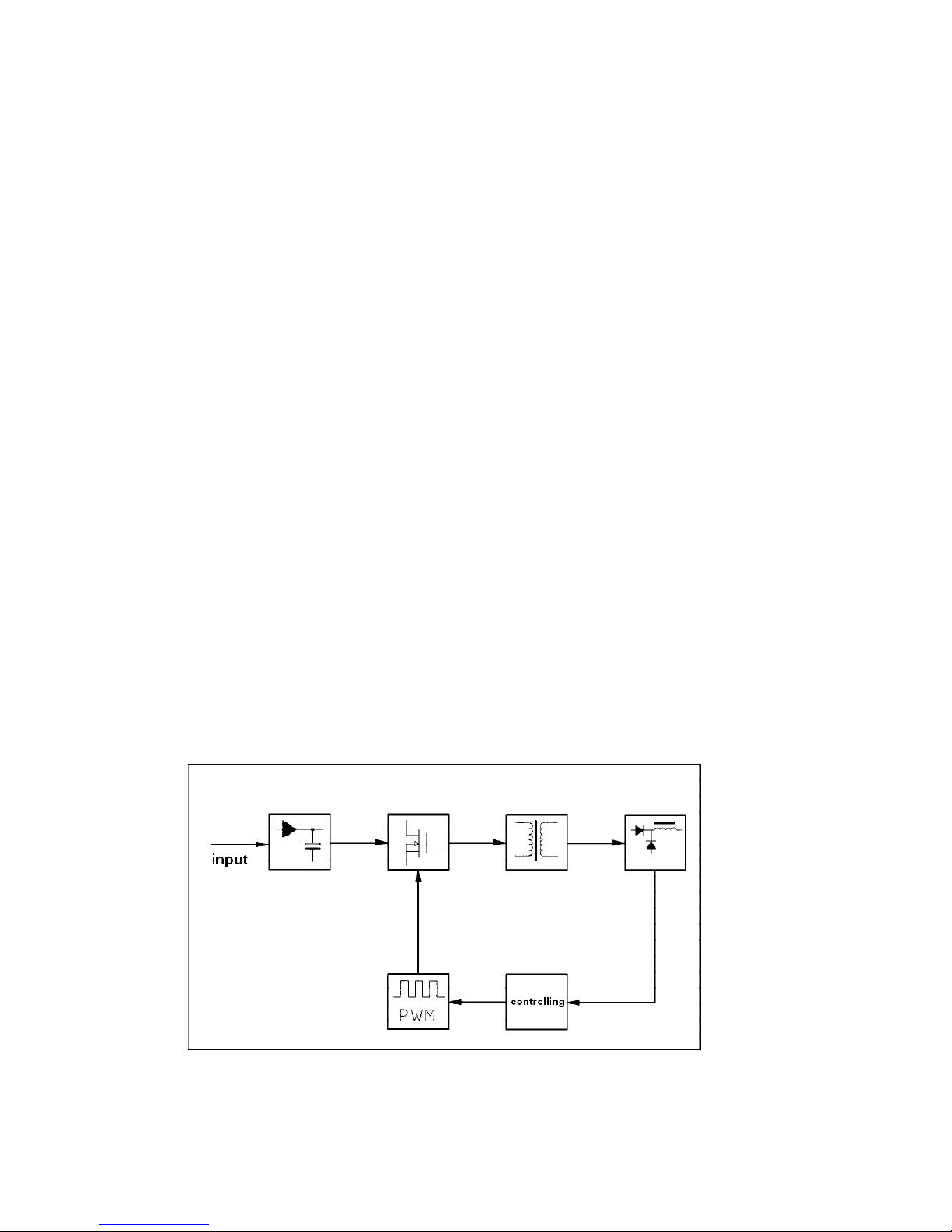

INMIG IH gas shielded welding machine is the inverter welding machine with the

international advanced inverter technology.

The general principle of it is to make the 50Hz/60Hz AC current into DC current, and

make the DC current into high frequency AC current basing on the high power

electronic element IGBT, whose frequency could be 20KHZ, reducing voltage and

rectification

Character:

1. IGBT inverter technology, current controlling model, high quality, steady

properties.

2. constant voltage output, high adaptability for electricity network (±15%)

3. electronic inductor controlling, less splash, deep weld pool and good forming

4. Hot start with slow wire feeding, welding with globule wiping off, high hot start

success rates.

5. suitable for 0.8mm thickness welding material

6. small size, light weight, simple operation

The efficiency of machine would be above 85%, and machine would be with energy

conservation function

Drawing

.

Page 5

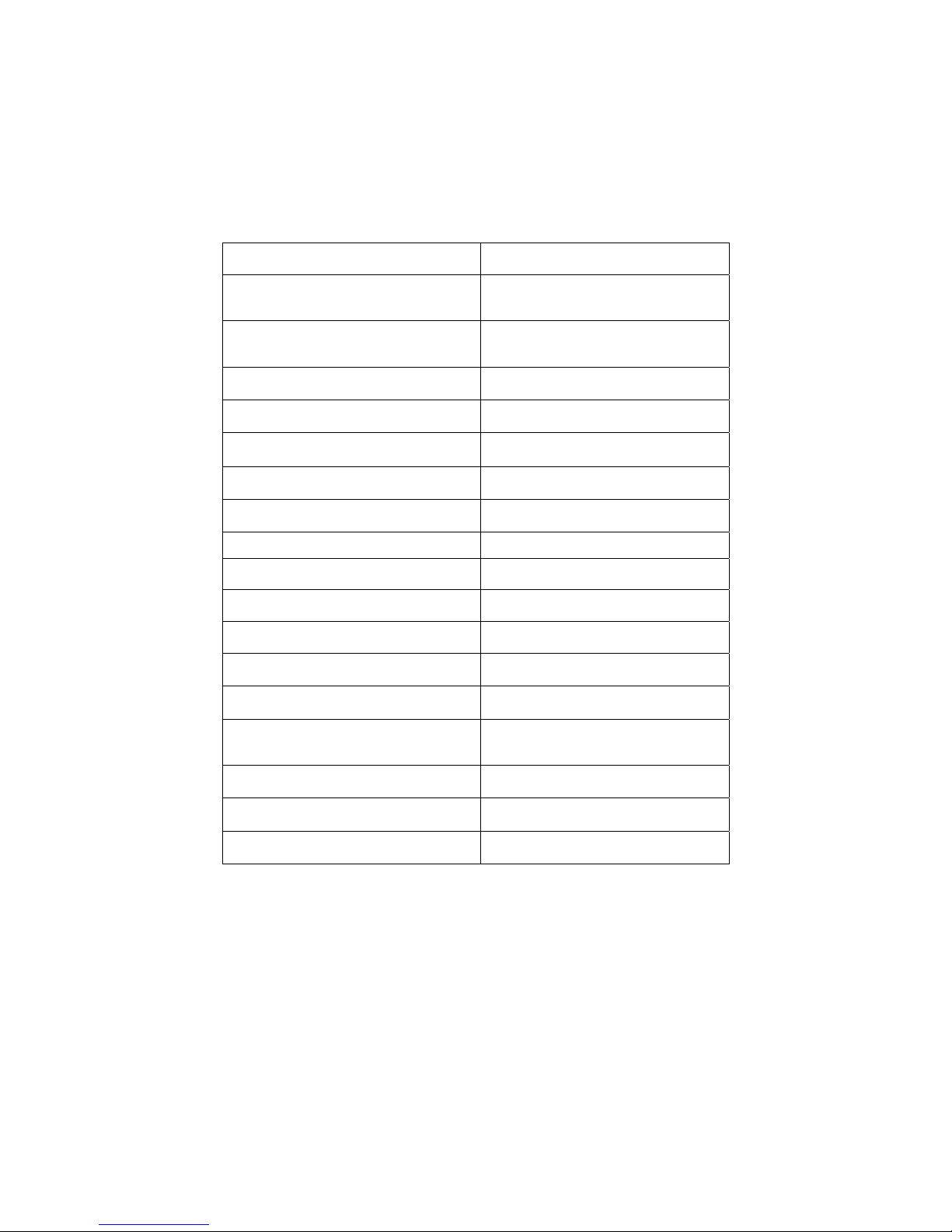

Parameter

Input current (A)

Parameter INMIG 250 IH

Input power Three phases 380V +/-15%

50/60 HZ

14

Power capacity (KVA) 9.2

Current adjustment ra nge (A) 50-250

Output voltage (V) 15-29

Duty cycle (%) 60

Power factor 0.85

Efficiency (%) 85

No Load V oltage 55

Wire feeder model INSIDE

Post blow time (S) 1 +/-0.5

Roller diameter (mm) 270

Welding w ire diameter (m m)

Welding thickness (mm)

>0.8

Isolation class F

Protection class IP21

WEIGHT 18

Page 6

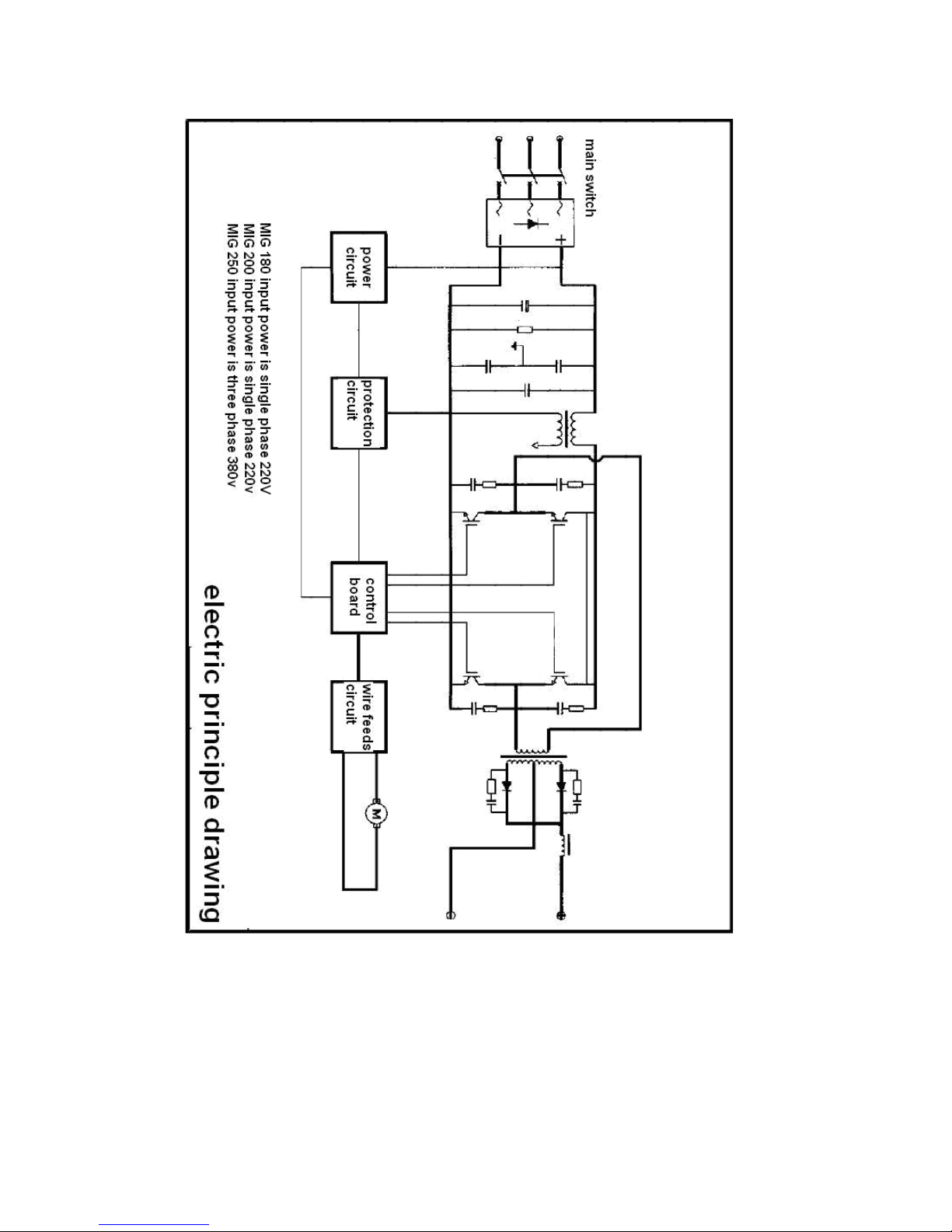

Wire connection

Assemble

Page 7

1. input wire connection

There is a power wire for each machine.

180/200’s power wire should be connecting to AC 220V; 250’s power wire should be

connecting to AC 220V, there is no phase order for three wires

2. output wire connection

.

Please connect the gas cylinder which is with the gas gauge to the CO2 enter door at

the rear of machine through gas tube.

Please connect the quick connector of grounding wire to the corresponding quick joint

of the machine; other end of grounding wire should be connecting to the working

piece.

Please connect torch to the joint of wire feeder and fasten it, and put the welding wire

into torch.

3. roller assemble

Please put the roller which is with welding wire on the axle of wire feeder; please

make sure the roller is put right and stable.

Please choose the right roll for the welding wire.

Release the the roll pinch, put the wire in groove, adjust the roll pinch to press the wire,

in order to keep the wire stable in groove, but the pressure could not be big for wire

feeding.

Roll should be running with clockwise to release the wire.

Please choose the dimension of roll basing on the dimension of wire for welding

Please touch the button to feed the wire out of torch

Page 8

Gas cylinder assemble

Please connect the gas cylinder which is with the gas gauge to the CO2 enter door at the rear

of machine through gas tube,and fasten it by gas tube lock

.

Please pay attention:

1. Please keep the gas cylinder far from high temperature area, and all possible high

temperature places, in order to avoid increasing the gas pressure for accident.

2. Please fasten the joint of gas cylinder, keep the gas not go out of cylinder.

3. Please do not kick gas cylinder and lie down the gas cylinder.

4. Please turn off the gas cylinder when there is no any person in front of the gas

gauge.

5. Please connect the heater power stock to the machine rear – 36vac connector.

6. Gas gauge should be assembled in upright situation; otherwise it cannot show the

parameter correctly.

7. Please choose the right gas gauge

8. Please keep the gas cylinder connector clean to protection the gas gauge goes

.

well

Please dressing the mask when you do the welding work.

Operation

1. Please turn on the the gas switch of welding machine, open the valve of the gas

cylinder, and adjust the gas gauge to the ideal parameter.

2. Please choose the torch tip basing on the welding wire.

3. please adjust voltage and current basing on the work piece

4. Inductance adjustment could be helpful for electric arc’ strength, soft or hard.

5. push the button of torch to begin the welding work

Welding current adjustment

Welding current and electric arc voltage would be very important for the welding

stability, welding quality and production efficiency. In order to make sure the welding

quality , please adjust the parameter of welding current and electric arc induct ance well,

usually, it would be chosen basing on the welding wire diameter and production

efficiency.

Please check the common parameter list below for the welding current and electric

arc:

Welding method Thin wire

CO2 flow

parameter

(L / min)

Thick wire

co2 welding

5-15 15-25 25-50

co2 welding

Thick wire big

current co2 welding

Page 9

CO2 welding current and voltage scope

Welding wire

diameter (mm)

0.6 40-70 17-19 160-400 25-28

0.8 60-100 18-19 200-500 26-40

1.0 80-120 18-21 200-600 27-40

1.2 100-150 19-23 300-700 28-42

1.6 140-200 20-24 500-800 32-44

Welding speed choice

Short cut transition

Current (A) Voltage (V) Current (A) Voltage (V)

submarine-launched transition

This should be adjusted for the welding quality and production efficiency. If the

welding speed was faster, protection effect would not be good, cooling speed should

be bigger, the result is the welding crack’s forming would not be good and it would not

be well for welding forming. If the welding speed was slower, it would be very easy to

burn through the work piece and to make welding crack structure bigger and more

rough. In real situation, welding speed would not be faster than 30m/hour.

Welding wire

extension length

Welding wire extension length‘s increasing would be helpful for welding wire fusion

quicken and increase the production efficiency. If the extension would be bigger,

welding wire would be very easy to welding break, bigger splash, and make the

welding process not steady. Usually, the length of welding wire should be the ten

times longer that the diameter of welding wire

.

CO2 gas flow parameter choice

Mainly considering the effect of protection. And, inside corner protection would be

better than the outside’s.

Welding parameter list

Welding current and arc voltage will be the key point for the welding stability, welding

quality and production efficiency. To keep the good welding quality, it should be a good

collocation between welding current and arc voltage. It should be choosing basing on the

diameter of welding stick and production efficiency.

The checking the list for the welding current and arc voltage for regular using

1.1 butt welding

Page 10

2.

3.

Page 11

4.

Page 12

1. Environment

(1)

The welding operation shall be operated in a relatively dry environment, and the

air humidity should not exceed 90 percent.

(2) The ambient temperature should be between -10 and 40.

(3) Do not weld under the sunlight or in the rain, and do not let water or rain go

into welding machine.

(4) Do not weld in dust or under the environment containing corrosive gases.

(5) Do not weld at the vibrant and easy-collision places.

2. Security key points

The welding machine has been installed protection circuit against over current

and overheat, which will automatically stop working when the temperature is higher

than the standard and welding machine will enter the state of protection when the flow

is excessive. But excessive use (such as welding current excessive) would have still

caused damage to the welding machine, so you need to pay attention to the

followings:

(1) To keep good ventilation!

Since the size of the welding machine is small, natural ventilation can not meet

the need of cooling it when strong current goes through it, we use a cooling fan to

make it work smoothly.

User should confirm the ventilation is not covered or blocked. The distance

between the machine and the surrounding objects must be kept no less than 0.3

meters. The user should always keep it good ventilation, which is very important to

work efficiency and service life of the machine.

(2) To prohibit electric current from overloading!

User Should observe the strongest load current (relatively to the selected load

sustained rate) at any time,so as to ensure the welding current against exceeding the

allowed maximum.

The life expectancy of welding machine will be significantly shorten,or even be

burned, by overload current.

(3) To prohibit over voltage!

The power voltage is listed in the main technique parameters such as these in

form1, in normal conditions; the voltage auto-compensation circuit in the welder limits

the welding current within normal range. If the power voltage exceeds the normal

range, the welding machine will be damaged. As a result, the operator should be fully

aware of the situation and proper protective measures should be taken.

Page 13

(4) There is one grounding screw on the back of every welder with the grounding mark.

Before use, selecting one cable with the cross section of more than 4mm2, connect

the shell of welding machine to ground to discharge electrostatic or avoid possible

accidents due to current leakage.

(5) If the welding machine exceeds the standard continuous loading time, the welding

machine would enter protective state and stop working. If this situation happens, it

indicates that the welding machine exceeds sustained rate of standard load. And

excessive heat trigger the temperature detect switch, which make the welder stop

working. At the same time, the yellow dictator at the front board goes out.

In this case, do not plug off the power so that the cooling fan starts to cool the

welding machine. When the yellow indicator lit up, it indicates the temperature lower

down to the normal range and welding work can be continued.

Maintenance

Regular maintenance and inspection are done to ensure the machine to work safely

and efficiently. Check whether the power of the welding machine is off before

checking the external connectors. Check the internal wiring five minutes after the

power of the welding machine is turned off, so that the capacitors of the machine are

fully discharged to avoid electric shock accidents and ensure the safety of the staff.

Reference Guide for Maintenance

Line maintenance items

1. The function of the power switch

2. Whether the cooling fan is

rotating normally

3. Whether the abnormal vibration,

noise or smell exists

4. Whether the cable connector is

overheated

5. Whether welded cable is

abnormally hot

6. Whether the cable is damaged

7. Whether a wire connector is loose

A regular maintenance

is done every one or two months

1. Remove dirt:

Compressed air is used to remove

dirt, in particular the dirt on inductors,

transformers, power transistors and

printed circuit boards.

2. Maintenance of the circuit

connectors

Check whether the input terminal, the

output connector, the external

connections are loose or rusty.

Tighten the loose places and remove

the rust to ensure good contact.

3. Check whether the grounding line is

well.

Page 14

The repairing principle of the welding machine should be made by our company and

the user can solve the problems met in using it under the direction of our company.

1. Issues to pay attention

(1)

It should rivet the tag of equipment number on the shut of the casing, or the inner

elements might be damaged.

(2)The connection between the welding cable and the connecting terminal of the

welding machine should be solid and reliable. Otherwise, the terminal can be burn

out which will result in the unstableness of the welding process.

(3) To keep the bare copper parts of the welding cable and the connecting terminal of the welding

machine from the metals on the ground to avoid the short-circuiting of the welding

machine output.

(4) To avoid the damage or break of the welding cables and the control cables.

(5) To avoid the deformation of the welding machine caused by being stroken. Do not

stack heavy load on the welding machine.

(6) To keep being ventilated.

2. Regular check and maintenance of the welding machine

(1)

The professional repairing staff should clean the welding power with the

condensed air for every 3- 6 months. Meanwhile, check the fastening piece in the welding

machine and no loose phenomenon should happen.

(2) check often that if the cable has been damaged and if the control knob is loose

and if the members on the panel has been damaged.

(3) Current contact nozzles and the wire feed rolls should be changed timely. The wire

feed tube should be cleaned frequently

.

3. Faults and solutions of welding machine

3.1

The following check shall be made before maintenance:

(1) Whether the position of switches on the front panel are right or not.

(2) Whether the line voltage of three-phase power is within 340V~420V; and open-phase or not.

(3) Whether the connection of welding machine power input cable is right or not.

(4) Whether the grounding line of welding machine is right and reliable.

(5) Whether the connection of welding cable is right or not, and whether the

connection is good or not.

(6) Whether the gas path is good or not, and whether CO2 gas regulator is normal or

not.

Note: The highest voltage in the welding machine reaches 600V. To guarantee

safety, it is prohibited to open the shell of welding machine at random.

When maintaining, pay attention to safety and prevent electric shock.

Page 15

FRONT VIEW

Digital Display

Meter V o ltage

(DSP001)

10K Potentiometer

for Inductance

Digital Display

Meter Current

(DSP001)

(POT004)

Output Connector

EURO Type with

Strip (OCN-EURO-S)

13 Pin Connector

Panel Mounted Female

(CON13PM

-

F)

Page 16

REAR VIEW

F

an

(FAN007)

Shunt (SHUNT-

Snubber Card

(PCB-SNB-B39)

S-300-75)

MOV (MOV001)

IGBT (IGBT5012)

Page 17

LEFT VIEW

Main

Transformer

(MTAX-B08)

Control Transformer

(CTRAX-B39)

Output Rectifier Card

(PCB-OUT-FRM001)

Page 18

TOP VIEW

Main PCB

(PCB-MIG-250 IH)

Drive Card

(PCB-DRV-04)

Capacitor Board

(PCB-CP-250 IH)

Input Bridge Module

with Surge Suppressor

Board (PCB-IB-01)

Page 19

BACK VIEW

MCB (MCB001)

Fuse Holder

Page 20

SPARE PART LIST INMIG 250 IH

DESCRIPTION Part Code

MAIN PCB PCB-MIG-250 IH

DRIVE CARD PCB-DRV-04

IGBT IGBT5012

INPUT BRIDGE MODULE WITH SURGE

SUPRESSOR BOARD

OUTPUT RECTIFIER MODULE CARD PCB-OUT-FRM001

FAN FAN007

CAPACITOR BOARD PCB-CP-250 IH

SNUBBER CARD PCB-SNB-B39

MCB MCB001

DIGITAL DISPLAY METER DSP001

CONTROL TRANSFORMER CTRAX-B39

MOV MOV001

SNUBBER PCB FOR OUTPUT FRM PCB-SNB-OUT-01

POTENTIOMETER FOR INDUCTANCE POT004

KNOB FOR THE POT KNOB001

OVERCURRENT PROTECTION PCB PCB-OC-250

MAIN TRANSFORMER MTRX005

OUT PUT CONNECTOR EURO TYPE

WITH STRIP

13 PIN CONNECTOR PANEL MOUNTED

FEMALE

13 PIN CONNECTOR MALE CABLE

SIDE

SHUNT SHUNT-S-300-75

LED GREEN LEDG01

LED YELLOW LEDY01

PCB-IB-01

OCN-EURO-S

CON13PM-F

CON13CM-M

WIRE FEEDER MOTOR WITH WIRE

FEED MECHANISM

24 V SOLANOID VALVE SV002

EURO CONNECTOR FEEDER SIDE EURO-BRASS-01

PRESUURE ARM PRARM001

PRESURE HOLDER PRHLD001

SUS TUBE SUS001

ROLER 0.8/1.0 INMIGRLR001

ROLER 1.0/1.2 INMIGRLR002

ROLER 1.2/1.6 Not Applicable

POTENTIOMETER FOR

CURRENT/VOLTAGE

INCHING SWITCH INCSW001

KNOB FOR THE POT ( Black ) KNOB002

WIRE FEED MECHANISM WITHOUT

MOTOR

WIREFEEDER

WFMTR002

POT003

WF-MECH-INMIG

Loading...

Loading...