Page 1

AIRCUT 100I/161IW/200IW

INVERTER AIR PLASMA CUTTING MACHINE

OPERATING MANUAL

(PLEASE READ IT CAREFULLY BEFORE OPERATION)

Warpp Engineers Pvt Ltd.

Source of Reliable welding and cutting equipment.

Unit no 36/15 Unique Industrial Estate,

Dhumal Nagar, Waliv,

Vasai East,Palghar 401208.

TEL: 08551819944, 8551817869, 851817744.

E mail: sales@warpp.co.in

Website: www.warpp.co.in

Page 2

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

1

Safety Depends on You

Warpp Engineers Pvt Ltd arcwelding andcutting equipment's aredesigned andbuilt with ample safety consideration.

However, proper

installing and operating can ensure your safety.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT CASUALLY WITHOUT READING THIS MANUAL THROUGHOUT.

Special Notes(Very Important):

1.

Pay

attention

to

avoiding

the

machine

falling

down

when

itisplaced

on

the

gradient

ground.

2.Itis

forbidden

to

unfreeze

the

pipeline

by

the

cutter.

3.

The

shield

rankofthis

series

of

cutter

is

IP21S,

so

working

in

rainisnot

suitable.

4.Thecutter has external static characteristic with rated duty cycle 100%, which means the machine can

work continuously at the rated cutting current. The machine has the function of thermal protection. When

the internal temperature exceeds a set temperature, thermal protection moves on and the abnormity

indicator lamp on the panel turns ON, then there is no output in cutter. The machine can become normal

and work only after the internal temperature drops down and the abnormity indicator lamp on the panel

turns OFF.

Purchase Date

:

Serial Number

:

Machine Model

:

Purchase Place

:

Page 3

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

2

Ca u t i o n s

Arc and arc rays can hurt.

All performing welding workers ought to have health qualification from the authority organization to

prevent you and others from arc radiation and burn. It should be prevented for children to enter into

dangerous area as well.

Becareful reading thefollowing important items andthe welder safety bye law from the authority

organization. Be sure that qualified professionals perform all installation, maintenance's and repair

procedures.

1Electric shock

:The welding circuits arenot insulated when welding. Ifyou touch the

two output electrodes of the machine with your bare skin at the same time, it will lead

toelectric shock, sometimes evenfatal dangers.Usersneed to follow the items below to

avoid electric shocks:

If possible, lay some insulating materials, which are dry and large enough, in your working

field. Otherwise, use the automatic or semiautomatic welding machine, DC welding machine as

possible as you can.

Components

in

the

automatic

and

semiautomatic

welding

machine

suchasthe

welding

wire

reel, feed wheel, contact tip and welding head are all electric components. .

Always

be

sure

the

machine

has

been

connected

perfectly

to

the

work

piece

with

the

work

cables and should be as close as possible to the working area.

The

work

piece

should

be

grounded

perfectly.

Make sure that the insulating material of the electrode holder, the grounding clamp, the

welding cable and the welding head are not affected by damp, mildewed or spoilt, and be replaced

momentarily.

Never

dip

the

electrode

in

water

for

cooling.

Never touch electric components oftwo welding machines at thesame time, because this

voltage is supposed to be two times of welding voltage while the grounding mode is not clear.

While

working

high

above

the

ground

or

other

places

having

the

riskoffalling,

please

be

sure

to wear safety belt to avoid losing balance caused by electric shock.

2 Arc

: Use an arc welding mask to protect your eyes and skin from sparks and the rays of

thearc,pay special attentiontothefilter glass,whichmust be conformabletothe

national standard.

Use

clothing

made

from

durable

flame-resistant

material

or

sailcloth

to

protect

your

skin

from hurting by the arc rays.

Remind

other

nearby

personnel

before

working

lest

arc

rays

hurt

them

by

accident.

3Fumes and Gases

:Welding may produce fumes and gases hazardous tohealth. Avoid

breathing these fumes andgases. While working in limited room,use enough ventilation

and/orexhaust tokeep fumesand gasesaway from the breathingzone, oruse the

respirator. Do not weld at the same time when using of degreasing, cleaning or spraying operations.

The heat and rays of thearc can react with thesegases to form phosgene, ahighly toxic gas,

Some

protective

gases

usedinwelding

might

displace

the

oxygen

in

the

air,

and

can

leadtohurt

or even death.

Read

and

understand

the

manufacturer

’sinstructions

for

this

equipment,

and

validate

the

Page 4

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

3

health certification of consumptive materials, make sure they are innocuous.

4 Spatter

: Spatter can cause fire or explosion.

Remove fire hazards from the welding area. Remember that spatter from

welding can easily go through small cracks and touch fire hazards. Protectall kinds

of lines going though welding area, including hydraulic lines in the wild.

Where compressed gases are to be used in the field, special precautions should be used to

prevent explosion.

When

welding

stops,

make

certain

thatnolive

partistouching

the

work

piece

or

the

work

stage. Accidental contact can create a fire hazard.

Do

not

weld

containers

or

lines,

which

are

not

proved

tobeinnocuous.

It is very dangerous to heat, cut or weld tanks or containers at entry holes. Does not start

work until the proper steps have been taken to insure that there is no flammable or toxic gas.

Spatter

might

cause

burn.

Wear

leather

gloves,

heavy

shirt,

cuffless

trousers,

high

shoes

and

a

cap over your hair to prevent from burning by spatter. Wear the ear shield when performing

sideways or face up welding. Always wear safety glasses with side shields when being in a welding

area.

The

welding

cables

should

beasclose

to

the

welding

areaaspossible,

and

the

short,

the

better. Avoid welding cables going through the building framework, lifting chains, AC or DC cables

of other welding machines and appliances. The welding current is strong enough to damage them

while having short circuit with them.

5 Cylinder

: Damage of it might cause explosion.

Make sure that the gas in the storage cylinder is qualified for welding, and the

decompression flow-meter, the adapter and the pipe are all in good condition.

Make

sure

that

the

installation

of

cylinder

isbythe

wall

and

bundled

tightly

byachain.

Be sure to put the cylinder in the working space with no crash or shake, and far from welding

area.

Itisforbidden

to

touch

cylinder

with

the

welding

clamp

or

the

work

cables.

Avoid

facing

the

cylinder

while

installing

the

decompression

flow-meter

or

the

gasometer.

When

not

working,

please

tighten

the

valve.

6 Power

: (For electrically powered welding and cutting equipment) Turn off input power

before installation, maintenances and repair, so that avoid accident.

Warpp

Engineers

Pvt

Ltd

welding

equipment

isΙclass

safeguard

equipment; please install

the equipment in accordance with the manufacturer’s

recommendations by specific persons.

Ground

the

equipment

perfectly

in

accordance

with

the

manufacturer

’srecommendations.

7 Power:(For engine driven welding and cutting equipment)

Work

in

ventilated

place

or

outdoors.

Donot addfuel nearto fire or during engine starting orwelding. When not

working, add fuel after engine is cooling down; otherwise, the evaporation of hot fuel

would result in dangers. Do not splash fuel out of the fuel tank, and do not start the

engine until complete evaporation of the outside fuel.

Page 5

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

4

Make sure that all the safeguard equipment, machine cover and devices are all in a

good condition. Be sure that arms, clothes and all the tools do not touch all the

moving and rotating components including V belt, gear and fan etc.

Sometimes having to dismantle some parts ofthe device during maintenance, butmust keep

safety awareness strongly every time.

Do

not

put

your

hand

close

to

fans

anddonot

move

the

brake

handle

while

operating.

Please

remove

the

connection

between

the

engine

and

the

welding

equipment

to

avoid

sudden starting during maintenance.

When

engine

is

hot,itis

forbidden

to

open

the

airtight

cover

of

the

radiator

water

tank

to

avoid hurt by the hot vapor.

8 Electromagnetic

: Welding current going though any area can generate

electromagnetic, as well as the welding equipment itself.

Electromagnetic

would

affect

cardiac

pacemaker,

the

cardiac

pacemaker

users

should consult one’s doctor first.

The

effect

of

electromagnetic

to

one’s

health

is

not

confirmed,

soitmight

have

some

negative effect to one’s health.

Welders

may

use

following

method

to

reduce

the

hazardous

of

electromagnetic:

a.

Bundle

the

cable

connected

to

the

work

piece

and

the

welding

cable

together.

b.Donot

enwind

partially

or

entirely

your

body

with

the

cable.

c.

Do not place yourself between the welding cable and the ground (work piece) cable, if the welding

cable is by your left side, then the ground cable should be by your left side too.

d.

The

Welding

cable

and

the

ground

cable

areasshort

as

possible.

e.Donot

work

near

to

the

welding

power

source.

9Lift Equipment

:carton orwooden boxes package the welding machines supplied by

Warpp Engineers Pvt Ltd

.There is no liftingequipment in its wrapper. Users

canmove it tothe prospective area by a fork-lift truck, and then open the box.

If

having

rings,

the

machine

canbetransited

using

rings.

While

Warpp

Engineers

Pvt Ltd. Welding Machine Manufacture reminds users, there is possible risk to

damage the welding machine. It isbetter topush the welding machine moving in

use ofits rollers

unless special situations.

Be

sure

that

the

appurtenances

are

all

removed

off

when

lifting.

When lifting, make sure that there is no person below the welding machine, and

remind people passing by at any moment.

Do

not

move

the

hoist

too

fast.

10 Noise

: Warpp Engineers Pvt Ltd,Welding Machine Manufacture reminds users:

Noise beyond the limit (over 80 db)can cause injury to vision,heart andaudition

depending ononeself.

Please consult local medical institution. Use the equipment with doctor’s permission

would help to keeping healthy.

Page 6

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

5

CONTENTS

Summary

.......................................................................................

6

Safety

and

Attention

..................................................................

7

Work

Environment

Conditions

..................................................

8

Technical

Parameters

...............................................................

8

System

instruction

......................................................................

9

Installation

and

operation

.........................................................

10

Cutting

technology

instruction

.................................................

19

Maintenance

...............................................................................

21

Troubleshooting

and

Repair

....................................................

21

Packing

list

................................................................................

23

Attached

figure

.........................................................................

24

Page 7

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

6

Summary

Model

description

AIRCUT - □□□

I /IW

GAS / WATER COOLED.

Rated cutting current

Air-medium

Cutting

Plasma arc cutting machine

Features

AIRCUT-101I/161IW/200IW inverter air plasma cutting machine is a new

generated

cutter of our company. It has good characteristics as following:

1)

This

cutting

machine

adopts

IGBT

inverter

technology

which

has

high

reliability

and efficiency. It is light weight.

2)

Pre-set

current

function.

Step-less

adjustable

cutting

current,

suitable

for

cutting

various thickness work-piece. To ensure cutting quality and save energy, low

current is applied to cut thinplate, and high current isapplied to cutthick plate.

3)

External

and

dynamic

characteristics

cutter

are

significantly

better

than

leakage-reactancetyped cutter. High success rate in striking arc. Stable cutting current.

Goodarcstiffness.Cleanandsmoothincision.Excellenttechnologyperformance.

4)Ithas

the

function

of

ascending

current

slowly,

which

can

effectively

extend

the

work life of wearing parts and cutting torch.

5)

Quite

suitable

for

CNC

automatic

cutting

and

has

all

signal

output

which

is

required by CNC control.

6)

The

cutting

current

is

very

stable

anditwill

notbeinfluenced

by

grid

voltage

fluctuation.

7)

100%

duty

cycle.

It

can

work

continuously

under

max

current.

8)

Have

over/

under

voltage

and

phase

missing

protection

function.

Usage

It is suitable for cutting kinds of metal materials like low carbon steel, alloy steel

and non-ferrous metal and is widely applied in the manufacturing of boiler pressure

container, chemical container, industrial power station construction, metallurgy,

aerospace industry, automobiles, building an so on.

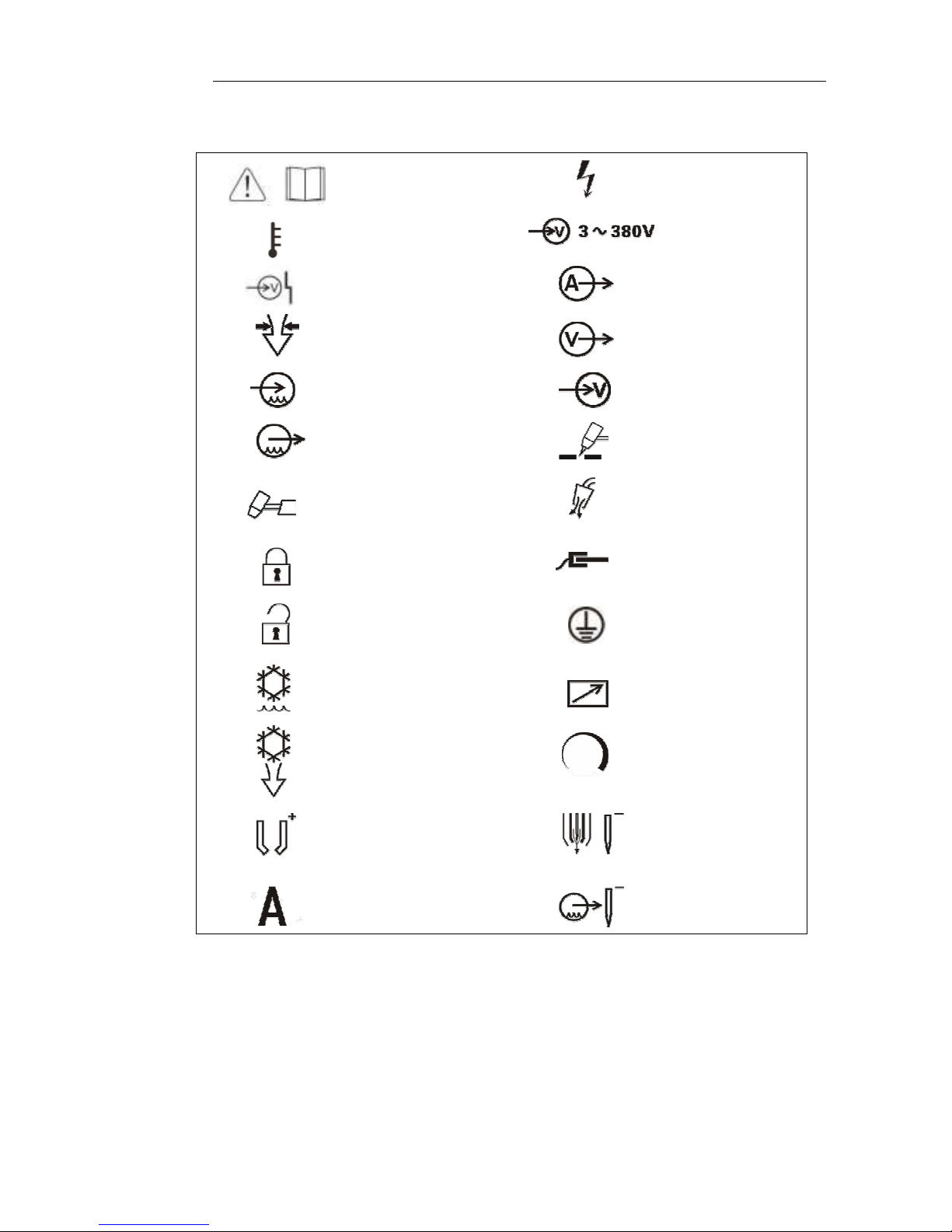

Symbol

instructions

Page 8

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

7

There are below symbols on this machine.

Coolant

liquid

and

torch electrode

Current

Plasma

gas

and

torch electrode

nozzle

of

The

connection

plasma torch

Increase/

Decrease

Air

cooling

Remote

control

Water

cooling

Protection

ground

lead

Unlock

Ground

lead

Lock

Check

gas

Plasma

torch

Cutting

liquid

Voltage

input

liquid

Coolant

input

Coolant

output

Voltage

output

Air

pressure

Output

current

Power

abnormal

Input

voltage

Over-heat

Dangerous

voltage

Read

the

manual

carefully

Page 9

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

8

Safety andattention

Please follow the notes for the safety of you and others.

It is forbidden to unfreeze the pipe line by cutting power or other usages except

for cutting.

The

cutter

casing

should

ground

reliably.

Please

make

sure

the

grounding

bolts

of power ground reliably in case of electric shock.

Cutter

is

the

equipment

with

high

voltage.

Please

wear

insulated

protective

shield when cutting.

When

exchanging

torch

and

wearing

parts,

please

turn

off

the

supply

power

first.

Protective

shield

should

be

worn.

In order to avoid any hurt to eyes from ultraviolet radiation and strong light and

to skin from spatter, please wear protective shield according to related rules and

regulations of labor protection.

Itisforbidden

to

inhale

harmful

gases.

The fumes and gases produced during cutting is hazardous to health. Please

wear protective shields and install aerator according to related rules and

regulations of labor protection.

Cutting

cannot

proceed

in

closed

container.

The

work-piece

just

after

being

cutisat

high

temperature.

Please

prevent

from

scald.

Protective gas cylinder and air compressor must be placed in a fixed position

and prevented from collision.

Cutter

and

cutting

place

should

be

far

away

from

flammable

materials.

Prevent foreign bodies from entering inside the machine. And protect the cable

from sharp materials.

Protect

the

machine

from

fallorcollision.

In case of fall or collision, it can be used only after professional checking.

In the surface or inside of the cutting work-piece, there should be no flammable

and explosive materials or chemical materials harmful to human.

Installation and repair person must have state-authorized electrician operation

certificate.

Cutting

operation

person

should

read

this

manual

carefully

and

know

the

operation method well.

Working Environment Requirements

1、 Environmental condition

Please use the machine in a clear place without any of dust, corrosive gas and

inflammables and explosives; Do not use it in open air and rain;

Page 10

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

9

Required air relative humidity should ≤90%(at 20℃),40℃≤50%(at 40℃)

;

Environment temperature range should be at-10

℃~40℃

;

The

coolant

liquid

can

notbefrozen

when

use;

Any metal materials can not be put on or insider the power source;

Keep the machine away from the wall of some other closure things at least 30cm,

two machines distance at least 30cm.

Use it under altitude lower than 1000m.

2、 Power supply condition

1)

Power supply:3~380V/50Hz;

2)

Voltage fluctuation range<±10%

;

3)

Frequency fluctuation range<±1%

;

4)

Unbalance rate of three phase voltage <±5%;

5)

When

use

engine

generator:

the

output

power

of

the

generator

have

tobe2

times higher than the rated power of the plasma power source, with

compensating coil;

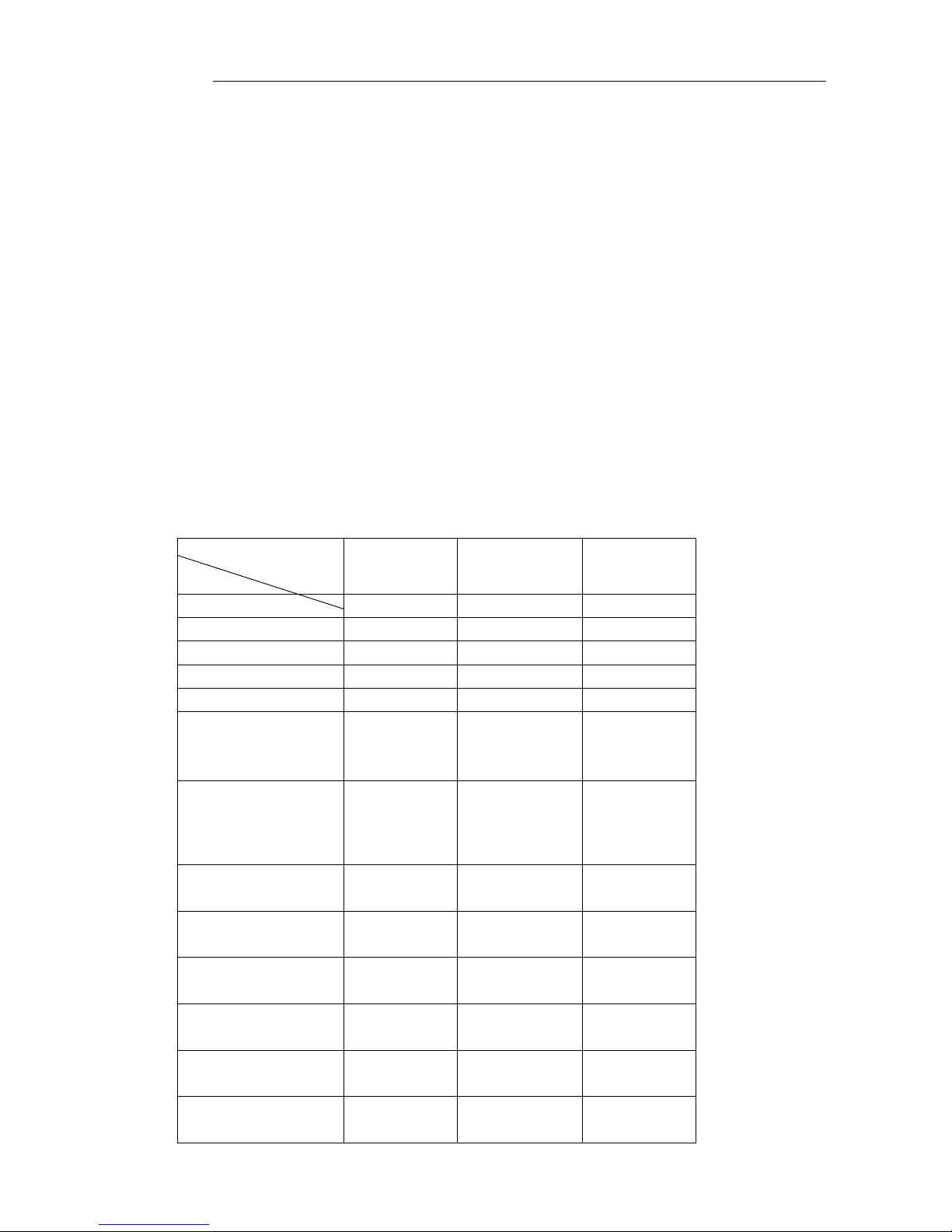

Technical parameters

1 Main technical parameters

Model

Parameter

AIRCUT

-

101W

AIRCUT

-161

IW

AIRCUT

-200

IW

Rated input capacity

17.8 KVA 32.2KVA 46.5KVA

Rated output current

100A 160A 200A

Rated output voltage

120V 144V 160V

Rated duty cycle 100%

Current adjust range

30~100A 40~160A 40~200A

Qualitycutting thickness

(Manualtype for

Carbon Steel)

0.3~22mm 1~35mm 1~45mm

Quality cutting

thickness

(Machine type for

Carbon

Steel)

0.3~12mm 1~18mm 1~25mm

Max.cutting thickness

(Carbon Steel)

40mm 55mm 65mm

Plasma gas

Compress

ed air

Compressed

air

Compressed

air

The working plasma gas

pressure

0.4~0.6MPa 0.4~0.6MPa 0.45~0.6MPa

Open circuit voltage

300VDC 315VDC 315VDC

Rated input voltage.

3~380V/50Hz 3~380V/50Hz 3~380V/50Hz

Torch cooling mode Air cooling

Air cooling

/

Water cooling

Air cooling

/

Water cooling

Page 11

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

10

Arc striking mode Non-contact

Insulation grade

F

Page 12

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

10

Protection grade

IP21S

Dimension mm

(L×W×H)

695×320×580

695×320×580

800×380×610 800×380× 810

NET WEIGHT 51kg 52kg 73kg 82kg

2、 Plasma gas condition

Gas pressure range:0.5MPa~0.7MPa

Gas supply pipe compression strength:≥1MPa

Gas supply pipe inner dimension:≥Φ8

Gas flow:≥180L/min

Filter

the

water

in

the

gas,

then

feed

into

the

plasma

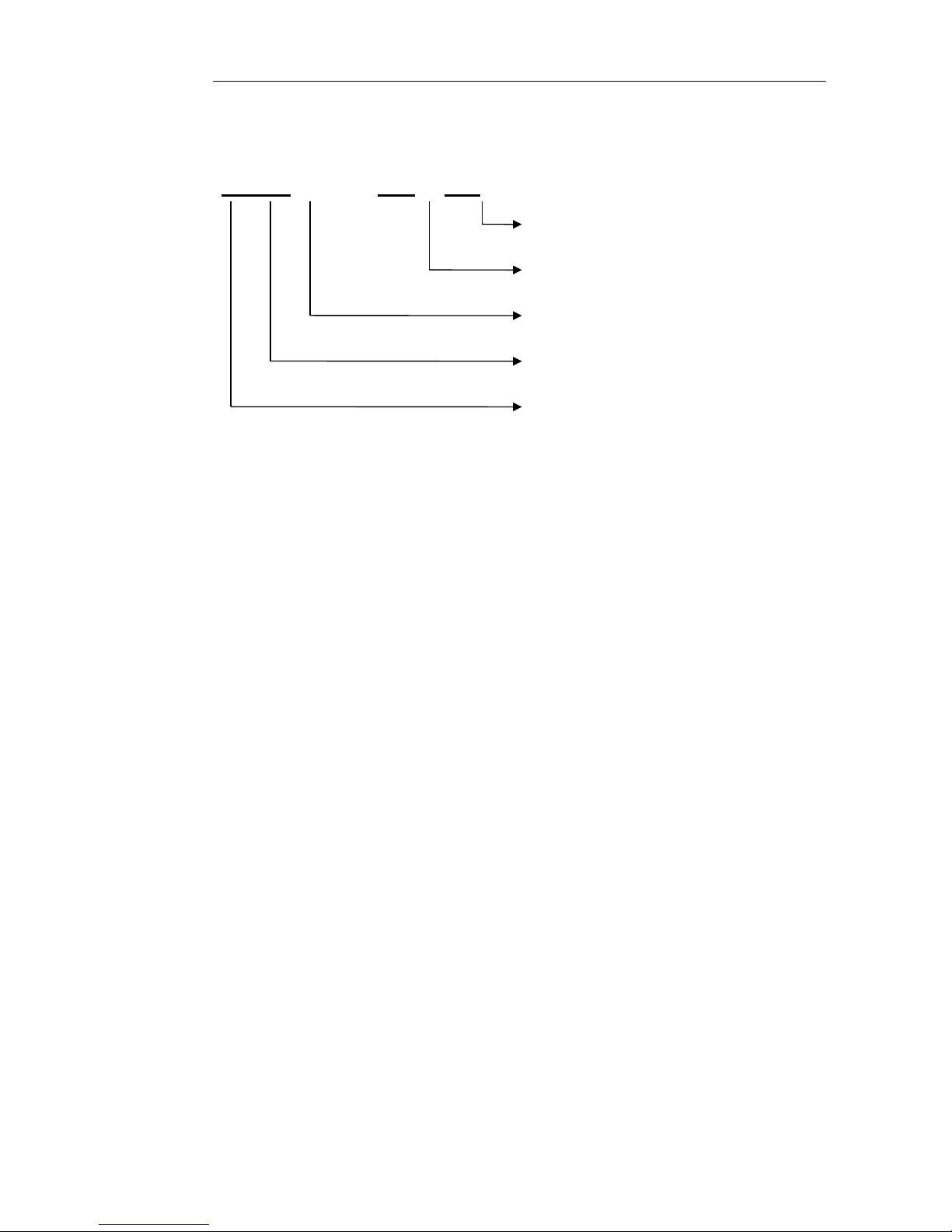

3、External characteristic curve

U

315V

285V

100A

120A 160A

I

200A

System instruction

Working

principles

The control circuit of this cutting machine adopts advanced electronic part IGBT

as the main inverter switch component. Three-phase AC power is converted to

20KHz high-frequency DC current after being rectified by three phase rectifier. Then

under the function ofIGBT inverter the DC current is inverted to AC high frequency

current,which is invertedto DCcurrent afterexperiencingvoltage reduction inhigh

frequency transformer,current rectifying in fast recovery diode. This DC current is

filtered through reactor, and the output cutting current is obtained. Control circuit

can control output current by controlling driven pulse width. The real time cutting

current, which is obtained through current sensor connected to output terminal in

series, is used as negative feedback control signal. After comparing with current

adjusting signal, the negative control signal is sent to PWM adjusting integrated

circuit, then acontrolled driving pulse is output to control IGBT.Thereby aconstant

output current can be maintained, and a steep dropping & constant current external

characteristic is obtained. Striking arc adopts high-frequency striking model. The

main circuit refers to appendix figure, and principle diagram of control circuit is

160A/144V

200A/160V

100A/120V

120A/128V

Page 13

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

11

shown as below figure .

Installation andoperation

1、 Moving and lifting

Power

source

should

be

shut

off

before

moving

the

cutter;

The cutter bottom shouldbe kept downwards during transportation. It is forbidden

to have cutter placed transversely or upended;

When

lifting,

it

must

be

lifted

vertically;

During thelong-distance transportation, it must prevent thecutter from raining and

moving back and forth inside box. Shock absorption foam should be placed around

cutter.

2、 Open the packing and check

Check

the

machine

and

packing

according

to

the

packing

list,ofthere

is

any

damage,

please

trytocontact

the

supplier.

3、 The fix and installation of the plasma power source

The mounting hole size of the automatic machine use plasma cutting machine

(

AIRCUT

-101I )

Page 14

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

12

The mounting hole size of the automatic machine use plasma cutting machine

(

AIRCUT

-161IW )

The mounting hole size of the automatic machine use plasma cutting machine

(

AIRCUT

-200IW )

Page 15

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

13

φ

8.2

7

5

φ

11535

65.5

4、 The connection of three phase input cable

1)

The

installation

have

to

accord

with

related

standard,

and

operate

by

professional

persons;

2)

Shut off the breaker of power, the connection operation only be allowed after

turning off;

3)

This machine use 3 phase 380V, 50Hz, user have to prepare relevant distribution box,

air breaker and power cables. The power condition as the below sheet:

Model The sectional area of

inputcopper cable (mm2)

The sectional area of

ground cable (mm2)

Fuse (A)

Contact capacity

(A)

AIRCUT

-

10

1I

≥6 ≥6 60 63

AIRCUT

-

160I

W

≥10 ≥10 80 80

AIRCUT

-

200I

W

≥16 ≥16 125 125

4)

The connection of power lead

Use eligible cables and sockets to connect it, and must be operated by a

qualified electrician.

5)

Connection

of

ground

cable

Connect the green-yellow wire of power source cable to ground ( Model

AIRCUT

-101I please connect it to ground on marking

of the machine

body) , the sectional area must match the requirements in above form, to ground

firmly. Ground connecting method should follow state standard.

4

3

29

Page 16

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

14

5、The connection of compressed air and the operation of pressure regulating

filter

(Thefunctionof pressureregulatingfilterplease check thebelow figure)

Gas pressure

regulating valve

Hoop

Inlet pipe

Draining water tip

1)

The compressed gas should meet the requirement mentioned in point “Plasma gas

conditions”. Connect the gas pipe with the gas inlet of air filter on the back panel

and hoop ittightly.

2)

Theusage ofpressure regulatingfilteris as follows.When itis toadjustpressure, lift

upair pressureregulating valve, androtate it.Left rotationaims to reduceoutlet gas

pressure, right rotation aims to increase outlet gas pressure. After the gas pressure

is adjusted properly, press down regulating valve.

3)

The air filter regulator should be checked periodically. If the water level reaches

two-thirds of filter glass, it must be drained, or this will affect incision quality. The

gas supply valve should be closed during water draining, and Gas Checking function

is selected in panel. When the indicated valve of gas pressure meter is zero, water

will drain out from drainage mouth automatically.

6、 Connection of cooling water (

AIRCUT

101 I does not have this function)

Connect

the

copper

nozzle

marked

with

“

water

inlet

”onthe

cutter

rear

side

with

water supply pipe, and tighten it. Connect the copper nozzle marked with

“Backwater” with water recycle pipe, and tighten it.

Notes: when use gas cooling torch, the torch selection switch on panel must be set

to air-cooled torch position, and the cooling water cannot be connected with. The

cooling water is for cooling torch only,and cutter power source does not need water

cooling.

7、 The connection of output terminal

1)

The

connection

of

torch

The torch model matched to plasma power source is as below:

Model

AIRCUT

101I

AIRCUT

-

161 IW

AIRCUT

-

200IW

Torch

model

P80

Air cooling

160

Water cooling

200

Water cooling

Remarks

Also work with P80 under 120A

current

Page 17

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

15

The selection of torch nozzle

Thebest current rangefor different nozzlesis different. Pleaseselect the

nozzle according to below form.

Nozzle aperture

diameter (mm)

1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6

Suitable current

(A)

20~30 30~40 40~65 70~90

80~100110~130140~170180~210220~25

0

Connection of air-cooling torch: first connect the torch cable connector M14 nut

with the copper nozzle signed with Air & Power on the front bottom panel, and

screw down the nut; then connect the torch pilot wire to terminal signed with

Pilot on the front panel and screw down the nut. Finally, connect the torch

control pin to the terminal signed with Control Signal on the front panel and

screw down the nut.

The connection of Trafimet air cooling torch

Special notes: it should not exceed the rated current of torch when use air

cooling torch, or it will be damaged by heat.

Connection of water-cooled torch (for

AIRCUT

-161IW/200IW): first

connect the torch cable connector M16 nut with the copper nozzle marked

with Water& Power output on the front panel, and screw down the nut.

Connect the backwater pipe M10 nut of torch with the copper nozzle

marked with Backwater on the front panel, and screw down the nut.

Connect the torch gas pipe M14 nut with the copper nozzle marked with

Air& Power output and screw down the nut. Then connect the pilot wire with

the terminal marked with Pilot on the front panel, and screw down the nut.

Finally, connect the control plug of torch with the socket marked with

Control Signal, and screw down the plug nut.

Connection of Hypertherm MAX200 machine use automatic torch (for

AIRCUT

-161IW/200IW):

Page 18

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

16

The requirements on connection of control plug when customers change

different torch from another factory.

Adopt WS20J4TQ 4-core pin from WEIPU Electrical Appliance Co., Ltd

Requirements on air cooling torch connection:

a)

Connect the 1, 2 pin of 4-core pin to switch control wire of cutting torch;

b)

Short connect 3, 4 pin of 4-core pin by gummed wire;

c)

Striking arc wire connects cold-press joint UT-8;

Requirements on water cooling torch:

a)

Connect the 1, 2 pin of 4-core pin to switch control wire of cutting torch;

b)

The3,4

pinof4-core

pin

don`t

connect

anyofwire;

c)

Striking arc wire connects cold-press joint UT-8.

2)

Connection of cutting ground cable

Connect the fast connector of cutting ground cable with the outlet marked with

CuttingGround cableon thefront panelandscrew downit clockwise.The otherend

of the cutting ground cable is firmly connected to work-piece.

8、 Connection of control signal (for automatic cutting equipment)

The

socket

model

of

the

connector

is:WS20J7TQ,

and

the

function

for

each

wire

pin is as following:

1)

Connector pin 1 and pin 2 is signal output of success arc striking, it is one group of

contactterminalof relay,and itsratedload capabilityis 3A/250VACor3A/30VDC.

2)

Connector pin 3 and pin 4 is start control wire of the cutter, its starting method is

controlledby operating selection switch. Usually 2-Stepis selected, that is,it starts

under short connection, and stops after cutting off.The two wire is used in parallel

with torch control socket pin 1, pin 2 on the front panel.

9、The connection of water cooling machine intelligent communication interface

(There

isnothis

interface

on

AIRCUT

-101Iwhen

AIRCUT

-16

1IW

/200

IW

useaswater

cooling,

this interface will be used)

The socket model of the connector is : WS20J7TQ, and the function for each wire

pin is asfollowing:

1)

Connector pin 1 and pin 2 is signal output of success arc striking, it is one group of

contactterminal of relay,it’s on closingstatus whenthe cutteris working, andit’son

Page 19

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

17

breaking status when the cutter is not working. Its rated load capability is

0.3A/125VAC or 1A/30VDC;

2)

Connector pin 3 and pin 4 is start control wire of the cutter, it is one group of

contact terminal of relay, it’s on closing status when the torch switch is on, and it’s

on breaking status when the torch switch is off. Its rated load capability is

0.3A/125VAC or 1A/30VDC;

3)

Connector pin 5 and pin 6 is protection signal that water cooling machine output to

plasma cutter, when short connect the pin 5 and 6, there will be no current and

voltage output from the plasma cutter.

10、 Panel and its functions (See the below figures for

AIRCUT

-101I,

AIRCUT

-161IW and

AIRCUT

-200IW)

1.

Digital ammeter: Displaying pre-set cutting current when not cutting, displaying real

cutting current whencutting;

2.

Cutting current adjusting knob: Adjusting cutting current;

3.

Power

indicator

light:

Indicating

if

the

cutter

isonpower

(The

light

only

on

AIRCUT

-16

1IW

/200

IW

);

4.

Air pressure indicator light : It is ON when the pressure of compressed

air exceeds 0.2Mpa. It is OFF when the pressure is less than 0.15Mpa;

5.

Starting

indicator

light:

When

the

light

ON

means

the

cutting

machine

has

started

;

6.

Overheating

indicator

light:

ItisON

when

the

cutter

inside

temperature

is

too

high

(Usually when the cooling fan is damaged);

7.

Power Input fault indicator light: It is ON when power source default phase or it’s

power lower than330VAC;

8.

Gas control selection switch: When it’s on “Checking gas”, gas valve opens to test

gasflow.Whenit’s on “Cutting”,the gas valveopens duringcutting automatically;

9.

Torch operation mode selection switch: When it turns on 2-Step, the torch switch

should be pressed at the process of cutting, and the cutting stops after loosening

the switch.Whenit turns on 4-Step, press the torchswitch and loosen it, the cutting

starts to work, and the stops after pressing the switch again;

10.

Cutting

ground

cable

socket:

To

connect

the

cutting

ground

cable;

11.

Torch striking terminal: To connect torch striking wire;

12.

The control socket of cutting torch: to connect the control signal wire of the cutting

torch;

Page 20

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

18

5

0Hz

4

6

7

5

14

1

5

16

17

1

2

8

TH IS S WI T CH IS ON L Y U SE D FO R P R OT E

CTI ON

O N

O F

F

S E R I A L N U M B

E R

V3~

38

0

V INP

UT

ARCVOLTAGECONTROLSIGNAL

2

6

A R C V O L T A GE

(

2A)

制造商: 成都华远电器设备 有限公司

R

地址 :成 都 市武 侯区 武 侯科 技园 武 兴四 路5号生产

厂: 成都 华 远电 器设 备 有限 公司

地址: 成都 双流西南 航空 港经 济开发区 空港 二路 1299号

名 称 :逆 变 式 空 气 等 离 子切 割 机

型 号:LGK

-120

IGBT

出厂编号:

3重量:52k

g

GB

1 5 5 7 9 . 1 - 2 0 1

30A/9 2V-1 2 0A/1 2 8

V

10 0%

12 0

A

1 2 8

V

3

=3 4A=3 4

A

F

9

12

27

13

11

10

AIRCUT

-101I panel function schematic diagram.

13.

Air & Power output terminal: the current output terminal is also the compressed air

output terminal. It is gas pipe connector to connect water-cooled torch when the

water-cooled torch is used, and it is connector to connect torch gas-cooled cable

when air-cooled torch is used;

3 4

18

2

5

6

25

7

15 16

14 24

1

8

A

19

17

9

1021

23

22

12 11 13 20

AIRCUT

-161IW panel function schematic diagram.

Page 21

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

19

14.

Power switch: Tocontrol the ON/OFF of 3-phase power supply of cutter;

15.

Power input: it’s connecting box on

AIRCUT

-101I and it’s input leads on

AIRCUT

161IW/200IW, to connect the 3 phase power. The green/yellow wire is

the ground lead, it should be connected with ground firmly;

16.

Arc

voltage

output:

AIRCUT

-101Iis

output

socket

(Pin

1is“+”

and

pin2is

“ - ”) . The default arc voltage output is 1:1;

AIRCUT

-161IW/200IW the arc

voltage

output wire is not connected out of the machine, If it is needed, please open the

cutter top cover, and use two-core rubber wire to connect the wire terminal on

printedboard LGK7-AP5,which has fourkinds of outputsignal: 1:1 ,1:20,1:50and

1:100;Please connect the wireaccording to the requirements,and pay attention to

the negative and positive electrode;

17.

Controlsignal connector: Tocontrol automaticcutting equipment (there is starting

signal and arc striking success signal);

18.

Hydraulic pressure indicating light: connect the cooling water supply,when water

flow is higher than 0.45L/min, the indicator will be on;

19.

Gas-cooling torch/water-cooling torch selection switch: gas-cooling torch is used

only when it switches to gas cooling, and water-cooling torch is used under water

cooling mode selected;

20.

Water/Power output connector: the cutting current output terminal is also the

water output connector, it is used to connect the water cooling cable;

21.

Torch backwater connector: It is used to connect the water recycle pipe;

22.

Waterinlet connector: to connect the water outlet pipe of water cooling machine;

23.

Backwater

connector:

to

connect

the

backwater

pipe

of

the

water

cooling

machine;

24.

Air pressure regulation filter:For adjusting the working pressure of compressed air

and filtering the water in air

;

25.

The water cooling machine intelligent communication interface: this connector only

be used when work with water cooling machine;

26.

Fuse holder of arc voltage signal;

27.

Ground protection terminal.

Page 22

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

20

200

A

160V

出厂编号

:

GB

15579.1-

2

1

max

3~5 0

H z

1ef1

3 4 18 5 6 24 14 15 25

7

2

R

WARP P WE LDER

电 源 指 示 气 压 水 压

8

切 割 过 热 供电 异 常

请另配电源开关!

3~380

V

16

非 自锁 水冷 割炬 切割

弧 压 输 出控 制讯 号

成都华远电器设备有限公司

地址:成都市武侯科技园武兴四路5号

40A/96V-200A/ 160V

17

-

INVERTERAIRPLASMACUTTINGMACHINE

X100%

I

U

U

=380

V I

=53

A I

= 53

A

防护等 级:IP21S 重 量:90kg

冷却 方式 :风 冷 绝 缘等 级:F

22

10

1211132021

AIRCUT

-200IW panel function schematic diagram

11、 Protection function introduction

1)

Air

pressure

protection

When the indicated value of the pressure meter,which is fixed on the back of

the cutter, is lower than 0.2 MPa, the protection circuit starts working and the

cutter cannot start;

Whenthe indicated value is lower than 0.15 MPaduring cutting, the cutting arc

will extinguish;

Note: When adjust the air pressure, the panel function must be set to ‘checking

gas’!

2)

Water

pressure

protection(

AIRCUT

-101Idoes

not

have

this

function)

When the water supply is lower than 0.45L/min, protection circuit starts

working and cutter cannot start;

When the water supply is lower than 0.4L/min during the process, protection

circuit starts working and cutting arc extinguishes automatically;

3)

Over-heat protection

When the ambient temperature is too high or the cooling fan is broken, the

cutter will be over heated under the rated current, and heat protection circuit

starts working, the cutting arc will extinguish automatically;

4)

Abnormal power supplyprotection

When 3 phases power supply misses phase, protection circuit starts working

and there is no arc striking;

When 3 phrase power supply is lower than 330VAC, protection circuit starts

working and there is no arc striking;

U

=3

20

0

I

GBT

f

2

2

A

1

型号:L

GK

-

Page 23

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

21

Note: the water and air pressure protection function is for protecting the torch

only!

5)

Notes of anti-interference (Specially pay attention when work on CNC automatic

cutting equipment)

Cover the whole torch cable (from torch holder to output terminal ) of the

cutterwith shieldinglayer,the shieldinglayer should bemetal hoseor shielding

net pipe made of aluminum or copper, metal materials which is magnetic

conducted can not be used, the shielding layer don't need to connect with

ground;

All the control lines which connected with plasma power source should be

shielding wire, the shielding layer should be connected ground well;

The control system of CNC cutting machine should be away from the cutting

table, torch cables and cutting torch head, especially the cutting torch heard.

When striking arc, the high frequency spark arc on the cutting torch head may

produce strong space spreading high frequency disturb signal, which may crash

the control system;

There should be shields on the controller of CNC system, and the shielding

layers should be ground connected well;

All the lines connected with CNC controller and cutting table should be shielding

wire(Such as thecontrol wire of step motor ,limitswitch etc.), and the shielding

layers should be ground connected well;

The

pileofthe

ground

cable

should

be

connected

with

ground

well.

Page 24

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

22

12 、 Operation

1)

Safety notes

Notes:

Operation strictly accordant with the following steps

Notice

Electric shock may

hurt or even kill man.

Cutting may cause fire or explosion

(Splashes may ignite flammable materials

nearby. Those materials should be 10m away

from the working place.

(Shutoffthe power during

connection

(Donot touch theconducted parts

Fume & dust is harmful.

(Donot breathe in the fume and

dust caused by cutting

(Cleanup the oilspot onwork

piece.

(Keep fresh air in working place

(Fume extraction equipment

should be prepared.

Arc may hurt your eyes and skin.

(Strong arc may hurt your eyes.

(Ultraviolet radiation generated by arc may

hurt skin and eyes. Please wear shielded

guard when cutting.

Overheated part may hurt your

skin.

(Donottouch the overheatedpart

on the work piece.

(Do not touch hot cable or torch

just by hands.

Fast moving thing may injure you.

(Do not put your hands orother things into

the fan shield.

(Cover the opened case shell well during

cutting operation.

Incase of injuryfor your skinandeyes, pleasewear required

guards according to Labor Security and Hygiene rules.Electrode

andnozzleshould bereplacedonlyafter the cutterispoweroff.

Operation should proceed according to related Labor and

Security regulations.

2)

Turn on the power switch after installation and connection. Then the power

indicator lamp isON;

3)

Start gas supply equipment and turn on the gas supply switch, the power indicator

lamp on the panel is ON. If the gas pressure is less than 0.25Mpa, the lamp will be

OFF, then the gas source should be checked;

4)

Startwater supplyequipment. Theindicatorlamp ofwater pressure onpanelis ON

whenopenswatersupply valve. (AIRCUT-101 I does nothavethisfunction)

Page 25

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

23

5)

Place the gas control switch to “Check Gas”, adjust the Adjusting knob of air filter

regulator to make the output pressure and flux fit cutting condition. After adjusting,

place the knob on “ Cutting “ position. Select panel operation method and control

switch point. At 2-Step point, the torch switch; should be pressed all the time

duringcutting.After loosening, thecuttingcomesto stop. At4-Step point, pressthe

torch switch and then loosen it, and cutting can start. User can make selection

according to his operation habit;

6)

Checking the panel indicator lamps. The indicator lamps status, under which cutting

can be operated, is shown as following sheet.

Indicator Power

Cutting

Gas

pressure

Water

pressure

Overheated

Supply

abnormal

Status

ON

OFF

ON ON

OFF OFF

Notes: there is no water pressure indicator on

AIRCUT

-101I and the water

pressure indicator will be OFF when gas-cooled torch is applied on

AIRCUT161IW/200IW cutter.

7)

Keep the torch nozzle 2mm~ 5mm away from work-piece. The axis line of nozzle

should be perpendicular to work-piece, and starts cutting from the edge of

work-piece. When the plate thickness is ≤12mm, a hole can be drilled on work-piece

and thencutting can be started around the hole.The cutting torch should inclined to

one side a little during drilling a hole on work-piece, so that the molten metal can be

blownaway easily.Todrill a holeby use of plasma arcis not proposed, because this

will damage nozzle easily, it is better to drill a hole in arc striking point first, then

strikes arc on the edge of hole. Press down torch switch, compressed gas sprays out

from nozzle, and cutting indicating lamp is ON. After gas pre-flows for 1 to 2 seconds,

high frequency is generated,arc is stroke,and cutting begins bymoving torch;

8)

When the control switch of operation method on front panel is at 2-Step point,

press down thetorch switch and cutting starts after arc striking. After loosening the

switch, there is no voltage output, and cutting ends, and compressed gas stops

supply in 9 seconds. Whenit is at 4-Steppoint, press downthe switch andloosen it,

and cutting starts after arc striking automatically. Press the switch again or press it

till the arc is off,then there is no voltage output, cutting ends, and compressed gas

stops supply in 9 seconds.

Cutting technologyinstruction

1、 The related main technical parameters

1)

Cutting

material

and

thickness

The selection of cutting technical parameters is based on the cutting material and

thickness. If the material is thick, it should adopt large current and nozzle with big

aperture. For different material under the same thickness, the parameter should also be

different.

2)

Nozzle

selection

Page 26

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

24

The three main dimension of nozzle are the diameter of nozzleφ, the hole pass

length ι and the compacted angle α, they all can affect the cutting. There should be a

certain proportion between ι and φ, the value is usually lower than 2, and it usually

takesι=1.5 ∼ 1.8 , the compact angle usually takes α=30°~60°, and now it usually

Φ

takes α=30°.

3)

Cutting

current

and

arc

voltage

The selection of cutting current should be according to the diameter of the nozzle,

therelationship betweenthe twoshould beas: I(currentA)=(70~100)×φ(mm).As the

increase of the metal thickness, the influence of arc current to the cutting speed will

become less. But as the increase of current, the burning damage will be worse for the

electrode and the nozzle. So when cutting a thick metal work-piece, usually the increase

of cutting speed is made by increasing arc voltage. The actual arc voltage is decided not

only by the gas type but also by the air flux and nozzle shape. Working voltage increases

with the increase of gas flux.

4)

Gas

flow

Q

The arc voltage increases as the increase of air flow, that is, the arc power, the

cutting speed, as well as the cutting capacity and quality is improved accordingly.

Because the arc compression level increases, the energy is more concentrated, the arc

beam temperature, the arc spraying speed, as well as the arc current impulsion increases.

But overlarge current may cause the instability of the plasma arc. Usually no change is

made to air flow for one torch. But it can be adjusted a little when the cutting torch or

cutting thickness isdifferent.

5)

Electrode

inner

contraction

∆

L

y

When electrode inner contraction

∆L

y

is so small that electrode extends into spray

hole, electrode is damaged seriously by air flow impact and the combination function

between high temperature gas and electrode. This leads to the instability of plasma arc,

weak compression effect, and weak cutting penetration ability that cutting cannot be

proceeded. If ∆Lyis too big, the arc is so unstable that the cutting ability is weakened.

The electrode end should be placed within siphoning zone of gas current under a relative

vacuum condition, and it will difficult to damage electrode by burning, as well as this is

beneficial for compression of arc. ∆Lyis about 2-4mm.

6)

The

distance

between

the

nozzle

and

the

work-piece

(d)

If the d istoo big, the blow power of plasma arc formolten metal decreases, sodoes

the cutting ability, and the burr on the bottom increases, meanwhile the instability of

thearc increases.However,if thed istoo small,it increasesthepossibility ofshort circuit

between the nozzle and the work-piece. Usually d should be as small as possible on

condition that no short circuit is caused between nozzle and work-piece. The d under

normal cutting of air plasma is usually 2~ 5mm. The work-piece can also contact with

the

nozzle

during

air

plasma

cutting,

that

is,

the

nozzle

glide

on

the

surface

of

the

work-piece. This cutting method is called contact cutting, and the cutting thickness is the

half as the ordinary cutting.

7)

Open

circuit

voltage

The power source with high open circuit voltage is required for cutting thick

work-piece.Theopen circuitvoltageis relatedwithair type,forexample,byusingargon

Page 27

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

25

the open circuit voltage may be lower, while it is higher by using air, nitrogen, hydrogen.

8)

Cutting

speed

The cutting speed is related with many parameters. The main parameters

determining cutting speed include work-piece thickness, cutting current, air flux and

nozzle aperture. A proper drag is allowed during cutting. The cutting speed should be

increased as much as possible, but the incision quality must be guaranteed.

2 、 Eliminate the cutting burr

9)

The

characteristics

of

the

incision

burr

The ordinary cutting surface is smooth and clean, but if the parameter

selection is not suitable, and electrode centering is not good, then burr may be

formed on the cutting surface.

Slag is formed by molten metal and its oxide which is adhesive to the bottom

edge of incision and solidified. The reason for forming this slag is that the molten

metal adhesive strength is bigger than the gravity and blow strength of metal oxide.

When cutting the alloy steel, the molten metal is difficult to be blown away

because of its bad fluidity, in addition, the alloy steel have bad thermal conductivity,

the incision bottomis over-heated easily,the left moltenmetal and incision bottom

melts into one, thereby the irremovable and tough burr is formed.

On the contrary, the incision bottom is difficult to be melted together with

molten metal, and the burr formed under incision is come off easily.

10)

The

factors

affecting

the

forming

of

burr

The fluidity of the molten metal is not good, when the power is too small or the

plasma arc compression effect is not good, the temperature of molten metal during

the cutting process is low, fluidity is weak, even if the air current blow force is

strong, it is still difficult to blowaway the metal completely, so the burr is formed.

When cutting the thick plate, the burr is caused by the drag of overlarge cutting

seam. During the cutting process, the heat received by different parts of metal is

different, the heat on the upper incision is larger than that of the lower incision, so

the upper part melting speed is faster than that of lower part, thereby a distance

between them isformed, it is calleddrag L of cutting seam.The drag size isrelated

to plasma arc shape and cutting speed. When the flame is short while the cutting

speed is too fast, drag L increases, so the vertical and horizontal blow forceof the

arc is formed, the vertical one helps to blow away the molten metal, while the

horizontal one makes the moltenmetal flow backward alongwith incision bottom,

this over-heated metal will melt parts of the bottom metal again, then the burr is

formed when they cool down and melt together.

The burr is caused by overheat bottom. When the cutting speed is too slow, but

the incision bottom is so over-heated that it melts, the liquid metal flows to bottom

metal and combines into one which makes the difficulty to blow away molten

metal by air current, and then the burr is formed.

The air current blow force is not enough. When cutting with plasma, the arc

blow forceconsists of the air current blow forceand the arcelectromagnetic force,

the air current blow force acts the main function. If the air current blow force is not

strong enough,it cannot ensureall the burris flown away,then theburr isformed.

11)

The

measurement

to

eliminate

burr

Page 28

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

26

Ensure the centering between electrode and nozzle precisely, so that the

compression of the plasma arc is not damaged, the concentration of flame and

cutting capacity can be guaranteed.

Enough power to ensure the fluidity of molten metal, as well as increase the

stability of the cutting speed and operation. This makes it possible to adopt large

air flux to enlarge the air blow force, and beneficial for eliminating burr.

Adjust suitable air flux and cutting speed. If the air flux is too small, the blow

forceis not enough, while if too big, the plasma arc will be shorten, the incision will

be “V” shape, the drag enlarge. The burr can be formed under both conditions.

When cutting speed is too slow,the incision is large and rough, the bottom is easy

to be over-heated, while the cutting speed is fast, the drag is enlarged, this is not

beneficial for eliminatingburr.

So under certain circumstance, there exists a proper selection range for air flux and

cutting speed.

12)

Diminish

the

cutting

surface

slanting

and

rounding

problem

The incision surface is a little slant and the upper side is a little round during

cutting with air plasma. Though the slanting range is acceptable during the cutting

process, in order to improve the cutting quality, people begins to pay attention to this

problem. Usually slowing down the cutting speed properly can avoid the slanting, but

this may enlarge the effect zone and incision width, as well as decrease the production

capacity, so this measurement is not wildly used. Recently, people can avoid the

slanting by improving the nozzle structure, this is called super cutting method. By

adopting multi-hole nozzle during the cutting process, the air current from the small

hole is parallel with that from the main hole, this can avoid the dispersing of the

plasma flame on metal top, and then a parallel incision, square upper side and no

metal slag seam on the lower side is obtained.

Troubleshooting & repair

1、If there is trouble caused by high voltage in the machine, a professional electrician or

serviceman of our company is required to repair it.

2、Please check following first when there is trouble.

1)

The

three-phase

power

should

be

380±40VAC

,

check

ifitmisses

phase

or

voltage

fluctuation exceeds its required range of power supply

;

2)

Check if the supply abnormity indicator lamp is ON. If it is ON, check if the

three-phase power switch of distribution box is damaged, and if the fuse and the

machine power wire are well equipped. Otherwise it will cause phase missing or bad

contact, which makes the machine work abnormally

;

3)

Check

if

the

torch

switch

and

its

wire

are

damaged

or

short-circuit,

andifthe

nozzle

and electrode aredamaged

;

4)Ifthe

control

plug

is

connected

mistakenly

after

user

exchanging

a

different

torch

fromanother manufacturer,please proceedthechecking asper“torch connection”

mentioned in instruction manual.

5)

Check if the cutting ground wire is well connected;

Page 29

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

27

6)

Check

if

the

water

in

compressed

air

filter

fixed

at

the

back

of

machine

is

drained

regularly

;

7)

Check

if

the

gas

pressure

indicator

lamp

on

the

panel

is

ON.

Ifitis

not

ON,

check

if

compressed gas pipe is well connected , and if the gas pressure is normal. When the

gas pressure is less than 0.3Mpa, the lamp is not ON.

8)

When the watercooling torch is applied, check if the water pressure indicator lamp

on panel is ON. If it is not ON, check if the cooling water current is normal.

9)

Checkif the overheatindicator lamp onpanel is ON.If yes, checkif the temperature

relay on the radiator is damaged or not.

10)

Open

the

machine

toptocheck

if

the

lead-typed

fuse

next

to

the

control

transformer

has been fused;

Ordinary trouble and repair as following sheet

Trouble

Reasons

Solutions

1. When the power

1.Three-phase power misses phase

1.Check three-phase power source

is

switched

on,

the

2.Supply

power

switch

is

damaged

2.Change

power

switch

lamp

and

the

digital

3.Power

control

fuse3Ais

broken

3.Change

power

control

fuse

meter

are

not

ON.

2.Supply abnormal

indicator lamp isON

without arc striking

1.Three-phase power misses

phase

2. Three-phase power is overload

under voltage

Check three-phase power source to

ensure the supply voltage accords with

the supply requirements.

3. No arc striking or

1.Theambient temperatureis too

high.

2.When cutting, cooling fan

rotates slowly or do not rotate, so

the cooling effect is weak.

3.Temperaturerelayis damaged

1. Let the cutter rest for a while,

and

will come to work normally later.

2. Check fan power source or

change

cooling fan

3.Change temperature relay

arc breaking during

cutting.

Overheat

indicator

lamp

is

ON.

4.It cannot

start.

Gas pressure

lamp is

not ON.

1.No gas pressure

2. The gas supply pressure is

too

low

3. LGK AP1 is damaged

1.connect the gas source

2.

Adjust

gas

supply

pressure

3.

change LGK AP1..

5. no arc striking,

1.Cutting ground wire is not well

connected.

2.Gas pressure is too high.

3.Torch electrode and nozzle

are

badly broken.

4.Torch electrode and arc striking

wire is short circuit, which cause

the damage of torch.

5. HF board is damaged.

1.C

onnectthecuttingground

wirewell

2.Lower the gas supply pressure

3.Change the electrode and nozzle

4.Change the torch

5. Change HF board

cutting

indicator

lamp, gas pressure

lamp

are

ON,

and

power

supply

abnormity indicator

lamp

and

overheat

lamp

are

not

ON.

1.Gas pressure is too high or too 1.Adjust gas pressure

low.2.Water

draining

regularly

2. The Air filter regulator cup is

3.The thickness of workpiece

should

6. Weak cutting

quality

filled.

3.Work-piece is too thick

4.Torchelectrode and nozzle

are

be

within

the

quality

cutting

range.

4.Change electrode and nozzle

5.Adjust torch angle

broken 6.Adjust cutting speed

Page 30

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

28

5.Plasma arc is not perpendicular

to

the

work-piece

6.Cutting speed is too fast or too

slow

7 Electrode and

nozzle work life is

very short.

1, Gas pressure is two low

2,Nozzle is too close to work-piece.

The distance is less than 2mm.

3.

nozzle aperture is small, and not

matched with applied current.

4.

electrode and nozzle is under

quality problem.

5.

the torch bought by user himself

is under quality problem.

1.Adjust gas pressure

2.The distanceshould bewithin 2mm

to 5mm

3.

selecta propernozzle matched with

applied current.

4.

change a good quality electrode and

nozzle.

5.

buy a good quality torch.

8.no arc striking,

and guiding arc

spraying out, but

there is high

frequency.

1.

fast recovery diode of secondary

rectifying is damaged.

2.

current-limiting resistor R6,R7,R8

of guiding arc is damaged.

3.

high frequency leakage in cutter

output circuit.

1.

change fast recovery diode under

same model.

2.

check and change the damaged

current-limitingresistor ofguiding arc.

3.

check leakage point, and strengthen

insulation function.

9.supply power trips

1.

three

phases

rectifier

is

damaged.

2.

IGBT module is damaged.

3.

other

components

in

main

control circuit is damaged.

1.

change a three phases rectifier under

same model.

2.

change IGBT module under same

model.

3.

check and change the damaged

components.

Page 31

AIRCUT

-10

1I,161IW,

200

IW

Inverter Plasma Cutting Machine

WARPP ENGINEERS PVT LTD

29

If the troubles cannot be resolved, please inform our local agent of the specific problems or contact us

directly.

Some popular components sheet as below:-

No. Name Model Remarks

1

IGBT module

CM100DC-24NFM

AIRCUT

-101I

CM150DC-24NFM

AIRCUT

161IW

CM200DC-24NFM

AIRCUT

-200IW

2

Hall sensor

TKC-100BS

AIRCUT

-101I

TKC-200BS

AIRCUT

-161IW,200IW

3

Air breaker

DZ47-63/3P D63

AIRCUT-

101I,161IW

CDB2-125/3P/D100

AIRCUT

-200IW

4

Control transformer

LGK7-1

5

Control transformer

LGK7-2

6

Electropneumatic valve

DF2-B-2/36V AC

7 Electropneumatic valve

Q22XD-5-36V AC

8

Cooling fan

200FZY2-D/AC220

9

Potentiometer

RV24YN-20S-B502

10 Temperature replay

JUC-6F-75℃

11 Pressure controller YKC 0.3/0.25

12 Control board

PL07

AIRCUT

-161IW,200IW

13

Program control board

LGKAP1

14 Main control board

LGK7-AP2

15

High frequency board HFAP1

16 Arc striking board

PL05

17 Air filter regulator

GFR-200-08

AIRCUT

-101I

GFR-300-10

AIRCUT

-161I,200IW

Packing list

1、

Plasma cutting power source 1

2、 Plasma cutting torch

3、

Ground cable 1

4

、

Certification 1

5、

Guarantee card 1

6、Operations manual 1

Plasma model

AIRCUT101

I

AIRCUT-161 IW AIRCUT-200 IW

Torch type

Air cooling

type

Air cooling type/water

cooling type

Air cooling type/water

cooling type

Quantity

1

Each 1 Each 1

Page 32

1 2 3 4 5 6 7 8

D

1

QF1

5

L1

C3

CBB22/100n/630V

C1 C2

9 V1

V2

71

SKM100GB12 8D

C8

G3

C9

E3

V3

SKM100GB12 8D

C7

G1

E1

V4

TM1

23

L4

TA2

RV1 R6 R7

C5

25

THF1

D

2

3

D40

4

6

7

FU1

1.5A

10

11

EV1

风扇

C25

R1 R2

G4

RV1

E4

72

73

C5

40U/1400VDC

G2

E2

74

22

V5

L5

28

R5

TA1

27

24

8

C17

TA2

L3

75

C6

76

12 5U/500VAC

C

68.

18.

415V

380V

220V

6.

110V

36V

TC1

8V

KT1

G4 E4

33

37

E3 G3

35

G2 E2 E1 G1

36

G2 E2 E1 G1

65

66.

C

P A1

34

67

415V

TC2

83 80V

18V

18V

LGK7- AP 2

36VAC

15V

7

13

SA2

B

SA1

SB1

20

C18

C19

RP1

5K

切割电流

HL1电源HL4

HL5

过热 欠压

B

16 13 52

50

51

53 61 59 6062

55

YV1

YV2

A

17

小气阀

99.

大气阀

14

54

77

78

57

BP1

气压开关

1:1弧压1:20

弧压

A

AIRCUT-101I

1 2 3 4 5 6 7 8

WARPP ENGINEERS PVT LTD

Attached diagram

:

main circuit diagram

LGK7- AP4

AIRCUT

-10

1

I

,

160

IW

,

200

IW

Inverter Plasma Cutting Machine

G4

E4 E3 G3

24 43A 44A 45A 46A 81 82 83 84 27

43 44 45 467778

41

13 18

383929 28

59

60. 62

404142

30

31

32

16

17

24 25

LGK7- AP5

24 25 47 48

99.

LGK7- AP 1

30

58

15

105

100.

99. 98.

AP3

90 68.

68.

43

44

45

63 64

46

HL2

HL3

气压

切割

Page 33

52

20

1 2 3 4 5 6 7 8

QF1

D

1

C3

CBB22/100n/630V

C1 C2

5

V1

R1R2

R15R1 6

L6

V2

71

CM200DC-24NFM

G3

E3

C4C5

V3

CM200DC-24NFM

C7

C6

G1

E1

V4

TM1

23

L4

RV2R6R7

C8

25

C15

THF1

D

2

3

4

D40

6

7

FU2

73

G4 G2

E4

E2

74

22

V5

28

27

R5

24

1.5A

EV1

8

12

C16

EV2

C17

C9

C10

72

C11C12

TA3

L3

C13

75 76

C14

L5

TA2 TA1

415V

380V

220V

6

68 110V

18 36V

C

13

TC1

8V

KT1

G4E4

33

37

E3G3

G3

G2E 2

35 36

E1G 1

PA1

C

LGK7-AP2

43

415V

TC2

8380V

18V

18V

FU1

2A

32

6059 6240 41 42

2928 39 38

6463 78a

46

7

103

15V

52

20

水流开关

RP1

4.7K

切割电流

HL1电源HL4

HL5

过 热 供 电 异 常

63

64

63a

64a

气冷

SA3-1

BP2

气 冷 枪 接 口

水 冷

1:1弧压1:20

弧压

B B

20b

53

53b

PL07

非自锁

自 锁

SA1

HL2

气 压

53526160 5962

55

HL3

启

动

78a

气冷

SA3-2

53a

SB1

78a

13

SA2

77a

水冷

HL6

水流量

20a

C18

C19

YV1

YV2

A

17

小气阀

大气阀

16

17

99.

99

56

57

BP1

气压开关

77

78

15

A

AIRCUT-161IW,200IW

1 2 3 4 5 6 7 8

64b

62 59b

16

50

13

54

51

LGK7-AP1

56a

56

303 1

58

WARPP ENGINEERS PVT LTD

.

LGK7- AP4

G2E 2E1G4E4 E3 G1

65

66.

43A 44A 45A46A 24 81 82 83 84 27

43 44 45 467778

41 13 18

AIRCUT

-10

1

I

,

16

1

IW

,

200

IW

Inverter Plasma Cutting Machine

67

68.

34

44

45

30

31

63b

2425

LGK7-A P5

24 25 47 48

59

59

62

62b

105 100 99 98

HFAP1

90

68

31

Page 34

Warpp Engineers Pvt Ltd.

Source of Reliable welding and cutting

equipment.

Unit no 36/15 Unique Industrial Estate,

Dhumal Nagar, Waliv,

Vasai East,Palghar 401208.

TEL: 08551819944, 8551817869, 851817744.

E mail: sales@warpp.co.in

Website: www.warpp.co.in

Loading...

Loading...