Warn Industries PullzAll 885002, PullzAll 885004, PullzAll 885003 Service Manual

987605A1 Page 1 of 49

SERVICE GUIDE

For

WARN PULLZALL 230v AC

P/N 885002, 885003 & 885004

REPAIR / REPLACEMENT INSTRUCTIONS

TROUBLE SHOOTING GUIDE

987605A1 Page 2 of 49

WARNING

This guide identifies potential hazards and has important safety messages that help you and

others avoid personal injury or death. WARNING and CAUTION are signal words that

identify the level of hazard. These signal words mean:

WARNING signals a hazard that may cause serious injury or death, if you do not follow

recommendations. CAUTION signals a hazard that may cause minor to moderate injury,

if you do not follow recommendations.

This guide uses NOTICE to call attention to important mechanical information, and

Note: to emphasize general information worthy of special attention.

Notice

This guide has been provided for use by WARN Authorized Service Centers. Any

other use is prohibited.

Caution

Moving parts entanglement hazard

Failure to observe these instructions could lead to minor or moderate injury

Always take time to fully read and understand the Instructions.

Never operate this product if you are under 16 years of age.

Never operate this product when under the influence of drugs, alcohol or medications.

Read instructions thoroughly

Notice

Equipment damage

Always refer to the Wiring Diagram for all wiring schematics and specific details on how

to wire this WARN product

.

Read instructions thoroughly.

987605A1 Page 3 of 49

CONTENTS

1. GENERAL DESCRIPTION 04

2. DISASSEMBLY AND ASSEMBLY 06

2.1. Suggested Tools 06

2.2. Housing 07

2.3. Gear Train Assembly 11

2.4. Motor 17

2.5. Wire Rope Assembly 22

2.6. Safety Hook 28

2.7. Tail Hook 31

2.8. Drum Assembly 36

2.9. Wiring Diagrams 37

2.10. Filter Assembly 45

2.11. Torque Specifications 47

3. PULLZALL TROUBLE SHOOTING 48

4. SERVICE PACK LIST 50

987605A1 Page 4 of 49

1. GENERAL DESCRIPTION

The PullzAll is a powerful, lightweight, easy-to-use handheld electric tool with the ability to lift or

pull up to 1,000 lbs / 454 kg. A strong Motor and Variable Speed Trigger Switch for power in and

power out operation, Wire Rope and Clasp Hook will allow you to move heavy items into place

smoothly and precisely. These features equate to saving both time and money.

The PullzAll will help get the job done easier, faster, and with less manual labor than a come-a-

long or chain fall, making you more productive. The PullzAll is for the tradesperson, farmer /

rancher, or anyone that needs to lift or pull up to 1,000 lbs / 454 kg. This makes PullzAll ideal for

construction, pipe fitting, iron work, equipment and plant maintenance, farm and ranch use, auto

shops, garages, machine shops, home improvement, hunting, camping, and more.

PullzAll 230v AC Specifications:

1. Part number 885002 (UK), 885003 (EU) & 885004 (AUS).

2. Light weight and portable.

3. Powerful 230 Volt AC Motor.

4. 1,000 lbs (454 kg) lifting / pulling capacity.

5. 15'(4.6m) of 7/32"(0.56cm) diameter Wire Rope.

6. Variable Speed Control for precision load placement.

7. Convenient forward/reverse Switch.

8. Electronic Load Limiter with LED indicator for operator feedback.

987605A1 Page 5 of 49

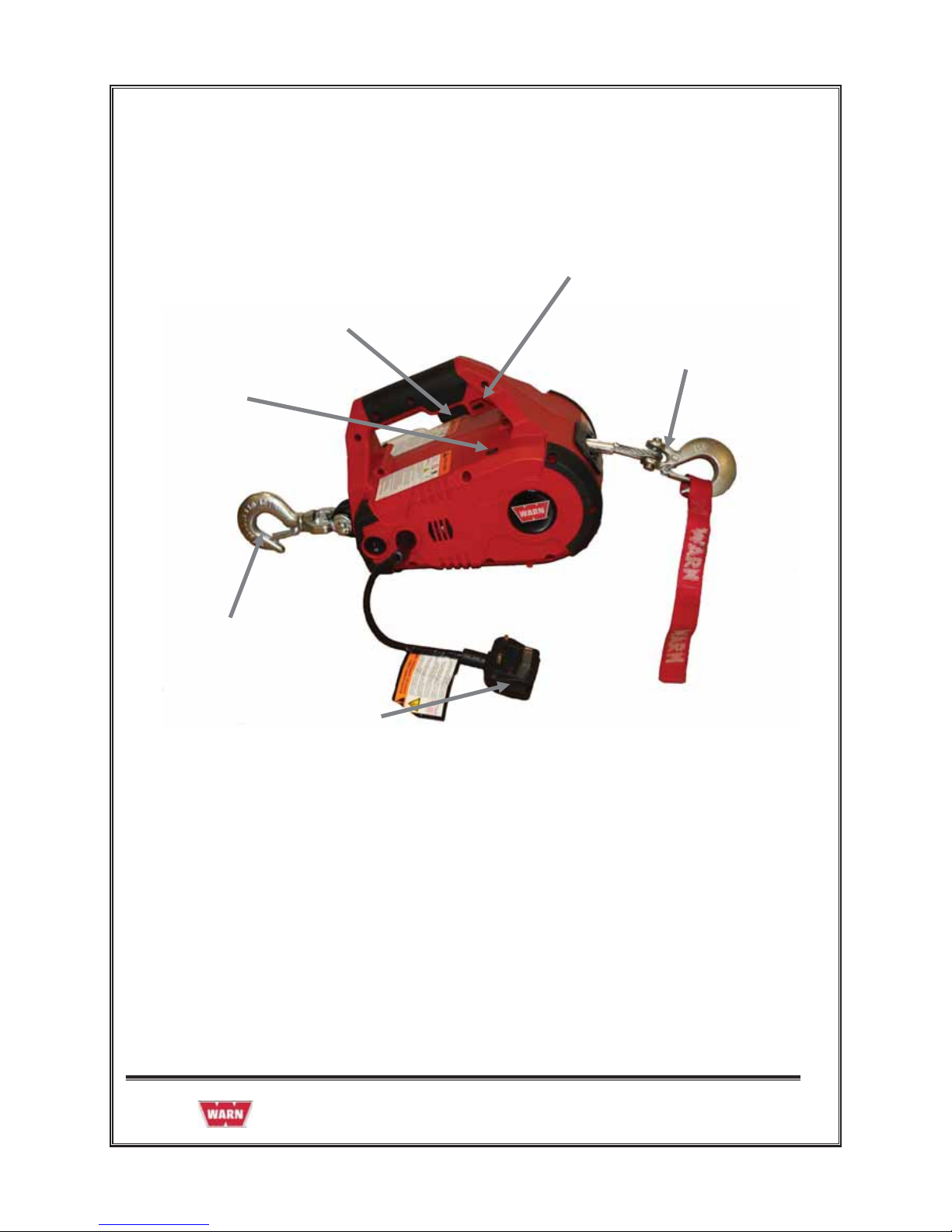

Runs on 230v

AC Power

15’ of 7/32” Wire

Rope with Industrial

Grade Hoo

k

Versatile Swivel

Anchor Hook

Electronic Load

Limiter with LED

Indicator for Operator

Feedback

Handle with Trigger

for Variable Speed

Control

Convenient

Forward/Reverse

1000 lbs/454 Kg

Lifting/Pulling

Ca

p

acity

987605A1 Page 6 of 49

2. DISASSEMBLY AND ASSEMBLY

2.1 SUGGESTED TOOLS

1. Hammer

2. Snap ring plier

3. Allen key set

4. Screw driver

5. Cutting plier

6. Pin remover (Punch)

7. Insulation tape

8. Gloves

987605A1 Page 7 of 49

2.2 HOUSING

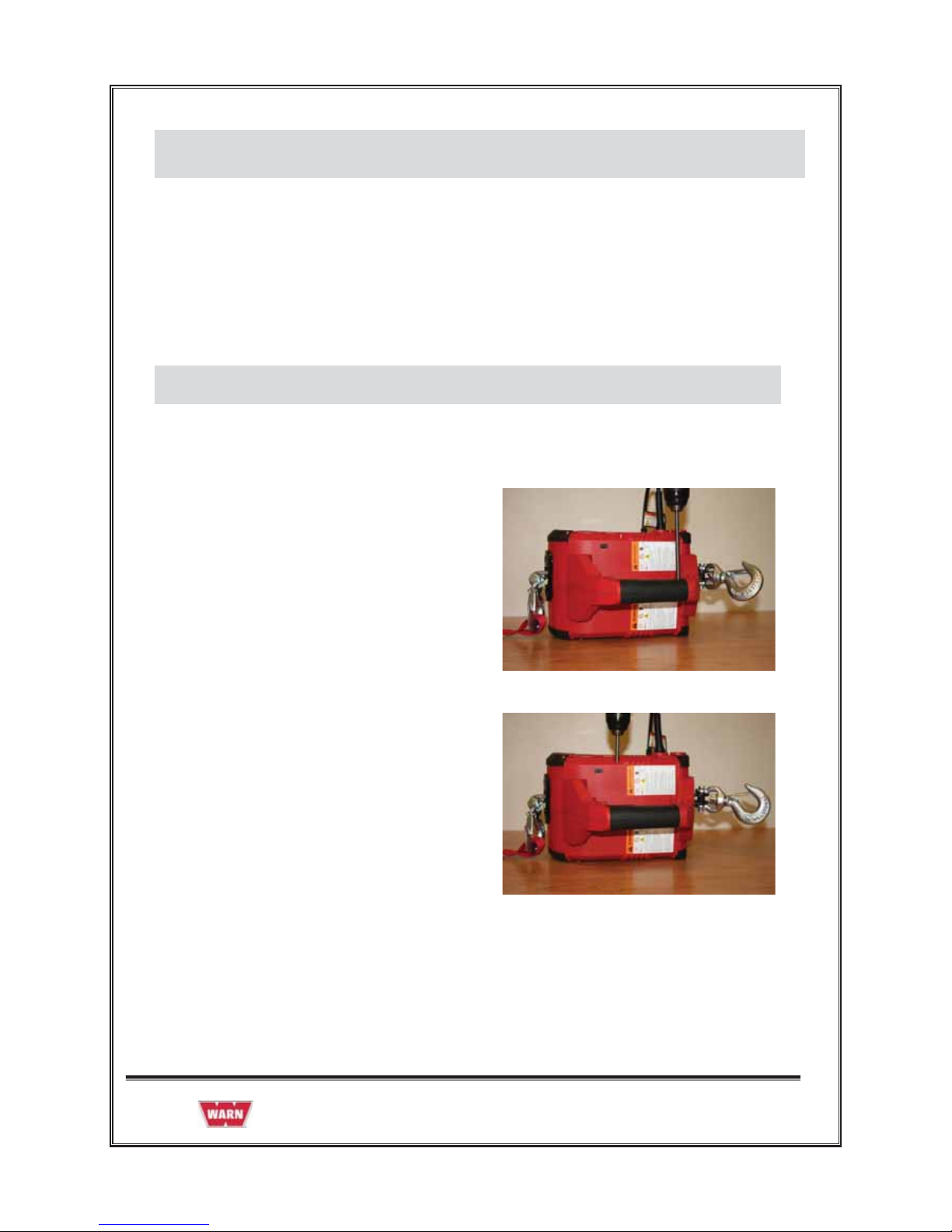

Before opening the Housing follow the below instructions:

Power Cord

Always unplug the product while rigging, when not in use or during maintenance and cleaning.

2.2.1 REMOVAL OF HOUSING

1. Remove the screws (#6 x .75), Qty 7

from Handle.

2. Remove the screws (#8 X 1.25), Qty 6

from the main body of the Housing

987605A1 Page 8 of 49

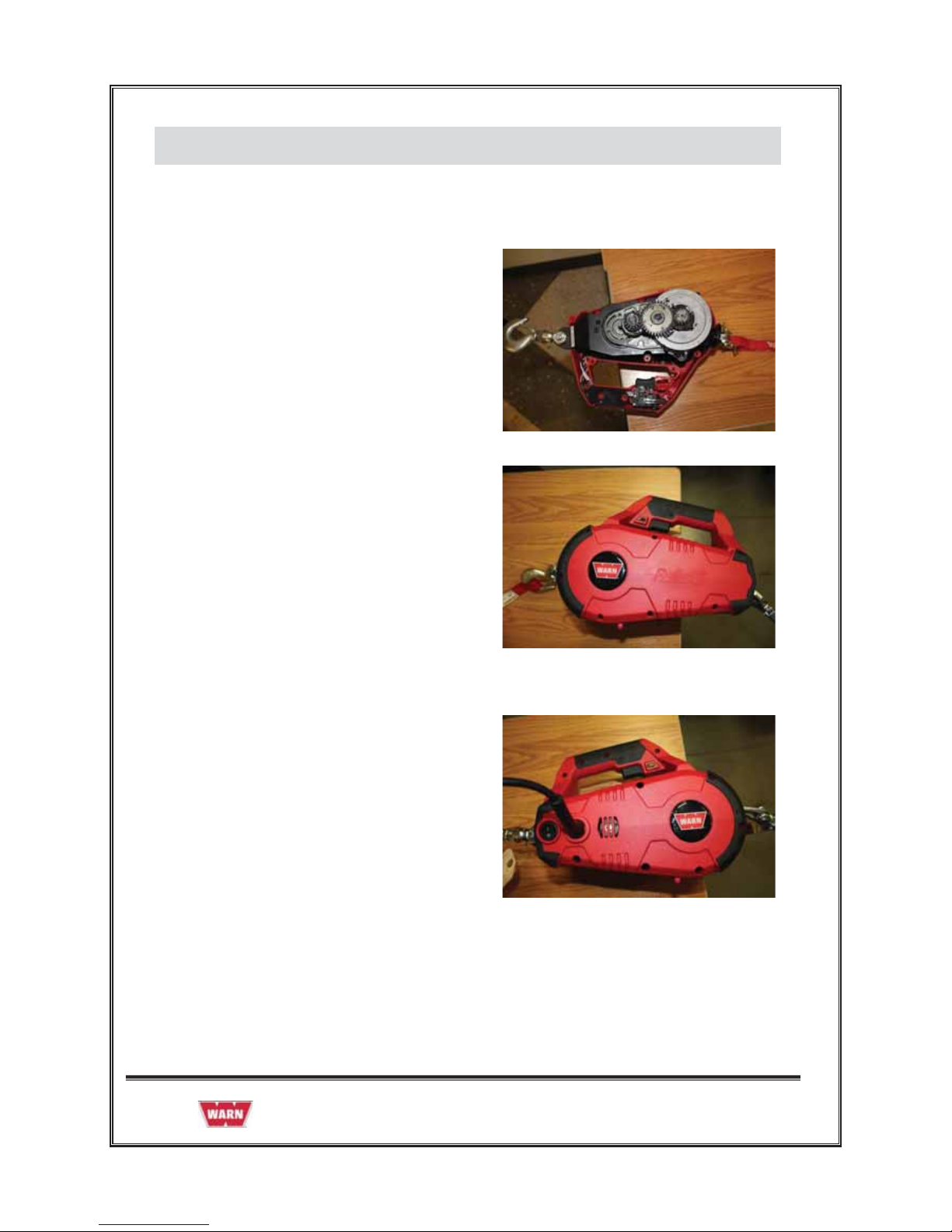

3. Keep the assembly on the work bench

facing the cover in the direction as shown

in the figure.

4. Remove the Plastic Housing -left hand

from the assembly as shown in the

figure.

5. Remove the Main Chassis from the

Plastic Housing - right hand and place it

on the work bench.

987605A1 Page 9 of 49

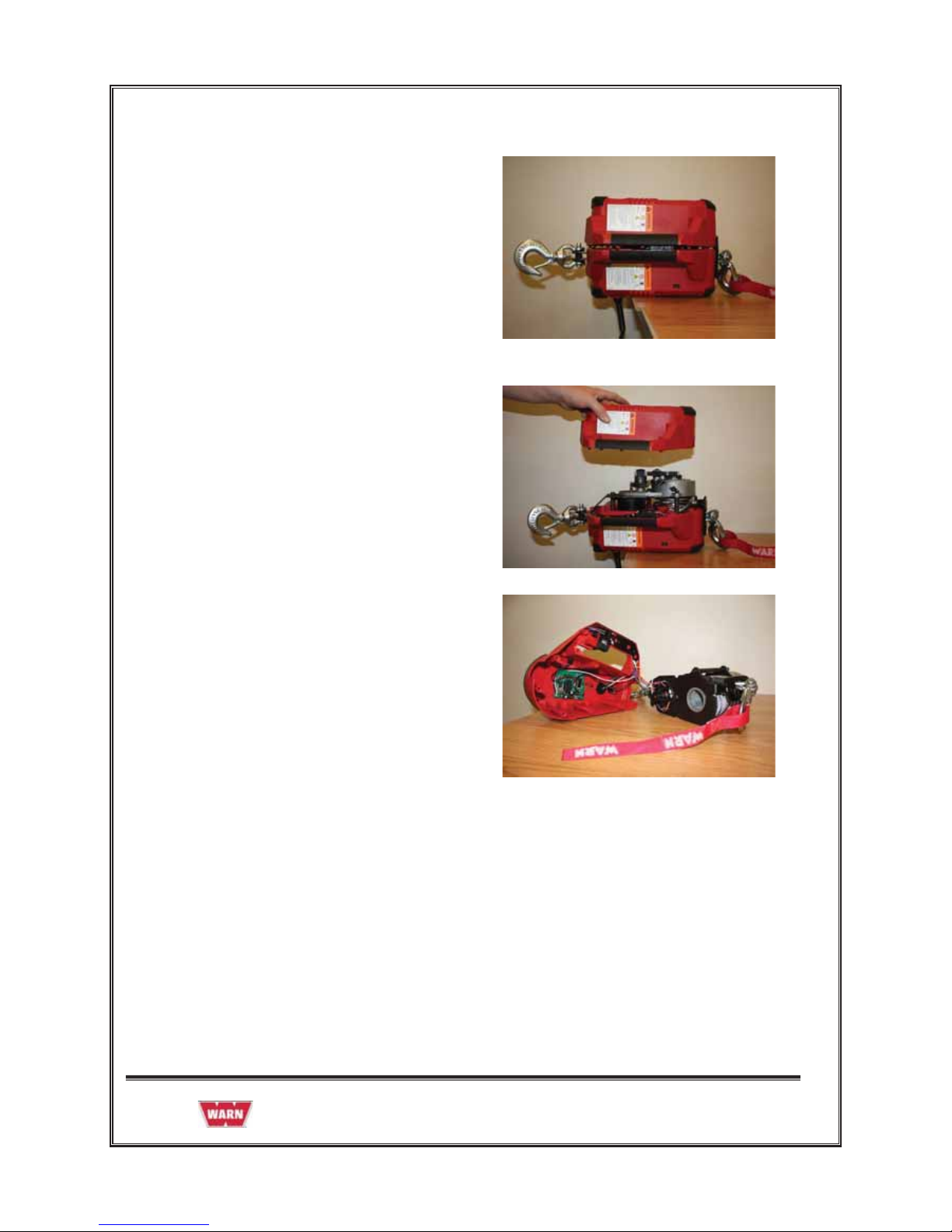

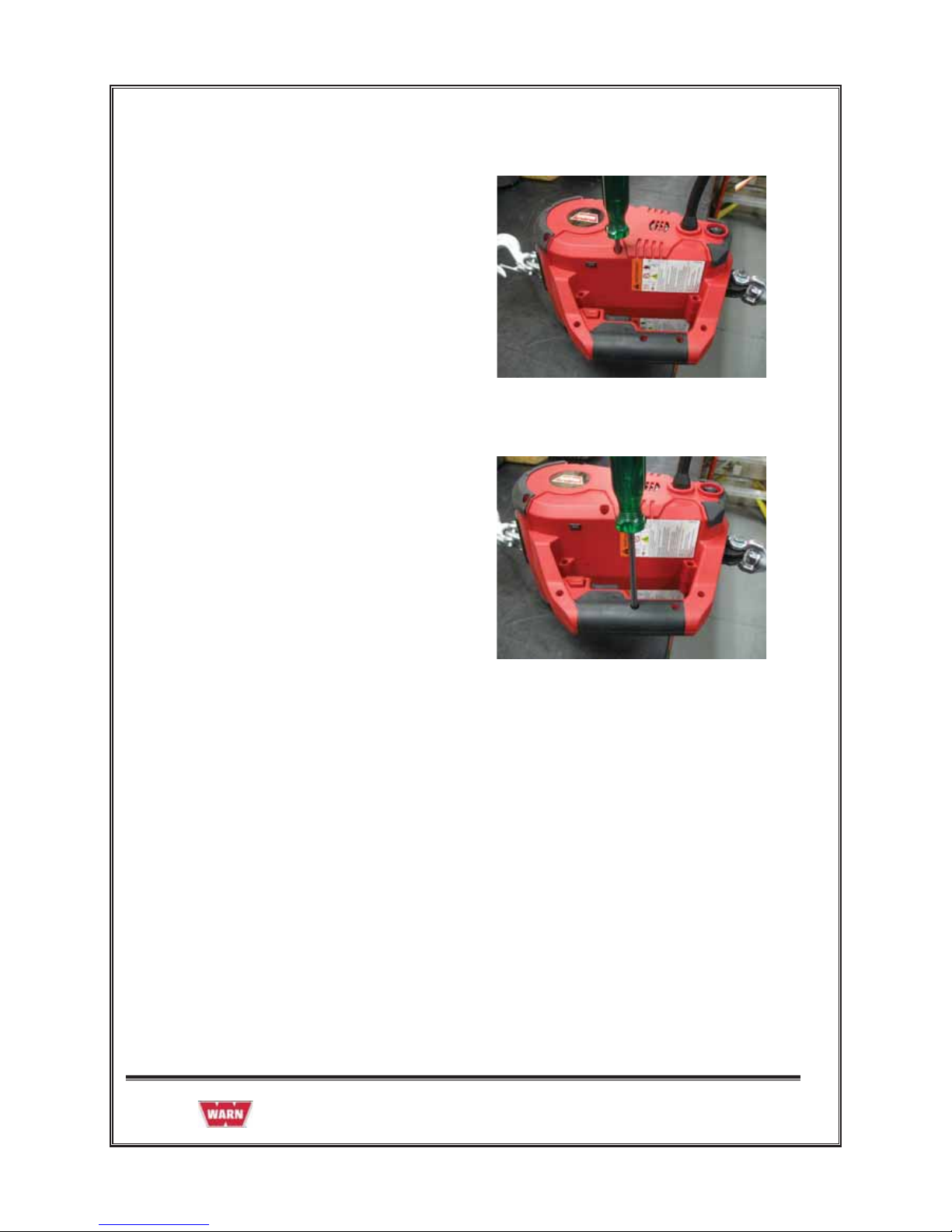

2.2.2 ASSEMBLY OF HOUSING

1. Install the Main Chassis in the Plastic

Housing - right hand as shown in the

figure.

2. Install the Plastic Housing -left hand on

the assembly as shown in the figure.

3. Flip the assembly as show in the figure.

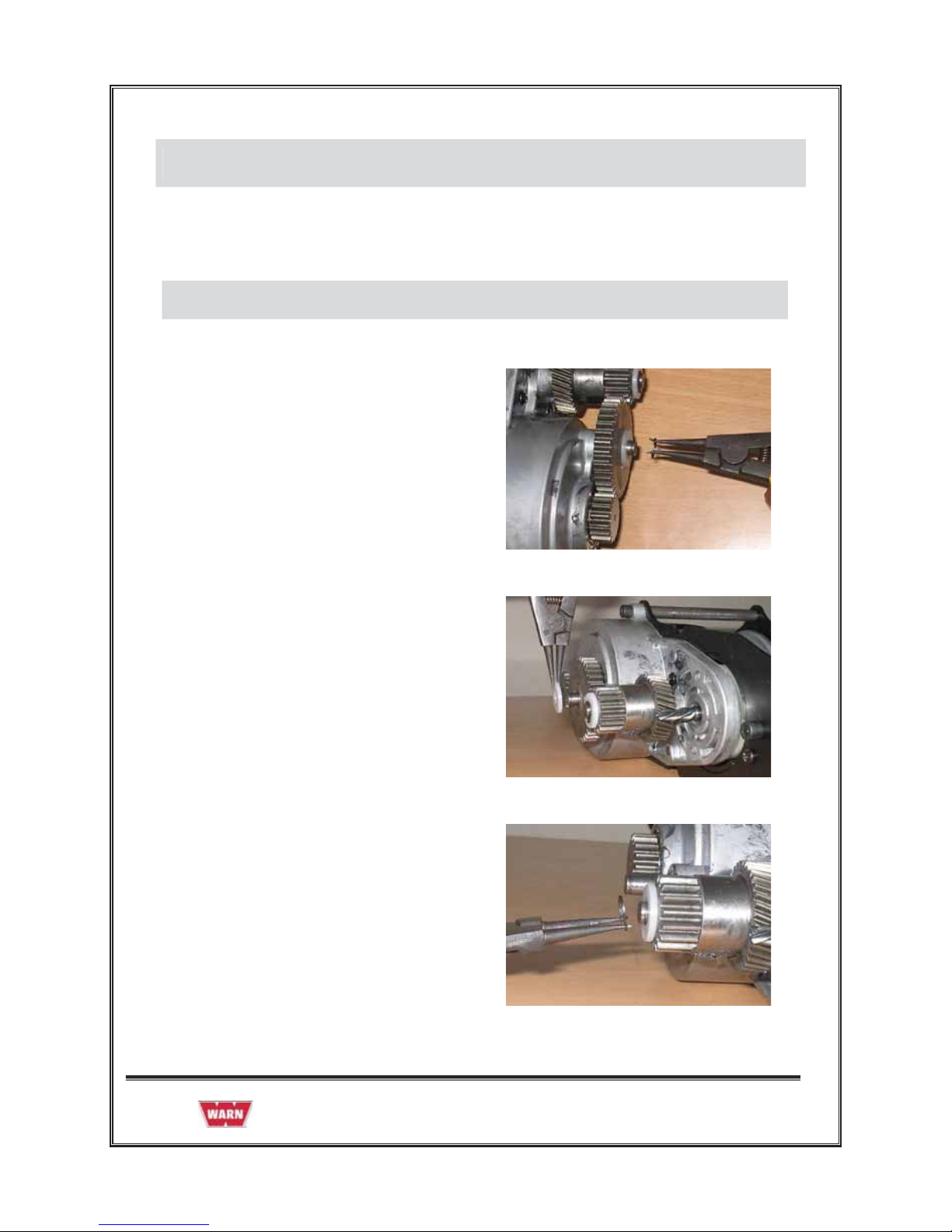

987605A1 Page 10 of 49

4. Install the screws (#8 X 1.25), Qty 6

from the main body of the Housing

5. Install the screws (#6 x .75), Qty 7

near Handle

Note: When replacing the Housings with a Housing Service kit, be sure to affix all appropriate

labels from the service kit onto the new housings, using the housings being replaced as a guide

for placement of your new labels. Your service kit will include extra labels for other languages

and markets that can be discarded after you select the ones needed for your product.

987605A1 Page 11 of 49

2.3 GEAR TRAIN ASSEMBLY

• If the gear sets are worn or damaged, the entire PullzAll must be replaced, no replacement

parts are available.

2.3.1 GEAR TRAIN ASSEMBLY REMOVAL

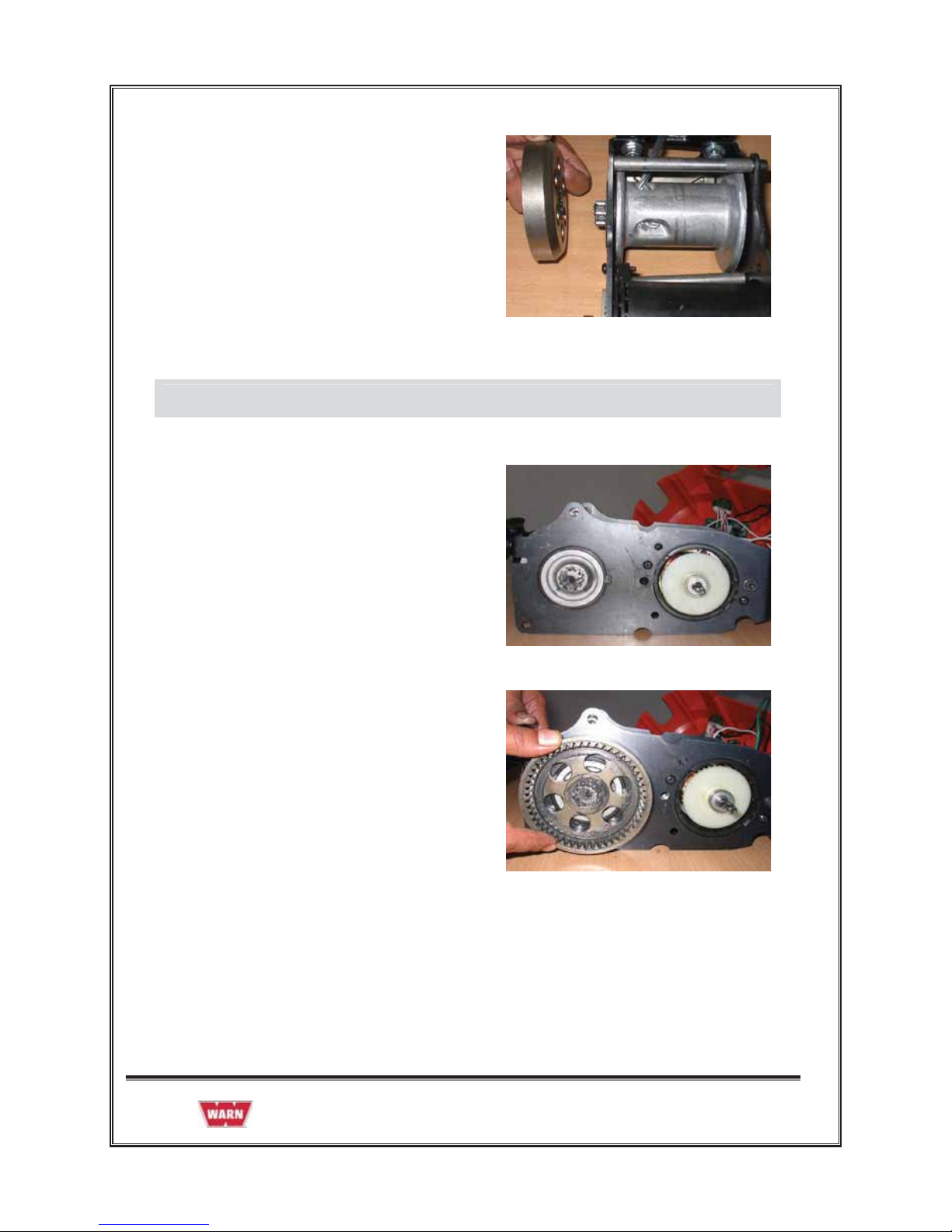

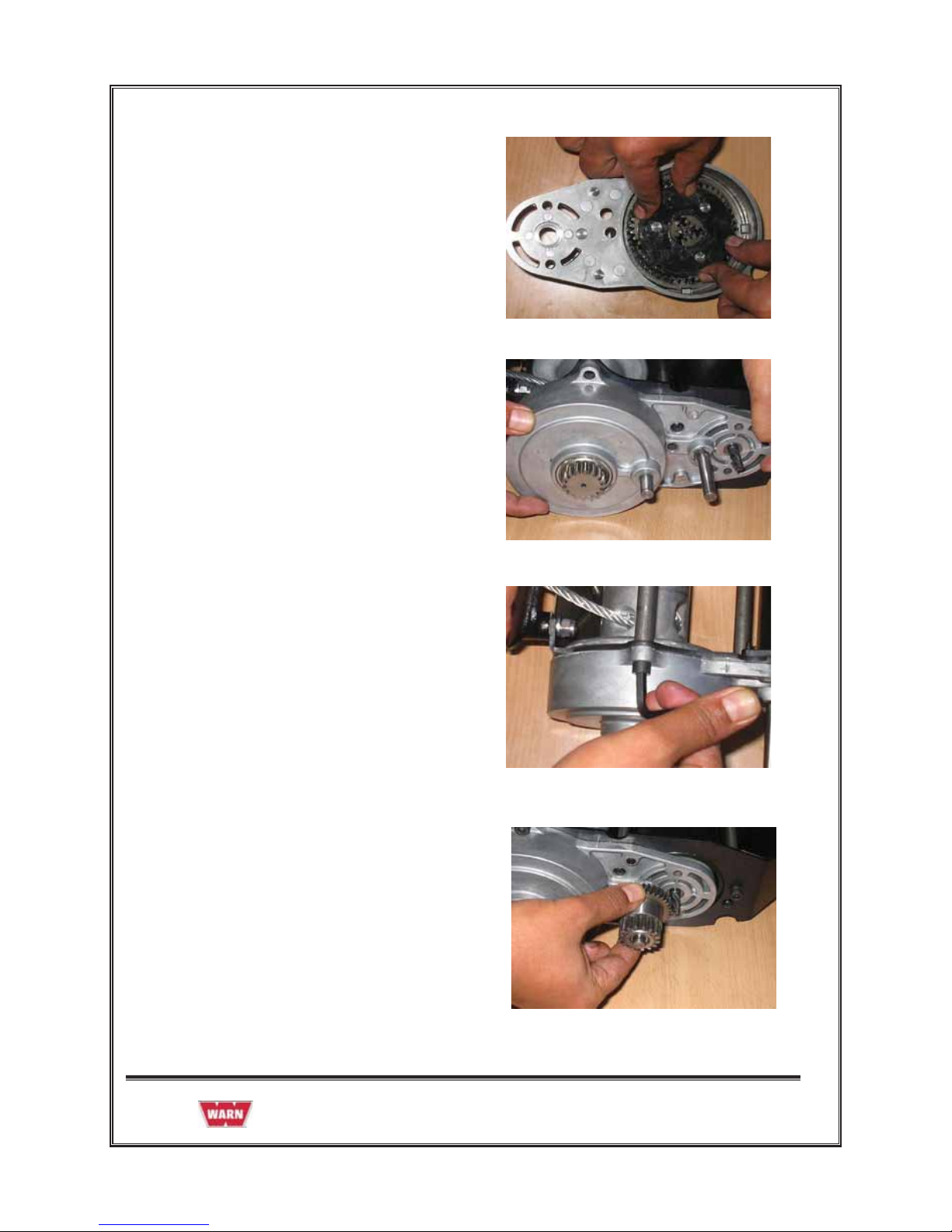

1. Remove Retaining Ring from Idler Gear

2. Remove Wear Washer from Idler Gear

3. Remove Retaining Ring from Helical

Gear . Remove Wear Washer from

Helical Gear.

987605A1 Page 12 of 49

4. Remove Helical Gear from Gear

Housing.

5. Remove 3 Cap Screws (#3 x .75)

from Gear Housing through Left side

Bracket of Chassis assembly.

6. Remove Gear Housing from left side

Bracket of Chassis assembly.

7. Remove Carrier Assembly from Ring

Gear.

987605A1 Page 13 of 49

8. Remove Ring Gear 51 T from left side

Bracket of Chassis assembly.

2.3.2 GEAR TRAIN REASSEMBLY

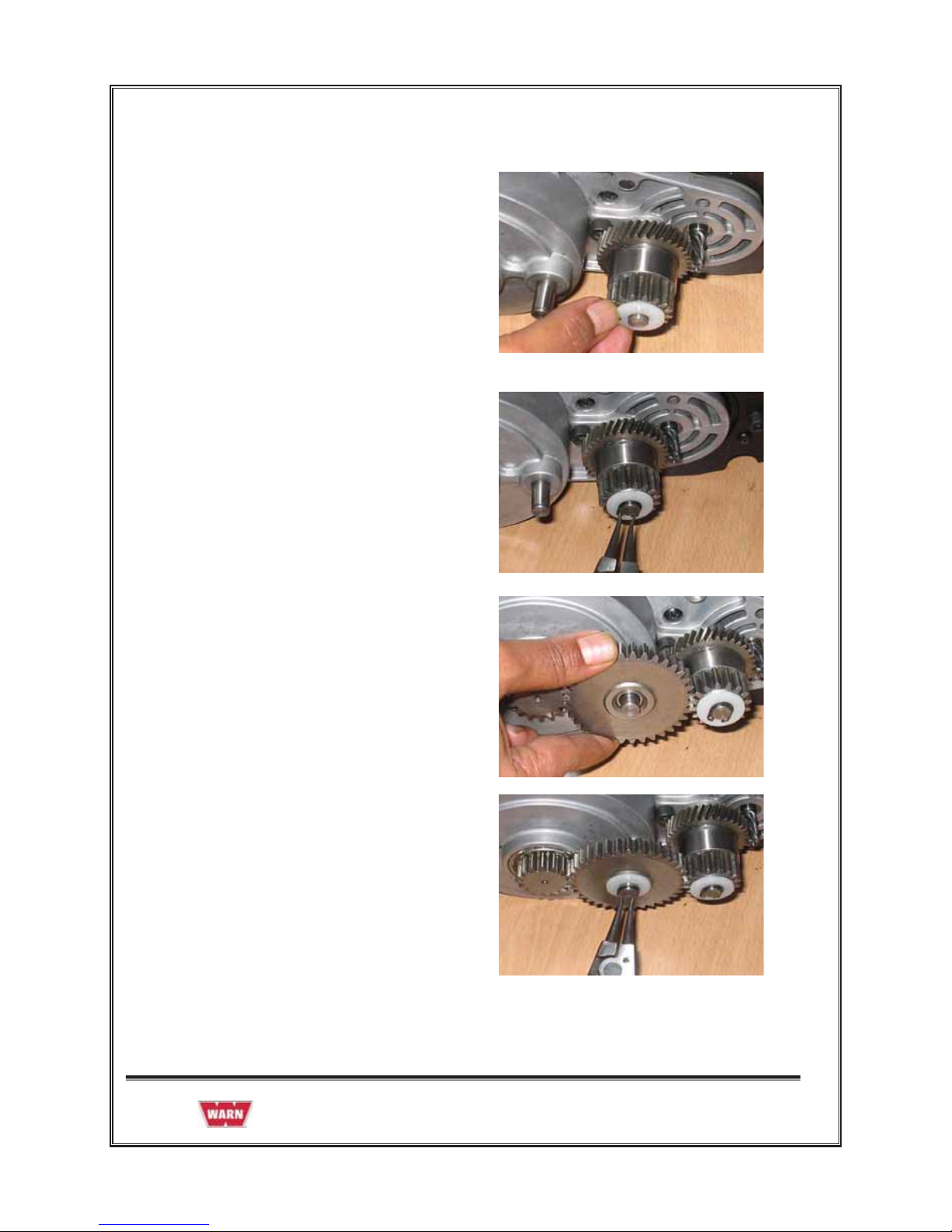

1. Install Gear Train assembly after

installation of Motor assembly.

2. Insert Ring Gear 51 T on Left side

Bracket of Chassis assembly as shown

in the figure.

987605A1 Page 14 of 49

3. Install Ring Gear 48T and Carrier

Assembly in Gear Housing .

4. Install Gear Housing on Left side

Bracket of Chassis assembly.

5. Install 3 Cap Screws (#3 x .75) in Gear

Housing through Left side Bracket of

Chassis assembly.

6. Install Helical Gear Press on Gear

Housing as shown in the figure.

987605A1 Page 15 of 49

7. Install Wear Washer on Helical Gear

Press.

8. Install Retaining Ring on Helical

Gear Press.

9. Install Idler Gear on Gear Housing.

10. Install Wear Washer and Retaining

Ring on Idler Gear.

Loading...

Loading...