Page 1

MID-FRAME WINCH

WITH SYNTHETIC ROPE

INSTALLATION AND OPERATOR’S GUIDE

GUIDE D’INSTALLATION ET OPERATEUR

87970A2

Warn Industries, Inc.

12900 S.E. Capps Road

Clackamas, OR USA 97015-8903

1-503-722-1200 FAX: 1-503-722-3000

www.warn.com

Customer Service / Service Clients: 1-800-543-9276

© 2016 Warn Industries, Inc.

WARN®, the WARN logo are registered trademarks of Warn Industries, Inc.

WARN® et le logo WARN sont des marques

déposées de Warn Industries, Inc.

Page 2

English...........................................................................1

Français.......................................................................17

Español........................................................................33

Deutsch ....................................................................... 49

Svenska ......................................................................65

87970A2

87970A2

Page 3

WARN INDUSTRIES * WINCH

1

Every winching situation has the potential for personal injury. In order to minimize that risk,

it is important to read ALL instructions and safety information regarding your product. Please

familiarize yourself with the operation of your winch before using it and be constantly safety

oriented. These instructions provide important safety information and instructions on how to

install and operate your winch.

In this kit you will find the following pieces of literature:

• Winch Installation Guide/ First Time Operation Instructions

• Product Warranty

SAVE THIS MA NUAL and other product literature for future reference and review frequently

for continuing safe operation.

Instruct all users of this product to review this manual before operating this product.

Additional Product Literature Available Online

:

• Basic Guide to Winching Techniqu es

• Provides a basic understanding of the winch and teaches basics of proper winching

techniques. It is a valuable resource to help winch safely and efficiently.

• Product Specification and Performance Data

• Provides product specifications, performance data and replacement parts information.

• Other product literature specific to some products

Go to

www.warn.com/corporate/literaturerequest.shtml

for additional or replacement

product literature available to view/download.

WARN INDUSTRIES * WINCH

2

ORIGI NAL INSTRUC TIONS

Winch

Installation and Operator’s Guide

TABLE OF CONTENTS:

SAFETY

Symbol Index .......................................................................................................................................................3

General Safety Precautions ......................................................................................................................... 4-7

Safe Working Conditions .................................................................................................................................8

INSTRUCTIONS

Mounting Winch ................................................................................................................................................. 9

Electrical Connections ....................................................................................................................................10

Operating Instructions ............................................................................................................................ 11-12

Installing the Rope ....................................................................................................................................12-14

Rope Inspection ........................................................................................................................................15-16

Warn Industries Inc.

12900 SE Capps Road

Clackamas, OR 97015

USA

Customer Service: (800) 543-WARN

(9276)

International: (503) 722-1200

Fax: (503) 722-3000

www.warn.com

WARN® and the WARN l ogo are registere d trademarks of Wa rn Industries, In c.

© 2016 Warn Industries, Inc.

87970A2

87970A2

Page 4

WARN INDUSTRIES * WINCH

3

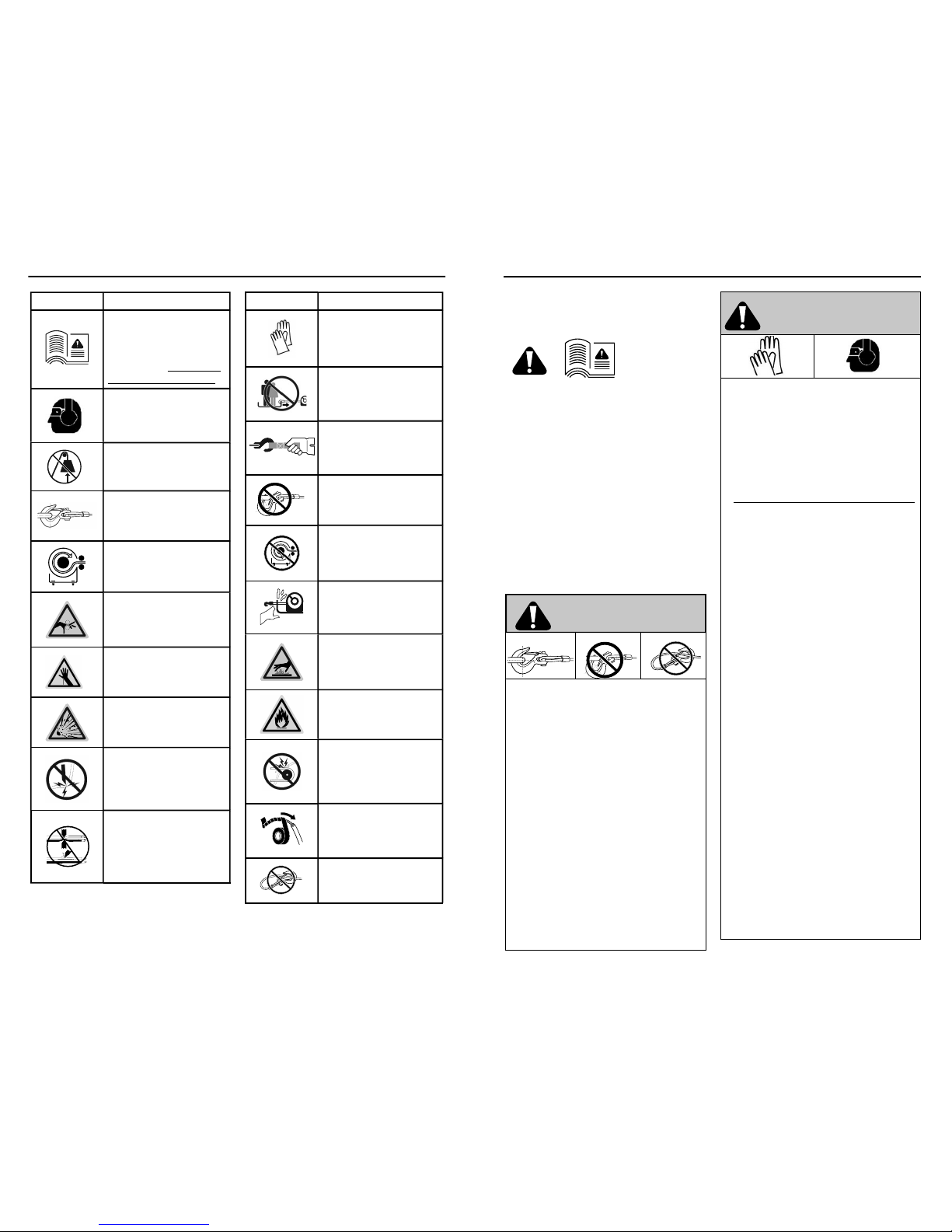

SYMBOL INDEX

SYMBOL EXPLANATION

Read All Product

Literature

Some literature available only

online at www.warn.com/

corporate/literaturerequest.shtml.

Always Wear Hearing and

Eye Protection

Never Use Winch as a

Hoist

Properly Seat Load in

Throat of Hook

Wind Rope on Bottom of

Drum

Finger/Fairlead Crushing

Hazard

Hand Piercing/Cutting

Hazard

Explosion/Bursting

Hazard

Never Route Electrical

Cables Across Sharp

Edges

Avoid Installing Electrical

Cables around Pinch and

Wear/Abrasion Points

SYMBOL EXPLANATION

Always Wear Leather

Gloves

Do Not Move People

Always Use Supplied

Hook Strap

Never Apply Load to

Hook Tip or Latch

Never Wind Rope Over

Top of Drum

Fairlead Pinch Point

Hot Surface Hazard

Fire and Burn Hazard

Never Route Electrical

Cables through or Near

Moving Parts

Exposed Wiring Hazard,

Insulate Exposed Wiring

and Terminals

Never Hook Back on

Rope

WARN INDUSTRIES * WINCH

4

GENERAL SAFETY PRECAUTIONS

As you read these instructions, you will see WARNINGS,

CAUTIONS, NOTICES and NOTES. Each message has a speci c

purpose. WARNINGS are safety messages that indicate a

potentially hazardous situation, which, if not avoided could

result in serious injury or death. CAUTIONS are safety messages

that indicate a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury. A CAUTION

may also be used to alert against unsafe practice. CAUTIONS

and WARNINGS identify the hazard, indicate how to avoid the

hazard, and advise of the probable consequence of not avoiding

the hazard. NOTICES are messages to avoid property damage.

NOTES are additional information to help you complete a

procedure. PLEASE WORK SAFELY!

Warnings and Cautions

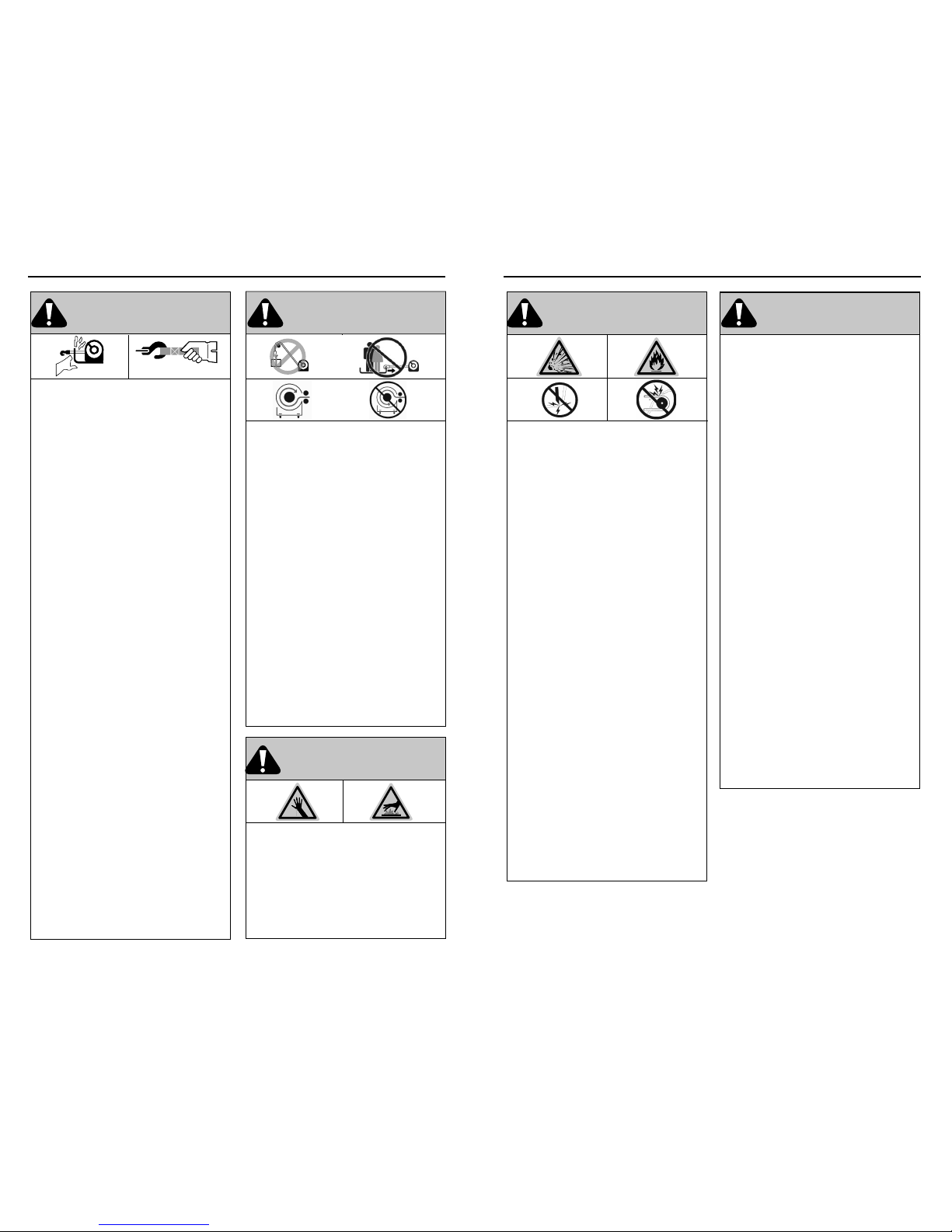

WARNING

MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to

serious injury or death.

General Safety:

• Always Know Your Winch. Take time to fully read the

Instructions and/or Operations Guide, and/or Basic Guide to

Winching Techniques, in order to understand your winch and

its operations, found online at http://www.warn.com/

corporate/literaturerequest.shtml.

• Never exceed winch or winch rope rated capacity. Double

line using a snatch block to reduce winch load.

• Always wear heavy leather gloves when handling winch

rope.

• Never use winch or winch rope for towing. Shock loads can

damage, overload and break rope.

• Never use a winch to secure a load.

• Never operate this winch when under the in uence of drugs,

alcohol or medication.

• Never operate this winch if you are under 16 years of age.

Installation Safety:

• Always choose a mounting location that is suffi ciently strong

to withstand the maximum pulling capacity of your winch.

• Always use grade 5 (grade 8.8 metric) or better hardware.

• Never weld mounting bolts.

• Always use factory approved mounting hardware,

components, and accessories.

• Never use bolts that are too long.

• Always complete the winch installation and hook

attachment before installing the wiring.

• Always keep hands clear of winch rope, hook loop, hook and

fairlead opening during installation, operation, and when

spooling in or out.

• Always position fairlead with warning readily visible on top.

• Always prestretch rope and respool under load before use.

Tightly wound rope reduces chances of “binding”, which can

damage the rope.

MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to

serious injury or death.

• Always ensure hook latch is closed and not

supporting load.

• Never apply load to hook tip or latch. Apply load only

to the center of hook.

• Never use a hook whose throat opening has

increased, or whose tip is bent or twisted.

• Always use a hook with a latch.

• Always ensure the operator and bystanders are aware

of the stability of the vehicle and/or load.

• Always keep wired remote control lead and power

cord clear of the drum, rope, and rigging. Inspect for

cracks, pinches, frayed wires or loose connections.

Damaged components must be replaced before

operation.

• Always pass remote lead thru window when used in

vehicle.

• Never hook back on rope.

WARNING

87970A2

87970A2

Page 5

WARN INDUSTRIES * WINCH

5

GENERAL SAFETY PRECAUTIONS

WARNING

MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to

serious injury or death.

Winching Safety:

• Always inspect winch rope, hook, and slings before

operating winch. Frayed, kinked or damaged winch rope

must be replaced immediately. Damaged components must

be replaced before operation. Protect parts from damage.

• Always remove any element or obstacle that may interfere

with safe operation of the winch.

• Always be certain the anchor you select will withstand the

load and the strap or chain will not slip.

• Always use supplied hook strap whenever spooling winch

rope in or out, during installation and during operation.

• Always require operators and bystanders to be aware of

vehicle and or load.

• Always be aware of stability of vehicle and load during

winching, keep others away. Alert all bystanders of an

unstable condition.

• Always unspool as much rope as possible when rigging.

Double line or pick distant anchor point.

• Always take time to use appropriate rigging techniques for

a winch pull.

• Never touch winch rope or hook while someone else is at

the control switch or during winching operation.

• Never engage or disengage clutch if winch is under load,

winch rope is in tension or drum is moving.

• Never touch winch rope or hook while under tension or

under load.

• Always stand clear of winch rope and load and keep others

away while winching.

• Never use vehicle to pull load on winch rope. Combined

load or shock load can damage, overload and break rope.

• Never wrap winch rope back onto itself. Use a choker chain

or tree trunk protector on the anchor.

WARNING

FALLING OR CRUSHING HAZARD

Failure to observe these instructions could lead to

serious injury or death.

• Always stand clear, keep hands clear, keep others away.

• Never operate winch with less than 10 wraps of rope around

the drum. Rope could come loose from the drum, as the rope

attachment to the drum is not designed to hold a load.

• Never use winch as a hoist or to suspend a load.

• Always be certain anchor will withstand load, use

appropriate rigging and take time to rig correctly.

• Never use winch to lift or move persons.

• Never use excessive eff ort to freespool winch rope.

• Always use proper posture/lifting technique or get lifting

assistance while handling and installing product.

• Always spool the rope onto the drum in the direction

speci ed by the winch warning label on the winch and/or

documentation. This is required for the automatic brake (if so

equipped) to function properly.

• Always spool the winch rope onto the drum as indicated by

the drum rotation label.

WARNING

CUT AND BURN HAZARD

Failure to observe these instructions could lead to

serious injury or death.

To avoid injury to hands and ngers:

• Always wear heavy leather gloves when handling winch

rope.

• Always be aware of possible hot surfaces at winch motor,

drum or rope during or after winch use.

WARN INDUSTRIES * WINCH

6

GENERAL SAFETY PRECAUTIONS

WARNING

IMPACT AND MOVING PARTS

ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to

serious injury or death.

To avoid injury to hands and ngers:

• Always know the Working Load Limit (WLL) of your rope.

• Always determine the suitability of a rope for a speci c

application.

• Never use the included rope on a winch with a rated line pull

greater than 10,000 lbs (4536 kg).

• Never use a rope if worn, damaged, abused, overloaded,

improperly maintained or over 1 year old.

• Never stand within the recoil (snapback) area.

• Never use rope over a rough surface without Chafe

Protection.

• Never bend rope around unprotected, sharp corners.

• Never leave clutch disengaged when not freespooling rope.

The automatic brake will not operate when clutch lever is in

freespool.

• Never exceed the load rating of 10,000lbs (4536 kg).

• Always replace rope every 12 months.

• Always use a WARN fairlead that is recommended for

synthetic rope.

• Always replace the WARN hawse fairlead if damaged or

abused with a WARN fairlead that is recommended for

synthetic rope.

WARNING

CHEMICAL AND FIRE HAZARD

Failure to observe these instructions could lead to

serious injury or death.

• Always remove jewelry and wear eye protection.

• Never route electrical cables across sharp edges.

• Never route electrical cables near parts that get hot.

• Never route electrical cables through or near moving parts.

• Always place the supplied terminal boots on wires and

terminals as directed by the installation instructions.

• Never lean over battery while making connections.

• Never route electrical cables over battery terminals.

• Never short battery terminals with metal objects.

• Always verify area is clear of fuel lines, fuel tank, brake

lines, electrical wires, etc., when drilling.

• Always consult operator’s manual for proper wiring details.

• Always insulate and protect all exposed wiring and

electrical terminals.

87970A2

87970A2

Page 6

WARN INDUSTRIES * WINCH

7

GENERAL SAFETY PRECAUTIONS

AVOID WINCH AND EQUIPMENT DAMAGE

• Always avoid side pulls which can pile up rope at one end of

the drum. This can damage rope or winch.

• Always ensure the clutch is fully engaged or disengaged.

• Always use care to not damage the vehicle frame when

anchoring to a vehicle during a winching operation.

• Never submerge winch in water.

• Always store the remote control in a protected, clean, dry

area.

• Always avoid continuous “Power-Out”. Heat build up from

continuous power out may damage the rope.

• Never expose the rope to harsh detergents, fuels, oils, or

Anti-freeze.

• Always use a chafe protector on all sharp edges to protect

rope.

• Never allow the rope to contact sharp objects. Severe

damage may result.

• Always respool rope in even wraps following any angled

winching activities.

• Never “jog” rope under load. Shock loads can momentarily

exceed capacity of rope and winch.

• Never install more than 100’ (CTI) / 80’ (XDC) of 3/8”

synthetic rope. Damage to the winch may result.

NOTICE

CAUTION

MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to

minor or moderate injury.

To avoid injury to hands or ngers:

• Never leave remote control where it can be activated during

free spooling, rigging, or when the winch is not being used.

• Never leave the winch remote control plugged in when

installing, freespooling, rigging, servicing or when the winch

is not being used.

CAUTION

CUT AND BURN HAZARD

Failure to observe these instructions could lead to

minor or moderate injury.

• Never let winch rope slip through your hands.

WARN INDUSTRIES * WINCH

8

SAFE WORKING CONDITIONS

WARNING

Always stand clear,

keep hands clear,

keep others away.

SAFE WORKING CONDITIONS

The operator should always

operate the winch from a safe

position when pulling a load. The

safe areas are: (1) Perpendicular to

the rope, (2) Inside the vehicle with

the hood up (if winch is mounted on

front of vehicle). These safe positions

will help prevent the rope from

striking the operator if the rope fails

when under load.

Operate winch from the fully

extended remote control cord length

whenever possible. The operator

must always be at least 8 ft. (2.44 m)

from the winch while operating. This

will prevent entanglement with the

fairlead and keep the operator out of

harms way during winch load pulling.

Never work around the rope

while under load.

Sound Emissions

The winch is designed so that

the sound emissions do not exceed

70 dBa from the operator’s station.

The operator must be at least 8

ft. (2.44 m) from the winch while

operating. If the winch is exceeding

70 dBa from the operator’s station,

have the winch inspected at an

authorized service center.

Cleaning

Use low pressure water to

clean synthetic rope. Do not use any

chemicals.

Do not direct high pressure

water (pressure washers, car washes,

etc.) between the drum support and

drum ange or clutch lever.

Use low pressure water and a

soapy rag or sponge to clean the

winch.

Avoid using chemicals that may

damage the nish.

Thoroughly clean salt residue

from the winch as soon as possible to

minimize corrosion.

Maintenance

Replace rope every 12 months

with WARN rope.

No lubrication is required for

the life of the winch unless the winch

has been submerged in water. If this

occurs, a quali ed service center

must complete service as soon

as possible to prevent corrosion

damage. If the control pack is

submerged, it must be replaced

when the winch is serviced.

Check battery cables and

electrical connections at 90 day

intervals to be certain they are clean

and tight at all connection points.

Inspect the rope before and

after each winching operation. When

damaged, replace with the size

speci ed in the Replacement Parts

List, or go to the Warn website at

www.warn.com.

The rope must always spool

onto the drum as indicated by the

drum rotation decal on the winch.

WARNING

Always require

operators and

bystanders to be

aware of vehicle

and or load.

NOTICE

Never submerge

winch in water.

CAUTION

Never leave remote

control where it

can be activated

during free spooling,

rigging, or when the

winch is not being

used.

87970A2

87970A2

Page 7

WARN INDUSTRIES * WINCH

9

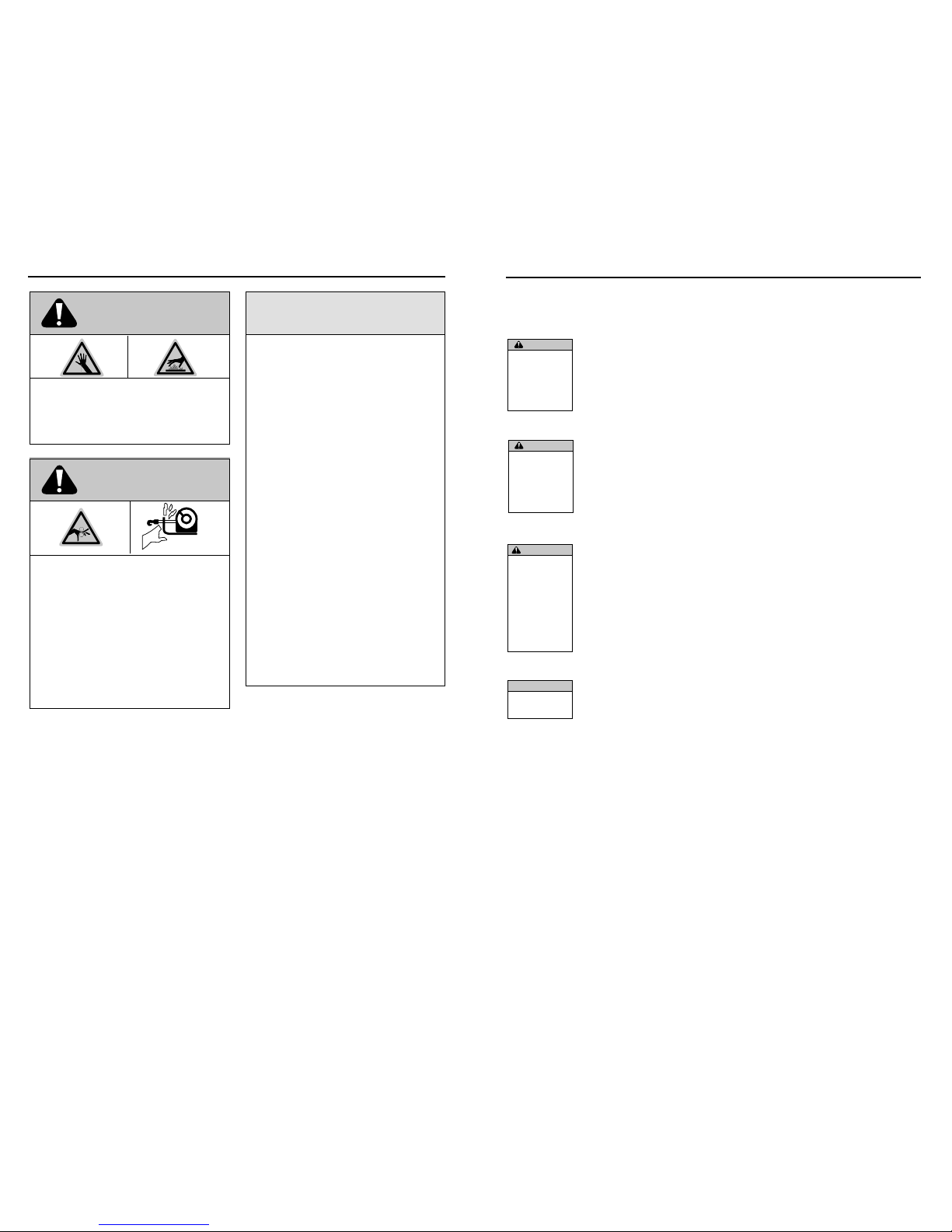

MOUNTING WINCH

MOUNTING WINCH

Choose a mounting location

that is suffi ciently strong enough

to withstand the loads you intend

to winch. Only the mounting

orientations shown are possible for

safe winching operation. All others

are improper and inappropriate.

The use of recommended bolt and

lock washer combinations torqued

to recommended levels will prevent

vibration during operation. The

mounting details indicate the proper

torque levels.

Remember the winch rope

must always spool onto the drum as

indicated by the drum rotation decal.

Refer to the following diagrams

for proper mounting orientation.

WARNING

Never use bolts that

are too long.

Mounting Details:

(1) Smooth and at, thickness = 1/4” (6.4 mm)

(2) 3/8” (9.525 mm) lockwasher X 4

(3) 3/8-16 X 1 1/4” long, grade 5 bolt X 4

Torque 30-35 ft. lbs. (41-47Nm)

(4) 1/2-13 Locknut

(5) 1/2 Flat washer

(6) 3/8-16 Sq. nut

(7) 1/2-13x2” button head bolt

(8) Aluminum Fairlead

Control Pack Installation

Mount the control pack

according to the instructions

included in the WARN mounting

system kit. Use the bracket included

in the kit.

WARNING

Always choose a

mounting location

that is suffi ciently

strong to withstand

the maximum

pulling capacity of

your winch.

WARNING

Always complete the

winch installation

and attach the hook

before installing the

wiring.

Plate Thickness Bolt Length

1/4” (7 mm) 1.25” (32 mm)

3/8” (10 mm) 1.5” (40 mm)

1/2” (13 mm) 1.5” (40 mm)

WARN INDUSTRIES * WINCH

10

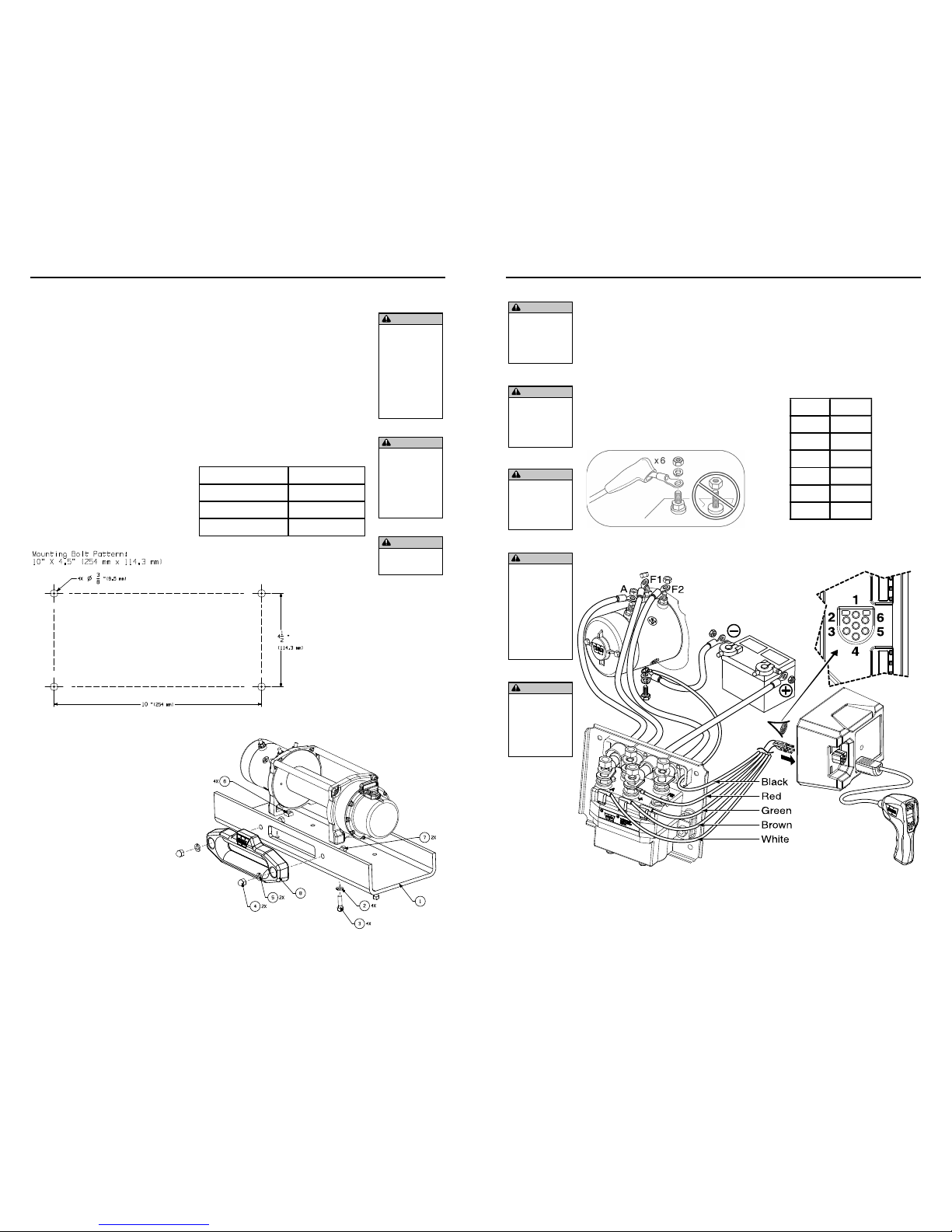

ELECTRICAL CONNECTIONS

Electrical Diagrams:

ELECTRICAL CONNECTIONS

Use the included insulating

boots on exposed connections to

prevent electrical shorting. Route

battery connection cables in areas

which will not cause them to chafe or

cut through the insulation causing a

potential short circuit.

Upon completion of installation,

check winch for proper operation.

WARNING

Never route

electrical cables

across sharp edges.

WARNING

Never route

electrical cables near

parts that get hot.

WARNING

Never route

electrical cables

through or near

moving parts.

WARNING

Always place the

supplied terminal

boots on wires

and terminals

as directed by

the installation

instructions.

Battery Recommendations

A fully charged battery and

good connections are essential to

the proper operation of your winch.

The minimum requirement for a 12

volt DC battery is 650 Cold Cranking

Amps.

WARNING

Always insulate and

protect all exposed

wiring and electrical

terminals.

Pin # Color

1 Brown

2 White

3 Black

4 Green

5

6 Red

87970A2

87970A2

Page 8

WARN INDUSTRIES * WINCH

11

OPERATING INSTRUCTIONS

WARNING

Never engage or

disengage clutch

if winch is under

load, winch rope is

in tension or drum is

moving.

WARNING

Never operate

winch with less

than 10 wraps of

rope around the

drum. Rope could

come loose from

the drum, as the

rope attachment

to the drum is not

designed to hold

a load.

NOTICE

Do Not power-out

rope more than 30

ft. without allowing

the winch to cool for

20 minutes before

powering rope

back in. Instead,

place the clutch in

freespool and pull

the rope off by hand.

FIRST TIME OPERATING

INSTRU CTIONS

In this section, we’ll show you the

first time operating instructions for

effective basic winch ing. For complete

winch operation and techniques read

the Basic Guide to Winching Techniques

found online at

http://www.warn.com/

corporate/literaturerequest.shtml.

Remote Control Switch

The winch is co ntrolled by the hand

held remote contr ol. The remote control

provides control of the power-out (forward)

or power-in (reve rse) rotation of the

spooling drum

.

Do not leave the remote plugged

into the winch when not in use. Leaving

the remote plugged in, may result in

a dangerous condition and/or battery

drain.

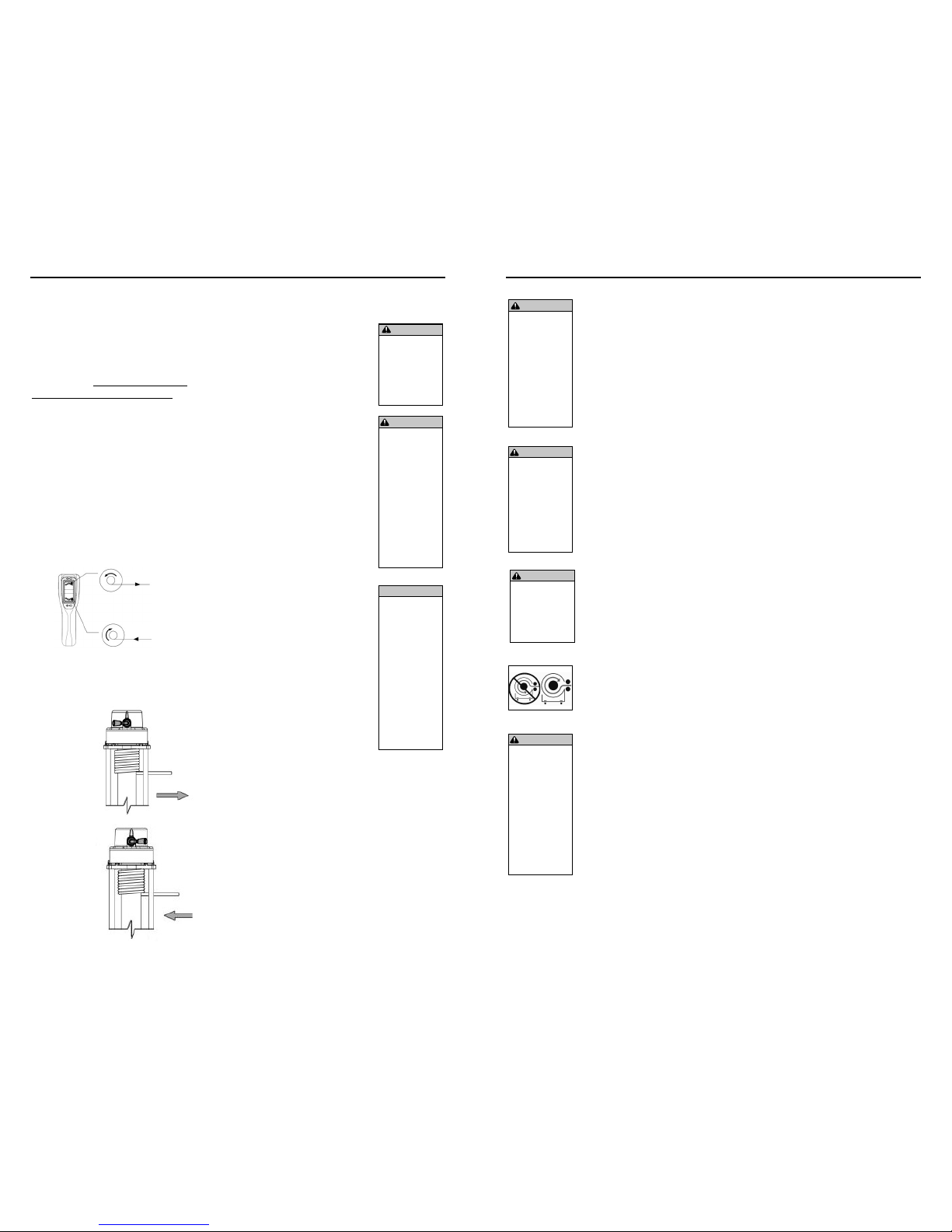

Clutch Operation:

When the clutch is engaged, the gear

train is coupled to the winch drum and

power can be transferred from the winch

Disengaged:

Engaged:

Vertical/Horizontal Remote:

motor. When the clutch is disengaged

the drum is in the freespool position and

the gear train and winch rope drum are

uncoupled allowing the drum to rotate

freely.

The clutch lever, located on the winch

housing opposite the motor, controls

the clutch position. To prevent damage,

always fully engage or fully disengage

the clutch lever.

Spooling Out

Freespooling is generally the

quickest and easiest way to spool out

wire rope. Before freespooling wire

rope out from the winch, power out

enough rope to remove any tension the

wire rope might be under. Disengage

the clutch. Then freespool by manually

spooling out enough wire rope for

the winching operation. See

The Basic

Guide to Winching Techniques

for more

information.

Always leave at least 5 wraps of

rope on the drum.

Spooling In Under Load

Never exceed winch’s rated line

pull.

Power-in the wire rope evenly and

tightly on the drum. This prevents the

outer wire wraps from sinking into the

inner wraps, binding, and damaging the

wire rope.

Avoid shock loads when spooling,

by pulsing the control switch to take

up wire rope slack. Shock loads can

momentarily far exceed the winch and

rope ratings.

Spooling In Under No Load

Spooling with an As sistant:

Have the

assistant hold the hook strap putting as

much constant tension on the wire rope

as possible. While keeping tension, the

assistant should walk toward the winch

while you operate the control switch

spooling in the wire rope. Release the

switch when the hook is a minimum of 6

ft. (2 m) from the fairlead opening.

Spool in the remainder for storage

as directed below.

IN

OUT

WARN INDUSTRIES * WINCH

12

OPERATING INSTRUCTIONS

Spooling Out

Freespooling is generally the

quickest and easiest way to spool out

rope. Before freespooling rope out from

the winch, power out enough rope to

remove any tension the rope might

be under. Disengage the clutch. Then

freespool by manually spooling out

enough rope for the winching operation.

See

The Basic Guide to Winching

Techniques

for more information.

Always leave at least 10 wraps of

rope on the drum.

Spooling In Under Load

Never exceed winch’s rated line pull.

Power-in the rope evenly and

tightly on the drum. This prevents the

outer wraps from sinking into the inner

wraps, binding, and damaging the rope.

Avoid shock loads when spooling,

by pulsing the control switch to take up

rope slack. Shock loads can momentarily

far exceed the winch and rope ratings.

Spooling In Under No Load

Spooling with an Assistant:

Have the

assistant hold the hook strap putting

as much constant tension on the rope

as possible. While keeping tension, the

assistant should walk toward the winch

while you operate the control switch

spooling in the rope. Release the switch

when the hook is a minimum of 6 ft. (2 m)

from the fairlead opening.

Spool in the remainder for storage

as directed below.

Spooling Alone:

Arrange the rope to be

spooled so it will not kink or tangle when

spooled. Be sure any rope on the drum is

tightly and evenly layered. Spool enough

rope to complete the next full layer on

the drum. Tighten and straighten the

layer.

Repeat process until the hook is a

minimum of 6 ft. (2 m) from the fairlead

opening.

Spool in the remainder for storage

as directed below.

Spooling Remainder for Storage

When the hook is within 6 ft. (2 m) of the

fairlead, disconnect the hook from the

anchor or load. Hold onto the supplied

WARNING

Always keep hands

clear of winch rope,

hook loop, hook and

fairlead opening

during installation,

operation, and when

spooling in or out.

WARNING

Always use

supplied hook strap

whenever spooling

winch rope in or out,

during installation

or operation to

avoid injury to

hands and ngers.

WARNING

Always wear heavy

leather gloves when

handling winch

rope.

WARNING

Never touch winch

rope or hook while

someone else is at

the control switch

or during winching

operation.

hook strap and hold tension on the

winch rope. Slowly power-in the winch

by “pulsing” the power-in switch on the

remote control until the hook is within 3

ft. (1 m) of the fairlead. Stop winching in

and attach the hook to a suitable anchor

point on the vehicle.

DO NOT POWER THE HOOK INTO

THE FAIRLEAD. This could cause damage

to the fairlead. Once the hook is suitably

attached to the vehicle, power-in the

remaining slack in the winch rope by

“pulsing” the power-in switch on the

remote control until there is minimal slack

in the winch rope.

Overloading/Overheating

This winch is rated for intermittent

duty. When the motor approaches stall

speed, very rapid heat buildup occurs

which may cause motor damage.

Double-line rigging (see

The Basic

Guide to Winching Techniques

) will reduce

the amperage draw, and reduce heat

buildup in the motor. This allows longer

continual use.

87970A2

87970A2

Page 9

WARN INDUSTRIES * WINCH

13

OPERATING INSTRUCTIONS

WARNING

Always prestretch

rope and respool

under load before

use. Tightly wound

rope reduces chances

of “binding”, which

can damage the

rope.

WARNING

Never touch rope or

hook while someone

else is at the control

switch or during

winching operation.

Spooling

THE FOLLOWING STEPS ARE VERY

IMPORTANT AND IF NOT PRECISELY

FOLLOWED THE LIFE OF THE WINCH

AND ROPE MAY BE COMPROMISED.

1. Mount the Warn Aluminum Hawse

Fairlead to the winch mount using

the supplied hardware. Always

mount the fairlead with the labels in

the upright position (labels on top

and clearly visible). Insert a 7/16” x

1 1/4” bolt through each of the two

fairlead mounting holes and through

the winch mount. Place a 7/16” at

washer onto each bolt. Install a 7/16”

lock nut onto each bolt and tighten to

35 ft. lbs.

6. It is now necessary to spool the

remaining rope onto the winch

drum. Choose a FLAT location that

is large enough to run out the entire

length of rope. Attach the hook end

of the rope to a suitable anchor point

and back the vehicle away from the

anchor point leaving approximately

6 ft of slack rope lying on the ground.

Before getting out of the vehicle, set

the parking brake, place the vehicle in

gear or park and turn the vehicle off .

7. Connect the remote control to the

winch. Standing approximately 8 ft

away from the winch, power in the

winch until there is 10 wraps onto the

winch drum. Disconnect the remote

control from the winch. Hold tension

on the rope with one hand; carefully

push the rope to the side of the drum

the rope is attached to so there are

no gaps between each coil on the

drum. Be sure to check that the rope

is winding off of the bottom of the

drum, not the top, or the automatic

load holding brake will not function

properly. (If the rope is winding off

the top you have powered the winch

“out” instead of “in” on the remote

control)

8. If there is still rope laying on the

ground, back the vehicle away until

the rope is off of the ground.

9. The following steps should be done

using two people for proper safety.

If you attempt to tension your rope

alone be sure to always engage the

parking brake, place the transmission

in gear and turn the vehicle off

every time you exit the vehicle to

inspect the winch rope. Never exit

the vehicle with a load on the winch

rope. Tensioning the rope is critical to

ensure a long product life. Tensioning

the rope prevents the rope from

sinking into the lower layers under

load.

10. Use care to evenly wrap each layer

to prevent damage to the rope.

2. Slide the abrasion sleeve over the

rope from the end opposite the hook.

Slide the sleeve back to the hook end

of the rope.

3. Apply Lock Tite 271 or equivalent

product to the supplied 1/4”-20 x 1/2”

long button head fastener.

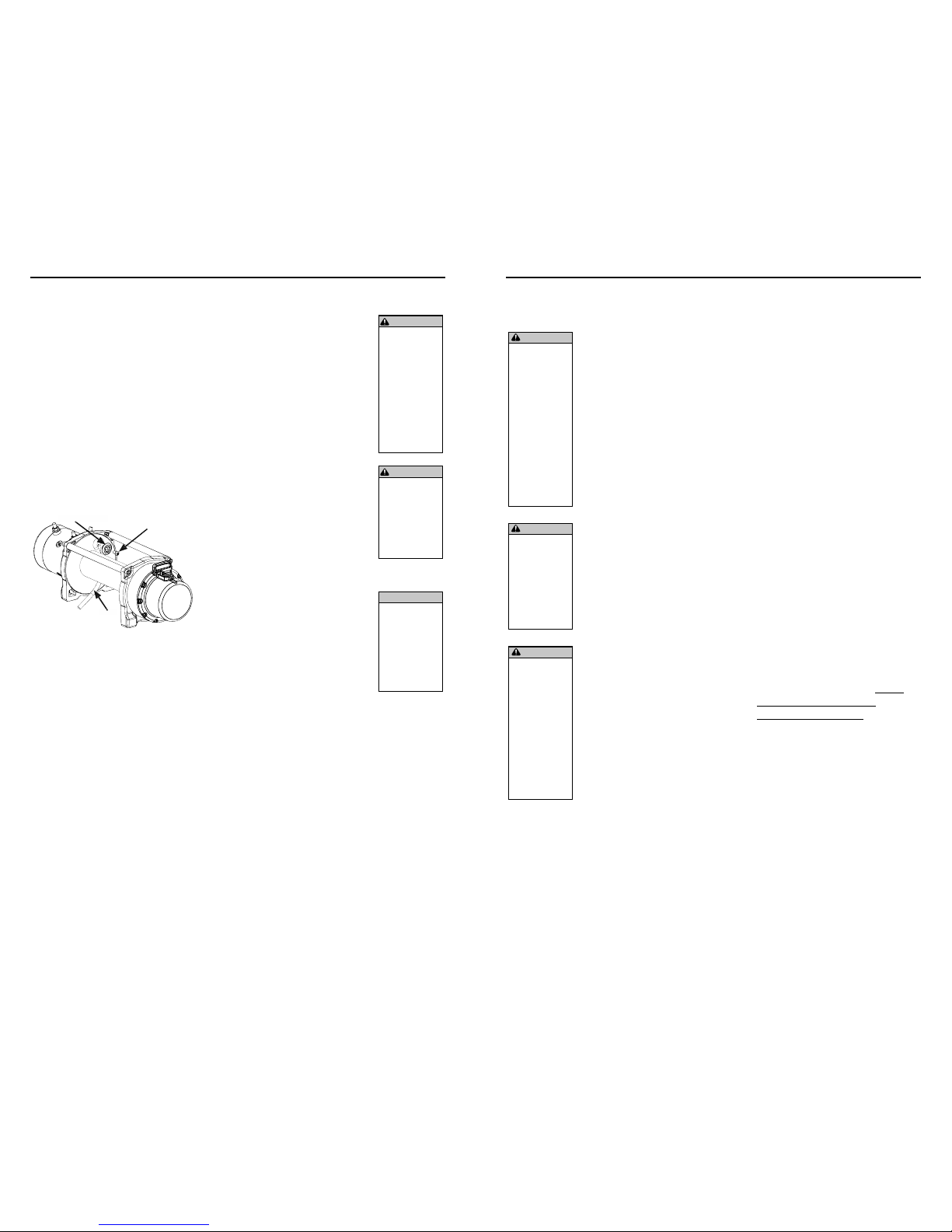

4. Install the new synthetic rope using

the button head fastener supplied

and the machined rope washer.

Insert the synthetic rope through

the aluminum fairlead and around

the winch drum from the bottom.

Insert the button head bolt into the

machined rope washer and place the

synthetic rope on the machined rope

washer. Install the button head bolt

in the 1/4-20 hole in the side of the

winch drum. See Figure for detail.

5. Tighten the 1/4-20 button head

bolt to 8 ft. lbs. Turn the winch clutch

level to the “engaged” position.

NOTICE

Never install more

than 100’ (CTI) /

80’ (XDC) of 3/8”

synthetic rope.

Damage to the winch

may result.

Rope

Rope Washer

1/4-20 x 1/2”

Button Head

Bolt

WARN INDUSTRIES * WINCH

14

INSTALLING ROPE

WARNING

Never operate

winch with less

than 10 wraps of

rope around the

drum. Rope could

come loose from

the drum, as the

rope attachment

to the drum is not

designed to hold

a load.

11. Pass the remote control through

the driver’s window for the driver of

the vehicle to operate. Instruct your

assistant to stand to the side of the

vehicle and away from the winch

rope. Your assistant should signal you

if the rope is winding correctly by

watching it move across the fairlead

as the rope is powered in. Start the

vehicle and place the transmission

in neutral. Release the parking brake

while applying moderate brake pedal

pressure. Power the winch remote in.

After winching in for approximately 6

ft, stop winching. Slowly let up off of

the brake pedal and then apply the

parking brake. This will ensure that

there is no load on the winch rope.

Then place the transmission in park

or gear and turn the vehicle off . Exit

the vehicle and inspect the winch

rope is being evenly wound onto

the winch drum and not sinking into

the lower layer. If the rope is sinking,

power the rope out and repeat this

step from the beginning with more

brake pedal pressure.

12. Once you are convinced the rope

is winding on the winch properly,

return to the vehicle. Pass the remote

control through the driver’s window

for the driver of the vehicle to

operate. Start the vehicle and place

the transmission in neutral. Release

the parking brake while applying

moderate brake pedal pressure.

Power the winch remote in. After

winching in for approximately 6 ft,

stop winching. Slowly let up off of

the brake pedal and then apply the

parking brake. This will ensure that

there is no load on the winch rope.

Then place the transmission in park

or gear and turn the vehicle off . Exit

the vehicle and inspect the winch

rope is being evenly wound onto

the winch drum and not sinking into

the lower layer. If the rope is sinking,

power the rope out and repeat this

step from the beginning with more

brake pedal pressure.

INSTALLING THE ROPE Cont.

13. Repeat step 12 until the vehicle

is within 6 ft of the winch anchor.

Once within 6 ft, slowly let up off of

the brake pedal and then apply the

parking brake. This will ensure that

there is no load on the winch rope.

Then place the transmission in park

or gear and turn the vehicle off . Exit

the vehicle. Disconnect the hook from

the anchor. While holding onto the

supplied hook strap, hold tension on

the winch rope and slowly power-in

the winch by “pulsing” the power-in

on the remote control until the hook

is within 3 ft. of the fairlead. Stop

winching in and attach the hook to a

suitable anchor point on the vehicle.

DO NOT POWER THE HOOK INTO

THE FAIRLEAD. This would cause

irreparable damage to the fairlead.

Once the hook is suitably attached to

the vehicle, power in the remaining

slack in the winch rope by “pulsing”

the power-in on the remote until

there is minimal slack in the winch

rope.

Rigging

For complete rigging fundamentals,

Read the Basic Guide to Winching

Techniques, found online at

http://

www.warn.com/corporate/

literaturerequest.shtml.

WARNING

Always spool the

rope onto the drum

in the direction

speci ed by the

winch warning label

on the winch and/

or documentation.

This is required for

the automatic brake

(if so equipped) to

function properly.

WARNING

Always use

supplied hook

strap whenever

spooling winch rope

in or out, during

installation and

during operation.

87970A2

87970A2

Page 10

WARN INDUSTRIES * WINCH

15

ROPE INSPECTION

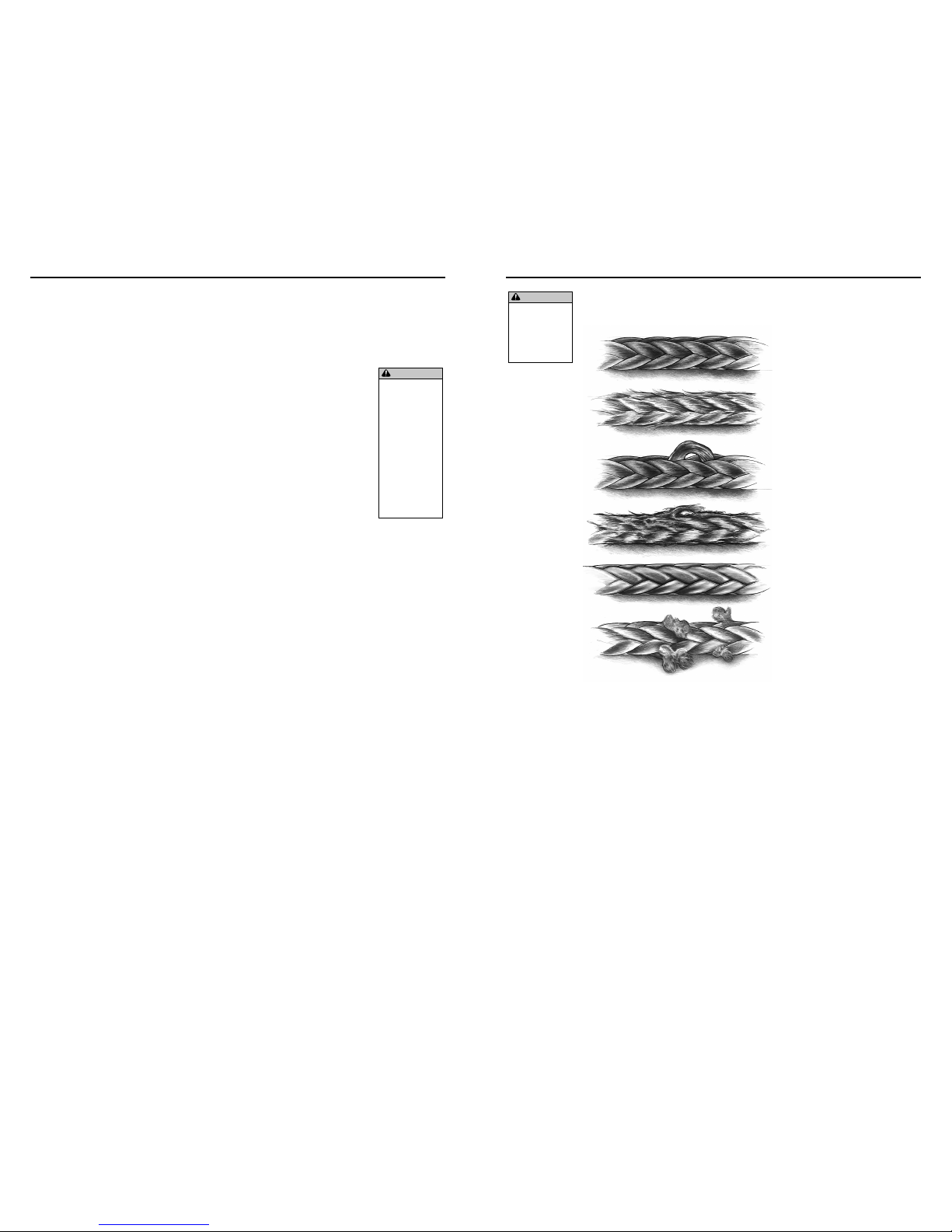

When rope is rst used, the outer

laments of the rope will quickly fuzz

up. This is the result of these laments

breaking and this roughened surface

will actually protect the bers

underneath. The condition should

stabilize, not progress. If the surface

roughness increases, excessive

abrasion is taking place and strength

is being lost. Look closely at both

the inner and outer bers. When

either is worn the rope is obviously

weakened. Open the strands and look

for powdered ber—this is a sign of

internal wear.

Rope should be replaced when:

• Rope bulk anywhere along the

length is reduced by 10% or

more by abrasion.

• Two or more adjacent strands

are cut.

• Flat areas or lumps are found

that are not eliminated by

exing rope.

• Excessive fused or melted bers

are found. Any such areas will

be stiff and the rope will have a

glazed appearance.

Rope Storage and Care

To ensure safety and

performance, the inspection and

maintenance of winching rope should

be among every user’s primary

concerns.

1. Inspect your winch rope for breaks,

cuts, abrasion and melted or fused

bers before each use.

2. Wash rope periodically to remove

dirt and grit. Simply rinse rope with a

garden hose, and allow it to air-dry.

DO NOT use solvents, bleach or

harsh detergents when washing rope,

and never apply a heat source to

speed drying.

3. Coil rope loosely, for storage, being

sure to remove any excess twists. To

maximize rope life, always store rope

line in a dark, dry place. Before using

any rope, refer to the following guide.

WARNING

Never operate

winch with less

than 10 wraps of

rope around the

drum. Rope could

come loose from

the drum, as the

rope attachment

to the drum is not

designed to hold

a load.

If the rope is damaged, remove

it from service immediately, and

replace it with undamaged rope.

Broken or cut strands reduce the

rope’s strength throughout its length

— not just in the area of damage. As

a general rule, retire your 12 strand

rope when more than 3 broken or cut

strands are visible, or if two adjacent

strands are compromised.

4. Replace your rope every 12

months with only WARN rope.

Normal Wear

When small surface bers break

on a rope, they create a fuzzy texture.

Known as “mild abrasion,” this is

considered good wear, and will not

aff ect the performance of the rope.

The nubby surface actually protects

the underlying ber from further

wear.

Excessive Wear–RETIRE THE ROPE

When bers are melted or

fused, it is generally the result of rope

abuse. Melted or fused polyester

bers result from bringing the rope’s

surface to a temperature in excess

of 430° F. Caused by excessive load

weights or powering out, these

damaged bers can compromise

strength, and should signal the rope’s

retirement.

Chemical Attack–RETIRE THE ROPE

(NOT ILLUSTRATED)

Localized discolorations could

potentially represent chemical attack

by anything from gear oil to battery

acid. When doubt exists, retire the

line.

WARN INDUSTRIES * WINCH

16

ROPE INSPECTION

WARNING

Always wear heavy

leather gloves when

handling winch

rope.

Examples:

Rope with original bulk.

Rope strand showing full volume.

Rope displaying 25% strand

volume reduction from

abrasion—rope should be

replaced.

Rope strand reduced by 25%

abrasion—rope should be

replaced.

Rope displays two adjacent

cut strands—rope should be

replaced.

Rope exhibits ber-set from

compression. A slight sheen is

visible. This is not a permanent

characteristic and can be

eliminated by exing the rope.

ROPE INSPECTION Cont.

87970A2

87970A2

Page 11

WARN INDUSTRIES * WINCH

17

Chaque situation de treuillage peut potentiellement occasionner des blessures. Afin

de minimiser ce risque, il est important de lire attentivement TOUTES les instructions

et informations de sécurité afférentes à votre produit. Veillez à vous familiariser avec le

maniement du treuil avant de l'utiliser et à vous préoccuper avant tout de la sécurité. Ces

instructions fournissent des informations et des consignes de sécurité importantes concernant

l’installation et l’utilisation du treuil.

Vous trouverez dans ce kit la documentation suivante:

• Guide d’installation du treuil / Instructions relatives à une première utilisation

• Garantie du produit

CONSERVEZ CE MANUEL et tous les autres documents relatifs au produit à titre de référence

et consultez-les fréquemment pour assurer un fonctionnement continu en toute sécurité.

Demandez à tous les utilisateurs de ce produit de lire le présent manuel avant de l'utiliser.

Autres documents relatifs au produit disponibles en ligne

:

• Manuel de base des techniques de treuillage

• Fournit une compréhension globale du treuil et vous enseigne les techniques de

treuillage. Il s’agit d’une ressource utile qui favorise l’utilisation efficace et sûre du

treuil.

• Caractéristiques du produit et données de performance

• Fournit les caractéristiques du produit, les données de performance et les

renseignements concernant les pièces de rechange.

• Autres documents rela tifs à des produits spécifiques

Consultez le site

www.warn.com/corporate/literaturerequest.shtml

pour accéder à d’autres

documents ou à des documents sur les produits de remplacement, disponibles en consultation/

téléchargement.

WARN INDUSTRIES * WINCH

18

TRADU CTION DE LA NOTICE ORIGIN ALE

Treuil Guide d'installation et manuel

del'utilisateur

TABLE DES MATIÈRES:

SÉCURITÉ

Index des symboles .........................................................................................................................................19

Mesures générales de sécurité ............................................................................................................. 20-23

Conditions de travail sûres ............................................................................................................................24

INSTRUCTIONS

Montage du treuil .............................................................................................................................................25

Raccordements électriques ..........................................................................................................................26

Instructions d’ utilisation ......................................................................................................................... 27-28

Installation du câble d’acier ................................................................................................................... 29-30

Inspection du câble d’acier ....................................................................................................................31-32

Warn Industries Inc.

12900 SE Capps Road

Clackamas, OR 97015

États-Unis

Service à la clientèle: (800) 543-WARN

(9276)

International: (503) 722-1200

Fax : (503) 722-3000

www.warn.com

Warn® et le logo WARN so nt des marques dép osées de Warn Indus tries Inc.

©2016 Warn Industries Inc.

87970A2

87970A2

Page 12

WARN INDUSTRIES * WINCH

19

INDEX DES SYMBOLES

SYMBOLE EXPLICATION

Lire tous les documents

relatifs au produit.

Certains littérature disponible

uniquement online www.warn.com/

corporate/literaturerequest.shtml.

Toujours porter un

dispositif de protection

auditive et oculaire

Ne jamais utiliser le treuil

comme palan

Positionner correctement

la charge dans la gorge

du crochet

Enrouler le câble sur le

dessous du tambour

Danger d’écrasement

des doigts dans le guidecâble

Risque de percement/

coupure des mains

Risque d’explosion/

rupture

Ne jamais faire passer

les câbles électriques

par-dessus des bords

tranchants.

Éviter les points de

pincement et d’usure/

abrasion lors de

l’installation des câbles

électriques

SYMBOLE EXPLICATION

Toujours porter des

gants de cuir

Ne pas déplacer des

personnes

Toujours utiliser la sangle

de crochet fournie

Ne jamais appliquer la

charge sur l’extrémité ou

le loquet du crochet

Ne jamais enrouler le

câble sur le dessus du

tambour

Point de pincement du

guide-câble

Risque de surface

chaude

Risque d’incendie et de

brûlure

Ne jamais faire passer

les câbles électriques

à travers des pièces

mobiles ou à proximité.

Danger de ls nus,

isoler les ls nus et les

terminaux

Ne jamais accrocher le

câble à lui-même

WARN INDUSTRIES * WINCH

20

MESURES GÉNÉRALES DE SÉCURITÉ

Les directives suivantes comprennent des indications

intitulées AVERTISSEMENT, ATTENTION, AVIS et REMARQUE. Chacune

d'entre elles comporte un objectif bien précis: AVERTISSEMENT

présente des consignes de sécurité soulignant un danger potentiel

qui, s’il n'est pas évité, peut entraîner des blessures graves ou la

mort. ATTENTION comprend des consignes de sécurité signalant

un danger potentiel qui, s'il n'est pas évité, peut entraîner des

blessures légères ou modérées. ATTENTION sert aussi à signaler une

utilisation dangereuse. ATTENTION et AVERTISSEMENT identi ent un

danger, indiquent comment l'éviter et montrent ses conséquences

possibles si on l'ignore. AVISprésente des consignes visant à éviter

les dommages matériels. REMARQUE donne des renseignements

additionnels qui aident à accomplir une procédure. TRAVAILLEZ

PRUDEMMENT!

Avertissements

et mises en garde

DANGER DE HAPPEMENT PAR DES PIÈCES

MOBILES

Le non-respect des consignes peut entraîner des

blessures graves ou la mort.

Consignes de sécurité générales:

• Il faut toujours avoir une bonne connaissance du treuil.

Prendre le temps de bien lire le manuel d’utilisation, et/

ou le manuel de base des techniques de treuillage, a n de

comprendre le treuil et son fonctionnement, trouvés en ligne à

http://www.warn.com /corporate/literaturerequest.shtml

.

• Ne jamais excéder la capacité nominale du treuil ou du câble

d'acier. Un câblage double avec poulie ouvrante permet de

réduire la charge subie par le treuil.

• Toujours porter des gants de cuir épais durant la

manipulation du câble du treuil.

• Ne jamais utiliser le treuil ou le câble du treuil pour faire du

remorquage. Cela peut endommager, surcharger et casser le

câble.

• Ne jamais se servir du treuil pour maintenir une charge.

• Ne jamais faire fonctionner l'appareil sous l'eff et de drogues,

de l'alcool ou de médicaments.

• Ne jamais laisser des personnes âgées de moins de 16 ans

utiliser ce treuil.

Consignes de sécurité se rapportant à l’installation:

• Toujours choisir une surface de montage suffi samment

résistante pour supporter la capacité de traction maximale du

treuil.

• Toujours utiliser un matériel de montage de catégorie 8,8 ou

supérieure.

• Ne jamais souder les boulons de montage.

• Toujours utiliser un matériel de montage, des composants et

des accessoires homologués par le fabricant.

• Ne jamais utiliser des boulons trop longs.

• Toujours achever le montage du treuil et la xation du crochet

avant d'eff ectuer le câblage.

• Toujours garder les mains éloignées du câble du treuil,

de la boucle du crochet, du crochet et de l'ouverture du

guide-câble durant l'installation et l’utilisation de l'appareil et

l'enroulement ou le déroulement du câble.

• Toujours positionner le guide-câble avec l'avertissement

visible sur le dessus.

• Toujours étirer au préalable le câble et l’enrouler sous charge

avant de l’utiliser. Un câble enroulé de manière serrée réduit le

risque qu'il coince et soit endommagé.

AVERTISSEMENT

DANGER DE HAPPEMENT PAR DES PIÈCES

MOBILES

Le non-respect des consignes peut entraîner des

blessures graves ou la mort.

•

Toujours

s’assurer que le loquet du crochet est fermé et

qu’il ne soutient aucune charge.

•

Ne jamais

appliquer la charge sur l’extrémité ou le loquet

du crochet. Appliquer la charge uniquement au centre du

crochet.

•

Ne jamais

utiliser un crochet dont l’ouverture de la gorge a

augmenté ou dont l’extrémité est courbée ou tordue.

•

Toujours

utiliser un crochet avec loquet.

•

Toujours

s’assurer que l’opérateur et les personnes

présentes sont conscients de la stabilité du véhicule et/ou

de la charge.

•

Toujours

garder le l de la télécommande et le cordon

d’alimentation à l’écart du tambour, du câble et du

câblage. S’assurer qu’il n’y a pas de ssures, de points de

pincement, de ls effi lochés ou de connexions desserrées.

Tous les composants endommagés doivent être remplacés

avant d’utiliser le produit.

•

Toujours

faire passer la télécommande par la fenêtre, si

on l’utilise de l’intérieur d’un véhicule.

•

Ne jamais

accrocher le câble à lui-même

AVERTISSEMENT

87970A2

87970A2

Page 13

WARN INDUSTRIES * WINCH

21

MESURES GÉNÉRALES DE SÉCURITÉ

DANGER DE HAPPEMENT

PAR DES PIÈCES MOBILES

Le non-respect des consignes peut entraîner des

blessures graves ou la mort.

Consignes de sécurité concernant le treuillage:

•

Toujours

inspecter le câble du treuil, le crochet et les élingues

avant de faire fonctionner le treuil. Tout câble de treuil effi loché,

tordu ou endommagé doit être remplacé immédiatement. Tous

les composants endommagés doivent être remplacés avant

d'utiliser le produit. Protéger toutes les pièces contre le risque de

dommages.

•

Toujours

s'assurer que tout objet ou obstacle pouvant gêner la

bonne utilisation du treuil est écarté.

•

Toujours

s'assurer que le point d'ancrage choisi peut supporter

la charge et que la sangle ou la chaîne ne glisse pas.

•

Toujours

utiliser la sangle de crochet fournie pourenrouler ou

dérouler le câble du treuil, durant l'installation ou l'utilisation.

•

Toujours

exiger de l'opérateur et des personnes présentes d’être

attentifs au véhicule et à la charge.

•

Toujours

être conscient de la stabilité du véhicule et de

la charge durant le treuillage. Veiller à ce que personne ne

s'approche. Alerter toutes les personnes alentour en cas

d'instabilité.

•

Toujours

dérouler autant de câble que possible avant de

procéder au câblage. Utiliser une ligne double ou choisir un point

d’ancrage distant.

•

Toujours

prendre le temps d'utiliser des techniques de câblage

adaptées avant d'utiliser le treuil pour tirer.

•

Ne jamais

toucher le câble du treuil ou le crochet lorsqu'une

autre personne est à l'interrupteur de commande ou durant le

fonctionnement du treuil.

•

Ne jamais

essayer d'embrayer ou de débrayer si le treuil est sous

charge, si le câble du treuil est entension ou si le tambour est en

train de tourner.

•

Ne jamais

toucher le câble ou le crochet lorsque lecâble est

tendu ou sous charge.

•

Toujours

se tenir à l'écart du câble du treuil et dela charge

durant l'utilisation et ne jamais laisser personne s'approcher.

•

Ne jamais

se servir d'un véhicule pour tirer une charge sur le

câble du treuil. La charge combinée ou un choc peut endommager,

surcharger et casser le câble.

•

Ne jamais

replier le câble du treuil sur lui-même. Utiliser

toujours une chaîne ou une protection detronc d'arbre sur le

point d'ancrage.

DANGER DE CHUTE OU D'ÉCRASEMENT

Le non-respect des consignes peut entraîner des

blessures graves ou la mort.

•

Toujours

rester à l'écart, en gardant les mains et les autres

personnes à l'écart également.

•

Ne jamais

utiliser le treuil avec moins de 10 spires de câble

enroulées autour du tambour. Le câble pourrait se dérouler du

tambour, étant donné que l'ancrage ducâble n'est pas conçu pour

retenir une charge.

•

Ne jamais

utiliser le treuil comme palan ou pour suspendre une

charge.

•

Toujours

s'assurer que le point d'ancrage peut supporter la

charge, et prendre le temps d'employer des techniques de câblage

appropriées.

•

Ne jamais

utiliser le treuil pour soulever ou transporter des

personnes.

•

Ne jamais

forcer trop fort pour dérouler le câble du treuil.

•

Toujours

utiliser une posture/technique de levage adéquate ou

demander de l'aide lors de la manipulation ou de l'installation du

produit.

•

Toujours

enrouler le câble sur le tambour dans le sens spéci é

par l’étiquette d'avertissement apposée sur le treuil ou la

documentation du treuil. Cela est nécessaire pour que le frein

automatique (le cas échéant) fonctionne correctement.

•

Toujours

enrouler le câble du treuil sur le tambour comme indiqué

par l’autocollant de rotation du

tambour.

RISQUE DE COUPURE ET DE BRÛLURE

Le non-respect des consignes peut entraîner des

blessures graves ou la mort.

Pour éviter de se blesser les mains et les doigts:

•

Toujours

porter des gants de cuir épais durant lamanipulation du

câble du treuil.

•

Toujours

penser aux surfaces chaudes au niveau dumoteur du

treuil, du tambour ou du câble durant ouaprès l'utilisation du

treuil.

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

WARN INDUSTRIES * WINCH

22

MESURES GÉNÉRALES DE SÉCURITÉ

DANGER D'IMPACT ET DE HAPPEMENT PAR

DES PIÈCES MOBILES

Le non-respect des consignes peut entraîner des

blessures graves ou la mort.

Pour éviter de se blesser les mains

et les doigts:

• Toujours connaître la limite de charge de service (LCS) de

votre câble.

• Toujours déterminer si le câble est adapté à l'application

envisagée.

• Ne jamais utiliser ce câble sur un treuil avec un eff or t en 1ère

couche supérieur à 4536kg.

• Ne jamais utiliser un câble s'il est usé, endommagé, maltraité,

surchargé, mal entretenu ou s'il a plus d'un an.

• Ne jamais se tenir dans la zone de recul.

• Ne jamais utiliser le câble sur une surface rugueuse sans

protection contre les frottements.

• Ne jamais appuyer le câble sur des coins acérés

nonprotégés.

• Ne jamais laisser l'embrayage débloqué lorsqu'on

n'eff ectue pas de déroulement en roue libre du câble. Le

frein automatique ne fonctionnera pas lorsque le levier

d'embrayage se trouve en position de déroulement en roue

libre.

• Ne jamais dépasser la charge nominale de 4 536 kg.

• Remplacer le câble tous les 12 mois, sans exception.

• Toujours utiliser un guide-câble WARN recommandé pour les

câbles synthétiques.

• S’il a été endommagé ou maltraité, toujours remplacer

le guide-câble écubier WARN par un guide-câble WARN

recommandé pour les câbles synthétiques.

RISQUES ASSOCIÉS AUX PRODUITS

CHIMIQUES ET RISQUE D'INCENDIE

Le non-respect des consignes peut entraîner des

blessures graves ou la mort.

• Toujours retirer les bijoux et porter des lunettes

desécurité.

• Ne jamais faire passer les câbles électriques

par-dessus des bords tranchants.

• Ne jamais faire passer les câbles électriques àproximité de

pièces qui s'échauff ent.

• Ne jamais faire passer les câbles électriques àtravers des

pièces mobiles ou à proximité.

• Toujours placer les capuchons fournis sur les ls et les bornes,

conformément aux instructions d'installation.

• Ne jamais se pencher au-dessus de la batterie

enprocédant aux connexions.

• Ne jamais faire passer les câbles électriques

par-dessus les bornes de la batterie.

• Ne jamais court-circuiter les bornes de la batterie avec des

objets métalliques.

• Toujours s'assurer que la zone ne contient pas deconduites

de carburant, de réservoir de carburant, de conduites de

frein, de câblage électrique, etc., avant de percer.

• Toujours consulter le manuel de l'utilisateur pour

lesinformations correctes de câblage.

• Toujours isoler et protéger tous les ls et bornes

électriques exposés.

AVERTISSEMENT

AVERTISSEMENT

87970A2

87970A2

Page 14

WARN INDUSTRIES * WINCH

23

MESURES GÉNÉRALES DE SÉCURITÉ

ÉVITER D’ENDOMMAGER LETREUIL ET

L'ÉQUIPEMENT

• Toujours éviter de tirer sur le côté, ce qui a pour eff et

d'empiler le câble sur l'une des extrémités du tambour. Cela

peut endommager le câble ou le treuil.

• Toujours s’assurer d’avoir complètement embrayé

oucomplètement débrayé.

• Toujours faire attention à ne pas endommager lechâssis du

véhicule si l'on décide de s'arrimer

à un véhicule pour pouvoir travailler avec le treuil.

• Ne jamais submerger le treuil dans l'eau.

• Toujours ranger la télécommande dans un endroit sûr,

propre et sec.

• Toujours éviter un «déroulement» continu. La chaleur

générée par un déroulement continu peut endommager le

câble.

• Ne jamais exposer le câble à des détergents agressifs, des

carburants, des huiles ou de l'antigel.

• Toujours utiliser une protection contre les frottements sur

tous les bords tranchants pour protéger le câble.

• Ne jamais laisser le câble entrer en contact avec des objets

coupants. Cela pourrait causer de graves dommages.

• Toujours rembobiner le câble en couches uniformes après

des activités de treuillage en angle.

• Ne jamais «secouer» le câble sous charge. Les charges

de choc peuvent dépasser momentanément la capacité du

treuil et du câble.

• Ne jamais installer plus de 30(CTI)/24(XDC)m de câble

synthétique 3/8po. Le treuil pourrait être endommagé.

AVIS

DANGER DE HAPPEMENT

PAR DES PIÈCES MOBILES

Le non-respect des instructions peut entraîner des

blessures mineures ou modérées.

Pour éviter de se blesser les mains oulesdoigts:

• Ne jamais laisser la télécommande dans un emplacement où

elle peut être activée durant la mise en roue libre, le câblage ou

quand le treuil n'est pas utilisé.

• Ne jamais laisser la télécommande du treuil branchée

durant l'installation, le déroulement en roue libre, le câblage,

l'entretien ou quand le treuil n'est pas utilisé.

ATTENTION

RISQUE DE COUPURE

ET DE BRÛLURE

Le non-respect des instructions peut entraîner des

blessures mineures ou modérées.

• Ne jamais laisser le câble du treuil glisser dans lesmains.

ATTENTION

WARN INDUSTRIES * WINCH

24

CONDITIONS DE TRAVAIL SURES

AVERTISSEMENT

Toujours resterà

l'écart, en gardant

lesmains et les

autres personnes à

l'écart également.

CONDITIONS DE TRAVAIL SÛRES

Pendant la traction d'une

charge, l'opérateur doit toujours faire

fonctionner le treuil en se tenant

enposition sûre. Les emplacements

sûrs sont: (1) perpendiculaires

aucâble, (2) à l'intérieur du véhicule

avec le capot relevé (si le treuil

est monté à l'avant du véhicule).

Ces endroits sûrs permettront

d'empêcher que le câble ne frappe

l'opérateur encas de rupture sous

charge.

Autant que possible, utiliser

le treuil avec le câble de la

télécommande complètement

déployé. Celui-ci doit toujours

demeurer à une distance minimale

de 2,44 m du treuil pendant son

fonctionnement. Cela évite d'être

happé par le guide-câble et maintient

l'opérateur dans une zone de sécurité

durant la traction de la charge.

Ne jamais travailler à proximité

d'un câble sous charge.

Niveau de bruit

Ce treuil est conçu de manière

à ce que le niveau de bruit émis ne

dépasse pas 70dBa à l’endroit où

setrouve le manipulateur. Celuici doit demeurer à une distance

minimale de 2,44m du treuil

pendant son fonctionnement. Faire

inspecter le treuil dans un centre de

service agréé si le bruit dépasse 70

dBa auniveau de l’opérateur.

Nettoyage

Utiliser de l'eau à basse pression

pour nettoyer le câble synthétique.

N'utiliser aucun produit chimique.

Ne pas diriger un jet d’eau haute

pression (laveuses haute pression,

lave-auto, etc.) entre le support

etle rebord du tambour ou le levier

d’embrayage.

Nettoyer le treuil à l’aide d’eau

sous faible pression et d’une éponge

ou d’un chiff on savonneux.

Ne pas utiliser de produits

chimiques qui pourraient

endommager la nition.

Nettoyer soigneusement les

résidus de sel du treuil le plus vite

possible a n de minimiser l'eff et

decorrosion.

Entretien

Remplacer le câble tous

les12mois par un câble WARN.

Le treuil ne nécessite aucune

lubri cation pendant sa durée de

vie, sauf s’il a été immergé dans l’eau.

Si cela se produit, faire réaliser une

inspection complète par un centre de

service dès que possible pour éviter

tout dommage dû à la corrosion. Sile

coff ret de commande est immergé,

il doit être remplacé au moment de

l’intervention de service sur le treuil.

Véri er les câbles de batterie

etles connexions électriques tous

les 90 jours pour s’assurer qu’ils sont

propres et correctement serrés à tous

les points de connexion.

Inspecter le câble avant et après

chaque utilisation du treuil. S’il est

endommagé, le remplacer par un

câble de calibre conforme à la liste

des pièces de rechange, ou se rendre

sur le site Internet Warn à l'adresse

www.warn.com.

Le câble doit toujours s’enrouler

sur le tambour dans le sens indiqué

par l’étiquette de rotation du

tambour apposée sur le treuil.

Toujours exiger

de l'opérateur et

des personnes

présentes d’être

attentifs au véhicule

et àlacharge.

AVIS

Ne jamais

submerger le treuil

dans l'eau.

ATTENTION

Ne jamais laisser la

télécommande dans

un emplacement

où elle peut être

activée durant la

mise en roue libre,

le câblage ou quand

le treuil n'est pas

utilisé.

AVERTISSEMENT

87970A2

87970A2

Page 15

WARN INDUSTRIES * WINCH

25

MONTAGE DU TREUIL

MONTAGE DU TREUIL

Choisir une surface de montage

suffi samment résistante pour supporter

les charges qui seront halées. Seules les

orientations de montage indiquées sont

recommandées pour utiliser le treuil en

toute sécurité. Toute autre orientation

du treuil est inadaptée et ne doit pas

être utilisée. Utiliser les boulons et les

rondelles d’arrêt recommandés, ainsi que

les couples de serrage recommandés

pour éviter les vibrations du treuil

pendant son fonctionnement. Les

détails demontage indiquent les valeurs

decouple adéquates.

N'oubliez pas que le câble dutreuil

doit toujours s’enrouler sur le tambour

dans le sens indiqué par l’étiquette de

rotation du tambour.

Se reporter aux schémas suivants

pour l'orientation de montage correcte.

Ne jamais utiliser

des boulons trop

longs.

Installation du coff ret

decommande

Monter le coff ret de commande

suivant les instructions jointes au kit

de système de montage Warn. Utiliser

la console comprise dans lekit.

Toujours choisir une

surface de montage

suffi samment

résistante pour

supporter la capacité

de traction maximale

du treuil.

Toujours achever le

montage dutreuil

et xer lecrochet

avant d'eff ectuer

lecâblage.

Épaisseur

de plaque

Longueur

de boulon

1/4” (7 mm) 1,25” (32 mm)

3/8” (10 mm) 1,5” (40 mm)

1/2” (13 mm) 1,5” (40 mm)

Détails de montage:

(1) Lisse et plat, épaisseur 6,4 mm

(2) Rondelle d’arrêt 9,525 mm (quantité = 4)

(3) Boulon catégorie 3/8-16 X 1 1/4” de long X 4

Couple de 30-35 pieds-livres. (41-47Nm)

(4) Écrou de blocage 1/2-13

(5) Rondelle plate 1/2po

(6) Écrou carré 3/8-16

(7) Boulon à tête bouton 1/2-13x2”

(8) Guide-câble en aluminium

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

Entraxe de xation :

WARN INDUSTRIES * WINCH

26

RACCORDEMENTS ÉLECTRIQUES

Schémas électriques:

RACCORDEMENTS ELECTRIQUES

Utiliser des capuchons d’isolation

inclus sur les connexions exposées

pour éviter les courts-circuits. Les ls de

batterie doivent passer par des endroits

qui ne risquent pas d'endommager

ou depercer l’isolation et de créer

desrisques de court-circuit.

Une fois l’installation terminée,

véri er que le treuil fonctionne

correctement.

Ne jamais faire

passer les câbles

électriques pardessus des bords

tranchants.

Ne jamais faire

passer les câbles

électriques à

proximité de pièces

qui s'échauff ent.

Ne jamais faire

passer les câbles

électriques à travers

des pièces mobiles

ou à proximité.

Toujours placer

les capuchons

fournis sur les

ls e t les bornes,

conformément

aux instructions

d'installation.

Recommandations concernant

labatterie

La charge de la batterie et

la qualité des connexions sont

essentielles pour que le treuil

fonctionne correctement. La capacité

de démarrage à froid minimum

requise pour une batterie de 12 Vc.c.

est de 650 A.

Toujours isoler et

protéger tous les ls

et bornes électriques

exposés.

Broche n° Couleur

1 Marron

2 Blanc

3 Noir

4 Vert

5

6 Rouge

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

Noir

Rouge

Vert

Marron

Blanc

87970A2

87970A2

Page 16

WARN INDUSTRIES * WINCH

27

INSTRUCTIONS D’UTILISATION

Instructions relatives à une première

utilisation

Dans cette section, nous allons vous

montrer les premières instructions

d’utilisation de temps pour le treuillage de

base efficace. Pour le fonctionnement et les

techniques de treuil complet lire le guide

de base de treuillage Techniques trouvés en

ligne à

http://www.warn.com/corporate/

literaturerequest.shtml.

Télécommande

Le treuil est contrôlée par la

télécommande à main. La télécommande

permet de contrôler la puissance de sortie

(vers l’avant) ou de la puissance en (arrière)

rotation du tambour d’enroulement.

Ne pas laisser la télécommande

branchée dans le treuil lorsque celui-ci n’est

pas en usage. Une télécommande qui reste

branchée risque de créer des conditions

dangereuses et de vider la batterie.

Fonctionnement de l’embrayage :

Lorsque l’embrayage est en prise, le

train d’engrenages est couplé au tambour

du treuil et l’entraînement peut alors être

transféré du moteur du treuil. Lorsque

l’embrayage est débrayé, le tambour est

en position de déroulement en roue libre

et le train d’engrenages et le tambour du

treuil se désaccouplent, ce qui permet au

tambour de tourner librement.

Le levier d’embrayage, situé sur le carter

du treuil en face du moteur, permet d e

Télécommande verticale:

Libéré:

En prise:

Ne jamais

essayer

d'embrayer ou de

débrayer si le treuil

est sous charge, si le

câble du treuil est en

tension ou

si le tambour est

en train de tourner.

Déroulement du câble

Le déroulement en roue libre

constitue généralement la façon la plus

rapide et la plus facile de dérouler le

câble. Avant de mettre le treuil en roue

libre pour dérouler le câble, dérouler au

moteur une quantité suffi sante de câble

pour soulager le câble de toute tension.

Débrayer. Vous pouvez maintenant

dérouler manuellement une quantité

suffi sante de câble pour pouvoir

travailler avec le treuil. Voir le Manuel de

base des techniques de treuillage pour de

plus amples informations.

Toujours laisser au moins 10spires

de câble sur le tambour.

Enroulement sous charge

Ne jamais dépasser l’eff ort en1ère

couche du treuil.

Enrouler mécaniquement le câble

sur le tambour de manière uniforme

et serrée. Cela empêche les spires

extérieures de s’enfoncer dans les

spires intérieures, ce qui peut coincer et

endommager le câble.

Pour éviter les charges dechoc

durant l’enroulement du câble, actionner

l’interrupteur de commande de manière

intermittente a n d'éliminer le mou

du câble. Les charges de choc peuvent

momentanément dépasser de loin la

capacité du treuil et du câble du treuil.

Enroulement à vide

Déroulement avec un assistant:

demander à un assistant de tenir la

sangle de crochet en appliquant une

tension aussi constante que possible

Ne jamais utiliser

le treuil avec moins

de 10 spires de câble

enroulées autour du

tambour. Lecâble

pourrait se dérouler

du tambour, étant

donné que l'ancrage

du câble n'est pas

conçu pour retenir

une charge.

AVIS

Ne pas dérouler le

câble de plus de 9m

sans laisser refroidir

le treuil pendant

20minutes avant

de recommencer

l'enroulement.

Utiliser plutôt

l'embrayage en

déroulement libre

en tirant le câble à

la main.

ENTRÉE

SORTIE

AVERTISSEMENT

AVERTISSEMENT

commander la position de l’embrayage.

Pour éviter tout dommage, tourner

complètement le levier d’embrayage dans

l’une ou l’autre position.

WARN INDUSTRIES * WINCH

28

INSTRUCTIONS D’UTILISATION

sur le câble. Tout en maintenant

la tension, il devra se déplacer

en direction du treuil pendant

l'actionnement de l'interrupteur de

commande pour enrouler le câble.

Relâcher l’interrupteur lorsque le

crochet parvient à une distance

minimale de 2m de l’ouverture

duguide-câble.

Enrouler le reste du câble pour

le ranger, de la manière indiquée

ci-dessous.

Déroulement tout seul: arranger le

câble à enrouler de manière à ce

qu’il ne s’entortille ni ne s’emmêle

pendant le rembobinage. Veillez

à ce que le câble soit enroulé sur

le tambour de manière uniforme

et serrée. Enrouler une quantité

suffi sante de câble pour compléter

une couche entière sur le tambour.

Serrer et étaler de manière égale la

couche de câble. Refaire de même

jusqu’à ce que le crochet soit à

une distance minimale de 2m de

l’ouverture du guide-câble.

Enrouler le reste du câble pour

le ranger, de la manière indiquée

ci-dessous.

Enroulement du reste du câble

pour le ranger

Lorsque le crochet se trouve à moins

de 2m du guide-câble, détacher

lecrochet du point d'ancrage ou dela

charge. En tenant la sangle de crochet

fournie, maintenir la tension sur câble

du treuil. Enrouler lentement le treuil

en appliquant de petites pressions

sur la touche «Power in» (enrouler)

de la télécommande jusqu'à ce que

le crochet soit à moins de 1m du

guide-câble. Arrêter le treuillage et

xer le crochet sur un point d'ancrage

approprié sur le véhicule.

NE PAS LAISSER PAS LE

CROCHET ATTEINDRE LE GUIDECÂBLE. Cela pourrait endommager

leguide-câble. Une fois le crochet

xé correctement au véhicule,

Toujours garder

les mains éloignées

du câble du treuil,

de la boucle du

crochet, du crochet

et de l'ouverture du

guide-câble durant

l'installation et

l’utilisation du treuil

et l'enroulement

ou le déroulement

ducâble.

Toujours utiliser le

cordon de crochet

fourni pour enrouler

ou dérouler le câble,

durant l'installation

ou l’utilisation pour

éviter de se blesser

les mains ou les

doigts.

Toujours porter

des gants de cuir

épais durant la

manipulation du

câble du treuil.

Ne jamais toucher

le câble du treuil ou

le crochet lorsqu'une

autre personne

est à l'interrupteur

de commande

ou durant le

fonctionnement du

treuil.

INSTRUCTIONS D’UTILISATION

Suite

enrouler le câble de façon à éliminer

le mou restant en appliquant de

petites pressions sur la touche

«Power in» (enrouler) de la

télécommande jusqu'à ce que le mou

soit minime sur le câble du treuil.

Surcharge/surchauff e

Ce treuil est conçu pour un

service intermittent. Lorsque le

moteur est sur le point de caler, une

accumulation rapide de chaleur se

produit et peut endommager le

moteur.

Le câblage double (voir le Manuel

de base des techniques de treuillage)

permet de réduire la consommation

de courant et de réduire ainsi