Warn Industries ATV Winch Multi-Mount 2.5ci User Manual

WARN INDUSTRIES, INC.

Installation and Specification

Guide for the

2.5ci

ATV Winch Multi-Mount

WARN INDUSTRIES, INC.* 12900 CAPPS ROAD * CLACKAMAS, OREGON 97015

(503)722-1200 * CUSTOMER SERVICE LINE 1-800-543-WARN * FAX (503)722-3000

PN 65405 A1

English..................................................................... ...1

Français.................................................................... ..9

Español ................................................................... 17

As you read these instructions, you will see WARNINGS and CAUTIONS. Each

message has a specific purpose. WARNINGS and CAUTIONS identify the hazard,

indicate how to avoid the hazard, and advise of the probable consequence of not

avoiding the hazard. PLEASE WORK SAFELY!

WARNINGS are safety messages that indicate a potentially hazardous situation,

which, if not avoided can result in serious injury or death.

CAUTIONS are safety messages that indicate a potentially hazardous situation, which,

if not avoided, may result in minor or moderate injury. A CAUTION may also be used to

alert against unsafe practice.

GENERAL SAFETY PRECAUTIONS

MOVING PART HAZARDS

To prevent serious injury and

property damage:

• Do not operate or install winch

without reading and understanding these instructions

and the Basic Guide to Winching Techniques.

• Keep hands clear of wire

rope, hook and fairlead opening during operation and

when spooling.

• Use supplied hook strap

for spooling wire rope.

• Stand clear of wire rope and

load during operation.

• Keep others away.

• Inspect winch installation and

wire rope condition before

operating winch.

• Do not use as a hoist.

• Do not use to move persons.

• Do not exceed winch’s rated

capacity.

• Never touch wire rope or

hook while in tension.

• Be certain the anchor you

select will withstand load.

• Never wrap wire rope back

onto itself. Use a choker chain

or tree trunk protector on the

anchor.

• Prior to initiating winching

operation be sure any element which can interfere with

safe winching is removed.

• Do not disengage clutch if

winch is under load or wire

rope is in tension.

WARNING!WARNING!

• Take your time. Sloppy rigging causes accidents.

• The wire rope must always

spool onto the drum as indicated by the drum rotation

label on the winch.

BATTERY HAZARDS

• Batteries contain gasses

which are flammable.

• Wear eye protection.

• Remove all metal jewelery.

• Do not lean over battery while

making connections.

• Failure to take proper precaution may result in fire or serious injury.

CAUTION!

TO AVOID INJURY AND PROPERTY

DAMAGE:

• Do not use winch to secure a

load during transport.

• Do not submerge

in water.

• Do not use to tow other

vehicles.

• Wear heavy leather gloves

when handling the wire rope.

• Never winch with less than 5

wraps of wire rope around the

drum.

• Caution should be used if the

vehicle is tied down during a

winching operation. This may

lead to damage to the frame.

• Before winching, inspect remote control lead for damage.

Figure 1. WARN 2.5ci winch

multi-mount kit

Figure 2. Winch dimensions:

12.62" L. x 4.5" D. x 4.75" H.

320mm L. x 12cm D. x 12cm H.

Specifications

Part number: PN 64500 (CE version: PN 64501)

Rated line pull: 2500 lbs. (1134 kgs.) single-line

Motor: 12V DC, .9hp (.7kW) permanent magnet

Control: Handlebar mounted Mini-rocker switch

Geartrain: 3-Stage Planetary

Gear ratio: 136:1

Lubrication: Aeroshell #17

Clutch (freespooling): Cam activated

Brake: Dynamic. Mechanical brake is available

as an option. (CE version includes

mechanical brake).

Drum diameter/Length: 2.0”/2.9”

Weight: 15.4 lbs. (7.0kgs.)

Wire rope: 50’, 3/16”diameter (15m, 5mm diam.)

Fairlead: Hawse

Recommended Battery: 12 Amp/hour minimum

for winching

Battery leads: 6 gauge

Duty Cycle: Intermittent

Finish: Grey

Performance Data

Line Pull Line Speed Motor Current

lbs (kgs) ft/min (m/min) Amps

0 24 (7.3) 18

500 (227) 19 (5.8) 51

1000 (455) 15 (4.6) 88

1500 (680) 11 (3.3) 125

2000 (907) 9 (2.7) 165

2500 (1134) 7 (2.1) 204

Above performance specs are based on first layer of drum

Pulling power Wire rope layer

lbs (kgs) 1st is closest to drum

2500 (1134) 1st

2200 (998) 2nd

1930 (875) 3rd

1700 (771) 4th

| Warn Industries, Inc.

1

WARN 2.5ci Winch Multi-Mount Installation and Specification Guide |

2

Step One: Safety First!

When installing your ATV winch system, read and

follow all mounting and safety instructions.

Always use caution when working with electricity

and remember to verify that no exposed electrical

connections exist before energizing your

winch circuit.

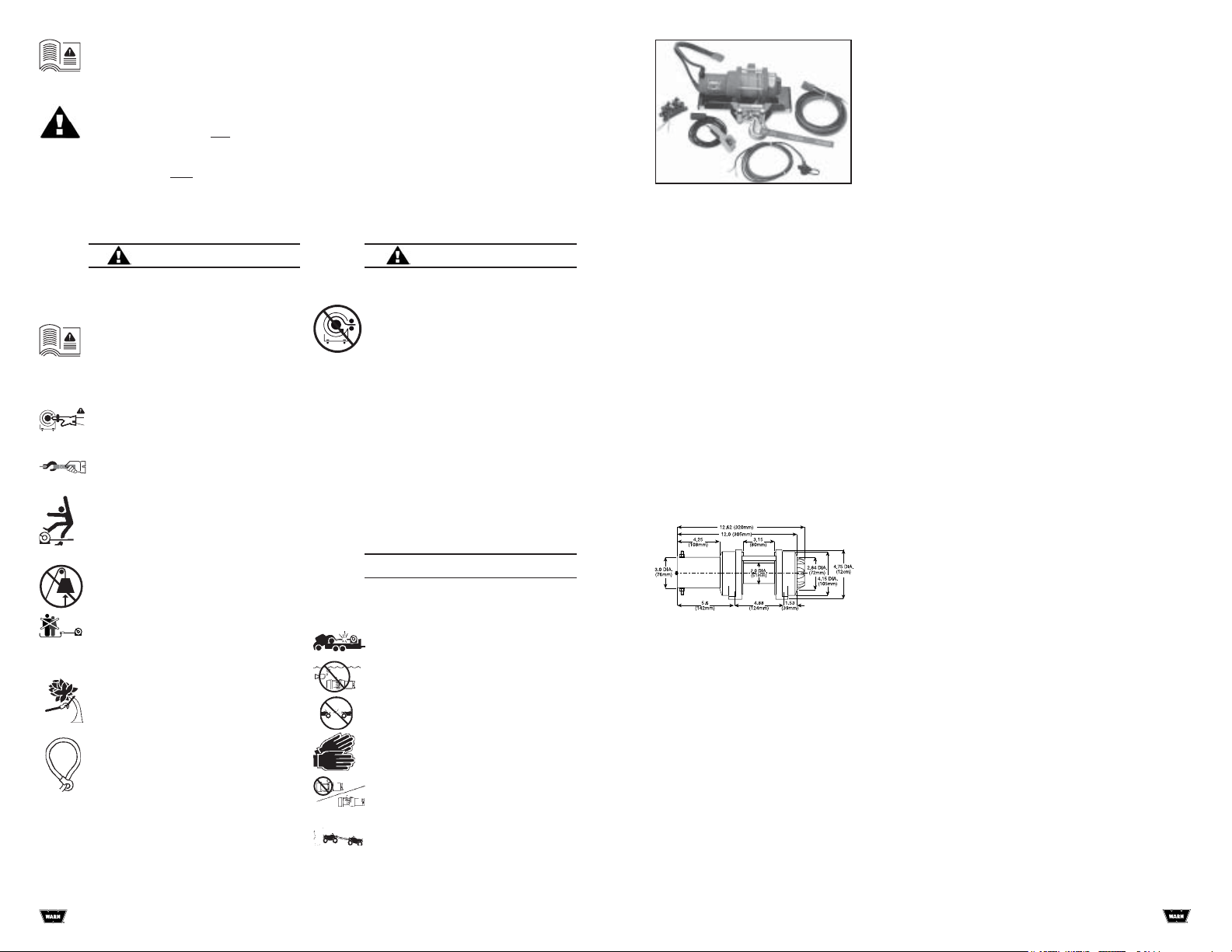

Figure 3: To install the complete kit, you will need to mount the winch, contactor,

and remote socket. Mounting locations may vary depending on make and model of the ATV. Read

and understand the following instructions to choose the appropriate mounting locations.

Figure 4: Orientation of winch to

mounting plate.

Figure 5. Contactor for the

WARN ATV winch

Step Two: Winch Mounting

Attach the roller fairlead to the multi-mount plate, use

the provided:

• 3/8-16 x 3/4 in., hex bolts

• 3/8 in. lock washers.

• 3/8 in. hex nuts.

Secure the winch to the multi-mount plate, use the

provided:

• 5/16-18 x 1 in., grade 5 hex bolts.

• 5/16 in. lock washers.

• Torque bolts to 12 ft-lb (17 N-m).

Attach the clevis hook to the wire rope at this time.

• Put clutch in freespool position.

• Manually feed cable loop through the roller fairlead.

• Attach hook to cable loop and re-engage clutch.

Step Three: Contactor Location

• The contactor is a primary safety feature in your

winch system. It disconnects your winch from its

power source when the ATV is not in use. The

contactor must be correctly installed to work

properly.

• It is recommended that the contactor be

mounted close to the battery and in a location

that is as clean and dry as possible. Exact

location will vary, depending on the ATV. Usual

locations include inside, on top, or on the side of

rear storage box, and on a few models, under

the seat.

• Ensure the contactor mounting location selected

provides sufficient clearance from all metal

structures such as frame tubes. DO NOT place

tools or other items in a position that might come

in contact with the contactor directly.

• Drill the mounting holes for the contactor at this

time, then move on to step four as it will be

easier to attach all the wiring to the contactor

before attaching it to the ATV. DO NOT mount the

contactor at this time.

| Warn Industries, Inc.

3

WARN 2.5ci Winch Multi-Mount Installation and Specification Guide |

4

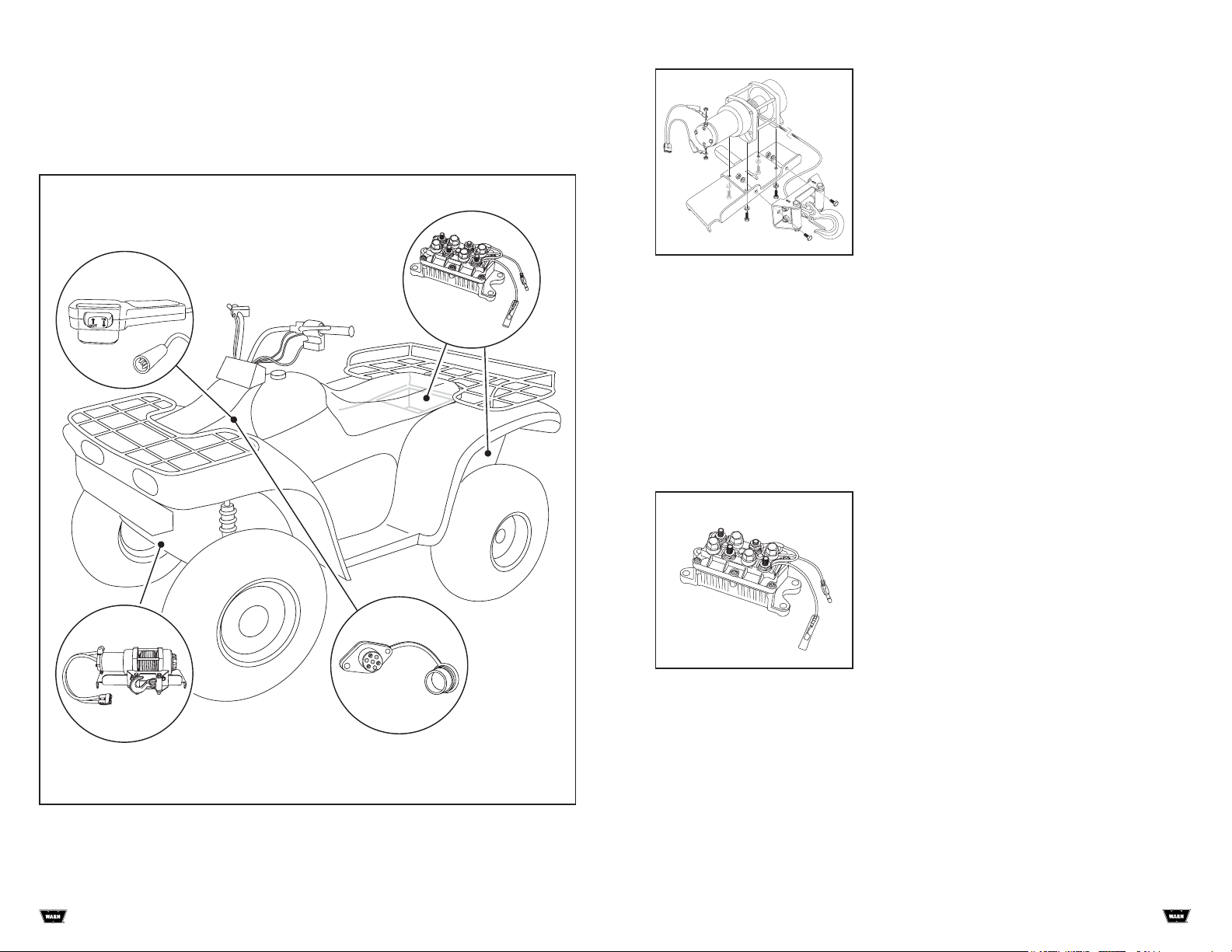

Step Four: Remote Socket

Installation

10-24 hex nut &

lockwasher

Keyway must

point down

10-24 hex nut &

hex head capscrew

Figure 6. Remote socket installation.

Figure 7: Use a test light to locate a

suitable wire.

WARNING!

TO PREVENT SERIOUS INJURY OR DEATH FROM

EXPLOSION:

• Do not drill into gas tank.

• Verify the area is clear behind the mounting

location before drilling.

1/4in. (6.4 mm) diameter, 2 places

7/8in. (44.5mm)

7/8in. (22.2mm) diameter

1-3/4in. (44.5mm)

Not to scale. Do not use as a template!

• After determining the mounting location for the

remote socket, drill three holes and install. (see

figure 6)

• Once the remote socket is mounted, route the two

bullet terminal wires back to where the contactor

will be mounted. Splice the end of the red 20ga wire

to a key controlled electrical wire of the ATV (use

the provided wire splice). Using a test light, locate a

suitable wire from the ATV key switch. The wire

should only have power when the key is in the "ON"

position.

Yellow

(6 ga.)

Blue

(6 ga.)

(6 ga.)

Blue

Yellow

(6 ga.)

Black

(6 ga.)

Green

Red

(20 ga.)

Black

Red

(6 ga.)

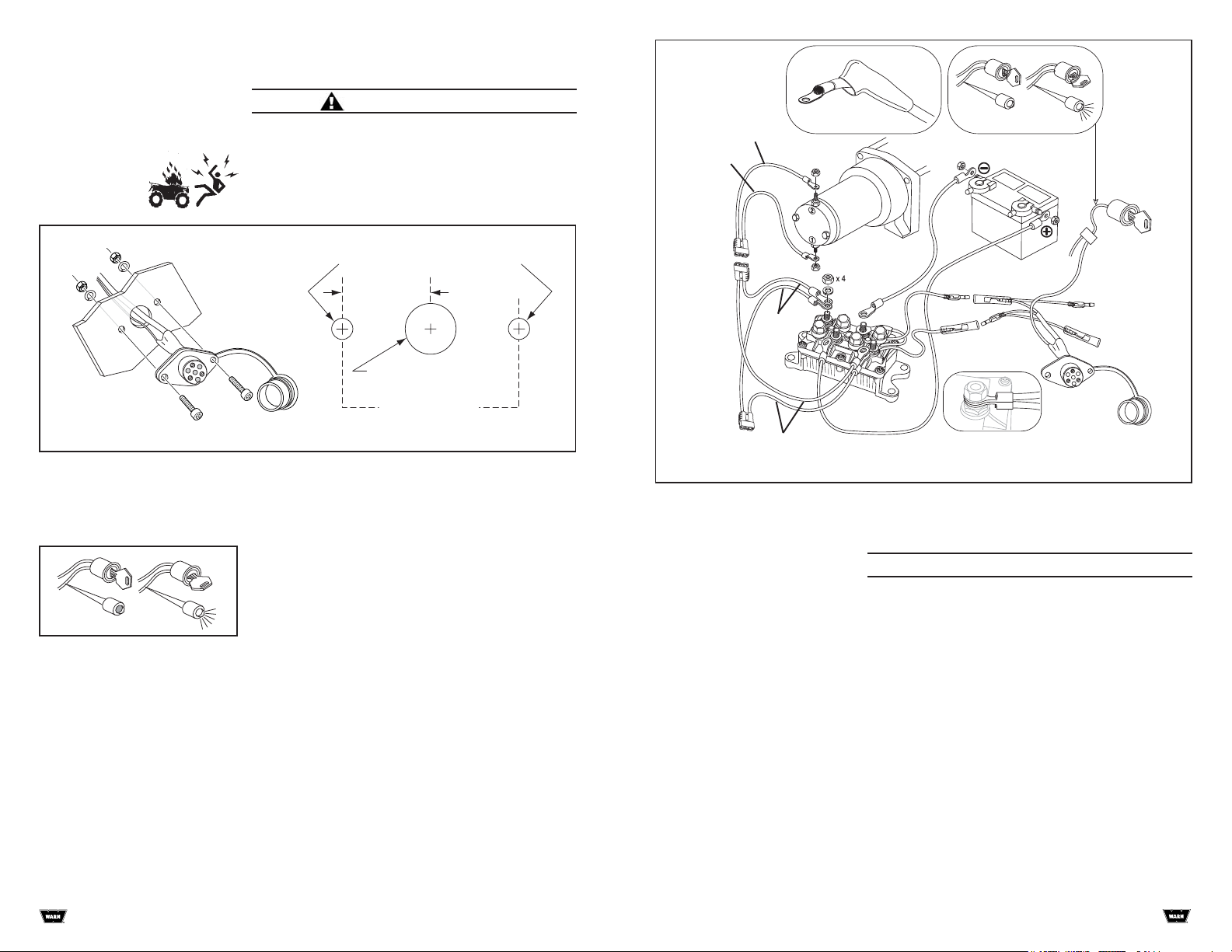

Figure 8. Wiring Installation diagram

Step Five: Wiring Installation

CAUTION!

Place the supplied terminal boots on wires before

securing to the contactor. All wires must be

attached to the contactor before mounting the

contactor to the ATV.

• Attach the yellow and blue labeled 21 in (0.5m) 6ga

wires to the yellow and blue motor terminals on the

winch. Yellow is marked #1 and blue is marked #2

on the end of the motor cap.

• Attach the yellow and blue 48 in (1.2m) and 96 in

(2.4m) 6ga wires to the contactor and connect to

the yellow and blue contactor posts. Reference the

lower right-hand corner of figure 8 to see how to fit

two wire terminals onto the contactor posts.

• Attach the terminals on the green and black remote

socket wires into the contactor (green to green, black

to black).

| Warn Industries, Inc.

5

WARN 2.5ci Winch Multi-Mount Installation and Specification Guide |

6

OUT

• Attach the 36 in. (0.9m), 6 ga. red wire to the

positive red contactor post and battery (shrink

wrapped end to battery). Attach the 36 in. (0.9m), 6

ga. black wire to the black contactor post and

battery.

• When possible, route the winch kit power (red) and

ground (black) wires along the ATV’s existing wire

routing paths under the seat and battery location

areas. Ensure the wiring is not pinched when the

seat is reinstalled.

• Attach the contactor to the predetermined position

on the ATV. Assure that cables do not cross sharp

edges, moving parts, or contact items that may

become hot.

• Secure loose wiring with zip ties or electrical tape

prior to final ATV reassembly.

2. Contact your dealer where you purchased your

winch. If, after discussing the problem with their

with their parts and service staff, you are still

unable to resolve the problem then go to step 3.

3. Call an Authorized WARN Service center from

the list provided on the back of the warranty

sheet included with the product. When calling,

please have the following information available:

winch model number and purchase date,

make, model and year of ATV.

4. If you are unable to resolve the problem to your

satisfaction, please call Warn Industries

Customer Service at: 1-800-543-9276. When

calling, please have the following information

available: winch model number and purchase

date, make, model and year of ATV. You may

also contact Warn Industries by visiting our

website: www.warn.com.

Step Six: System Check

IN

Before using the winch, verify the following:

• Wiring to all components is correct. All loose wires

are tie wrapped tight.

• There are no exposed wiring or terminals. Cover

any existing terminal exposures with terminal

boots, heat shrink tubing or electricians tape.

• Turn ATV key switch to ON position. Check winch

for proper operation. The wire rope should spool

in and out in the direction indicated on the

switch.

CAUTION!

KNOW YOUR WINCH:

• Take time to fully understand your winch and

the winching operation by reviewing the Basic

Guide to Winching Techniques included with

your winch.

Service

Should you encounter a problem during installation or

operation of your winch, please follow these steps

toward resolving the problem:

1. Refer to your operator’s guide and installation

instructions. It has illustrations and detailed

information on the installation and safe and

proper operation of your winch. it also includes

a replacement parts list and assembly

diagrams. If you are unable to resolve the

problem, then go to step 2.

Warranty

Please refer to the warranty sheet enclosed with

your winch for details.

Replacement Part Numbers

Ordering information: Parts may be obtained

through your local dealer or distributor.

Part Number Description

PN 60076 Wire rope assembly, 3/16” x 50’

PN 36031 Motor, 2.5ci, 12 VDC

PN 62135 Contactor, 12 VDC

PN 64849 Remote control, 10 ft.

PN 62258 Remote control socket

PN 28929 Roller fairlead kit

PN 39557 Hook, 5/16 Clevis slip with strap

PN 38293 Strap, hook

The above list represents the most commonly

requested replacement parts. A full listing of

replacement and service parts are available.

Check with your WARN authorized dealer or on the

web: www.warn.com

| Warn Industries, Inc.

7

WARN 2.5ci Winch Multi-Mount Installation and Specification Guide |

8

Loading...

Loading...