Warner Instruments BC-535 User Manual

BC-535 Preliminary, Rev. 060126

WWaarrnneerr IInnssttrruummeennttss

BBiillaayyeerr CCllaammpp AAmmpplliiffiieerr

MMooddeell BBC

C--553355

Warner Instruments

1125 Dixwell Avenue, Hamden, CT 06514

(800) 599-4203 / (203) 776-0664

(203) 776-1278 - fax

BC-535 Preliminary, Rev. 060126

TTaabbllee ooff CCoonntteenntts

s

NOMENCLATURE....................................................................................................................................5

Text conventions.....................................................................................................................................5

Device panel abbreviations....................................................................................................................5

CONTROL DESCRIPTION......................................................................................................................6

Front panel..............................................................................................................................................6

Hold......................................................................................................................................................6

Offset ....................................................................................................................................................7

Meter ....................................................................................................................................................7

Outputs.................................................................................................................................................8

Capacitance compensation...................................................................................................................8

Power ...................................................................................................................................................9

Rear panel ...............................................................................................................................................9

Headstage.............................................................................................................................................9

Circuit and chassis grounds.................................................................................................................9

Gain Telegraph ..................................................................................................................................10

Filter Telegraph .................................................................................................................................10

Im output ............................................................................................................................................11

External Command In ........................................................................................................................11

Capacitance Output............................................................................................................................11

Cap Sync Out......................................................................................................................................11

External speaker.................................................................................................................................11

ADDITIONAL INFORMATION............................................................................................................11

Headstage connections .........................................................................................................................11

Model membrane..................................................................................................................................12

SETUP........................................................................................................................................................13

Basic design...........................................................................................................................................13

Faraday cage......................................................................................................................................13

Vibration isolation..............................................................................................................................14

Membrane support .............................................................................................................................14

Amplification......................................................................................................................................15

Filtering..............................................................................................................................................15

Acquisition hardware and software ...................................................................................................16

Data analysis......................................................................................................................................16

Data archival......................................................................................................................................16

Stirring ...............................................................................................................................................16

BC-535 Preliminary, Rev. 060126

Perfusion ............................................................................................................................................17

Oscilloscope .......................................................................................................................................17

INITIAL TEST..........................................................................................................................................18

Amplifier setup .....................................................................................................................................18

Overview................................................................................................................................................18

Initial conditions...................................................................................................................................18

Hold voltage test.................................................................................................................................19

Input noise test without model membrane..........................................................................................20

Input noise test with model membrane...............................................................................................20

Test instrument Im output....................................................................................................................21

Cap test...............................................................................................................................................21

Autozero .............................................................................................................................................21

Capacity compensation ......................................................................................................................22

OPERATION ............................................................................................................................................23

Setup of the bilayer chamber...............................................................................................................23

Input offset............................................................................................................................................24

Input offset adjustment .......................................................................................................................24

Bilayer formation..................................................................................................................................24

Commands.............................................................................................................................................25

APPENDIX................................................................................................................................................26

Theoretical considerations...................................................................................................................26

Shielding .............................................................................................................................................26

Grounding ..........................................................................................................................................26

Membrane capacitance calculations...................................................................................................28

Suggested References ...........................................................................................................................29

Specifications.........................................................................................................................................30

Chloriding electrodes ...........................................................................................................................32

Techniques for chloriding silver wires................................................................................................32

Accessories and replacement parts.....................................................................................................33

Warranty...............................................................................................................................................33

Service....................................................................................................................................................33

Service notes.......................................................................................................................................33

Certifications.........................................................................................................................................35

Glossary.................................................................................................................................................38

BC-535 Preliminary, Rev. 060126

The Warner BC-535 Bilayer Clamp Amplifier is a resistive-feedback voltage clamp amplifier

designed specifically for applications using planar lipid bilayer membranes. The unique circuitry and

dedicated design of this amplifier allows Warner to present an instrument of broad capability and

superior quality at a cost significantly below that of our competitors.

The operational range of the

BC-535 has been enhanced by the introduction of dual feedbackresistor circuitry within the headstage. This enhancement allows the amplifier to comfortably pass

currents of up to 2 nA while preserving the sub-pA sensitivity of the instrument. In addition, the range

of the digital hold control has been extended to 400 mV for internally generated commands and the

amplifier supports up to 1 V at the external command input, for a sum capability of 1400 mV hold

potential.

The remaining functionality of the BC-353 is built on the renown capabilities of the BC-525D and

includes junction potential auto-zeroing, a unique multi-step, digital hold potential circuit, audio

monitoring of membrane formation, and direct readout of the membrane capacitance.

Features of the BC-353 include

9 Dedicated design for bilayer applications

9 Digital, multi-step hold potential control

9 Hold potentials to ±1400 mV

9 Currents to ±2000 pA

9 Input offset with Auto-Zero

9 Direct membrane capacitance measurement

9 Low-pass 4-pole Bessel filter

9 Audio output

9 Capacitance compensation circuitry

THIS EQUIPMENT IS NOT DESIGNED NOR INTENDED

FOR USE ON HUMAN SUBJECTS

BC-535 Preliminary, Rev. 060126 5

NOMENCLATURE

Text conventions

This manual refers to amplifier controls at three functional levels; control blocks, specific controls

within a block, and settings of specific controls. To reduce confusion, we have employed several text

conventions which are specified below. Since our goal is to provide clarity rather than complexity, we

welcome any feedback you may wish to provide.

¾ Warner Instrument product numbers are presented using

¾ References to instrument panel control blocks are specified using

¾ References to specific controls within a block are specified using

bold type.

UNDERLINED SMALL CAPS.

NON-UNDERLINED SMALL CAPS.

¾ Finally, references to individual control settings are specified in italic type.

¾ Special comments and warnings are presented in highlighted text.

Any other formatting should be apparent from context.

Device panel abbreviations

The BC-353 has several abbreviations on the front panel. They are listed here for quick

reference. In addition, these and other terms are collected and incl uded in a Glossary at the back of

this manual.

Term Meaning Section

Vc command voltage METER, OUTPUTS

Im output current METER, OUTPUTS

CMD IN commend in

CAP TEST capacitance test METER

CAP COMP capacitance compensation CAP COMP

Warner

A Harvard Apparatus Company .

Instruments

BC-535 Preliminary, Rev. 060126 6

CONTROL DESCRIPTION

The instrument front panel is divided into six control blocks titled HOLD, OFFSET, METER, OUTPUTS,

CAP COMP, and POWER. The instrument rear panel has BNC connectors for the GAIN and FILTER

, I

TELEGRAPHS

connector (for the headstage), a 15 pin D connector, binding posts for

OUTPUT, CAP SYNC, MEMBRANE CAPACITANCE, and EXTERNAL COMMAND IN. A 9-pin DIN

M

CIRCUIT and CHASSIS GROUND,

and a SPEAKER OUTPUT are also located on the rear panel.

Front panel

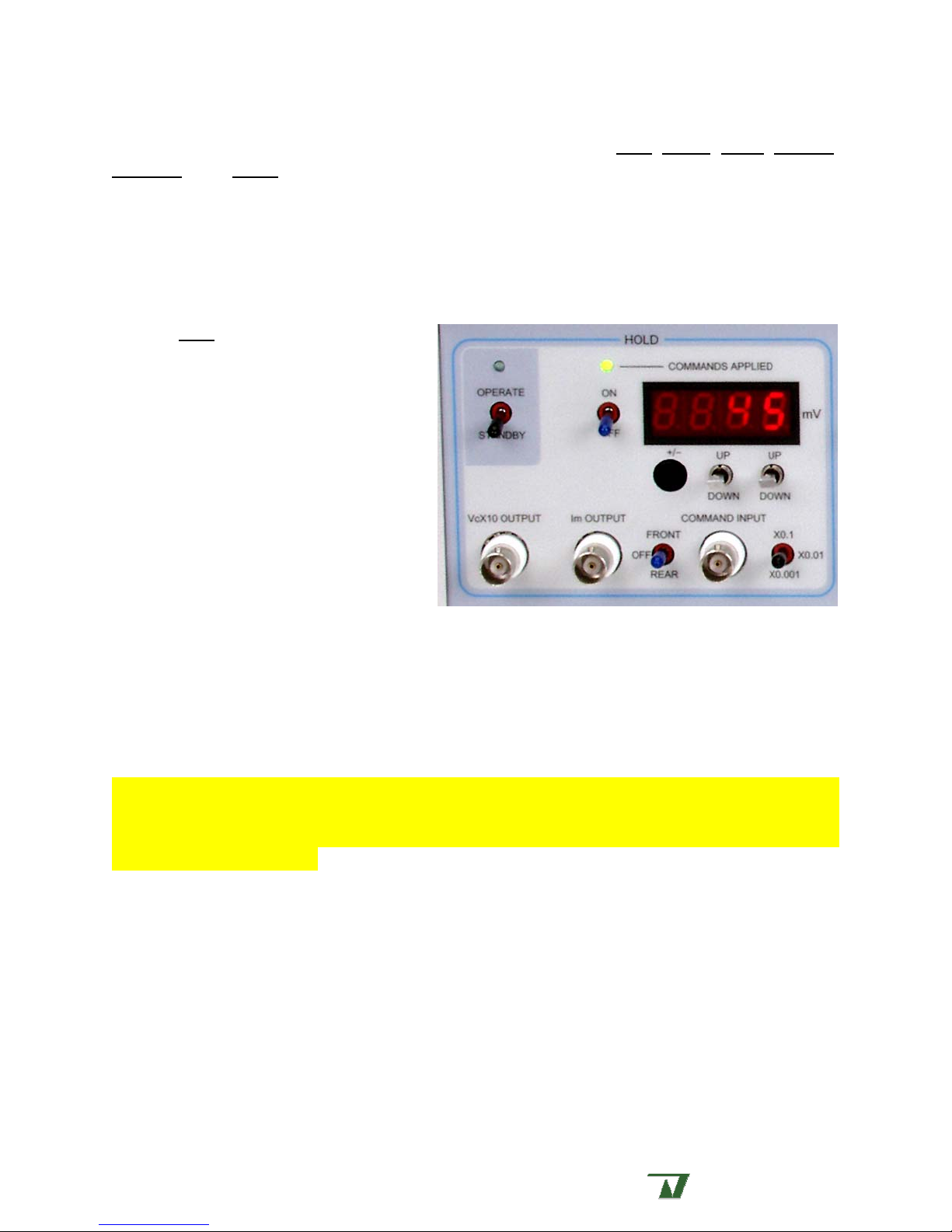

Hold

The HOLD block contains a meter and

controls for the application of internal or

external V

The appropriate membrane holding

potential is achieved by summing the

selected

external) with the

which results in a corrected transmembrane

voltage. An LED indicates

APPLIED to the headstage.

HOLD commands.

m

HOLD voltages (internal plus

INPUT OFFSET voltage

COMMANDS

The internal

HOLD control is comprised

of a digital circuit providing discrete

adjustment of the command potential. Two toggle switches directly below the

COMMANDS APPLIED

meter are used to step the applied command by ± 10 or ± 1 mV, respectively. A black push button is

used to quickly swap the polarity of the applied holding potential. The maximum range for this control

±

400 mV.

is

The internally generated

ON/OFF TOGGLE SWITCH to the right of the meter.

HOLD command can be disabled by selecting the off position on the

Note: The METER will still display the programmed hold voltage when the ON/OFF TOGGLE SWITCH is

selected to off. However, the programmed command will not be applied and the COMMANDS APPLIED

LED will remain unlit. This feature allows the user to select or change the holding potential wi thout

applying it to the membrane.

The V

This output reports the sum of potentials from V

x 10 OUTPUT monitors the voltage command applied to the headstage mul tiplied by 10.

c

HOLD, CMD IN, and PULSE GENERATOR. Connection is

m

made via BNC’s located on both the front and rear panels of the amplifier.

The I

output BNC’s are located on both the front and rear panels of the instrument.

I

m

External commands are applied to the amplifier via the

on both the front and rear panels. The

OUTPUT reports the membrane current modified by ampli fier gain and/or internal filtering.

m

COMMAND INPUT BNC connectors located

FRONT/REAR TOGGLE SWIT CH either disables all external input or

selects the location for command inputs. Selectable attenuation values are x0.1, x0.01, or x0.001.

Externally generated

COMMAND INPUTS are summed with the internally generated HOLD voltage.

Warner

A Harvard Apparatus Company .

Instruments

BC-535 Preliminary, Rev. 060126 7

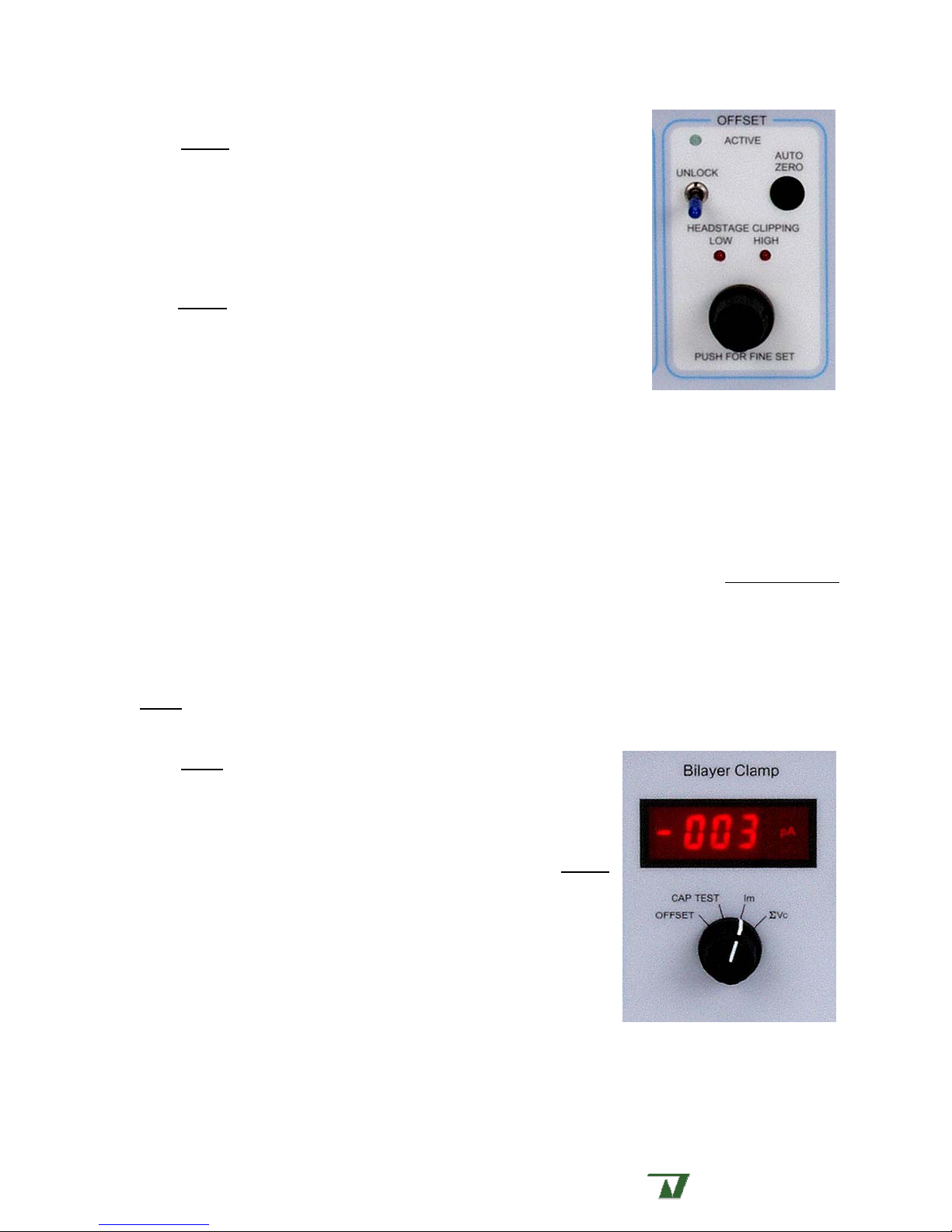

Offset

The OFFSET block contains the INPUT OFFSET and the AUTO-ZERO

controls.

The

INPUT OFFSET section is comprised of a rotary potentiometer with

low/high LED’s, the

ACTIVE LED. This section is used to compensate for junction potentials

produced by dissimilar solutions or other electrode potential differences.

The OFFSET circuit (AUTO-ZERO and OFFSET CONTROL) must be armed

prior to use. Thi s is achieved by use of the

of the momentary-on style and is operated by an upward movement.

When the circuit is armed the

can then be easily achieved by use of the

POTENTIOMETER. The circuit can be disarmed by a second movement of the UNLOCK TOGGLE.

The

AUTO-ZERO control provides the most direct means for setting the junction potential. When

armed, pressing the pushbutton initiates a cycle wherein the amplifier searches for and sets the offset

potential. The offset circuit is automatically disarmed at the completion of the cycle. Cycle time is

approximately 1 s.

AUTO-ZERO pushbutton, the UNLOCK toggle, and an

UNLOCK TOGGLE. This toggle is

ACTIVE LED will be lit. Offset adjustments

AUTO-ZERO control or ROTARY

ROTARY POTENTIOMETER is used to provide manual adjustment of up to ±120 mV at the

The

headstage input. Manual adjustment is only available when the offset circuit is armed.

of the rotary control can be achieved by pressing the control in while turning.

provided to indicate which direction the manual

offset control should be adjusted to achieve a null

Fine adjustment

Low/high LED’s are

junction potential setting. The offset circuit must be manually disarmed when using this control.

In both cases, the applied OFFSET potential can be monitored on the METER by selecting OFFSET in

METER block.

the

Meter

The METER block contains a 3.5 digit LED METER and a four

position switch for selecting

voltage command (ΣV

Selection of

headstage via the

c

OFFSET displays the potential applied to the

MANUAL or AUTO-ZERO control located in the OFFSET

OFFSET, CAP TEST, current output (I

).

block. Offset potential is displayed in units of pA. Alternatively, this

display indicates the potential required to bring I

to zero when the

m

command input is set to zero.

Selection of

CAP TEST places the instrument into capacitance test

mode. This useful mode dynamically tests and reports the membrane

capacitance. Capacitance values are reported on the meter in units of

pF. A rear panel BNC also reports the calculated membrane capacitance whenever

selected. Reported units are 1 mV/pF.

), or

m

CAP TEST is

Selection of Im displays the value of the DC current presented at the Im OUTPUT BNC. The meter is

capable of displaying currents up to ±1999 pA.

Warner

A Harvard Apparatus Company .

Instruments

BC-535 Preliminary, Rev. 060126 8

Selection of ΣVc displays the sum of all command voltages (Vm HOLD and COMMAND INPUT) applied

to the headstage. The meter is capable of displaying command voltages up to ±1999 mV. The meter

displays DC values and will average AC signals or pulses.

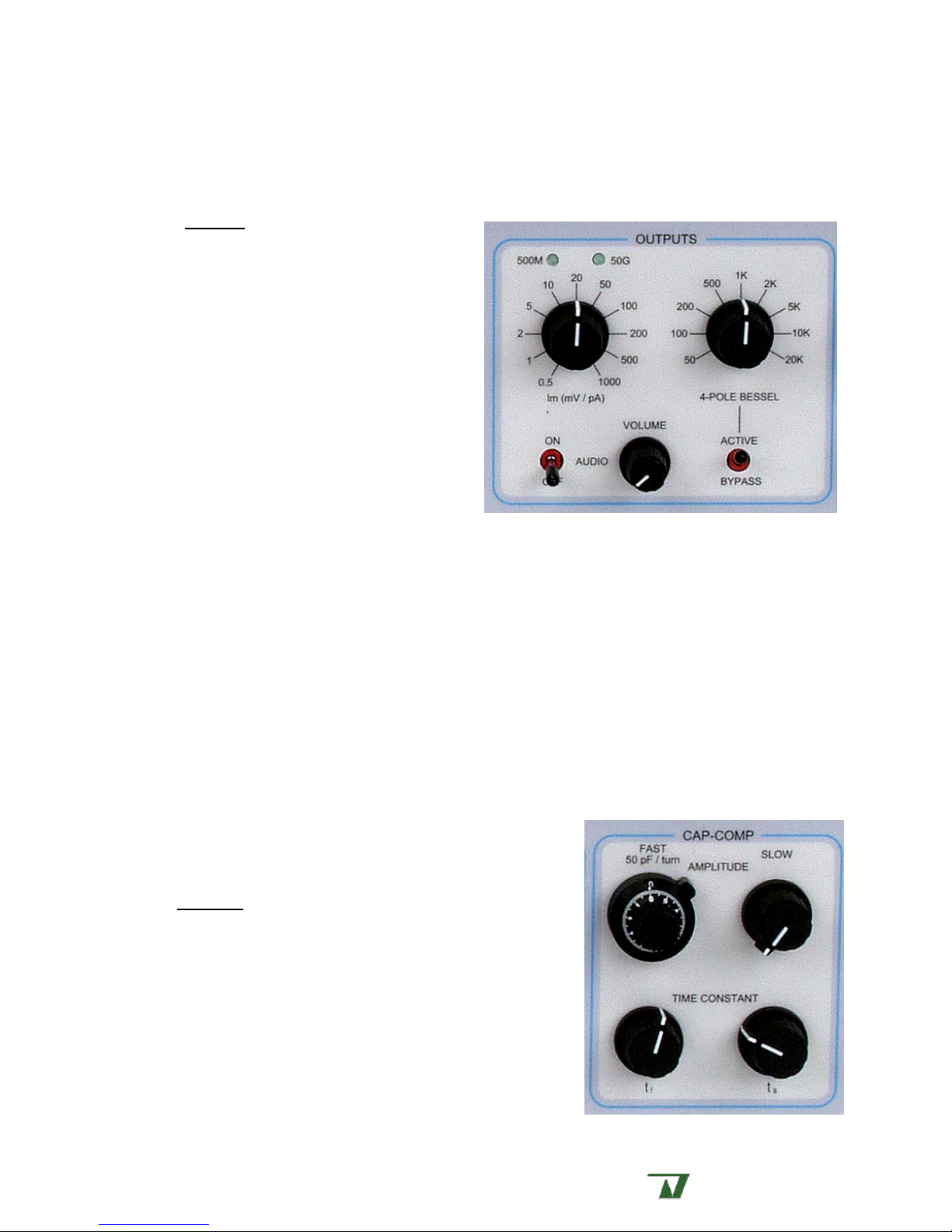

Outputs

The OUTPUTS block contains controls for

selecting the I

filtering using the built-in 4-pole Bessel filter. This

block also contains the audio output controls.

Amplifier gain is selected via an 11 position

selector switch. Gain settings are from 0.5 to

1000 mV/pA in 1-2-5 steps. For transmission to

external devices, the selected gain setting appears

as a defined voltage at the

on the instrument rear panel.

Internal filtering of the Im signal is selected

via a 9 position selector switch. Filter settings are

from 50 Hz to 20 kHz in 1-2-5 steps. A

TOGGLE switch bypasses the 4-pole Bessel filter and presents the full bandwidth (75 kHz) of the

amplifier at the I

selected filter setting appears as a defined voltage at the

rear panel.

GAIN of the amplifier and signal

m

GAIN TELEGRAPH BNC

BYPASS

OUTPUT. Filtering is applied post-gain. For transmission to external devices, the

m

FILTER TELEGRAPH BNC on the instrument

The AUDIO section is comprised of an on/off toggle and volume control. Audio output is useful

during membrane formation to monitor the successful application of lipids. An open hole prior to

membrane formation produces a characteristic low frequency sound while the same aperture with

membrane produces a different characteristically higher frequency sound. The pitch of the signal is

keyed to the membrane capacitance and will increase as the capacitance increases allowing non-visual

monitoring of membrane ‘thinning’.

Capacitance compensation

The capacitance compensation circuit allows for cancellation

of large currents (capacity currents) generated when a step

potential is applied to the bilayer membrane.

CAP COMP block contains controls for the adjustment of

The

AMPLITUDE and TIME CONSTANT for both FAST (0-10 µs) and SLOW

(0-10 ms) components of the current. The adjustment is made

in pairs, that is, the

first adjusted to minimize the transient, followed by adjustment

of the

SLOW pair. Each pair is adjusted in turn as many times as

required to completely minimize the transient.

AMPLITUDE control for the FAST component is a ten turn

The

potentiometer with a counting dial and can be used to provide a

FAST pair (AMPLITUDE and TIME CONSTA NT) is

Warner

A Harvard Apparatus Company .

Instruments

BC-535 Preliminary, Rev. 060126 9

reading of the capacitance in pF. The dial is calibrated to 50 pF/turn.

Power

Immediately adjacent to the CAP COMP block is the master power switch for the

BC-535. An LED indicates power on status.

Rear panel

The instrument rear panel has BNC connectors for GAIN and FILTER TELEGRAPHS, I

OUTPUT, CAP SYNC, EXTERNAL RESET IN, and EXTERNAL COMMAND IN. A 9-pin DIN

connector (for the headstage), a 15 pin I/O

CHASSIS GROUND, and a SPEAKER OUTPUT are also located on the rear panel.

INTERFACE, binding posts for CIRCUIT and

M

The photo below shows the various attachment points on the instrument rear panel. Connections

are described right-to-left.

Headstage

The HEADSTAGE is housed in a small aluminum enclosure and connects to the amplifi er via a 1.8 meter

cable. A 9-pin DIN connector is provided for this attachment.

Note: When routing the headstage cable from your Faraday cage to the instrument, we recommend

intertwining the headstage and ground cables to minimize ground loops.

Circuit and chassis grounds

CIRCUIT and CHASSIS GROUND binding posts are provided at the rear of the amplifier to allow

modification of instrument grounding.

The CHASSIS GROUND binding post is internally connected to the green-wire ground of the power

plug. Therefore the instrument does not normally require a separate ground. However, it may becom e

necessary to independently ground the chassis of the

and not incorporated into a rack.

The CIRCUIT GROUND binding post allows external connection to the internal ground circuitry of

the amplifier. This post is used to provide a common circuit ground point for all active components

(Faraday cage and contents, SUNStir-3 assembly, temperature controller, etc.) withi n the bilayer rig,

thus preventing ground loops.

In general, the internal circuitry of the

connected to chassis ground. However, when necessary, the

to tie the circuit and chassis grounds to a common potential. This is the default configuration when the

instrument is shipped from the factory.

BC-535 when it is used as a freestanding devi ce

BC-535 maintains a virtual ground and is not normally not

CIRCUIT GROUND binding post can be used

Warner

A Harvard Apparatus Company .

Instruments

BC-535 Preliminary, Rev. 060126 10

Note: We recommend separating the circuit and chassis grounds by di sconnecting the bridging bar

between the associated ground posts. Loosen the posts and slide the bridge to one side.

Gain Telegraph

The GAIN TELEGRAPH i s a stepped voltage output designed to communicate the instrument gain

setting to your acquisition software. DC voltages are stepped from 0.0 V to 5.5 V, in steps of 500 mV.

GAIN TELEGRAPH voltage outputs for the associated amplifier I

settings are selectable in the front panel

Gain (mV/pA) Gain Telegraph (V)

I

m

standby 0.0

0.5 0.5

1 1.0

2 1.5

5 2.0

10 2.5

20 3.0

50 3.5

100 4.0

200 4.5

500 5.0

1000 5.5

OUTPUTS block, see page 8)

GAIN are specified below. (Im GAIN

m

Filter Telegraph

The FILT ER TELEGRAPH is a stepped voltage output designed to communicate the instrument filter

cutoff frequency setting to your acquisition software. DC voltages are stepped from 0.5 V to 5.0 V, in

steps of 500 mV and are specified below. (

block, see page 8)

Filter Frequency (Hz) Filter Telegraph (V)

50 0.5

100 1.0

200 1.5

500 2.0

1k 2.5

2k 3.0

5k 3.5

10k 4.0

20k 4.5

bypass 5.0

FILTER settings are selectable in the front panel OUTPUTS

Warner

A Harvard Apparatus Company .

Instruments

BC-535 Preliminary, Rev. 060126 11

Im output

The Im OUTPUT signal present on the instrument front panel is mirrored on this rear panel BNC.

Use of this output rather than the front panel BNC can unclutter your work environment.

External Command In

External COMMAND IN signals can be input via BNC connectors on either the instrument front

panel or the instrument rear panel. Input location is selectable by the front/rear

toggle switch located in the

HOLD control block on the instrument front panel. Use of the rear input

COMMAND INPUT

can unclutter your work environment.

Capacitance Output

The calculated membrane capacitance is output on this BNC when the instrument is in CAP TEST

mode. Switching the

METER selector switch to CAP TEST activates the CAP TEST circuit. This feature is

useful for recording the calculated membrane capacitance into a chart recorder or data acquisition

system. Capacitance output values are 1 mV/pF.

Cap Sync Out

This signal is used to synchronize an oscilloscope or other device with the BC-535 when using the

CAP TEST function. The SYNC OUT signal is keyed to the peak of the triangular wave for CAP TEST which

corresponds to the leading edge of the resulting square wave. The

square wave and is 100 µs in duration.

SYNC OUT signal is a standard TTL

External speaker

A standard ¼” RCA jack is provided for attachment to an external speaker for use in

environments where the ambient noise exceeds the volume capabilities of the internal speaker.

ADDITIONAL INFORMATION

Headstage connections

The HEADSTAGE is housed in a small aluminum enclosure and connects to the amplifier via a 1.8

meter cable. Electrode connections are made to two 1 mm mini-jacks marked

(reference). A third mini-jack (

GND; circuit ground) is located on the side of the headstage for

connecting to shields or grounding equipment.

The ground connection on the headstage merits specific discussion. The headstage case is

internally connected to the command potential (

INPUT electrode) of the headstage. As a result, the

headstage does not require a separate ground. However, the isolated grounding jack on the headstage

is provided as a means to ground a small Faraday cage through the headstage if the user desires.

Notes:

1. If the Faraday cage is grounded through the headstage (not recommended), then do not run

a separate ground connection from the Faraday cage to any other ground point.

2. Do not connect the ground on the headstage to either the input or ref electrode as this will

disable the amplifier.

INPUT and REF

Warner

A Harvard Apparatus Company .

Instruments

BC-535 Preliminary, Rev. 060126 12

Model membrane

The BC-535 is shipped with a model membrane, the MC-1, which can be used to test the

performance of the amplifier. The

resistor. The precision of this resistor is ± 5%.

MC-1 connects to the two 1 mm mini-jacks on the headstage marked INPUT and REF. The

The

green grounding wire on the

MC-1 contains a 100 pF capacitor connected in parallel with a 1 GΩ

MC-1 is attached to the isolated grounding jack on the headstage.

Warner

A Harvard Apparatus Company .

Instruments

BC-535 Preliminary, Rev. 060126 13

SETUP

For those with little experience in bilayer work, we suggest a review of Ion Channel

Reconstitution edited by C. Miller, Plenum Press, New York, 1986. In particular, Chapter 5, "How To

Set Up A Bilayer System", covers many important aspects of the subject. Several other pertinent

references are included in the appendix at the back of this manual.

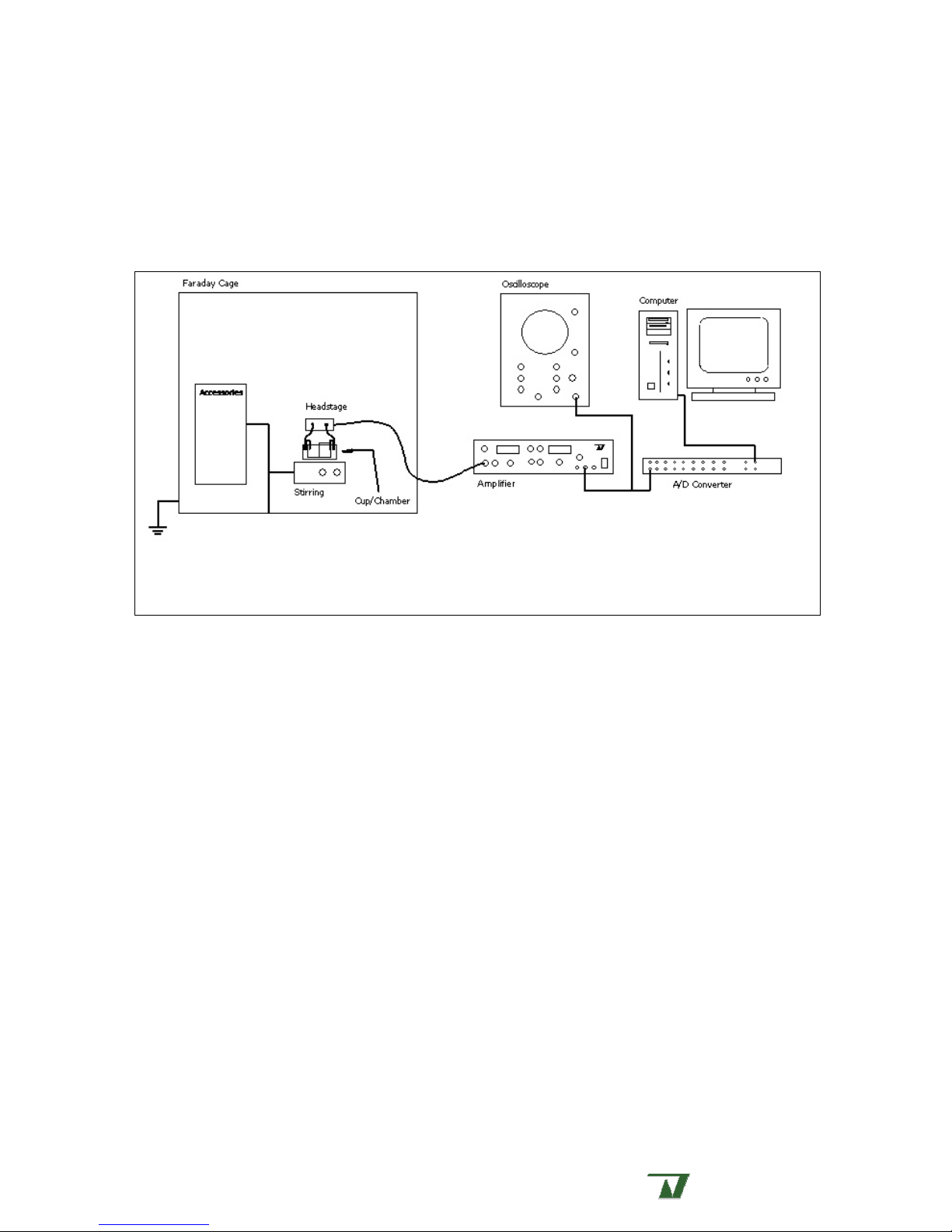

Figure 1. Schematic representation of a BLM setup.

Basic design

A planar lipid bilayer (BLM) workstation, used to record currents through actively gating, ion

conducting single channels, is a complex apparatus requiring several components working in concert.

These components include a means to support the lipid membrane, high gain amplification, shielding

of electromagnetic interference, shielding of mechanical vibration, mechanisms for stirring and

changing solutions, signal filtering, data acquisition analysis, and a means to archive acquired data.

A schematic representation of a basic BLM layout is shown in Figure 1. Warner Instruments

provides all components used in the assembly of a BLM workstation, including Faraday cages,

vibration isolation tables, a dedicated bilayer clamp amplifier, high quality signal filtering devices,

illumination and stirring mechanisms, cups and chambers, and perfusion apparatus.

The components listed above may be assembled in various ways to achieve a working system.

Regardless of the configuration used, care must be taken in the design of a BLM workstation to

minimize both mechanical and electrical noise sources since single channel currents are often only a

few pA in magnitude. In this section we describe the basic design of a BLM workstation.

Faraday cage

A Faraday cage is an enclosure designed to shield the sensi tive electronics in the h eadstage from

electromagnetic interference generated by noise sources in the vicinity of the apparatus. These

sources include exterior lighting, nearby instrumentation and electrical wiring. The cage can be

fabricated from any conducting material and is grounded. While the design of the

BC-535 facilitates

Warner

A Harvard Apparatus Company .

Instruments

Loading...

Loading...