Page 1

Electromagnetic Particle Clutches

Models: PMC-10A3, PMC-20A3, and PMC-40A3

P-223-2

819-0369

Installation Instructions

Page 2

2

Warner Electric • 800-825-9050 819-0369

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation Instructions . . . . . . . . . . . . . . . . . .2

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . .4

Mechanical Data . . . . . . . . . . . . . . . . . . . . . . .4

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . .5

PMC-10 and 20 Dimensions . . . . . . . . . . . .5-6

PMC-40 Dimensions . . . . . . . . . . . . . . . . . . . .7

Warranty . . . . . . . . . . . . . . . . . . . . .Back Cover

Introduction

This service manual provides information

required for the installation, wiring, and maintenance of Warner Electric's Magnetic Particle

Micro Clutch series. It also includes dimensions

and specifications. The three models covered in

this service manual are PMC-10A3, PMC-20A3,

and PMC-40A3. These models with their flanged

input hubs, also lend themselves to be mounted

as brakes. For selection information, please refer

to your Warner Electric Tension Control Systems

Catalog.

Warner Electric's Magnetic Particle clutches

provide smooth and controllable torque for a

variety of applications, including tension control,

cycling, and positioning. Quick response is

achieved by applying full rated voltage. Lower

voltage can be applied for softer engagements.

Extremely accurate tension control can be

achieved when these brakes are used with one

of Warner Electric's wide range of tension controls for electric clutches.

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Installation Instructions

Introduction

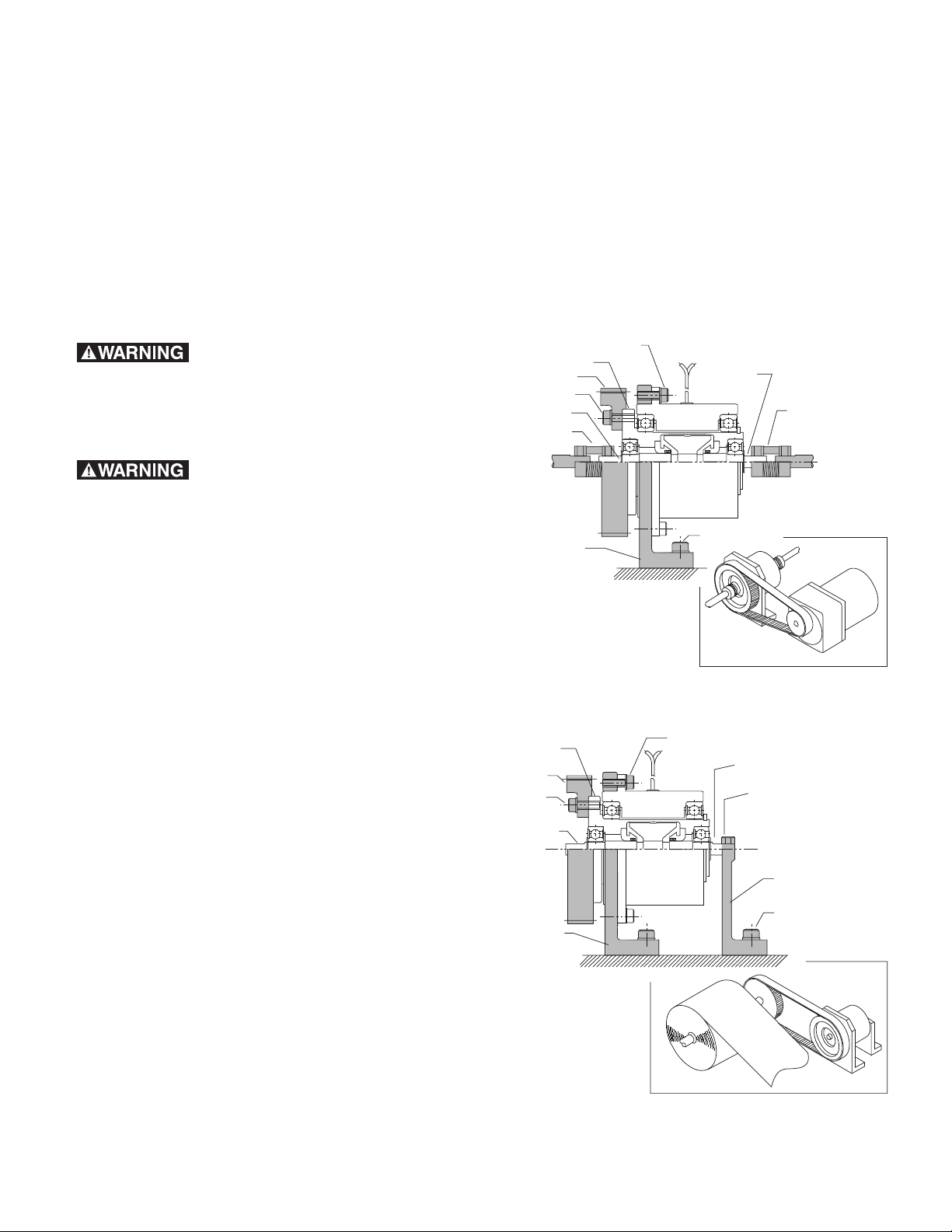

The design of the PMC-A3 series clutches

makes them easy to mount in various configurations. They have a mounting flange on the outside diameter of the housing. The input is a

flanged hub, which is concentric to the double

ended output shaft. See Figure 1 for typical

mounting. To use the PMC-A3 as a brake, the

output shaft must be secured. See Figure 2.

Make sure all power is turned

off to this equipment when installing, as

injury (or even death) may result from contact

with live wires or rotating shafts.

Mounting bracket

Mounting bracket

Capscrews

Socket

head cap

screws

Set screws

Input hub

Timing pulley

Output shaft

Capscrews

Output shaft

Socket

head cap

screws

Input hub

Timing pulley

Output shaft

Capscrews

Flexible

coupling

Mounting

Bracket

Capscrews

Flexible

coupling

Output shaft

Figure 2* - Mounted as a brake

*Note: Shaded items are customer supplied

Figure 1* - Mounted as a clutch

Page 3

3

Warner Electric • 800-825-9050 819-0369

Pre-Mounting

Note: Unit performance can be affected by

prolonged exposure to humid environments.

Please store in a dry location.

Note: The equipment covered by this service

manual must be installed in accordance with

these instructions. Failure to do so may damage the equipment and void the warranty.

1. Remove the magnetic particle clutch from its

shipping carton and inspect it thoroughly to

ensure that it has arrived in good condition.

When handling, please take care not to damage lead wires.

2. Check the input hub to make sure it turns

freely when the output shaft and housing are

held stationary. The powder inside the unit

may settle due to shock and vibration caused

during shipping. This can make rotation

noticeably difficult and can be easily remedied by turning the unit upside down and

gently tapping the outside to loosen the powder.

3. Make sure the location chosen for mounting

will not expose the unit to water or oil. If

water or oil gets into the powder cavity, the

performance of the unit may be affected. If

the unit is mounted next to a gearbox, special care should be taken to prevent oil from

working its way into the unit.

4. If couplings are used to make drive system

connections, the mounting surface must

properly locate the housing to ensure that

alignment is within the coupling manufacturer's specifications.

Mounting

Note: Do not use excessive force when mount-

ing couplings, pulleys, or sprockets on shafts.

Note: For proper function, mount magnetic

particle units horizontally.

For mounting dimensions, please refer to pages

5-7 of this service manual.

As A Clutch

Step 1: Bolt Unit in Place

Mount the unit to a vertical surface, using customer supplied fasteners. See Figure 1.

Step 2: Make Mechanical Connections

Mount couplings, pulleys, or sprockets to the

male shafts per the manufacturer's recommendations. The pulleys, sprockets, couplings,

mounting brackets, and bolts are customer supplied. (The output shaft can be used as the input

and the input hub as the output, but the output

inertia will be higher.)

As A Brake

Step 1: Bolt Unit Into Place

Secure the mounting flange and the output shaft

as shown in Figure 2. Take care to insure that

alignment is true and there is no binding in the

bearings.

Step 2: Mount Pulley, Sprocket, or Coupling

Bolt the pulley, sprocket, or coupling to the

input hub of the unit. The pulleys, sprockets,

couplings, mounting brackets and bolts are customer supplied.

Page 4

Mechanical Data

Drag Maximum Inertia

Unit Part Torque Torque Speed Input Output Weight

Number (lb. in.) (lb. in.) (rpm) (in. lb.2) (in. lb.2) (lbs.)

PMC-10A3 5401-270-111 8.6 .25 1800 .239 .0291 2.0

PMC-20A3 5401-270-121 17 .51 1800 .413 .0752 2.9

PMC-40A3 5401-270-131 34 1.0 1800 1.14 .372 5.5

4

Warner Electric • 800-825-9050 819-0369

Electrical Connections

To avoid injury (or even death),

always make certain all power is off before

attempting to install or service the control or

any electrical equipment.

The PMC-A3's operate on DC voltage. Warner

Electric offers a full line of AC powered controls

to meet the needs of almost every application.

The service and installation instructions included

with each Warner Electric control show the

proper electrical connections.

After wiring your Magnetic Particle unit, confirm

that the control circuit is functioning. Without

rotating the input shaft, verify that voltage is

applied when the control output is turned on.

Also, if appropriate, set the current for the proper output. Your magnetic particle unit is now

ready for operation. For information on start up

and maintenance, see page 4 of this manual.

Electrical Data

Electrical Coil Data

To rque Torque

Unit Size Voltage Resistance Amperes Watts Build Up Decay

[ohms @ 75°F (25°C)] [@ 75°F (25°C)] [@ 75°F (25°C)] (msec) (msec)

10 24 35.1 0.684 16.4 20 8

20 24 31.6 0.760 18.2 30 10

40 24 26.3 0.912 21.9 40 12

Note: Build up time equals time for torque to build to approximately 63.2% of steady state value

after a step change in voltage. Decay time equals time for current to drop to approximately 36.8%

of the steady state value after a voltage change.

Start Up

The powder in the magnetic particle units sometimes settles during shipment and will need to

be redistributed. A simple run-in procedure

should be performed to ensure proper performance.

Run in Procedure

Notes: 1. Before running in, make sure the unit

does not bind. See step 2 of the premounting instructions.

2. If mounted as a clutch, the output

shaft must be locked to prevent it

from turning.

Set the control output voltage for 5 to 6 volts.

Turn off the control and run the input for one

minute. Run at a speed close to, but not

exceeding 1000 RPM. Then cycle the unit at 5

or 6 volts for five seconds and off for ten seconds. Repeat this for 20 cycles.

When the powder is redistributed properly, the

torque will be consistent and proportional to

current.

Page 5

5

Warner Electric • 800-825-9050 819-0369

Maintenance

Heat

Make sure your unit does not overheat. This

occurs when the heat generated is greater than

the heat dissipation capability of the unit. The

maximum allowable surface temperature for the

PMC-A3 series unit is 167° F.

Slip Applications

With most controls, torque is easily adjusted.

However, care must be taken when adjusting

torque to make sure that too much heat is not

generated in the unit. The heat generated is proportional to torque and slip rpm. Refer to the

sizing procedure in the catalog to make sure the

unit has adequate heat dissipation capability.

Also, do not increase the slip speed or the

torque without verifying that the unit can dissipate the heat.

Cycling Applications

In cycling applications, the speed and inertia of

the load and the cycle rate determines the heat

generated. Refer to the selection procedure in

the catalog to verify that the unit can handle the

thermal energy generated in your application.

Also, do not increase the speed, cycle rate, or

inertia without checking the units ability to dissipate the heat generated.

Contamination

Do not expose the unit to water or oil. If water

or oil gets into the powder cavity, the performance of the unit may be affected. If the unit is

mounted next to a gearbox, special care must

be taken to prevent oil from working its way into

the unit.

PMC-10A3 and PMC-20A3 Dimensional Data

Note: All dimensions are nominal unless otherwise noted.

Model A B C D E F G H I J K L M N

mm mm mm mm mm mm mm mm mm mm mm mm mm mm

(in.) (in.) (in.) (in.) ((in.) (in.) (in.) (in.) (in.) (in.) (in.) (in.) (in.) (in.)

PMC-10A3 58 77 14 4 15 12 12 8 6 10 10 51 76 30

(2.28) (3.03) (0.55) (0.16) (0.59) (0.47) (0.47) (0.31) (0.24) (0.39) (0.39) (2.01) (2.99) (1.18)

PMC-20A3 69 116 33 4 22 25 24 15 6 20 20 51 92 35

(2.72) (4.57) (1.30) (0.16) (0.87) (0.98) (0.94) (0.59) (0.24) (0.79) (0.79) (2.01) (3.62) (1.38)

Shaft Dimensions U V

PQRST

Thread Thread Bolt Hole Bolt

Size Depth Circle Size Circle

mm (in.) mm (in.) mm (in.) mm mm mm mm mm mm

(in.) (in.) (in.) (in.) (in.) (in.)

54.000

2.1260 58.000 2.2835 7.000 0.2756 6—M46464.5 68

53.970 2.1248 57.970 2.2823 6.985 0.2750 0.24 — (0.24) (1.81) (0.18) (2.68)

54.000

2.1260 69.000 2.7165 12.000 0.4724 11.5 11.5 M4 6 46 4.5 82

53.970 2.1248 68.970 2.7154 11.988 0.4720 (0.45) (0.45) (0.24) (1.81) (0.18) (3.23)

Page 6

6

Warner Electric • 800-825-9050 819-0369

Dimensions

Lead Wire

Length = 300mm

V

- 4 through holes

U

- 4 threaded holes

R

(11.8 inches)

T

S

Output shaftboth ends

Q

P

K

F

E

I

D

B

G

J

M

A

N

L

H

C

PMC – 10 & 20

Page 7

7

Warner Electric • 800-825-9050 819-0369

Lead Wire

Length = 300mm

4-ø 4.5 (0.18)

on a 100 (3.94) B.C.

(11.8 inches)

12.018

12.000

0.4731

0.4724

()

4-M4 T 6 (0.24) on a 60 (2.36) B.C.

112

(4.41)

Hollow output

shaft - both ends

86.000

85.965

3.3858

3.3844

()

70.000

69.970

2.7559

2.7547

()

20

(0.79)

4

(0.16)

59

(2.32)

86

(3.39)

50

(1.97)

97

(3.82)

21

(0.83)

8.7

(0.34)

10

(0.39)

22

(0.87)

4

(0.16)

15

(0.59)

6

(0.24)

PMC – 40

Dimensions

Page 8

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notied and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specic legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certied prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-223-2 819-0369 6/05 Printed in USA

Loading...

Loading...