Page 1

P-2016

ARC

ARC

Magnetic Capping Headsets

Service & Installation Instructions

An Altra Industrial Motion Company

Page 2

ARC Installation Procedure

Wrench ats

Customer

Supplied

Chuck

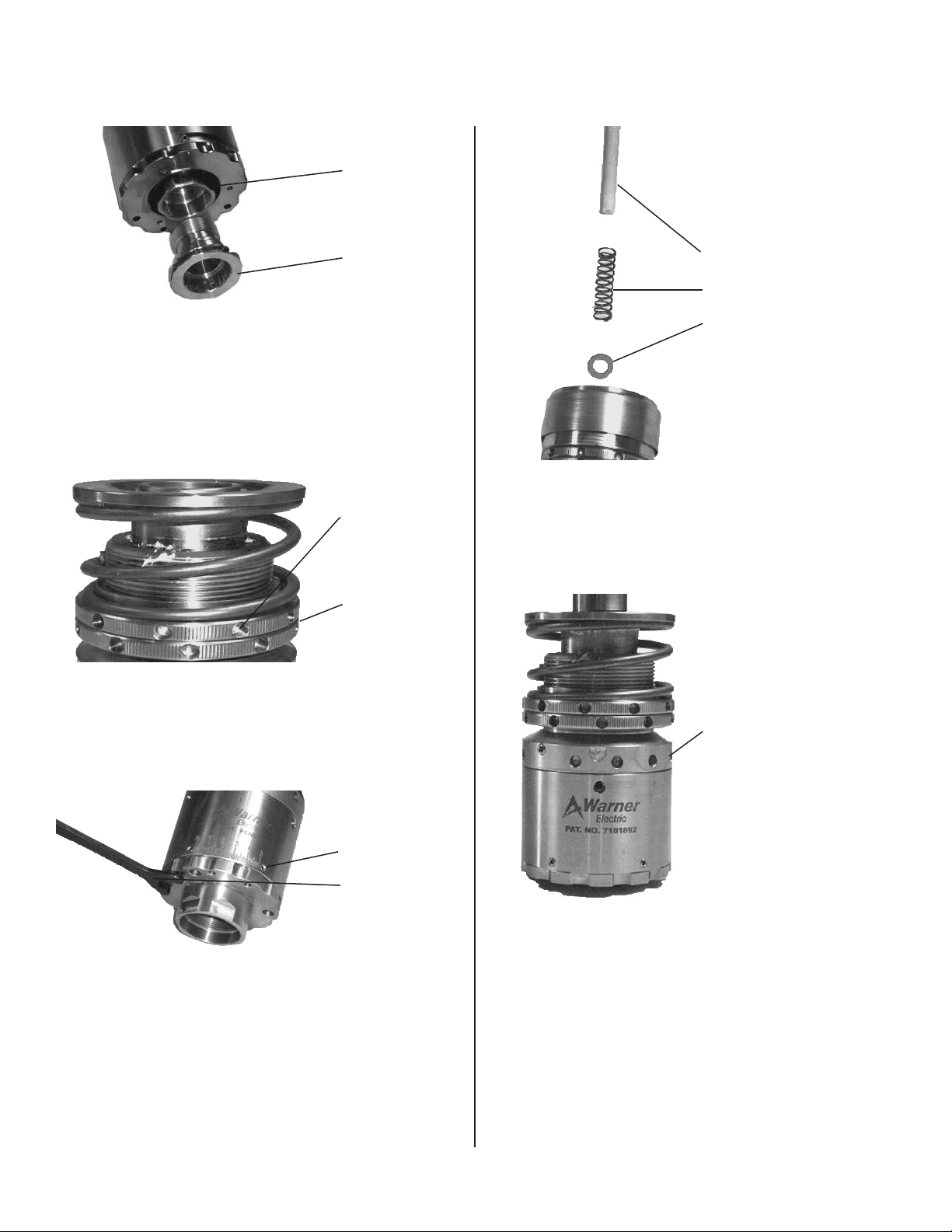

Figure 1

Install chuck (not supplied). Use appropriate openend wrench (YTL4-0009 or YTL4-0007) depending

on headset model to hold headset output.

See Figure 1.

Spanner

Holes

Jam Nuts

Figure 2

Knock-out Rod

Spring

Spring Seat

Figure 4

Apply anti-seize compound to spindle shaft.

Install spring seat and spring (not supplied) if

required. See Figure 4.

Set the top-load assembly using provided spring

setting chart. Lock the jam nuts using O.D. spanner

wrench (YTL3-0009). See Figure 2.

Set Screws

Face

Spanner

Wrench

Figure 3

Set the preliminary static torque using provided

torque setting chart. Loosen set screws with hex

key wrench, turn end cap with face spanner wrench

(YTL2-0002), tighten set screws to 8-10 lb-in. Over

tightening is not necessary and will strip the screws

or possibly damage the housing body. See Figure 3.

Spring Seat

Figure 5

Install headset on spindle. Turn onto threaded

spindle until headset is fully seated on spindle.

Tighten headset securely using O.D. Spanner

wrench (YTL3-0009). See Figure 5.

2 Warner Electric • 800-825-9050 P-2016 • ARC

Page 3

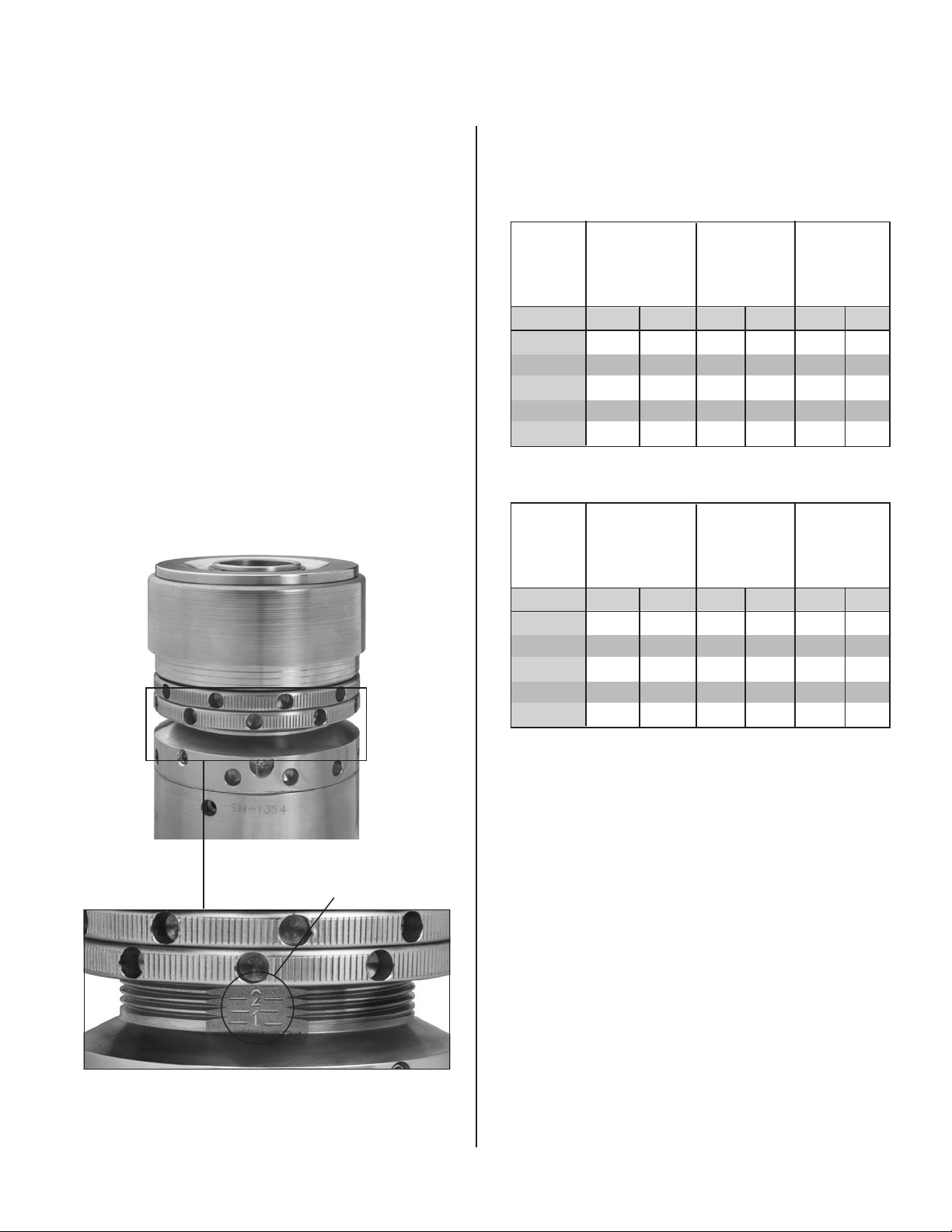

Setting Top Load Spring Force

1. Determine initial spring setting from spring

force chart below.

2. Compress the spring with the locking ring just

enough to allow the adjustment ring into its

correct setting.

3. Move the adjustment ring to the desired

setting. Bring the locking ring down and jam

the rings together with a spanner wrench.

4. For optimum results check download force

with a force scale.

5. Set headset on the scale and manually

compress the spring downward 5mm. Take

the force reading at this position. The lines on

the spring cover are .100” (2.5mm) apart, so

two lines equal the recommended .200” (5mm)

compression.

Top Load Spring Force

Setting Chart

Spring Force at 0.200” (5mm) Deection

Standard

Spring

Setting

lb Kg lb Kg lb Kg

1.0 34 15 24 11 50 23

1.5 39 18 27 12 58 26

2.0 44 20 31 14 66 30

2.5 49 22 34 15 73 33

Max 54 24 38 17 80 37

Spring

YTP1-0010

Plain

Spring Force at 0.100” (2.5mm) Deection

Standard

Spring

Setting

Spring

YTP1-0010

Plain

Low

Spring

YTP1-0003

Grey

Low

Spring

YTP1-0003

Grey

High

Spring

YTP1-0008

Black

High

Spring

YTP1-0008

Black

Top Load Settings

lb Kg lb Kg lb Kg

1.0 29 13 20 9 43 20

1.5 34 15 24 11 50 23

2.0 39 18 27 12 58 26

2.5 44 20 31 14 66 30

Max 49 22 34 15 73 33

NOTE: The charts above provide actual spring

loads without any added load due to the

weight of the headset. These spring loads are

valid for any headset. Not all headsets have

the full range of settings; some headsets do

not have a ‘3.0’ setting, other headsets do not

have ‘1.0’ or ‘1.5’ settings. The spring loads

are calculated at the given deection as listed

in the chart.

Figure 6

Warner Electric • 800-825-9050 P-2016 • ARC 3

Page 4

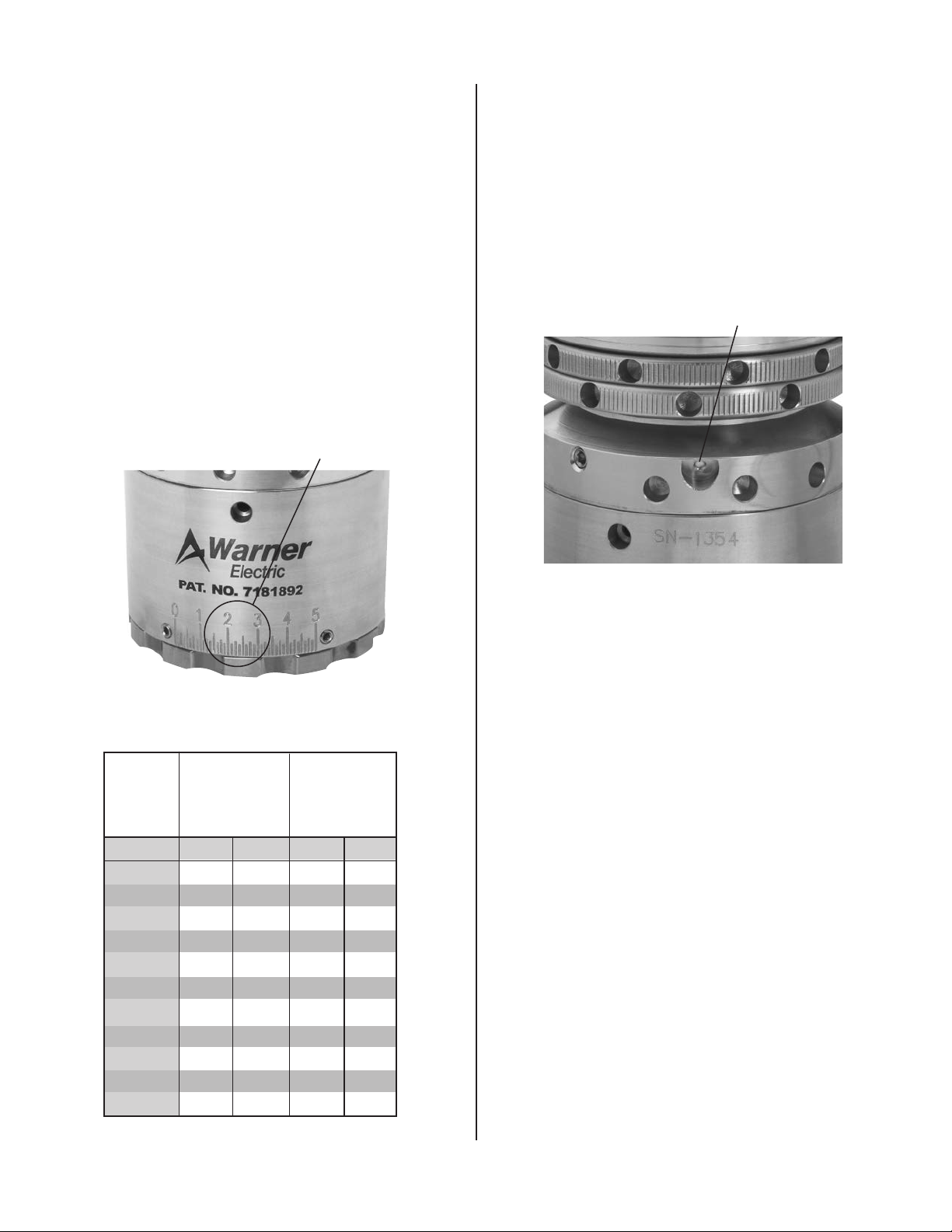

Setting Application Torque

1. Determine initial clutch setting from torque chart

below.

Recommended Maintenance

Schedule

Lubricate the upper assembly every 500

hours of run time.

2. Loosen the torque adjustment screws. Rotate the

adjustment ring using the face spanner wrench to

the desired setting and then retighten the torque

adjustment screws. Do not use the set screw in

the slot on the backside of the housing for torque

adjustment. Tighten set screws to 8-10 lb-in.

Over tightening is not necessary and will strip the

screws or possibly damage the housing body.

3. For optimum results, check setting with a torque

wrench and FIX-0007 or FIX-0010.

Application

Torque Setting

Figure 7

- Using a grease injector needle, apply lubricant

into the grease port.

- Recommended grease: No. 2 Food Grade

Grease

Grease Port

Figure 8

Disassemble, clean, and replace all wearing

parts in the headset every 7000 hours of

machine run time.

Application Torque Setting Charts

Application

Clutch

Setting

lb-in Ncm lb-in Ncm

0.00 2.00 22.5 2.5 28.2

0.50 3.50 39.5 4.0 45.2

1.00 5.00 56.5 5.0 56.5

1.50 8.50 96.0 8.5 96.0

2.00 10.50 118.6 11.0 124.3

2.50 13.50 152.5 15.0 169.5

3.00 16.00 180.7 18.5 209.0

3.50 17.50 197.7 22.0 248.5

4.00 18.50 209.0 24.0 271.1

4.50 19.00 214.6 25.5 288.1

5.00 19.50 220.3 26.0 293.7

Torque-Low

Inertia

Magnet

Application

Torque

(Ncm)

Standard

Magnet

- See rebuild instructions for detailed information

on disassembly and assembly of Warner

headsets.

- Dependent upon machine speed and

washdown procedure, some environments

may require more frequent rebuilds.

Rebuild Kits available:

• M4.5-BK (Bearing and Hardware Rebuild Kit)

• M4.5-MK (Magnet Rebuild Kit)

• M4.5-PK (Push rod Rebuild Kit)

• M4.5-TL (Replacement Top Load Assembly)

*Contact customer service for the exact kit part

number for your specific headset model.

4 Warner Electric • 800-825-9050 P-2016 • ARC

Page 5

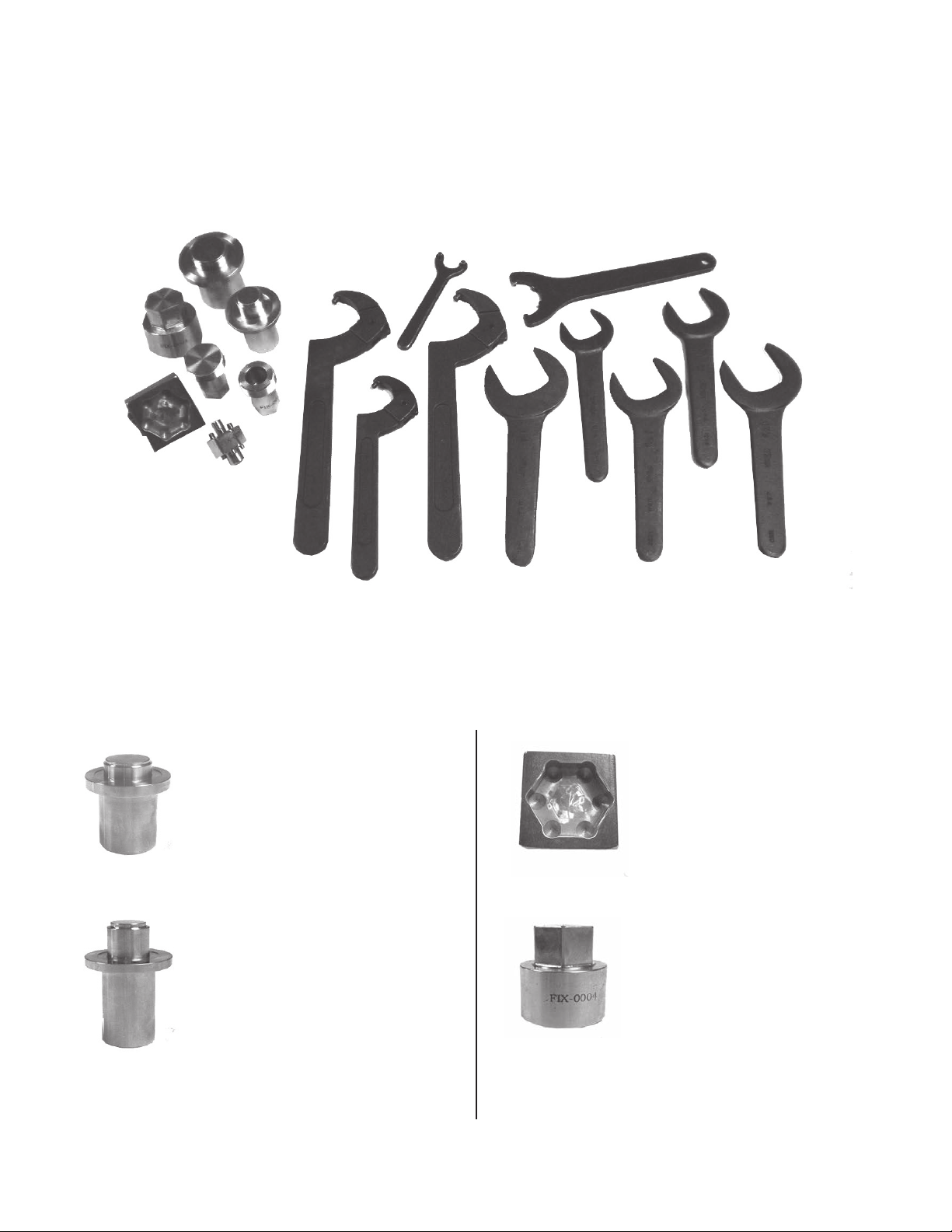

Installation Tools and Fixtures

FIX-0001 – Bearing installation

and removal fixture for the ZRC

style bearings.

FIX-0003 – Use to hold the

output of ARC style unit during

disassembly. Earlier revision levels

with a larger output dimension

Figure 10

Figure 12

FIX-0002 – Bearing installation

and removal fixture for the ARC

that will not fit in this fixture can

be clamped directly in a vice.

FIX-0004 – Upper assembly nut

removal fixture for ZRC style unit.

style bearing.

Figure 11

Warner Electric • 800-825-9050 P-2016 • ARC 5

Figure 13

Continued on page 6.

Page 6

Tool Kit Component Parts Cont.

Figure 14

Figure 15

FIX-0019 – Clutch nut removal

xture for some ZRC style units.

Not included in tool kits. May be

ordered on an as-needed basis.

FIX-0005 – Upper assembly nut

removal xture for ARC style

unit.

FIX-0007 – Torque checking

xture for some ARC models.

Figure 18

Figure 19

YTL3-0009 (Qty 2) &

YTL3-0008 – Adjustable

O.D. Spanner Wrenches

used for adjusting top load

and separating top load

and clutch body.

YTL4-0009, YTL4-0005,

YTL4-0008, YTL4-0010,

YTL4-0007 – Open end

wrenches used to install

and remove chucks

on several ARC & ZRC

models.

YTL2-0002 – Face

Spanner Wrench for

adjusting end cap and

setting static torque on

ARC & ZRC units.

Figure 16

Figure 17

FIX-0010 – Torque checking

xture for some ARC & ZRC

models.

Figure 20

Figure 21

YTL3-0005 – ER-25

Spanner Wrench used for

upper assembly adapter

removal for some ZRC

style units.

6 Warner Electric • 800-825-9050 P-2016 • ARC

Page 7

Clutch Rebuild Procedure

Figure 22

Remove set screw between clutch and top load

assembly using a 1/8” 3mm hex wrench. See

Figure 22.

ARC

Figure 25

Remove three socket head cap screws using a

9/64” 3mm hex wrench. See FIgure 25.

FIX-0005

FIX-0003

Figure 23

Separate top load assembly from clutch using

two spanner wrenches (YTL3-0009) and soft

hammer. Sometimes a steel hammer may be

required to loosen this joint. See Figure 23.

Figure 24

Figure 26

Place FIX-0003 in a vice. Place clutch in the fixture

and put FIX-0005 on top. Loosen nut and lift off

housing. See Figure 26.

Figure 27

Remove seal and bearing from housing. See Figure

27.

Figure 28

Remove two set screws using a 3/32” 3mm hex

wrench. Remove third set screw in the slot on

Remove seal and bearing from housing. See Figure

28.

the backside of the housing. See Figure 24.

Warner Electric • 800-825-9050 P-2016 • ARC 7

Page 8

FIX-0002

Figure 29

Press bearing out of housing using FIX-0002 and an

arbor press. See FIgure 29.

FIX-0002

Figure 33

To replace the magnet on end cap, break the

magnet with a hammer. Remove broken magnet

pieces and old screws. Install new magnet and

new screws. Epoxy magnet holes with epoxy

packet from rebuild kit. Make sure epoxy does

not build up on surface of magnet more than

.010” (0.25mm). See epoxy instructions below

(Figure 34)

Figure 34

Figure 30

Turn housing over. Press new bearing in housing

using FIX-0002 and an arbor press. See Figure 30.

Figure 31

Put in new seal. See Figure 31.

Figure 32

Figure 35

Install magnet plate into housing. Line up any

three holes and insert screws. See Figure 35.

Separate magnet stack and clean all magnets –

replace as required. Use an alcohol based cleaning

solvent to clean the black driver magnets. Do not

Figure 36

use anything abrasive when wiping the black driver

magnets. Use a Scotch Brite deburr wheel to polish

the hysteresis magnet. See Figure 32.

8 Warner Electric • 800-825-9050 P-2016 • ARC

Tighten the three socket head cap screws with a

9/64” 3mm hex wrench. See Figure 36

Page 9

Figure 37

Insert shaft into housing. See Figure 37.

Figure 41

Apply a thin layer of grease to the adjustable end

cap driver magnet. See Figure 41.

Torque Index

Mark

Figure 38

Apply a thin layer of grease to the driver magnet.

See Figure 38.

Figure 39

Install spacer. See Figure 39.

Torque

Settings

Figure 42

With torque settings on the housing and torque

index mark on end cap facing you - place housing

on end cap. Use caution as magnets will attract

to each other. Tap in place with soft hammer if

necessary. See Figure 42.

Install Seal,

Apply Grease

Figure 43

**On newer models install seal and apply a thin layer

of grease to top of seal. If your end cap does not

have a groove in it to accept the seal, skip this step.

See Figure 43.

Figure 40

Install hysteresis magnet. Align on shaft and

allow it to drop carefully down to the spacer. Use

caution as magnets will attract to each other.

See Figure 40.

Warner Electric • 800-825-9050 P-2016 • ARC 9

Page 10

Apply Blue

Loctite

Figure 44

Apply a small amount of blue loctite (242

threadlocker) on the inner thread of the nut; screw

into place. See Figure 44.

FIX-0005

FIX-0003

Figure 45

Using FIX-0003 and FIX-0005 to hold the clutch in

place, torque to 45 ft-lbs. (508Ncm). See Figure 45.

Figure 47

Install two ¼” (M6) set screws. See Figure 47.

Figure 48

Apply grease to top of seal. See Figure 48.

Figure 49

Torque test the unit before re-installing upper

assembly and installing headset on machine.

Using 1” face spanner wrench (YTL2-0002) to set

the torque at setting 5. See Figure 49.

Figure 46

Install .472” (12mm) long set screw. See Figure 46.

10 Warner Electric • 800-825-9050 P-2016 • ARC

Page 11

Figure 50

Using FIX-0007 or FIX-0010 and a torque wrench,

check to make sure the torque is smooth and

reaching the specified maximum torque. If torque

is not smooth or is very high, disassemble clutch

to look for mechanical rubbing or parts assembled

incorrectly. Check the epoxy over the magnet

screws for signs of rubbing. If the epoxy is rubbing,

carefully trim the epoxy down to specification. See

Figure 50.

Figure 51

Figure 53

Remove spring plate, upper spring cover (if

applicable), spring, and lower spring cover (if

applicable) from top-load assembly. See Figure 53.

Figure 54

Remove internal shaft and inspect for wear, replace

as necessary. Clean all parts. See Figure 54.

Set torque to desired setting using face spanner

wrench (YTL2-0002) and tighten set screws. See

Figure 51. Tighten set screws to 8-10 lb-in. Over

tightening is not necessary and will strip the screws

or possibly damage the housing body.

ARC

Top Load Rebuild Procedure

Figure 52

Using a small standard screwdriver remove snap

ring. See Figure 52.

Figure 55

Install new pins, apply a thin layer of grease to

internal shaft and pins. See Figure 55.

Figure 56

Remove seal and replace. See Figure 56.

Warner Electric • 800-825-9050 P-2016 • ARC 11

Page 12

Figure 57

Apply a thin layer of grease the seal and bore. See

Figure 57.

Figure 58

Install shaft in top load assembly. Make sure all 4

pins stay engaged during insertion. See Figure 58.

Figure 61

Thread together the clutch and top-load

assembly. See Figure 61.

Figure 62

Tighten using spanner wrenches (YTL3-0009)

and a soft hammer. See Figure 62.

Figure 59

Set top-load on FIX-0002 so that the shaft does not

push in while compressing the spring. Install lower

spring cover (if applicable), spring, upper spring

cover (if applicable), and spring plate. See Figure 59.

Figure 63

Install set screw with 1/8” 3mm hex wrench;

Figure 60

tighten. See Figure 63.

Compress spring plate and install snap ring. Make

sure that the snap ring seats fully into groove. See

Figure 60.

12 Warner Electric • 800-825-9050 P-2016 • ARC

Page 13

Rebuild Kits and Rebuild

Exchange Programs

Warner Electric Capping Headsets

Magnetic Headset Rebuild Kits

End-users can purchase rebuild kits to rebuild the

magnetic headsets themselves. It is recommended

that the end-user keep both bearing and magnetic

kits on hand in order to reduce maintenance

downtime.

Factory Rebuild Program

End-users can ship their headsets back to Warner

Electric for a full factory rebuild and certification.

Upon receipt, Warner Electric will rebuild and factory

certify headsets. Typical turnaround for headsets is

1-2 weeks. Expedited services are available upon

request. Additional fees will apply. End-user will be

invoiced for the rebuilt headset when the rebuilt

headset is shipped. The end-user is responsible for

freight to and from factory.

Headset Exchange Program (TWO YEAR

AGREEMENT):

Once end-users own Warner Electric headsets, they

have the option of signing up for a Warner Electric

Headset Exchange Program for rebuilt headsets. In

this case, end-users would receive rebuilt headsets

from Warner Electric at a predetermined time during

the year in exchange for their used Warner Electric

headsets. End-user signs an agreement for the

headset exchange program for 2 years. Pricing for

the headset exchange program will be paid once per

year, on the date the agreement is signed and on

the agreement anniversary date. At the beginning of

the agreement period, the end-user must specify the

headset model, how many heads are to be rebuilt,

and what time(s) during the year rebuilt headsets are

expected. Warner Electric will ship rebuilt headsets

to end-user at the predetermined date. Within two

weeks from receipt of rebuilt headsets, the end-user

is required to return their used headsets. The enduser is responsible for freight to and from the factory.

End-user signs an agreement for the headset

exchange program for 3 years. Pricing for the

headset exchange program will be paid once per

year, on the date the agreement is signed and on the

agreement anniversary dates. At the beginning of

the agreement period, the end-user must specify the

headset model, how many heads are to be rebuilt

and what time(s) during the year rebuilt headsets are

expected. Upon receipt of initial payment, Warner

Electric will ship rebuilt headsets to the end-user. On

the predetermined rebuild dates, Warner Electric will

ship rebuilt headsets to end-user. Within two weeks

from receipt of rebuilt headsets, the end-user is

required to return their used headsets. At the end of

the 3 year agreement period, the end-user will own

their magnetic headsets. The end-user is responsible

for all freight to and from the factory.

On-site Service Support

Warner Electric Capping Headsets

On-site service support is available for installation

of new Warner headsets, rebuild support of existing

Warner headsets, training, etc. Our factory-trained

and certified service department with over 50 years

combined experience can help prevent costly delays

and down time of your capping operation.

Precision Tork is the ONLY Service Group

that is factory authorized to work on

the Warner Electric headsets.

Services Provided:

• Installation of new equipment

• Machine audits and troubleshooting

• Service and repair of filling and capping

equipment

• Consulting: New Installations-existing issues for

filling and capping

• Develop new design for efficient production

• Assist with planning of preventative maintenance

programs

• Operator and mechanical training

• Highly qualified trained field engineers ready to

work on the following bottling equipment:

Headset Lease Exchange Program

(3 YEAR AGREEMENT)

Warner Electric offers an option for end-users to

receive factory rebuilt Warner Electric headsets at

no initial purchase fee if they sign up for a 3 year

headset exchange program with Warner Electric. At

the end of the 3 year agreement period, the end-user

will own their Warner Electric headsets.

Warner Electric • 800-825-9050 P-2016 • ARC 13

Precision Tork Service Benets:

• We manufacture the headsets!

• Most up-to-date designs available only through

Precision Tork.

• Our service technicians are trained to rebuild

your headsets to their existing revision level OR

upgrade them to the latest technology.

Page 14

• Component parts and rebuild kits on hand so

you do not incur downtime.

• Coming soon…secure website for headset

information and parts ordering with a credit card.

To schedule a certied Warner Service

Technician contact Melissa Bottke at

1-888-350-1891

Upgrade Kits

Warner Electric Capping Headsets

Benets of upgrading your M4.5 Headsets:

1. Eliminate setscrew stripping during torque

adjustment

• Larger adjustment screws in housing makes

it easier to adjust the torque and helps prevent

stripping of the screw head. Old setscrew in a

10-32 utilizing a 3/32” wrench. The new

setscrew is a 1/4-28 utilizing a larger 1/8”

wrench.

2. Longer bearing and magnet life

• Bottom seal in end cap helps to prevent water

and other contaminants from getting inside of

the headset. Easy to retrofit in the field.

Material Requirements

Anti-Seize Compound

• Apply to spindle at time of headset installation

Cleaning Solution

• Alcohol based cleaning solvent used to wipe

and clean parts during rebuild.

Grease

• Citgo Clarion Food Grade Grease, HTEP NLGI

No. 2 Grade used to lubricate headset.

Loctite

• Blue Removable - 242 threadlocker used to

secure components within the headset.

Epoxy

• Five minute epoxy – Amber, Devcon dev-pak

adhesive 14270 used to fill counter-bores in

the magnet plate.

Information for Ordering

Spare Parts

It is important to stock spare parts on hand to avoid

unnecessary downtime. Warner recommends that

you stock at least two spare headsets per machine

and a few bearing and magnet rebuild kits so that

you have the necessary parts on hand if you need

them.

Here’s how to order:

1. Find the headset part number or serial number

engraved on the housing body.

2. Call 1-888-350-1891

3. See Cross-reference list below for part number

Information.

4. Parts are in stock and ready for immediate

delivery.

5. Step-by-step instructions available.

How to order spare parts – required information:

1. Purchase Order Number.

2. Warner headset model number/part number OR

serial number (only on models manufactured July

2007 and later).

3. Warner Component or Kit Part Number.

4. Preferred distributor to order from. All orders will be

routed through local distribution. Pricing and lead

time can be quoted by calling the Manufacturing

Facility at (888) 350-1891.

14 Warner Electric • 800-825-9050 P-2016 • ARC

Page 15

NOTES

Warner Electric • 800-825-9050 P-2016 • ARC 15

Page 16

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product

manufactured and sold by it which proves to be defective in material or workmanship within a period of one (1)

year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric

LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges

prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by

writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois

61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If

found defective under the terms of this warranty, repair or replacement will be made, without charge, together

with a refund for transportation costs. If found not to be defective, you will be notified and, with your consent, the

item will be repaired or replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident,

neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply

to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective

product and in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of

any kind incurred by reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither

assumes nor authorizes any other person to give any other warranty or to assume any other obligation or liability

on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT,

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER

EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHERWISE, INCLUDING, BUT NOT LIMITED TO,

ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have

other rights which vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice.

Weights do not include weight of boxing for shipment. Certified prints will be furnished without charge on request

to Warner Electric.

www.warnerelectric.com

31 Industrial Park Road

New Hartford, CT 06057

800-389-3771

Fax: 815-389-2582

P-2016-WE 3/14 Printed in USA

An Altra Industrial Motion Company

www.altramotion.com

Loading...

Loading...