Page 1

Conduit Box Kit No. 5200-101-010

-1391

P

819-0198

Installation Instructions

Page 2

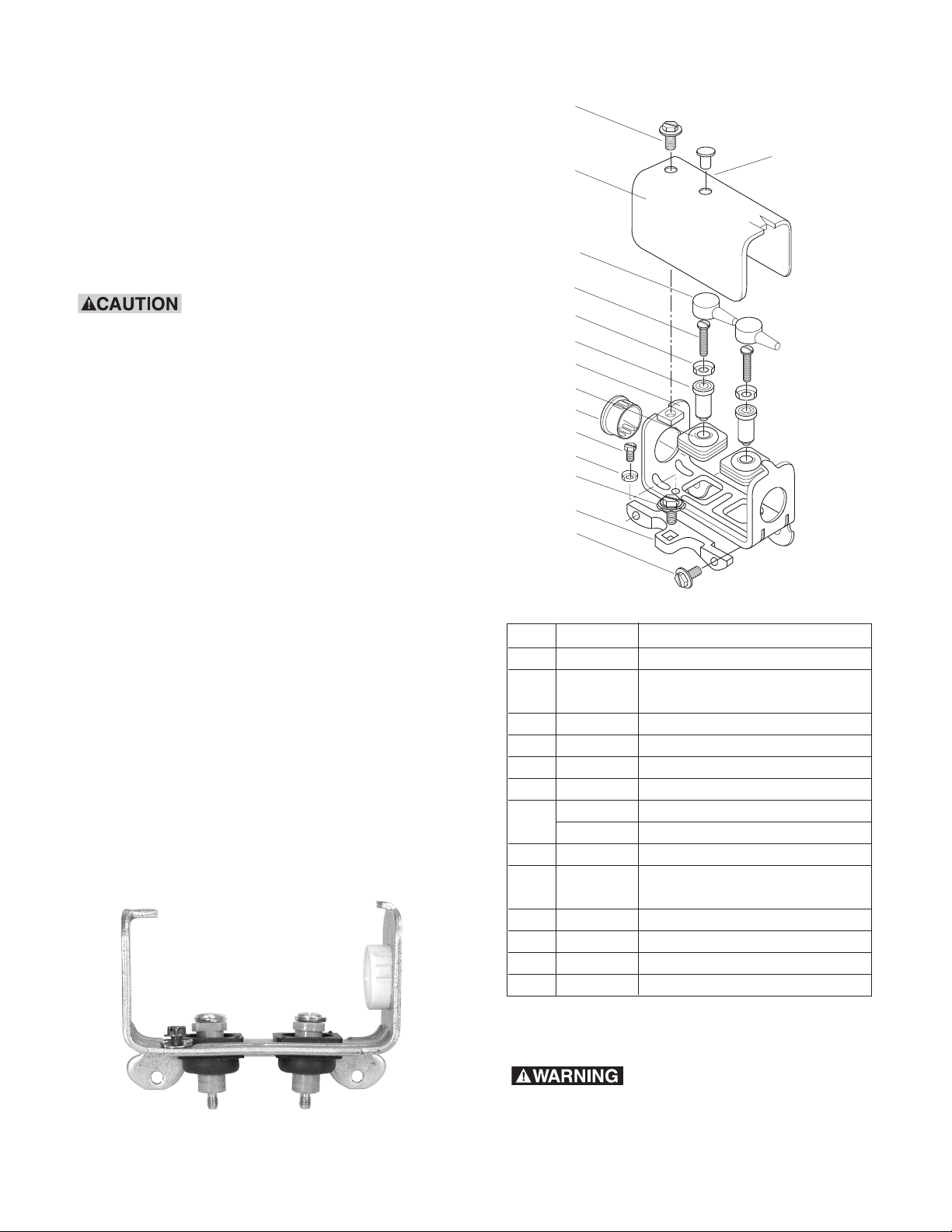

4

10

8

11

9-1

*7

3

6

5

9

9-1

1

2

2

1

4

Introduction

Components

Conduit box kit No. 5200-101-010 contains all

components needed to assemble a conduit box

for 375, 400, 475, 500, 650, ER-825, and ER-1225

clutches and brakes.

When properly installed, this conduit box is

designed to provide a proper means for field wiring

terminations. It conforms to the requirements of

Underwriters Laboratories.

Do not connect rigid conduit

directly to the conduit box. A minimum of 12” of

flexible liquid tight conduit or other suitable

flexible wiring with appropriate fittings is

required. Flexible wiring is required to prevent

side loading of bearing on bearing mounted

clutches and possible deformation or breakage

of the conduit box or clutch/brake components

during assembly.

Step 1

Assemble a customer supplied flexible wiring

connector into desired end of conduit box (3).

Press protective plug (5) into unused conduit hole.

Thread green washer head hex screw (9) into

round hole in base of conduit box. Place terminal

ring (9-1) over screw before inserting.

Snap two wire grommets (6) into square holes in

conduit box base. The grommet crowns should

be toward the outside of the box and the rubber

flanges should be on both sides of the conduit

box.

Push two terminal spacers (7) through rubber

grommets. Number 6 spacers fit in sizes 375, 400,

and 475. Sizes 500 to 1225 use number 8 spacers.

(See Figure 1)

Figure 1

Warner Electric • 800-825-9050 P-1391 • 819-0198

2

Parts List for kit 5200-101-010

Item Quantity Part Name

11Bracket

21Screw, Hex, Washer Head

and Sems Conical Washer

31Box, Conduit

43Screw, Hex, Washer Head

51Plug, Protective

62Grommet, Wire

*7 2 Spacer No. 8 Thd.

2 Spacer No. 6 Thd.

82Cap terminal

91Screw, Hex, Washer Head,

Green

9-1 3 Terminal, Ring

10 1 Cover

11 2 Screw, No. 8 Brass

12 1 Plug, Protective

*The No. 6 spacers are required on Sizes 375, 400 and 475. All

others use No. 8.

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Page 3

Step 2

asten bracket (1) to clutch field/brake magnet

F

with one No. 10-32 hex washer head screw (2).

The screw is self-tapping, threads are not

provided in the magnet bracket adapter. The

square projection on the magnet fits into the

square hole in the bracket. The curved side of

the bracket mounts toward the magnet. The

bracket flange is toward the flange side of the

magnet. (See Figure 2)

Step 4

onnect electric supply cable to the fitting

C

installed on the conduit box. If an external

power supply is furnishing DC current to the

clutch or brake, proceed to Step 5 and skip

Step 6. If a Warner Electric CBC-100 power

supply is being installed in the conduit box, skip

Step 5 and proceed to Step 6.

Step 5 - DC Connection

Slide one terminal cap (8) onto each of the two

supply conductors, small end first. Connect the

two supply conductors (with rubber caps) to the

magnet or field terminals using two No. 8 brass

screws (11) and ring terminals (9-1). The

stripped wires can wrap around the screw

between the terminal ring and the screw head or

other ring type terminals may be used. Electrical

supply connections must confirm to local

electrical codes. Install plug (12) into cover hole.

Figure 2

Step 3

Mount conduit box to bracket. The conduit box

flange must be toward flange side or the magnet

(rear of bracket). Thread terminal spacers into

field/magnet before fastening conduit box to

bracket. Do not over tighten, excessive torque

will pull thread insert out of magnet/field. Secure

conduit box to bracket with two No. 10-32 hex

washer head screws (4). (See Figure 3)

Step 6 - AC Connection

When a CBC-100 power supply is used, refer to

installation sheet P-266 provided with the

CBC-100, following instructions carefully. To

mount the CBC-100 to the conduit box, place

the control into the cover so the curved surfaces

conform, line up the cover hole with the control

mounting hole and fasten with screw provided in

the mounting kit. Connections to the magnet or

field terminals are as outlined in Step 5.

Step 7

A ground wire is recommended for grounding of

the conduit box and brake magnet or clutch

field. Connect this wire with the green ground

screw (8) to the hole in the bottom of the box.

Consult electrical local codes regarding

grounding requirements.

Step 8

Install cover (10) by sliding the slot in the cover

over the tab on one end of the conduit box and

secure the cover on the opposite end with one

No. 10-32 hex washer head screw (11).

Figure 3

Warner Electric • 800-825-9050 P-1391 • 819-0198

3

Page 4

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-1391 819-0198 8/11 Printed in USA

An Altra Industrial Motion Company

Loading...

Loading...